Connecting construction between prefabricated bridge pier and bearing platform and capable of positioning attitude

A bridge pier and attitude technology is applied in the field of connection structure between prefabricated bridge piers and caps. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

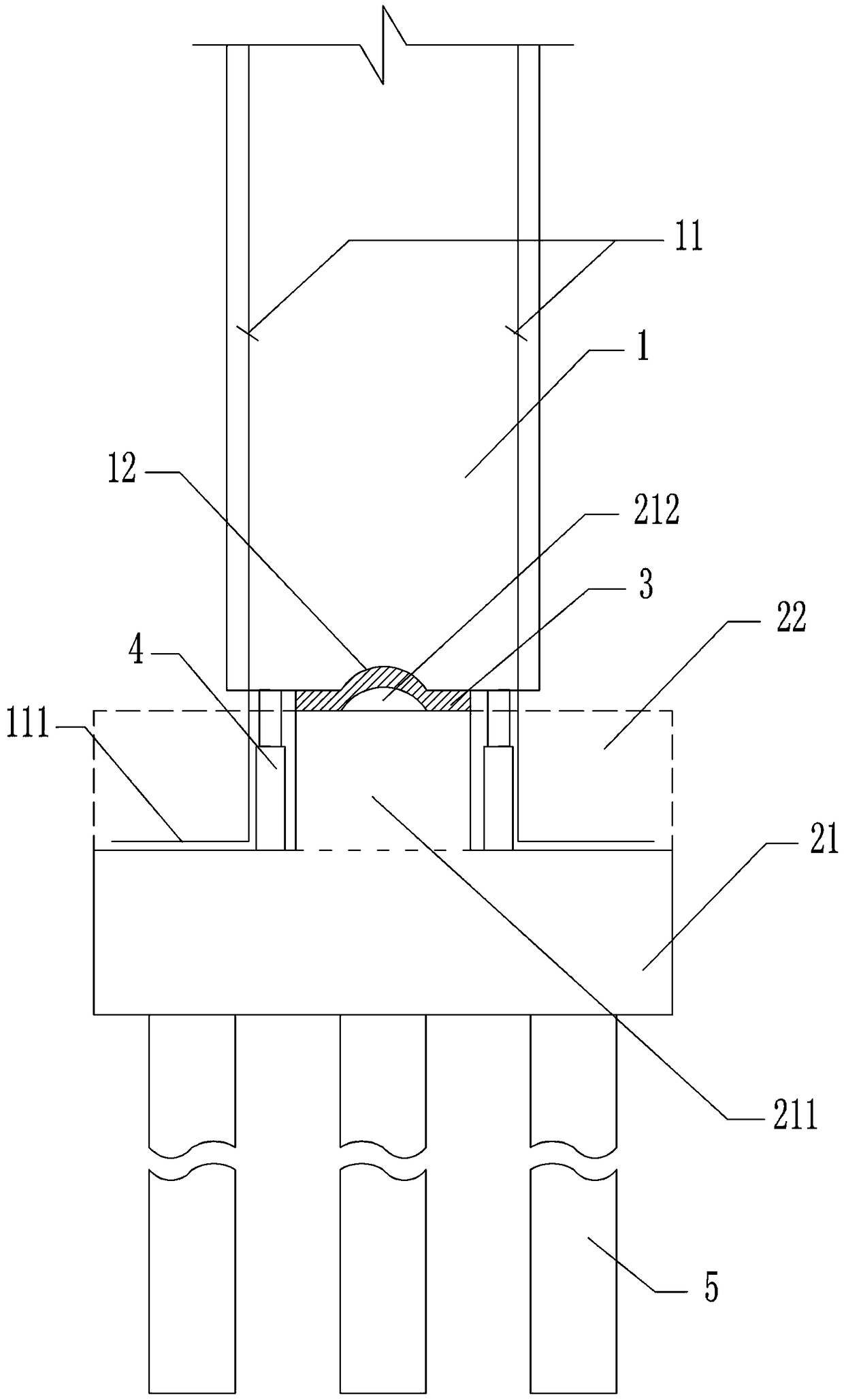

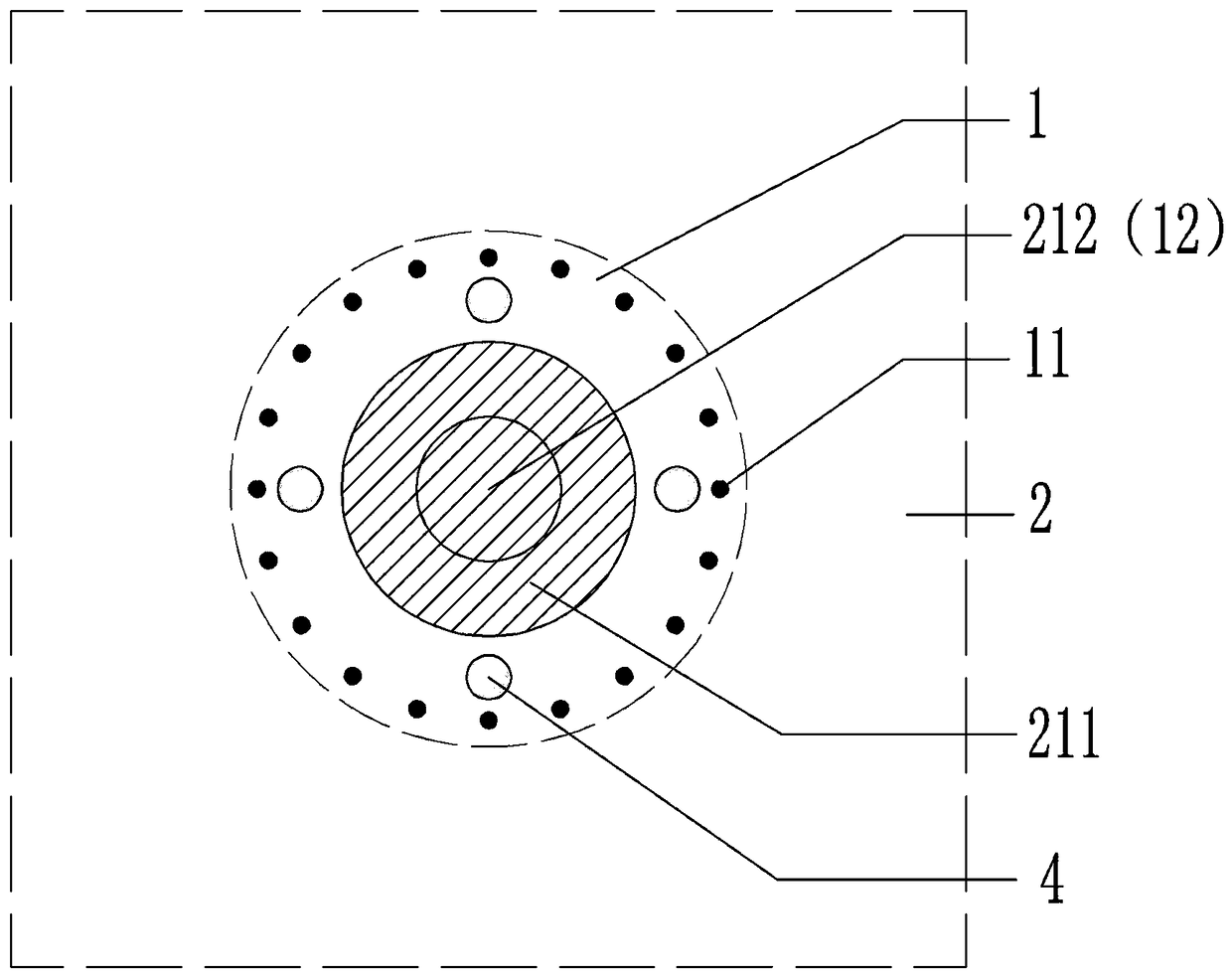

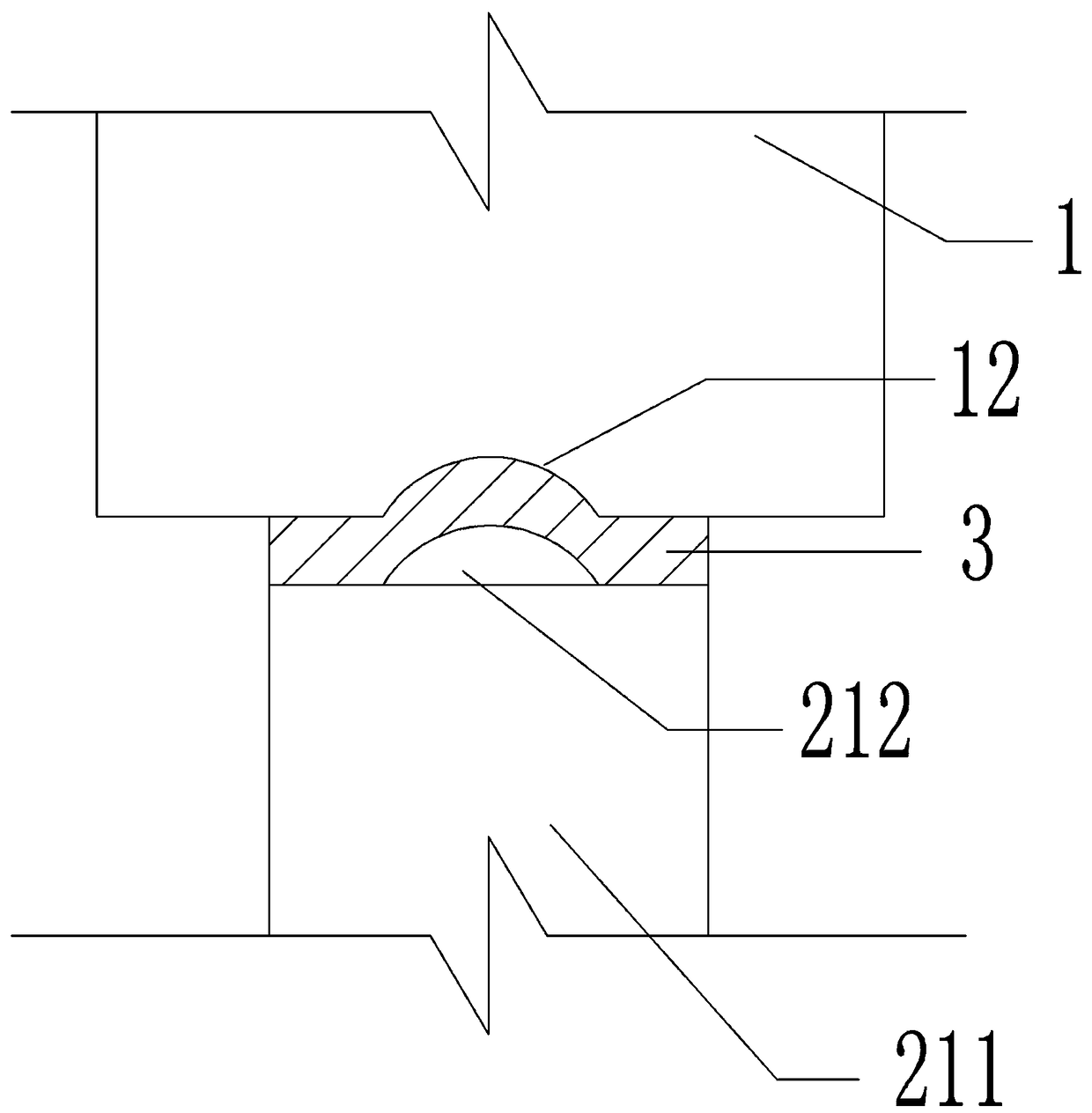

[0026] Such as figure 1 and 2 As shown, a prefabricated bridge pier and platform cap connection structure with a positionable posture includes a prefabricated bridge pier 1 and a platform cap 2 located below the prefabricated bridge pier. , the center of the first pouring part is provided with a boss 211, and the boss 211 is aligned with the center of the prefabricated pier 1, and the prefabricated pier 1 is provided with a plurality of longitudinally stressed steel bars 11 arranged circumferentially around the projection of the boss on the prefabricated pier. Stressed steel bar 11 protrudes from the bottom of prefabricated pier 1 and extends along the height direction of boss 211. Post-casting part 22 is located around boss 211 and makes longitudinal stressed steel bar, pre-casting part and post-casting part closely combined. Longitudinal stressed steel bar 11 goes deep into the post-casting part 22.

[0027] The pre-cast part 21 of the cap can be cast on site or prefabrica...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that the end of the longitudinally stressed steel bar is straight and extends to the root of the boss, such as Figure 4 As shown, there is no need to bend the end of the longitudinally stressed steel bar, which can save the bending process, and the linear design can also achieve an excellent positioning and connection effect.

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that the convex positioning tenon is cone-shaped, such as Figure 5 As shown, the cone-shaped section is an isosceles trapezoid.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap