Method for on-line monitoring of spring of high-voltage circuit breaker mechanism by using force measuring sensor

A technology of force measuring sensor and high-voltage circuit breaker, applied in circuits, parts of protection switches, status indication of switchgear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

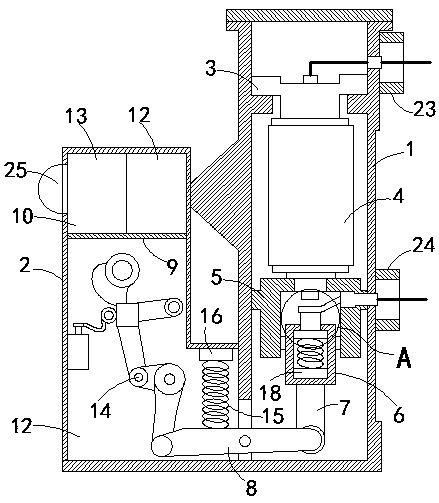

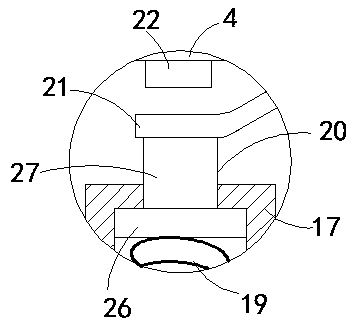

[0023] refer to Figure 1-3 , a method for online monitoring of the mechanism spring of a high-voltage circuit breaker with a load cell. The circuit breaker includes a main case 1 and an auxiliary case 2 connected at its front end and connected to its interior. The main case 1 is sequentially arranged from top to bottom. There are upper support 3, vacuum interrupter 4, lower support 5, opening and closing mechanism 6, insulating pull rod 7 and rotating rod 8. It is worth mentioning that the sub-housing 2 is divided into a control room 10 by a horizontal partition 9 and control room 11.

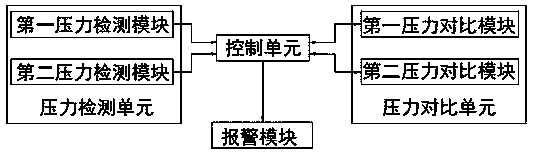

[0024] The sub-housing 2 is divided into a control room 10 and an operating room 11 by a partition 9 arranged horizontally. A controller 12 and an alarm 13 are installed in the control room 10. Specifically, the alarm 13 includes an alarm lamp 25 arranged at its front end , and the alarm 13 runs through the sub-housing 2 and extends to the outside of it, and uses sound and light to alarm, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com