Welding-free-type wide limb combination special-shaped skeleton

A special-shaped and skeleton technology, applied in the field of welding-free wide-leg combined special-shaped skeleton, can solve the problems of special-shaped skeleton body damage, difficult to guarantee welding construction quality, and narrow welding space, and achieve the effect of improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

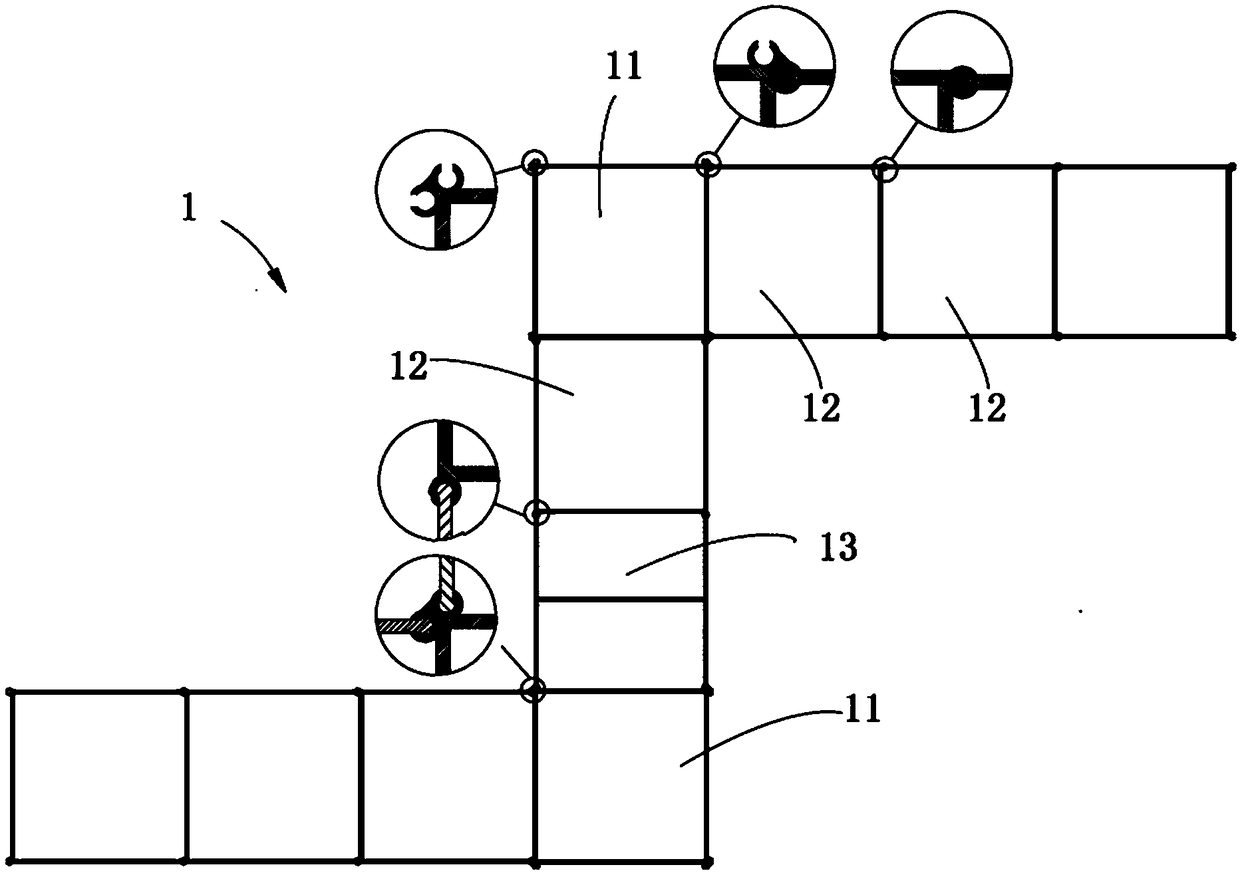

