A sandblasting and zinc-blasting robot moving mechanism and sand-blasting and zinc-blasting equipment

A mobile mechanism and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as low labor efficiency, large human injuries, and harsh operating environments, so as to reduce labor intensity of workers, high quality of zinc spraying, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

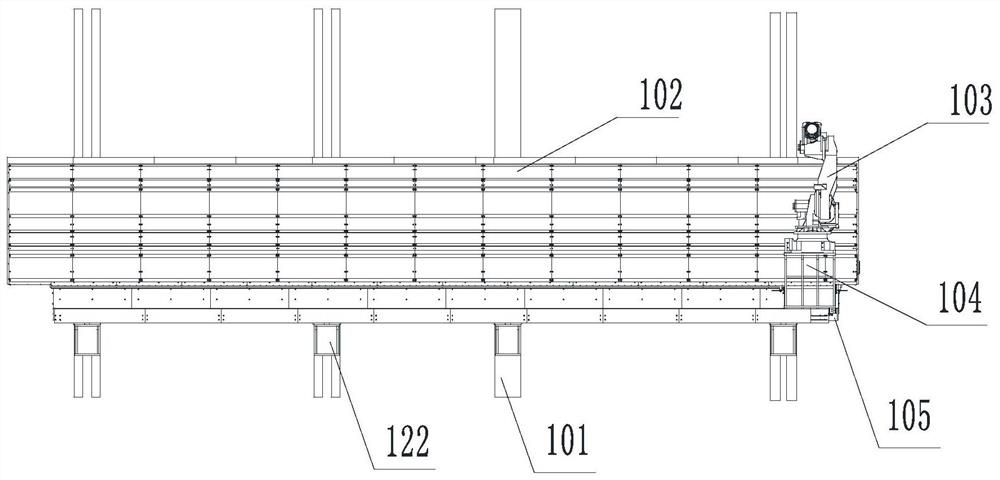

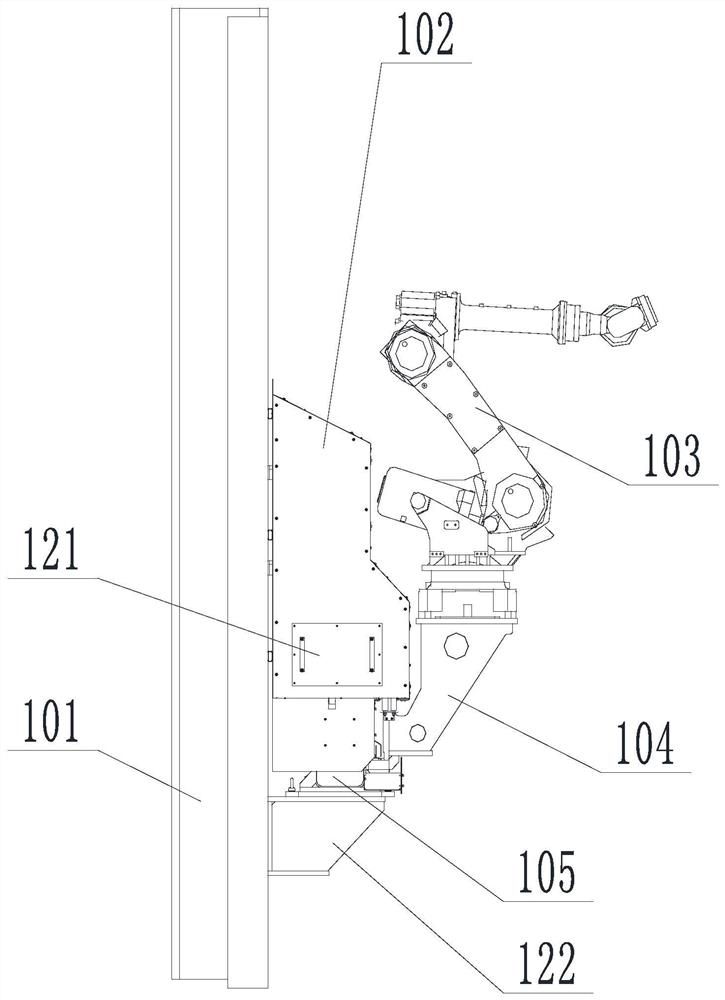

[0048] Such as figure 2 , image 3 , Figure 4 , Figure 5 Shown is Embodiment 1 of the present invention. In this embodiment, a sandblasting and zinc spraying robot moving mechanism 1 is provided, including a plurality of columns 101, through which a load-bearing beam 105 is arranged, and a lateral walking mechanism 104 is arranged on the load-bearing beam 105. The sand-blasting and zinc-spraying robot 103 is installed on the lateral traveling mechanism 104, and the lateral traveling mechanism 104 includes a driving mechanism, and the sand-blasting and zinc-spraying robot 103 reciprocates along the load-bearing beam 105 under the drive of the driving mechanism.

