Intelligent fully mechanized mining equipment

A fully mechanized mining equipment, intelligent technology, applied in mining equipment, mining equipment, earthwork drilling and other directions, can solve the problems of paralysis, chain reaction, equipment production process can not operate normally and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

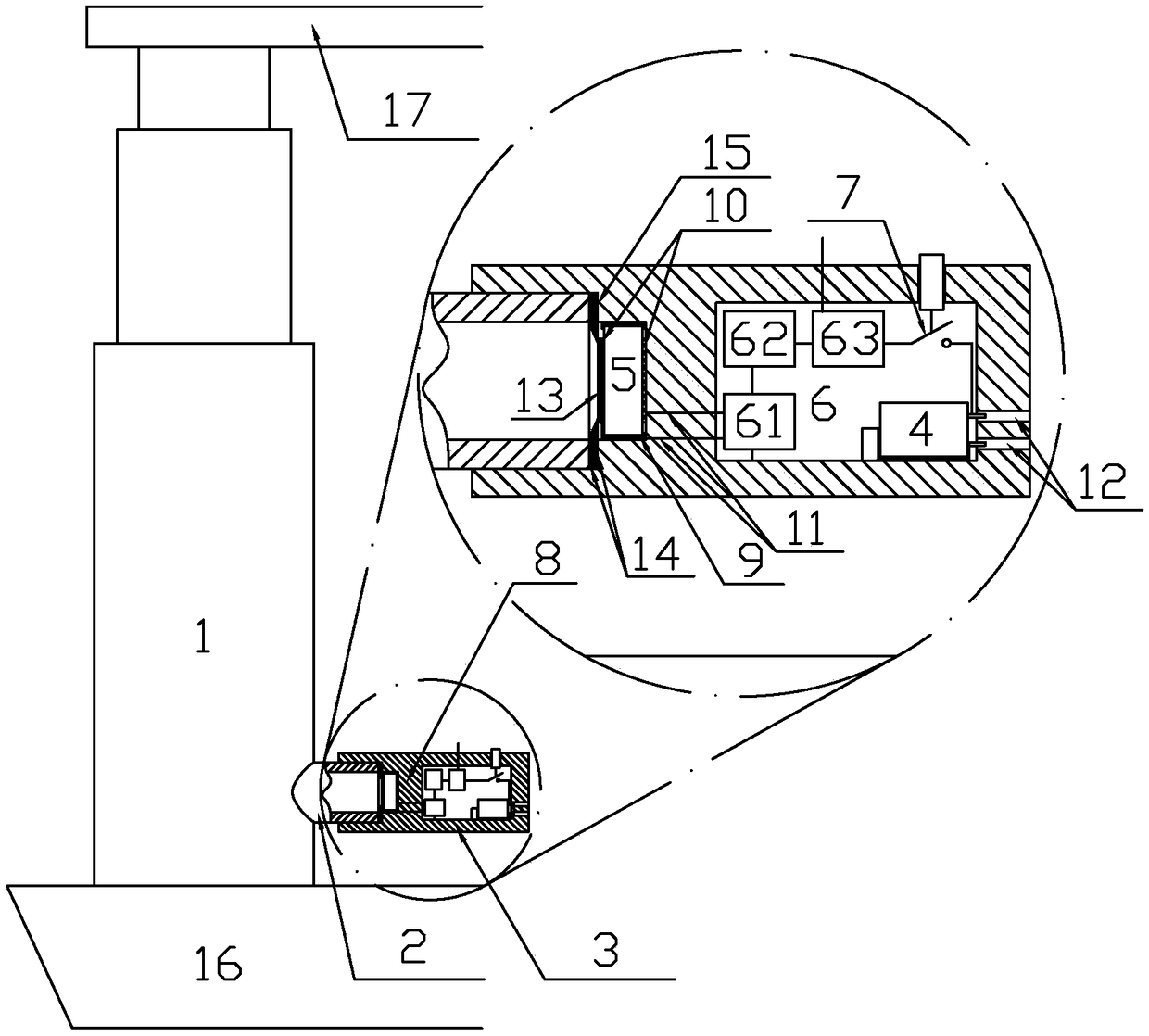

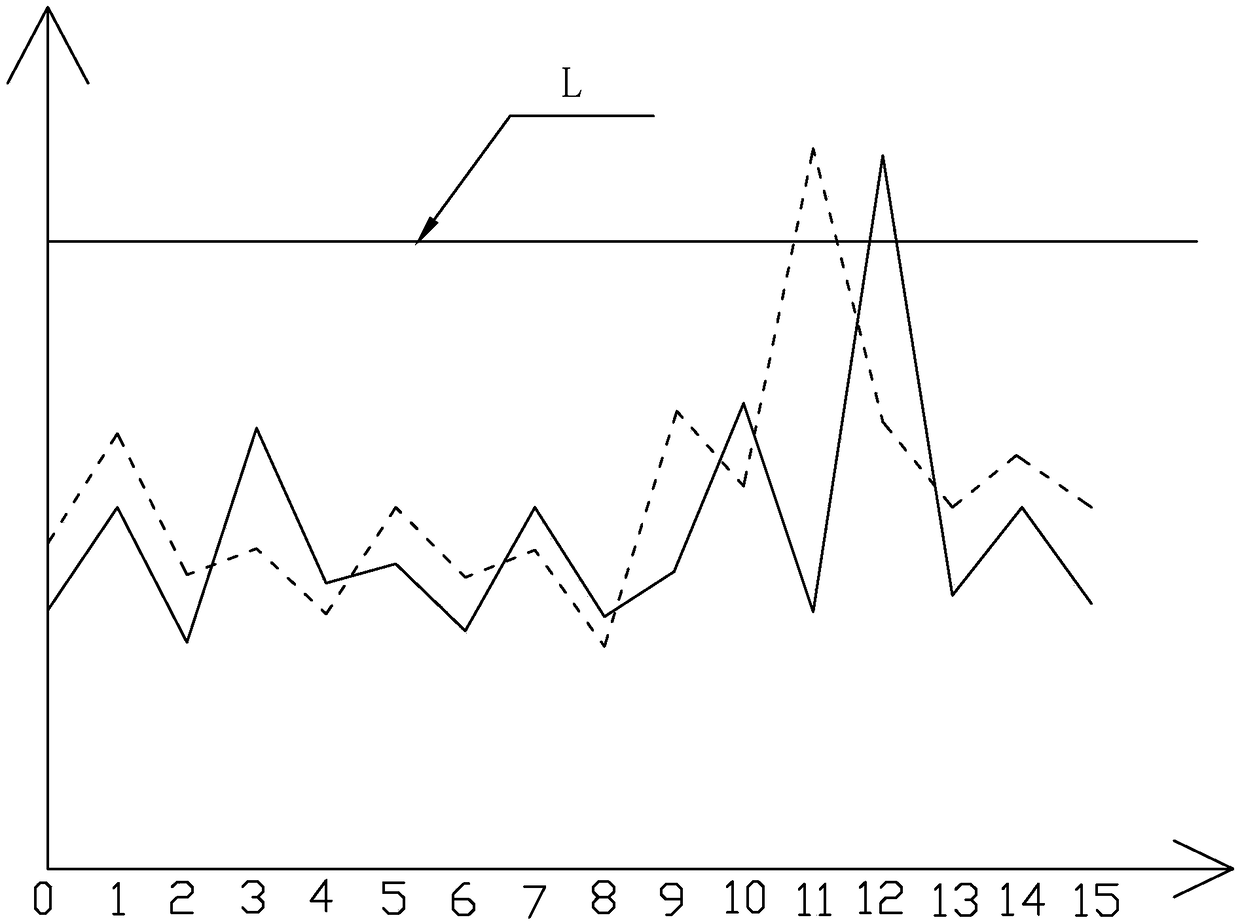

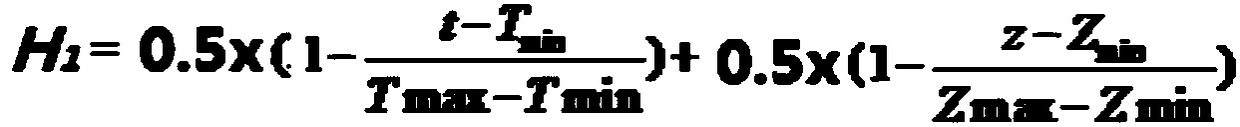

[0047] Embodiment 1: The intelligent fully mechanized mining equipment includes intelligent fully mechanized mining equipment, including working face hydraulic support, coal shearer, scraper conveyor, reloader, belt conveyor, fan, pump station and underground monitoring host, working face hydraulic support It includes the middle bracket and the end brackets at both ends of the middle bracket. The middle bracket and the end bracket are respectively equipped with a hydraulic column 1 and a traction cylinder. Equipped with a driving motor, the feature is that: the underground monitoring host is equipped with a mining fiber grating demodulator, and the driving motors of the coal mining machine, scraper conveyor, reloader, belt conveyor, fan, and pumping station are respectively equipped with mining Fiber Bragg grating temperature sensor and mining fiber Bragg grating vibration sensor, wherein the mine fiber Bragg grating temperature sensor is installed on the output shaft of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com