Assembly type green belt structure and construction method thereof

A green belt, prefabricated technology, applied in the direction of infrastructure engineering, excavation, water supply devices, etc., to achieve the effect of speeding up the construction progress, continuous water conduction function and water storage function, and good aesthetic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

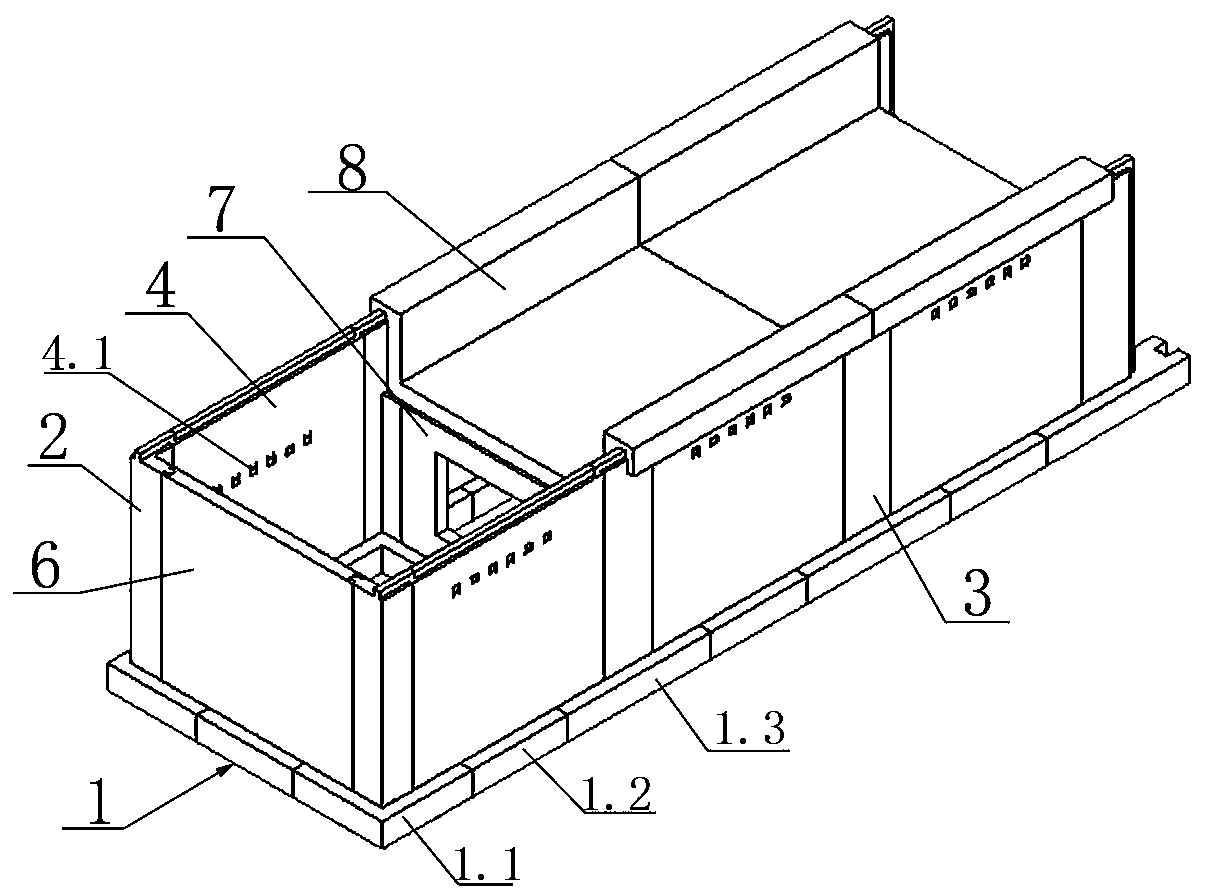

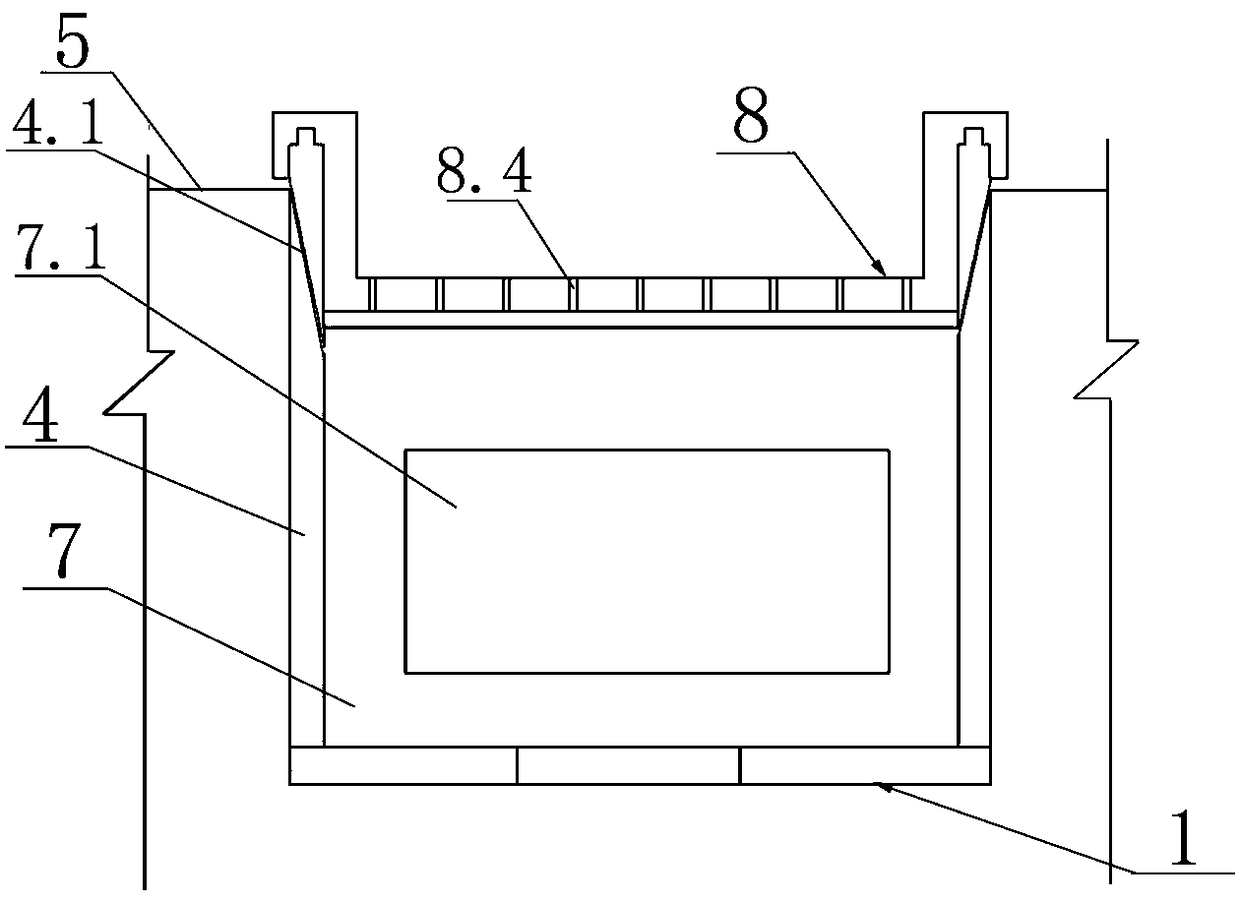

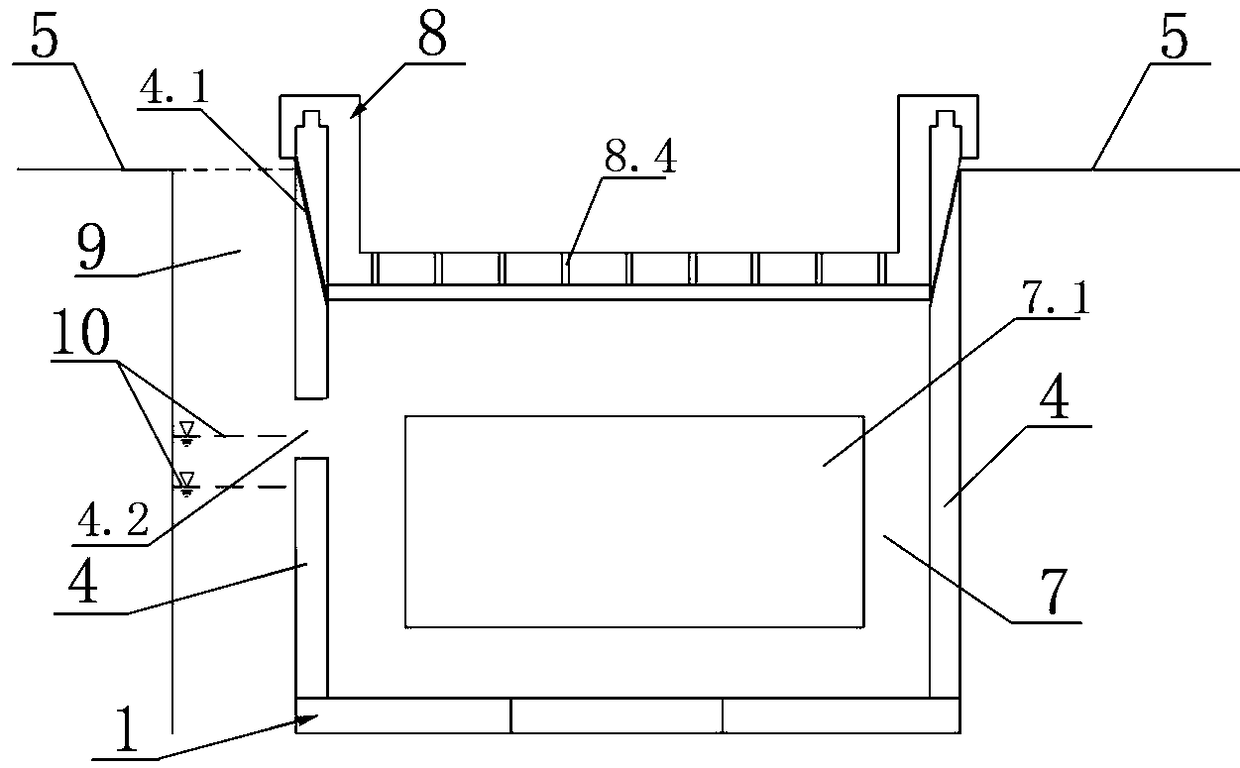

[0057] Such as Figure 1-15 As shown, this prefabricated green belt structure is set at the position of the road central divider or the green belts on both sides of the road; the prefabricated green belt structure is a box structure, including a foundation 1; the foundation 1 is rectangular, and its The length of the horizontal side is adapted to the width of the green belt; corner columns 2 are arranged at the four corners of the foundation 1, and side columns 3 are correspondingly arranged on the opposite side of the foundation 1; wherein, the side columns 3 are along the longitudinal side of the foundation 1 Arranged at intervals; between the side columns 3 and the side columns 3 and between the side columns 3 and the corner columns 2 are connected with a longitudinal plate 4; the top of the longitudinal plate 4 exceeds the road surface of the road structure 5 on both sides of the green belt; The upper part of the board 4 and the position corresponding to the road surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com