Charging pile special for ships

A technology for charging piles and ships, which is applied in charging stations, electric vehicle charging technology, electric vehicles, etc., to achieve the effect of worry-free operation and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

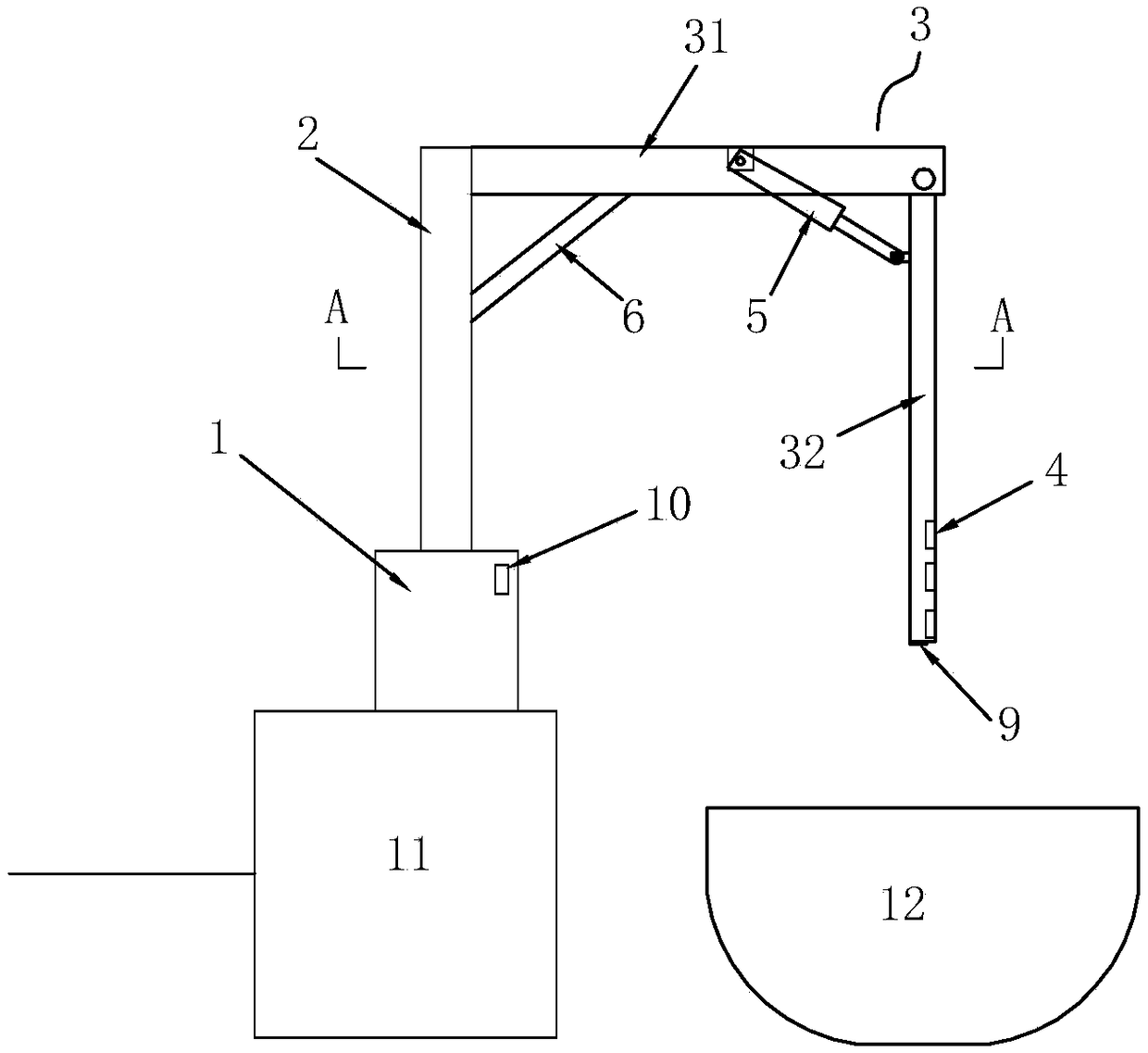

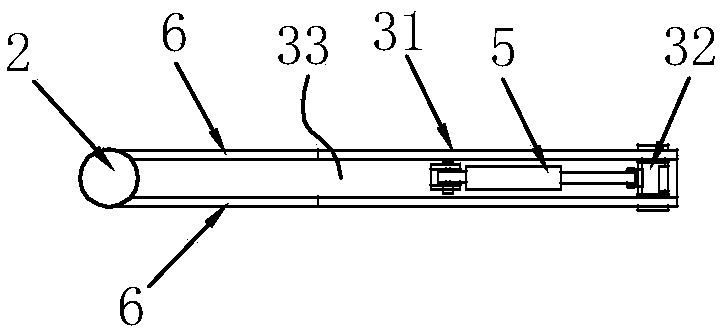

[0031] refer to figure 1 with figure 2 The special charging pile for water ships shown includes an electric pile base 1, a column 2, a charging arm 3 and a charging socket 4. The electric pile base 1 is a fixed body of a column 2, and the column 2 is a hollow body. There is also a control circuit inside the electric pile base 1 or the column 2, the electric pile base 1 fixes the column 2 at a designated position, the charging arm 3 is composed of a cross arm 31 and a swing arm 32, the cross arm 31 One end is fixedly installed on the column 2, and the other end is rotationally connected with the swing arm 3. The charging socket 4 is arranged on the swing arm 32, and the control circuit is used to control the charging function of the charging pile.

[0032] In the embodiment, the control circuit includes conventional technologies such as an IC circuit, a display screen, and function buttons, and the power line of the control circuit is embedded in the electric pile base 1 , th...

