Spiral high-birefringence-structure elliptic-polarization-maintaining optical fiber manufacturing process

A technology with high birefringence and elliptical polarization, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of limited continuous drawing length and unstable drawing of elliptically polarized optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

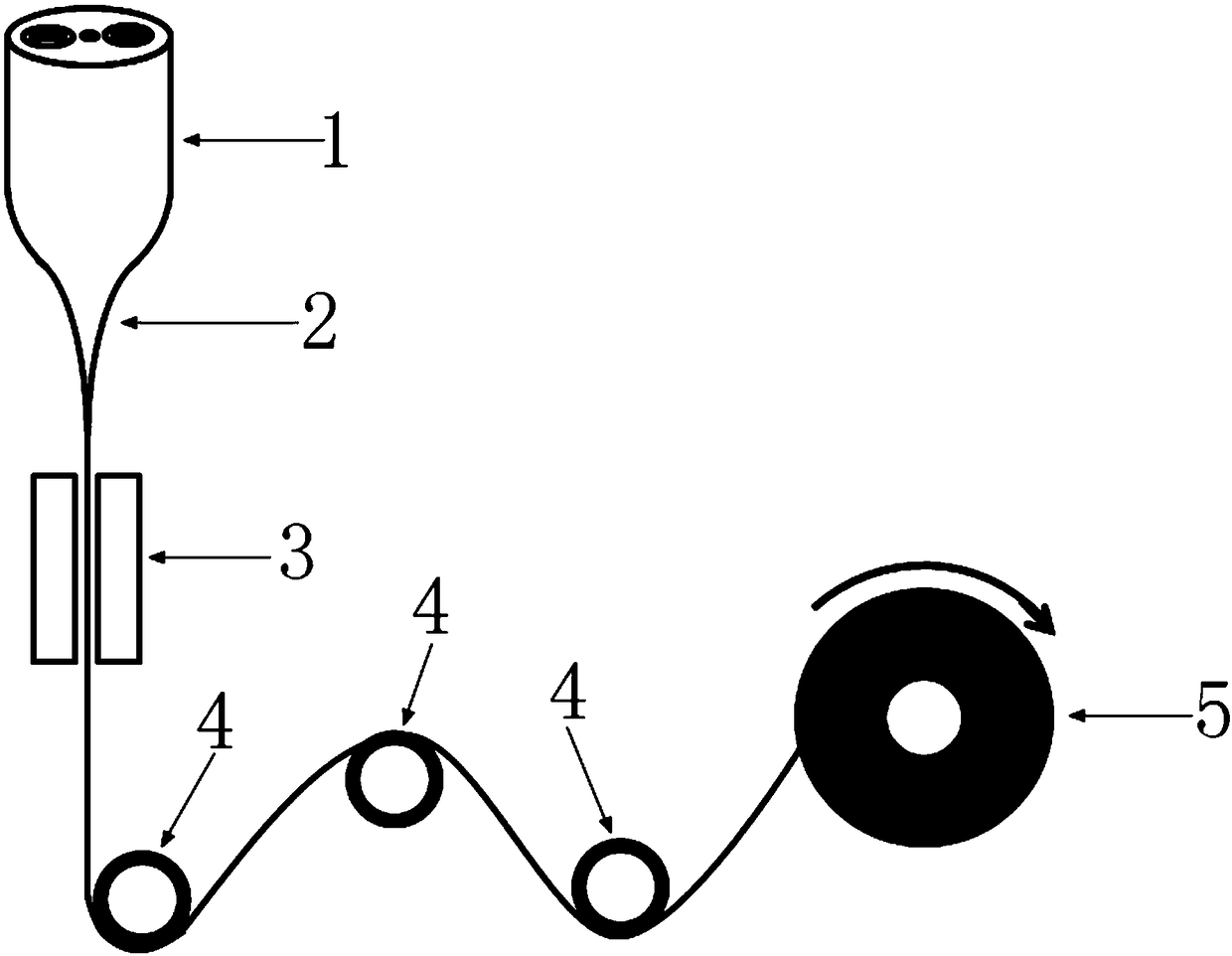

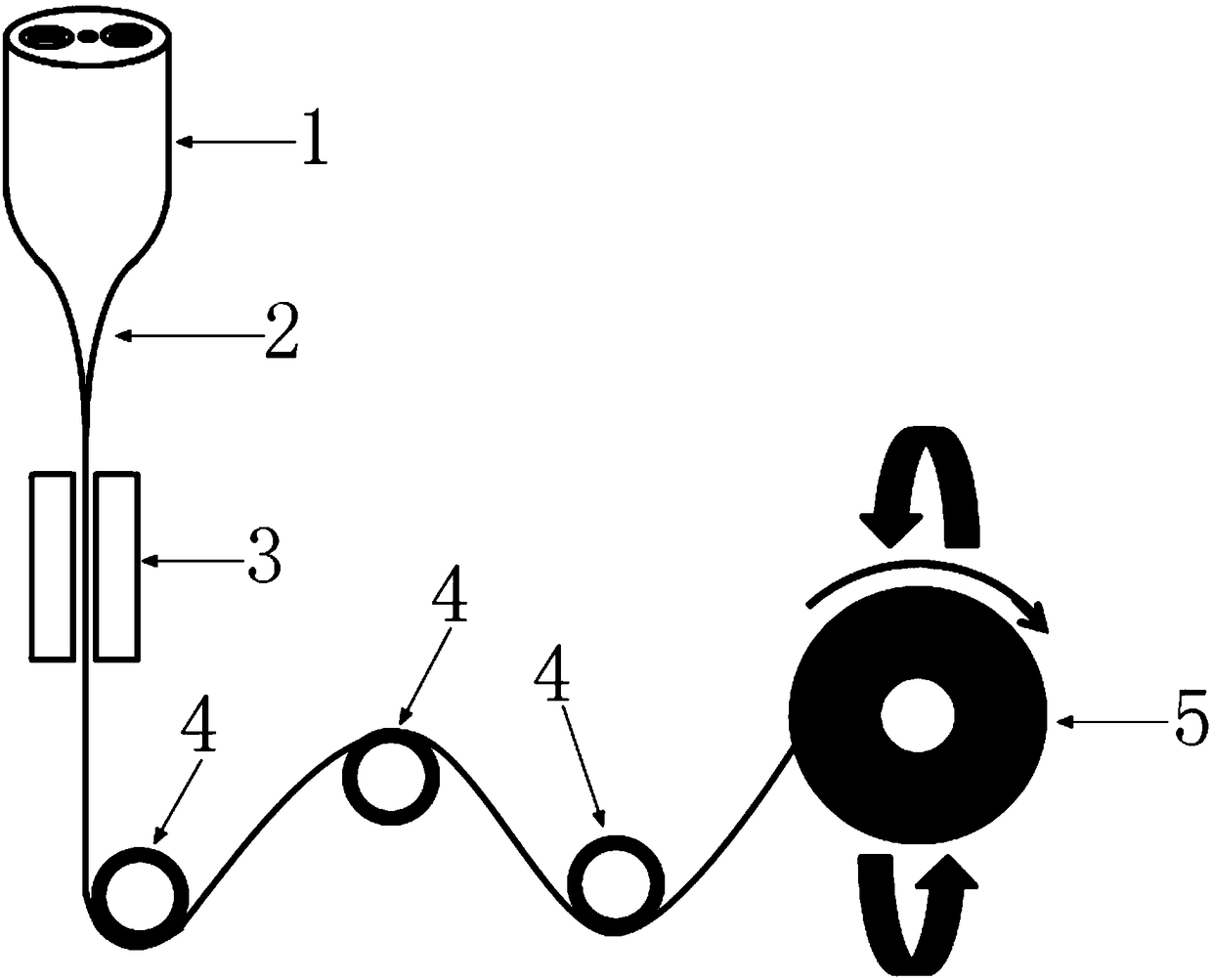

[0020] The manufacturing process of the helical high birefringence structure elliptic polarization-preserving optical fiber provided by this embodiment, such as image 3 As shown, the lower end of the optical fiber preform 1 is heated in the high-temperature heating zone 2, and is drawn into a bare optical fiber with a diameter meeting the requirements. The surface of the bare optical fiber is coated with a layer of coating material in the optical fiber coating zone 3, and then Guided by the fiber guide wheel 4, it winds on the receiving reel 5 at last.