[0049] The load-bearing beam 105 bears the weight of the entire production line. In this embodiment, the load-bearing beam 105 is made of large-size rectangular steel pipes, and its structural strength can meet the design requirements. Both ends of the load-bearing beam 105 are provided with end plates for sealin...

Embodiment 2

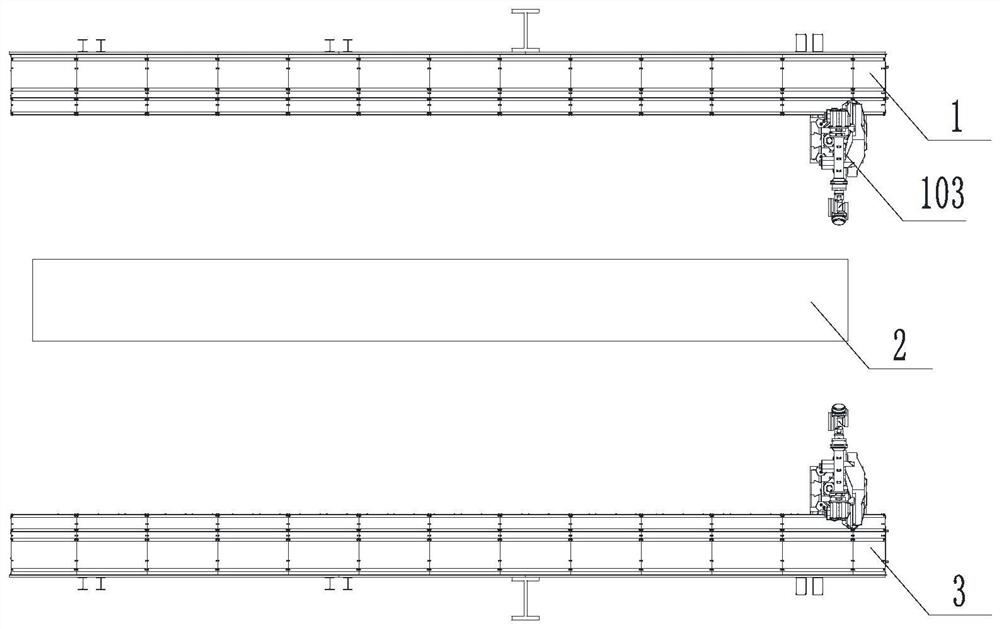

[0086] Such as figure 1 Shown is Embodiment 2 of the present invention, in which a sandblasting and zinc spraying equipment is provided, including a sandblasting and zinc spraying robot 103, and also a sandblasting and zinc spraying robot moving mechanism 1 in Embodiment 1 or Embodiment 2 .

[0087] The sandblasting and zinc spraying robot 103 adopts the existing multi-axis robot with multiple degrees of freedom and flexible operation. The spray gun device is installed at the end of the arm, which can meet the sandblasting and zinc spraying requirements of workpieces with complex shapes.

[0088] Two sets of moving mechanisms of sandblasting and zinc spraying robots can be set relatively in the sandblasting and zinc spraying equipment, and the structures of the moving mechanisms of the two sets of sandblasting and zinc spraying robots are the same, such as figure 1 Sandblasting and zinc spraying robot moving mechanism 1 and sandblasting and zinc spraying robot moving mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com