Pull-resisting piece for prefabricated house structure and preparation method of pull-resisting piece

A technology for structures and houses, which is applied in the direction of building construction, construction, etc., can solve the problems of large thickness and low pull-out resistance of pull-out parts, and achieve enhanced pull-out resistance, strength and pull-out resistance, convenient processing and The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A preparation method for a pullout-resistant part for a prefabricated house structure, comprising the following steps:

[0058] S1. Process the stainless steel plate of the specified size and set it aside. The shape of the stainless steel plate is the unfolded shape of the pull-out parts. There is a trapezoidal steel plate on both sides of the rectangular steel plate. According to the size of the back plate, base, triangular reinforcing rib and rectangular reinforcing rib , draw the folding line;

[0059] S2. Transport the stainless steel plate to the construction site of the prefabricated house, cut the trapezoidal steel plate according to the folding line, and separate the two areas of the rectangular reinforcing rib and the triangular reinforcing rib;

[0060] S3. Bend the rectangular reinforcing rib and the triangular reinforcing rib upward by 90° according to the folding line between the rectangle and the trapezoid, and then fold in half according to the folding li...

Embodiment 1

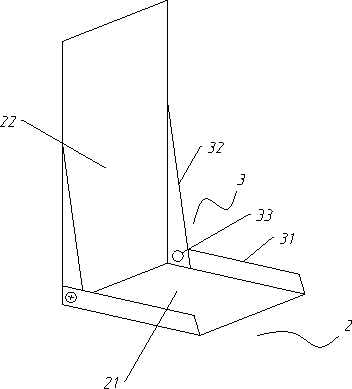

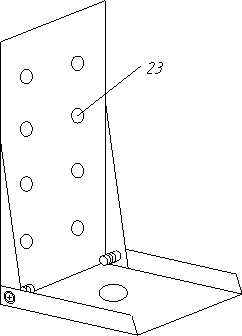

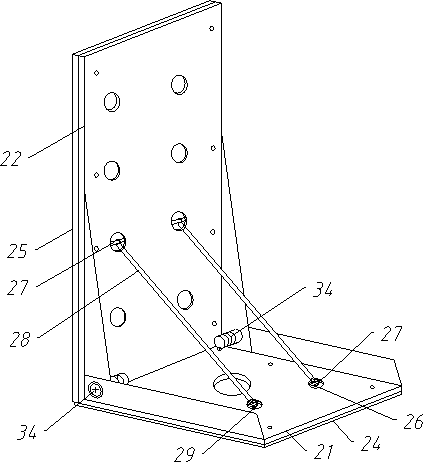

[0068] Including L-shaped plate body 2, both sides of L-shaped plate body 2 are provided with reinforcing ribs 3, L-shaped plate body 2 includes a base 21 and a back plate 22, the back plate 22 is vertically arranged at the end of the base 21, and the reinforcing ribs 3 It includes rectangular reinforcing ribs 31 arranged on both sides of the base 21 and triangular reinforcing ribs 32 arranged on both sides of the back plate 22 , the rectangular reinforcing ribs 31 and the triangular reinforcing ribs 32 overlap each other at the junction of the base 21 and the back plate 22 , And the rectangular reinforcing rib 31 and the triangular reinforcing rib 32 are all provided with mounting holes 33 at the joints, and fasteners 34 are arranged in the mounting holes 33, the base 21 and the back plate 22 are made of stainless steel, the base 21 and the back plate 22 The width is 80mm, and the length is 100mm and 200mm respectively. The length of the rectangular reinforcing rib 31 is consi...

Embodiment 2

[0070] Including L-shaped plate body 2, both sides of L-shaped plate body 2 are provided with reinforcing ribs 3, L-shaped plate body 2 includes a base 21 and a back plate 22, the back plate 22 is vertically arranged at the end of the base 21, and the reinforcing ribs 3 It includes rectangular reinforcing ribs 31 arranged on both sides of the base 21 and triangular reinforcing ribs 32 arranged on both sides of the back plate 22 , the rectangular reinforcing ribs 31 and the triangular reinforcing ribs 32 overlap each other at the junction of the base 21 and the back plate 22 , And the rectangular reinforcing rib 31 and the triangular reinforcing rib 32 are all provided with mounting holes 33 at the joints, and fasteners 34 are arranged in the mounting holes 33, the base 21 and the back plate 22 are made of stainless steel, the base 21 and the back plate 22 The width is 100mm, and the length is 120mm and 240mm respectively. The length of the rectangular reinforcing rib 31 is cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com