Clamping tool for automobile repair and maintenance

A technology for clamping tooling and automobile maintenance, applied in the direction of workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of reducing maintenance costs, occupying space, disadvantages, etc., to ensure cleanliness, stability, and outstanding The effect of material characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

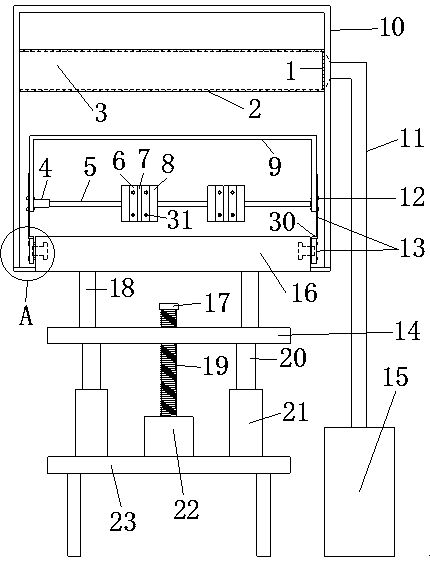

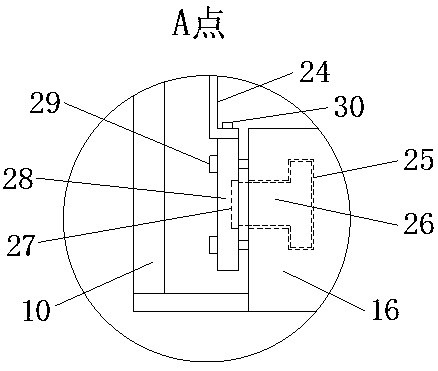

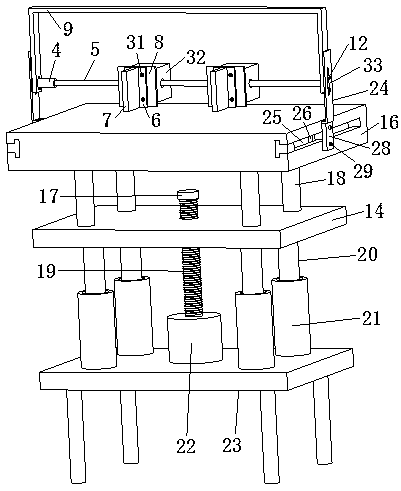

[0029] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0030] A clamping tool for automobile maintenance, as shown in the figure, it includes a frame 23 and a workbench 16 installed on the frame 23, the top of the workbench 16 is fixedly connected with a dust removal cover 10 with an open front end, The dust removal housing 10 is provided with a dust removal mechanism; the dust removal mechanism includes a dust removal cylinder 3, the two ends of the dust removal cylinder 3 are fixedly connected to the dust removal housing 10, and the axial direction of the dust removal cylinder 3 is adjusted to the front and rear The brackets 9 are parallel, and the outer peripheral surface of the dust removal cylinder 3 is covered with a dust removal filter cloth A2. One end of the dust removal cylinder 3 and the corresponding dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com