Embodiment 2

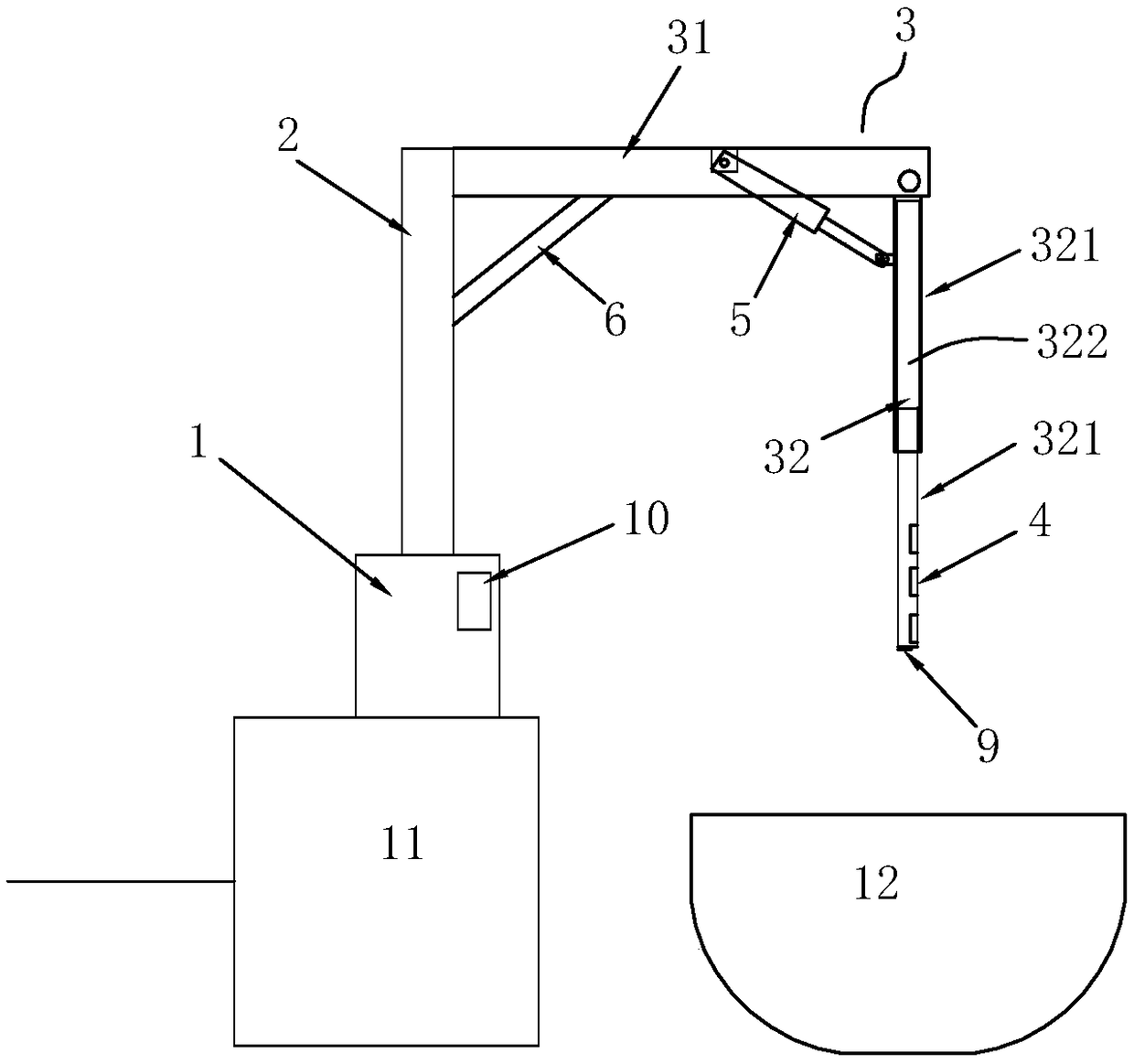

[0036] refer to Figure 4 As shown, the technical characteristics of this embodiment are: the swing arm 32 is composed of a multi-section telescopic arm 321, and the multi-section telescopic arm 321 is provided with a push-pull rod 322. Under the action of the push-pull rod 322, the swing arm 32 forms a telescopic Structure, the push-pull rod 322 is a hydraulic push rod, and the rest are the same as the above embodiment.

[0037] When this embodiment is applied, the multi-segment telescopic arm 321 is a plurality of elongated tubes with multiple sizes nested in each other, and a push-pull rod 322 is arranged inside the tube, and the push-pull rod 322 drives the small tube to expand and contract in the large tube to form a telescopic function, that is, multi-segment telescopic The arm 321 controls the telescopic movement of the multi-section telescopic arm 321 through the push-pull rod 322, thereby adjusting the length of the swing arm 32, that is, adjusting the distance from t...

Embodiment 3

[0039] refer to Figure 4 As shown, the technical feature of this embodiment is: the column 2 is rotatably installed on the electric pile base 1 . Specifically, the column 2 is installed on the electric pile base 1 through two bearings 7, and the two bearings 7 allow the column 2 to be rotatably installed on the electric pile base 1, such as an installation on the electric pile base 1. The fixed inner cavity of the column 2, the upper and lower ends of the inner cavity are respectively provided with a circular notch for installing the bearing 7, the bearing 7 is fixedly installed at the position of the circular notch, and the column 2 is installed on the electric pile base 1 through the rotation of the bearing 7 superior. In order to avoid the winding problem of the power line of the charging pile when the column 2 rotates, an electric slip ring 8 is provided at the docking position between the column 2 and the electric pile base 1, and the electric slip ring 8 is located bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com