Elevator shaftway adjusting device

An adjusting device and elevator shaft technology, applied in the field of elevators, can solve problems such as the inability to safely, reliably and effectively adjust the verticality of the elevator shaft, and achieve the effects of facilitating disassembly and installation, reducing equipment, and saving installation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

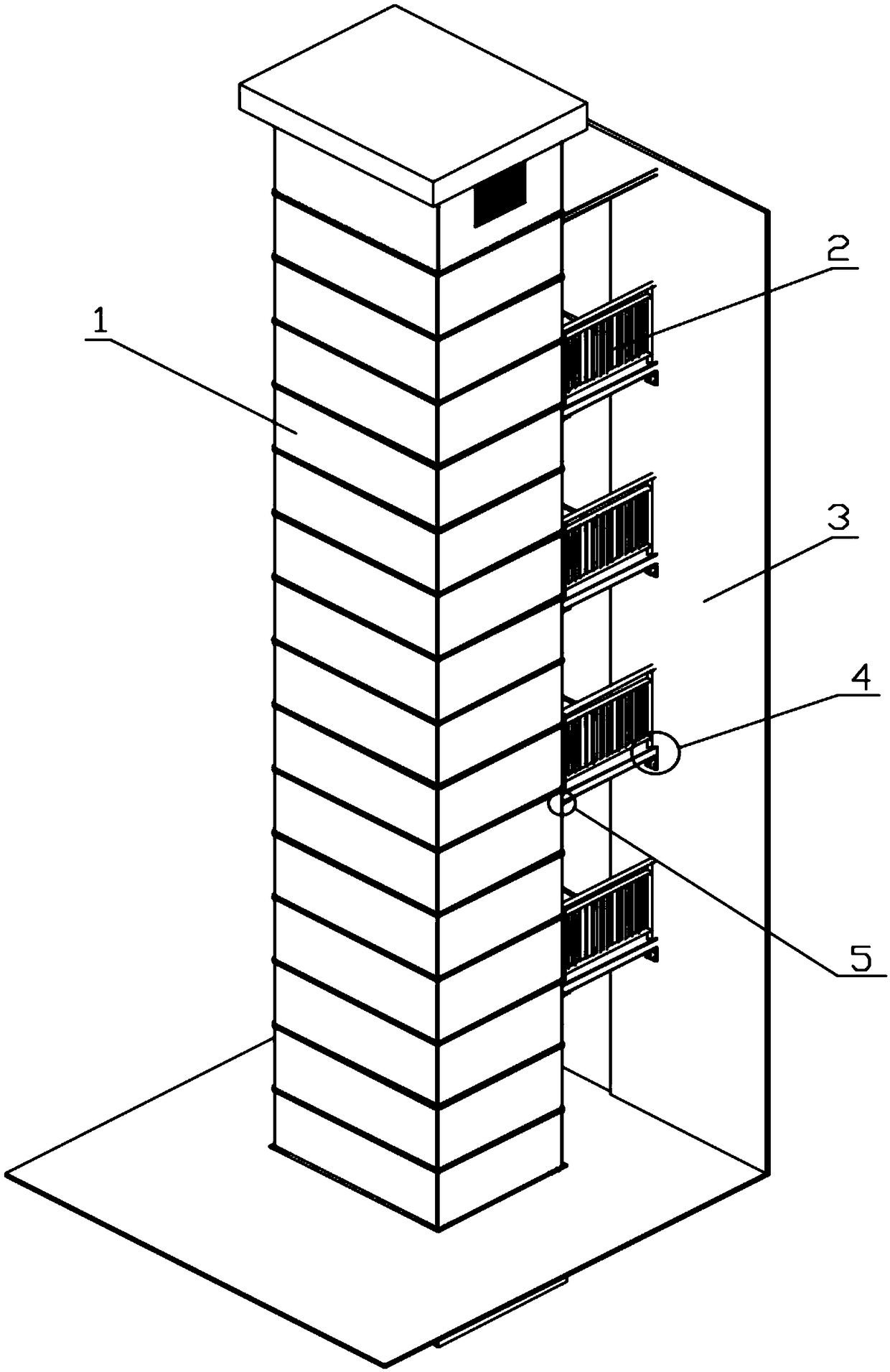

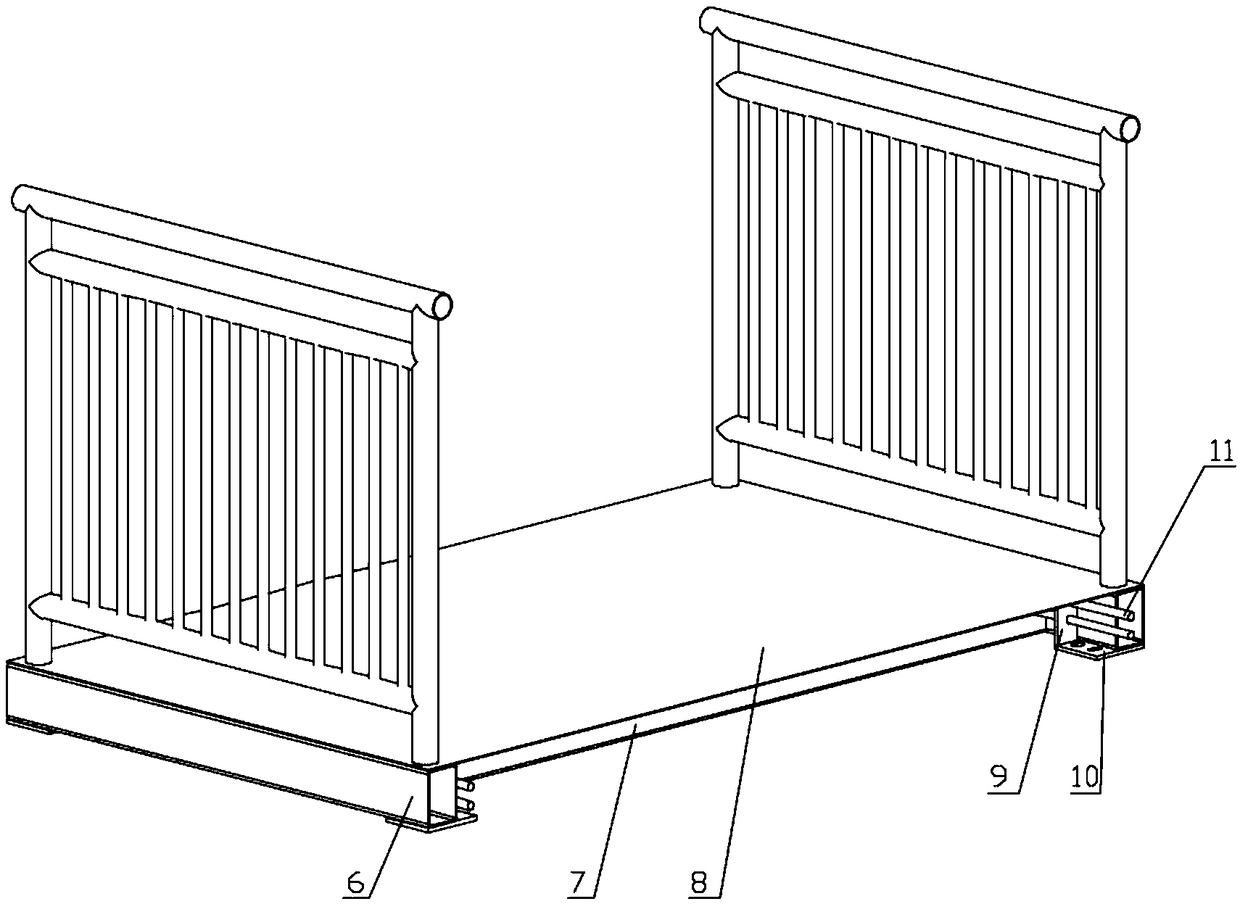

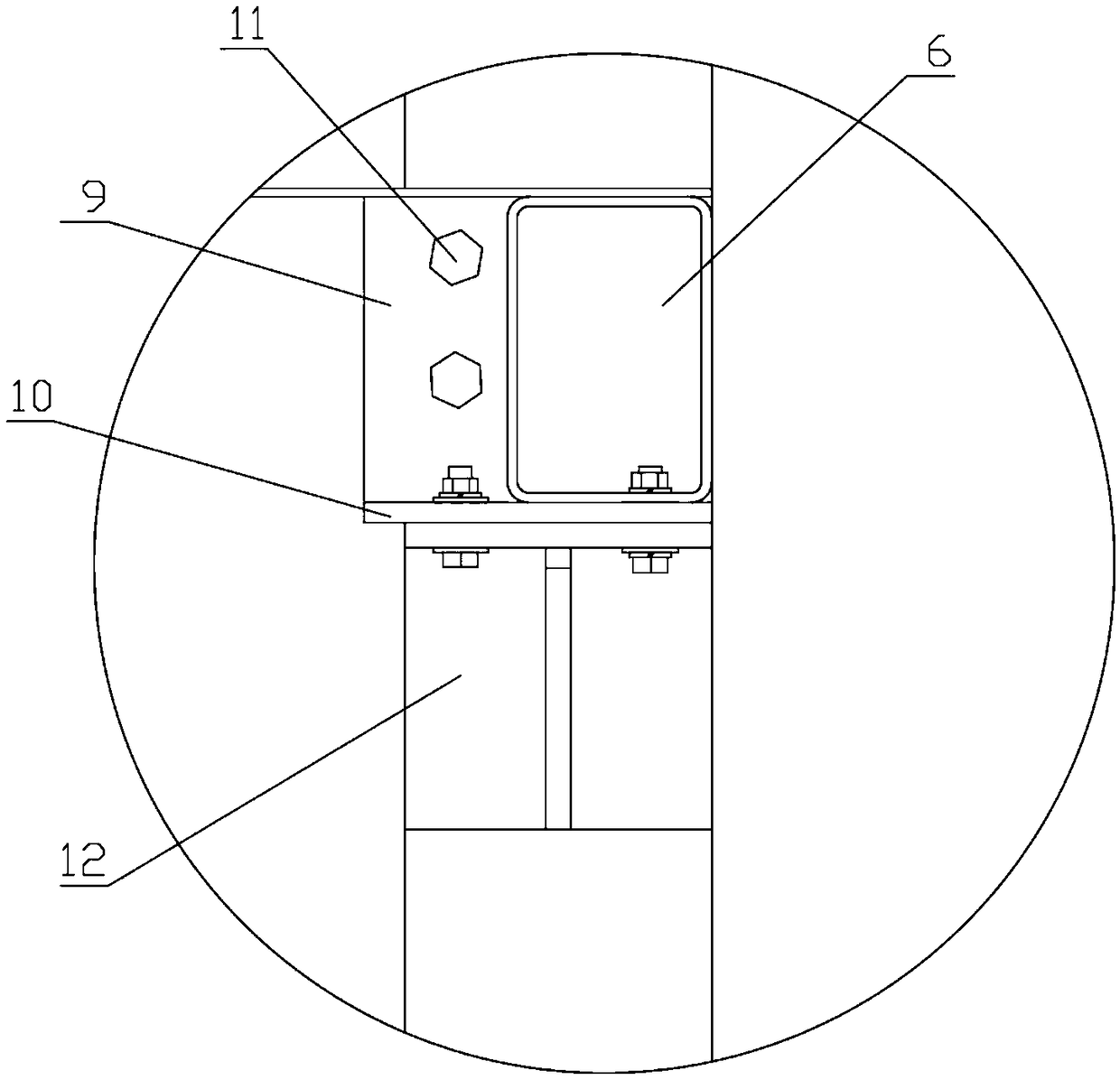

[0015] As shown in the accompanying drawings, a kind of elevator hoistway adjustment device includes a steel structure shaft 1 and a corridor bridge 2. The first through hole; the corridor bridge 2 is arranged between the steel structure shaft 1 and the building 3, and the connection between the corridor bridge 2 and the steel structure shaft 1 is provided with an adjustment structure 5; the adjustment structure 5 includes an adjustment nut 14, an adjustment block 9, The adjusting bolt 11 and the adjusting nut 14 are arranged on the hoistway column 13 and correspond to the position of the first through hole. The adjusting block 9 is arranged under the floor of the gallery bridge 2 corridor and corresponds to the main girder 7 of the gallery bridge. The adjusting block 9 A second through hole is arranged on the top, and the second through hole corresponds to the first through hole. The adjusting bolt 11 is arranged in the second through hole, and the head of the adjusting bolt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com