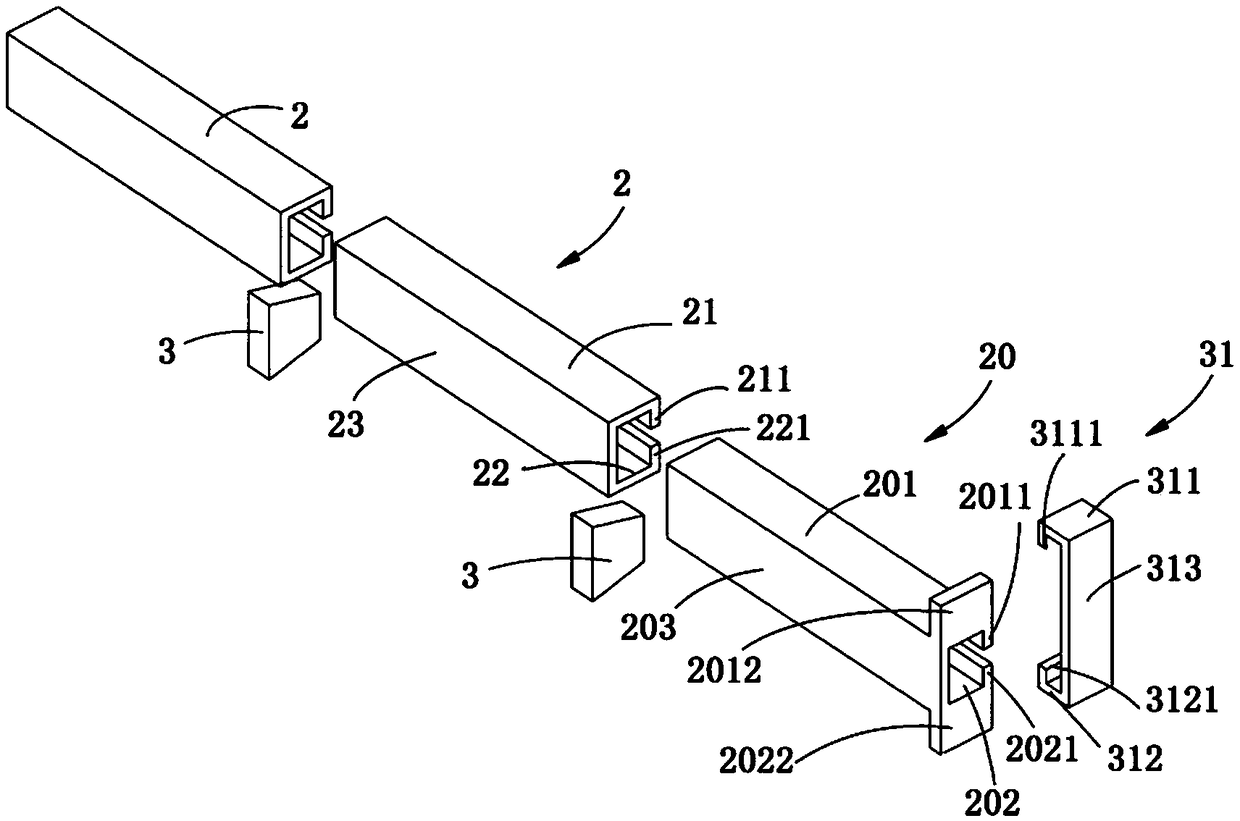

[0041] see figure 1 , image 3 As shown, the present invention provides a welding-free wide-leg combined special-shaped skeleton, which includes several unit sections 1 and connecting slots 2. The unit sections 1 include A unit 11, B unit 12 and C unit 13 all having cuboid shapes. , the connecting slot 2 is shaped as a long frame structure with two ends running through and a C-shaped notch formed on the end surface, wherein:

