Rollover resistant control method of forklift

A control method and anti-rollover technology, which is applied to vehicle components, elastic suspensions, suspensions, etc., can solve problems such as misalignment of forklift support planes and driving planes, potential safety hazards for operators and cargo, and lateral instability. Improve the anti-rollover ability, improve active safety, and improve the effect of body posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

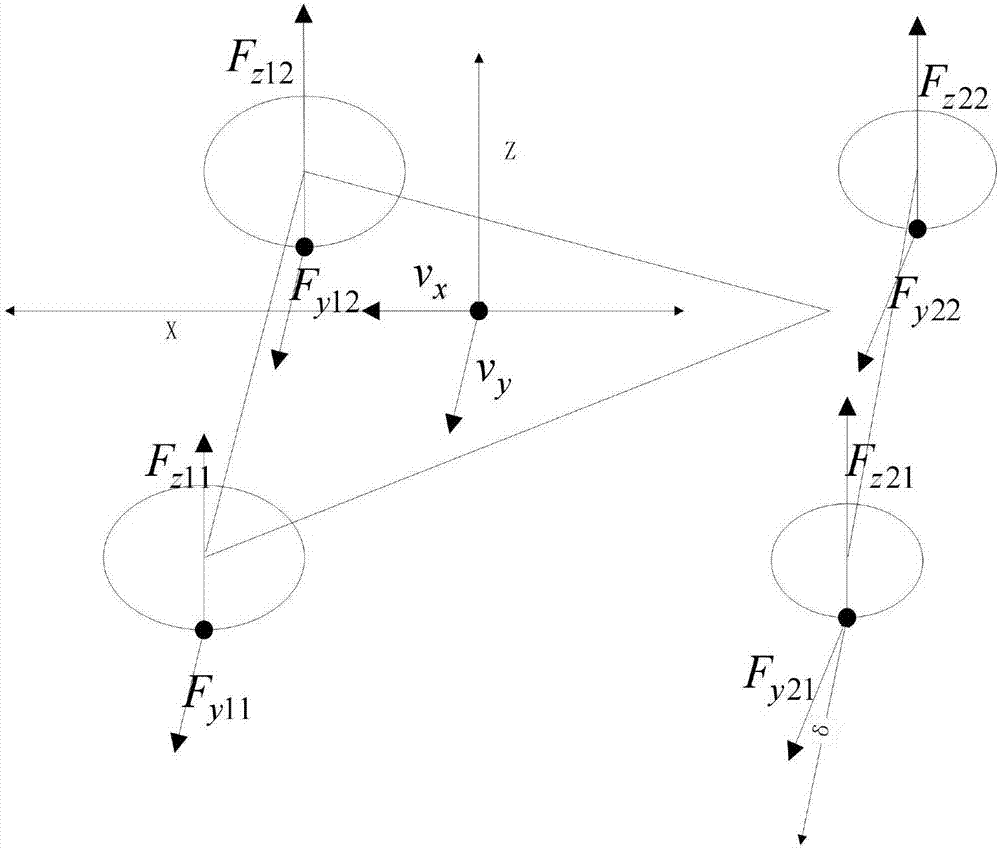

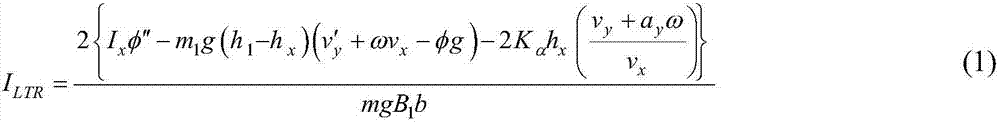

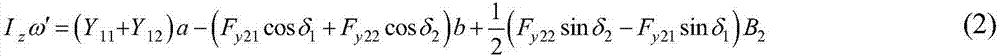

[0065] Embodiment: the forklift anti-rollover control method of the present invention is applied to a certain type of 2.5 ton counterbalanced forklift. The parameters of the counterbalanced forklift are as follows:

[0066] Product of inertia I of the vehicle around the XZ axis x =18313kg.m 2 ; tire cornering stiffness K α =135kN.m -1 ; Vehicle mass m = 4639kg; Frame mass m 1 =1160kg; height of center of mass h 1 =702mm; front wheel track B 1 =1000mm; rear wheel track B 2 = 970mm; front and rear wheelbase L = 1700mm; horizontal distance a from the center of mass to the front axle = 212mm; horizontal distance from the center of mass to the rear axle b = 1488mm; height of the hinge axis of the steering axle h x =275mm;

[0067] Install the gyroscope at the center of mass of the forklift, and collect the forklift roll angle φ, roll angular acceleration φ″, yaw rate ω, and longitudinal acceleration a y and the velocity of the center of mass, and calculate the component v o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com