[0021] In the above drawing process, such as image 3 As shown, the optical fiber preform 1 does not rotate, and during the drawing process, the take-up reel 5 not only rotates around its axis of rotation, but also flips at a high speed. Vertical, so that the drawn optical fiber produces torsion, and this torsion can easily overcome the friction of the fiber guide wheel 4 (the fiber guide wheel 4 can have multiple in the wir...

no. 2 example

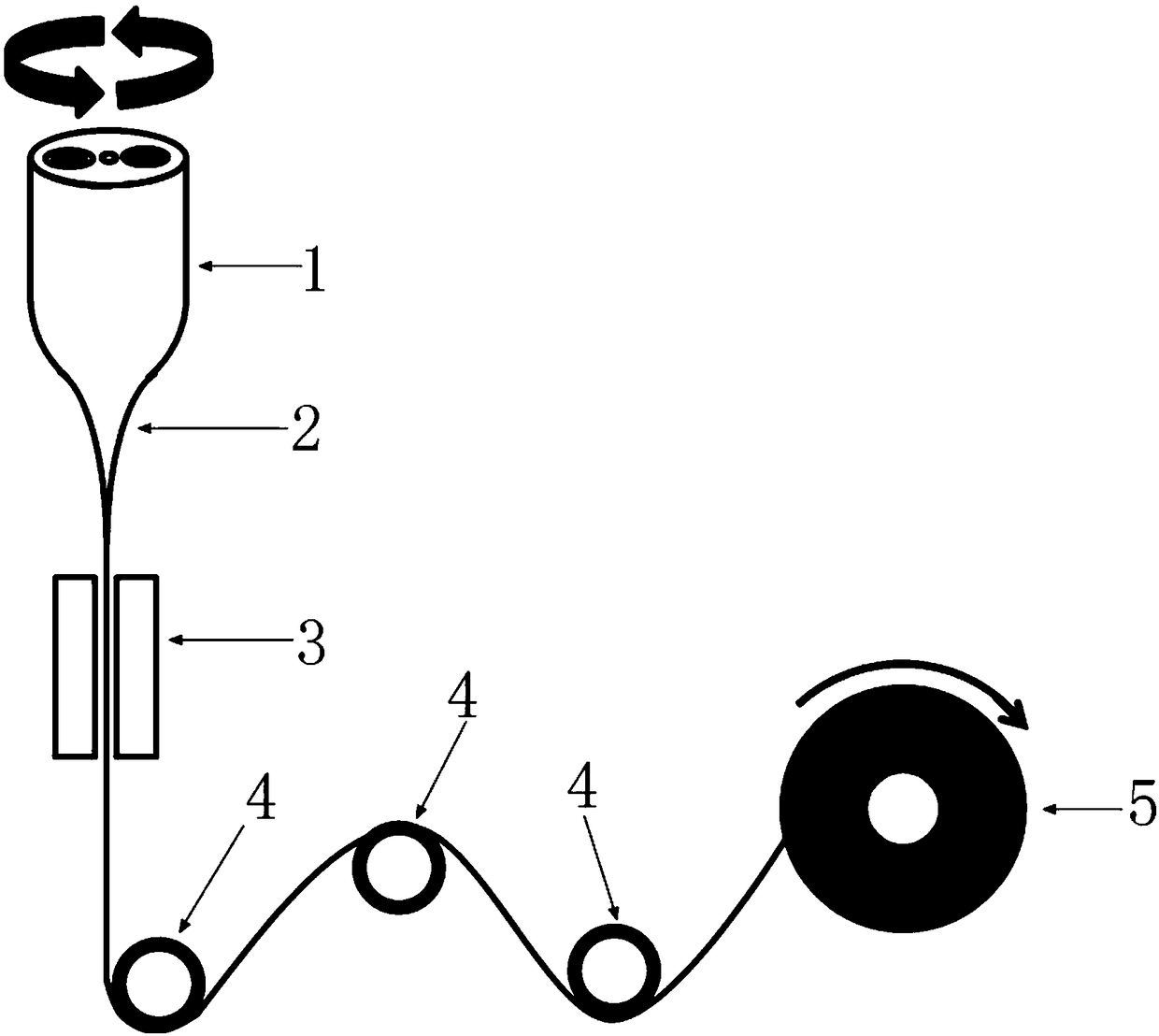

[0029] The manufacturing process of the helical high birefringence structure elliptic polarization-preserving optical fiber provided by this embodiment, such as Figure 4 As shown, the difference from the first embodiment is that the optical fiber preform 1 is changed to a rotating state, and the lower end of the optical fiber preform 1 is heated in the high-temperature heating zone 2, and is drawn into a bare optical fiber with a diameter that meets the requirements. A layer of coating material is coated in the optical fiber coating area 3 , then guided by the optical fiber guide wheel 4 , and finally wound on the take-up reel 5 . The reel 5 rotates around its shaft while turning over at high speed. The central axis of the reel 5 overturned is perpendicular to the axis of rotation of the reel 5 , and the direction of rotation of the optical fiber preform 1 is in line with the The twist direction of the optical fiber generated by flipping is opposite, so that the twist of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com