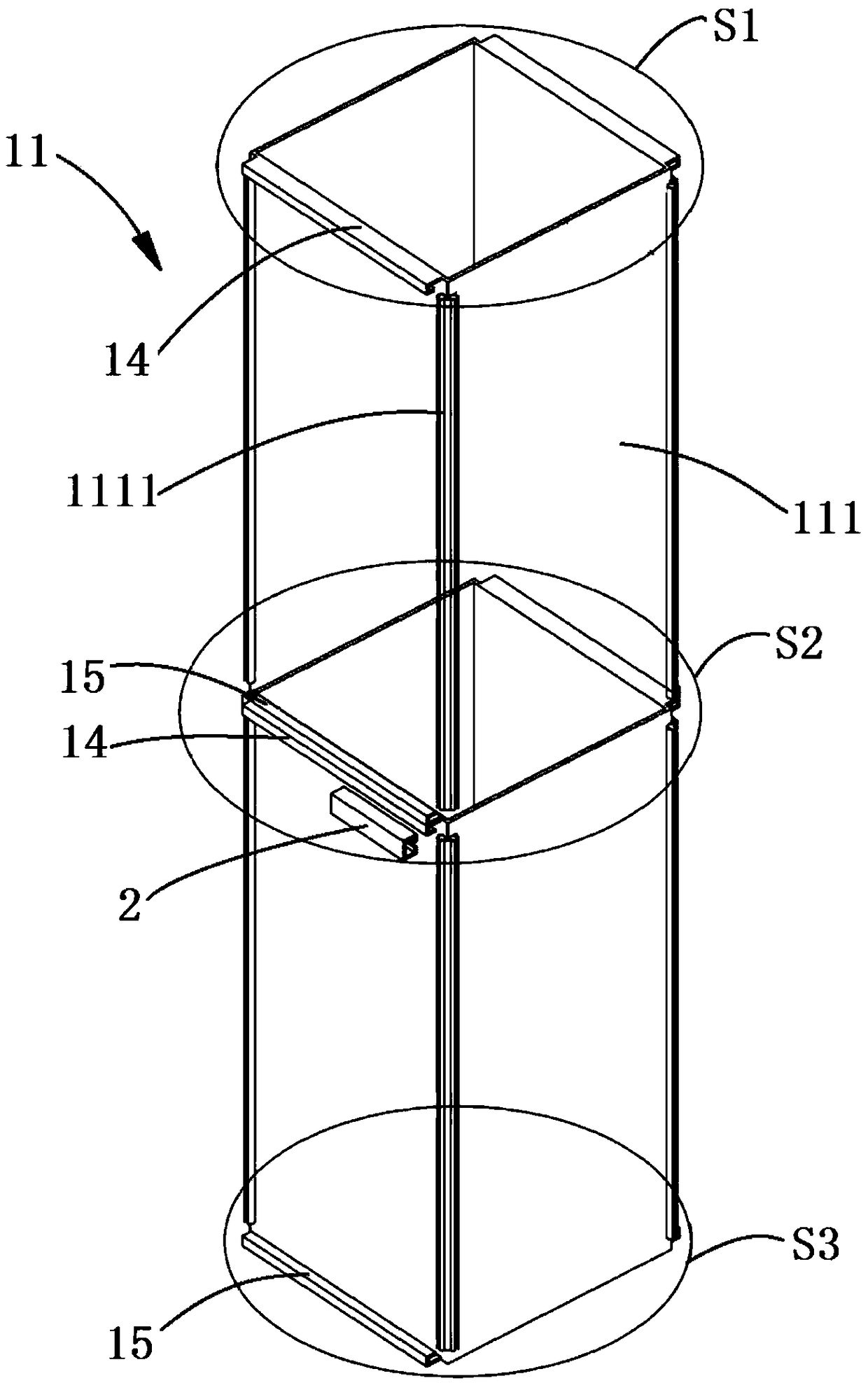

[0042] Such as figure 2 , Figure 4 to Figure 7 As shown, the A unit 11 is shaped as a hollow cuboid member with openings at both ends, the A unit 11 includes four supporting facades 111, and the direction extending along the intersection of two adjacent supporting facades is defined as Z The directions extending along the two sides perpendicular to the intersection line in the two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap