Gantry waggling detection method suitable for forward-moving forklift

A detection method and gantry technology, which are applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of lack of testing standards, error in testing results, strong subjectivity, etc., and achieve low cost and testing equipment. Less and easier to measure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

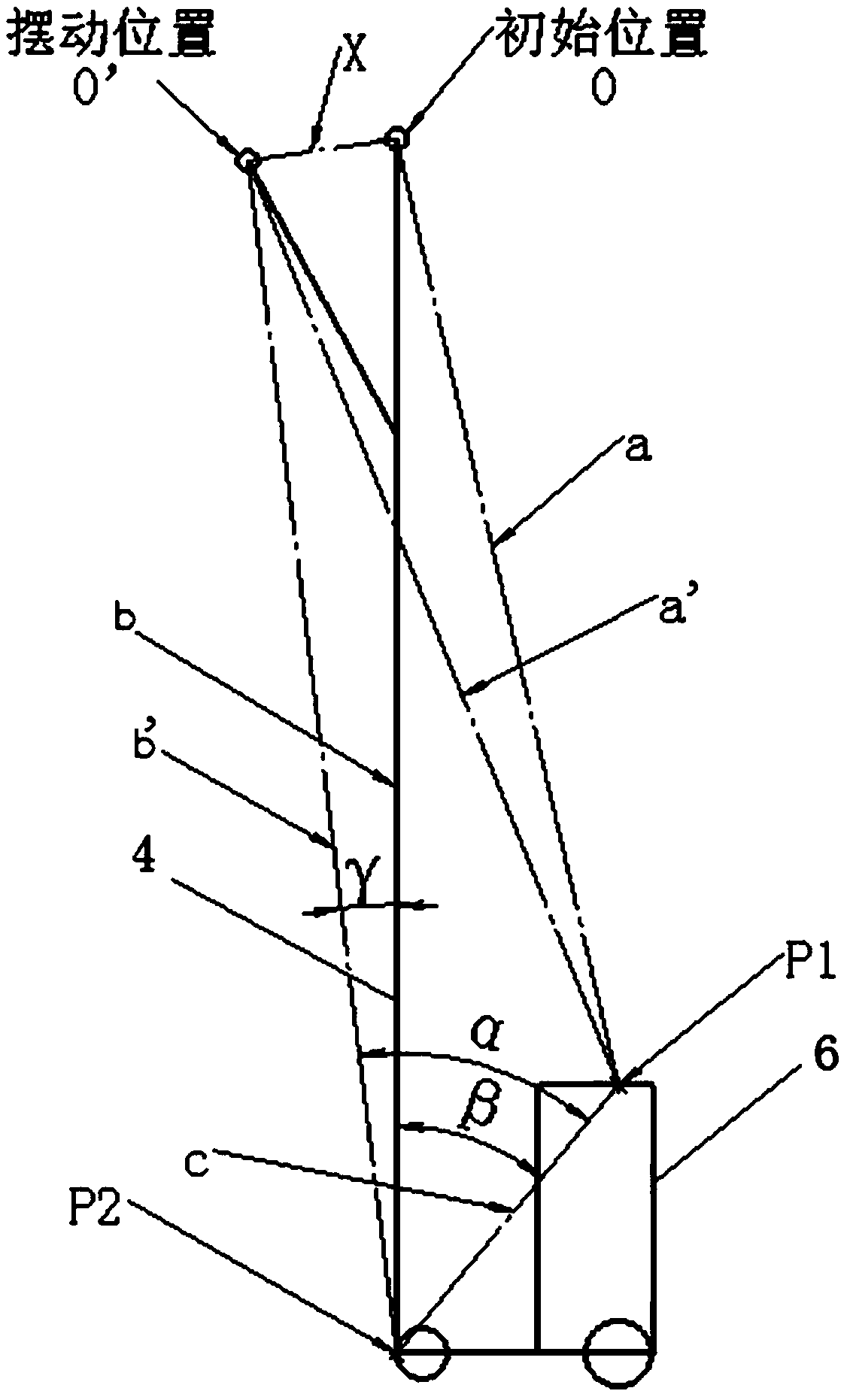

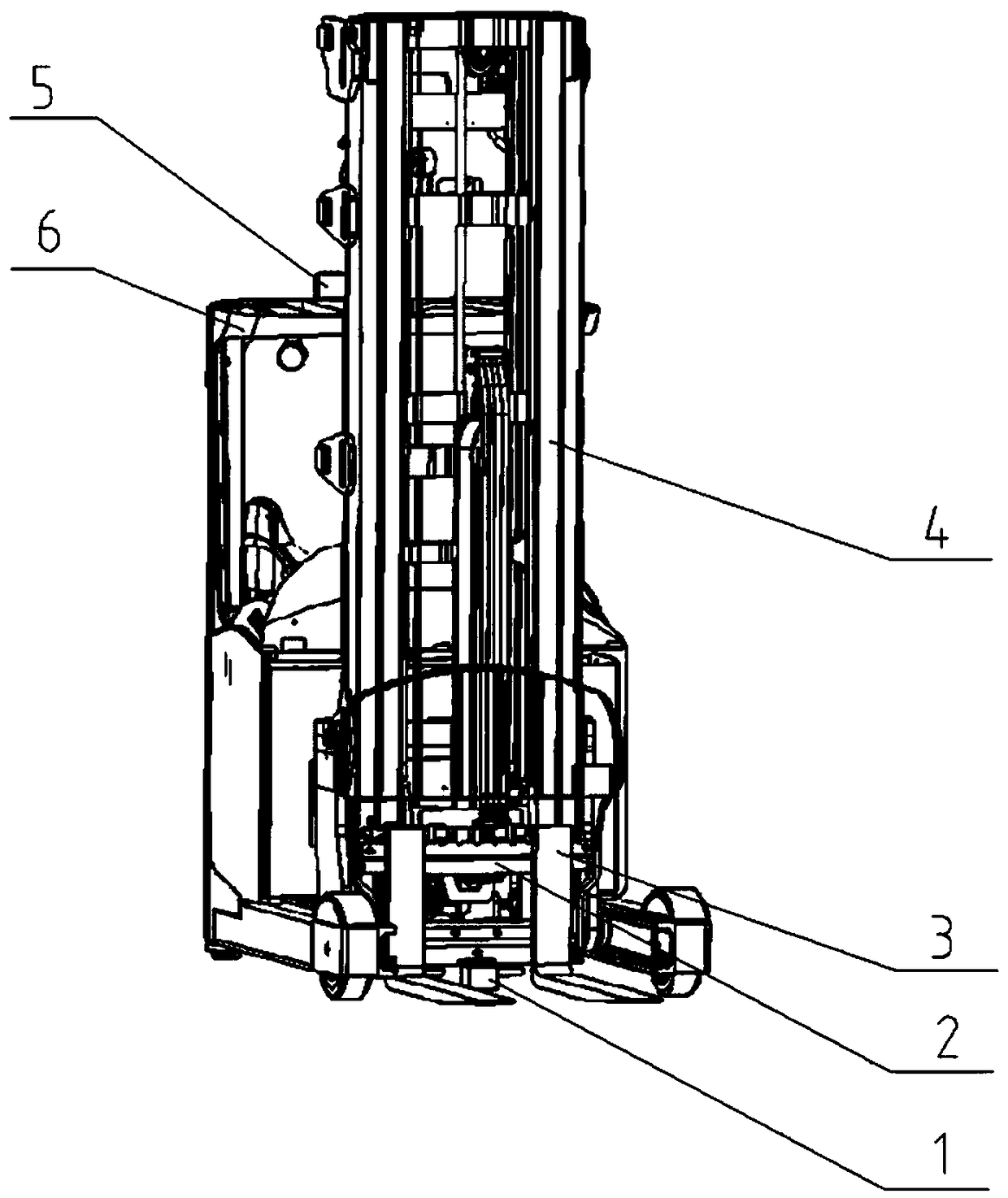

[0028] This embodiment provides a mast 4 shaking detection method suitable for a reach-type forklift, including the following steps:

[0029] (1) When the forklift is fully loaded and not lifted, stretch out to the maximum limit position toward the fork 3 of the forklift; take the middle position of the bottom of the mast 4 as the initial measurement point P2, and place the wire displacement sensor on the At the initial measurement point P2, zero calibration is performed on the stay wire displacement sensor. The initial measurement point P2 is the first installation position 1 of the cable displacement sensor.

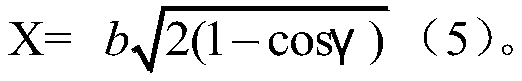

[0030] (2) Take the center position of the crossbeam on the fork frame 2 as the initial investigation point O, connect the stay wire of the stay wire displacement sensor to the initial investigation point O; then extend the door frame 4 to the highest limit position in the vertical upward direction , record the distance b between the initial measurement point P2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com