Pod removing machine used for soybeans

A pod removal machine, soybean technology, applied in the direction of application, agricultural machinery and tools, cutting equipment, etc., can solve the problems of easy shock, increased burden, unfavorable production and life, etc., to reduce burden, low manufacturing cost, easy to use The effect of maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

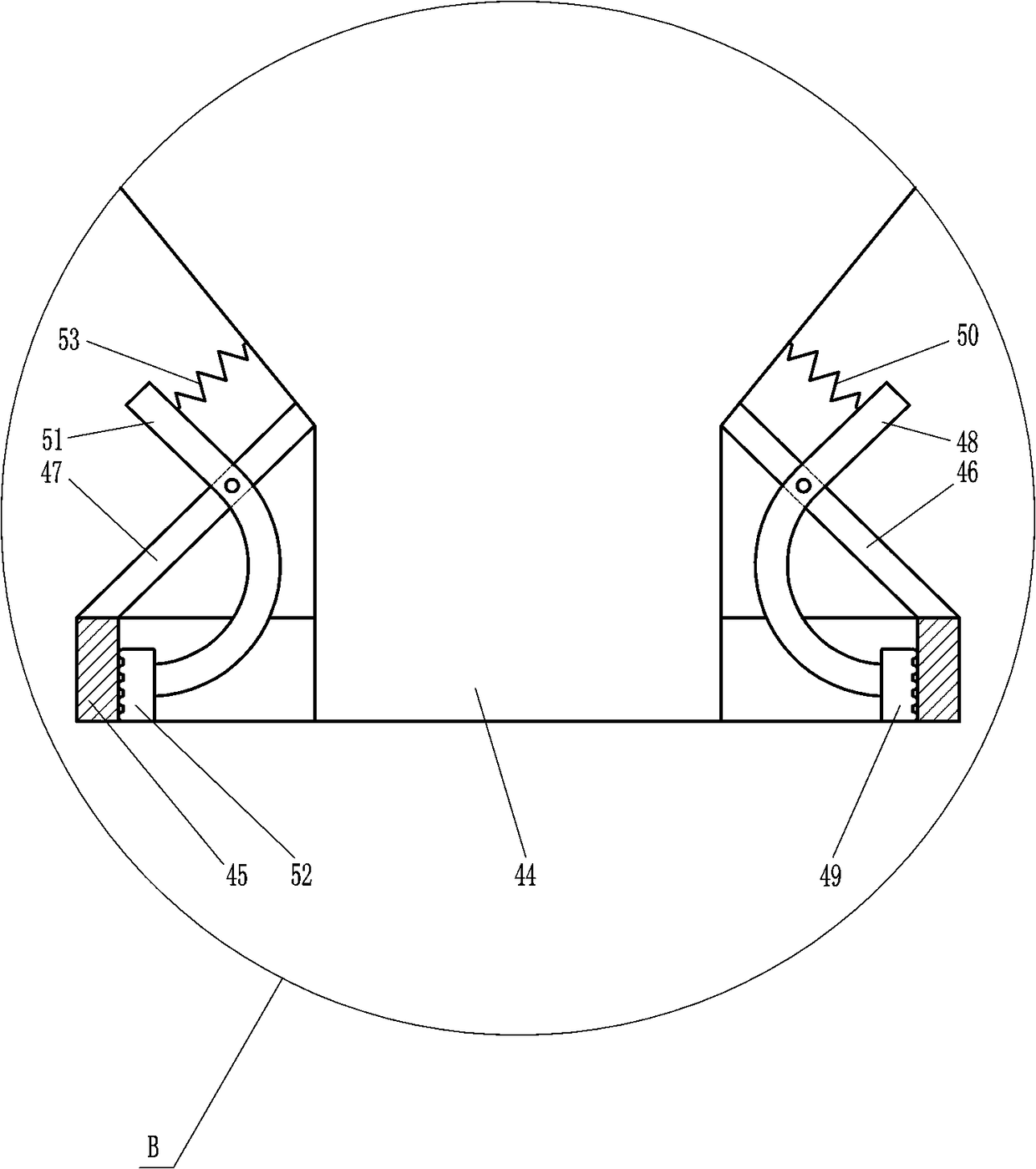

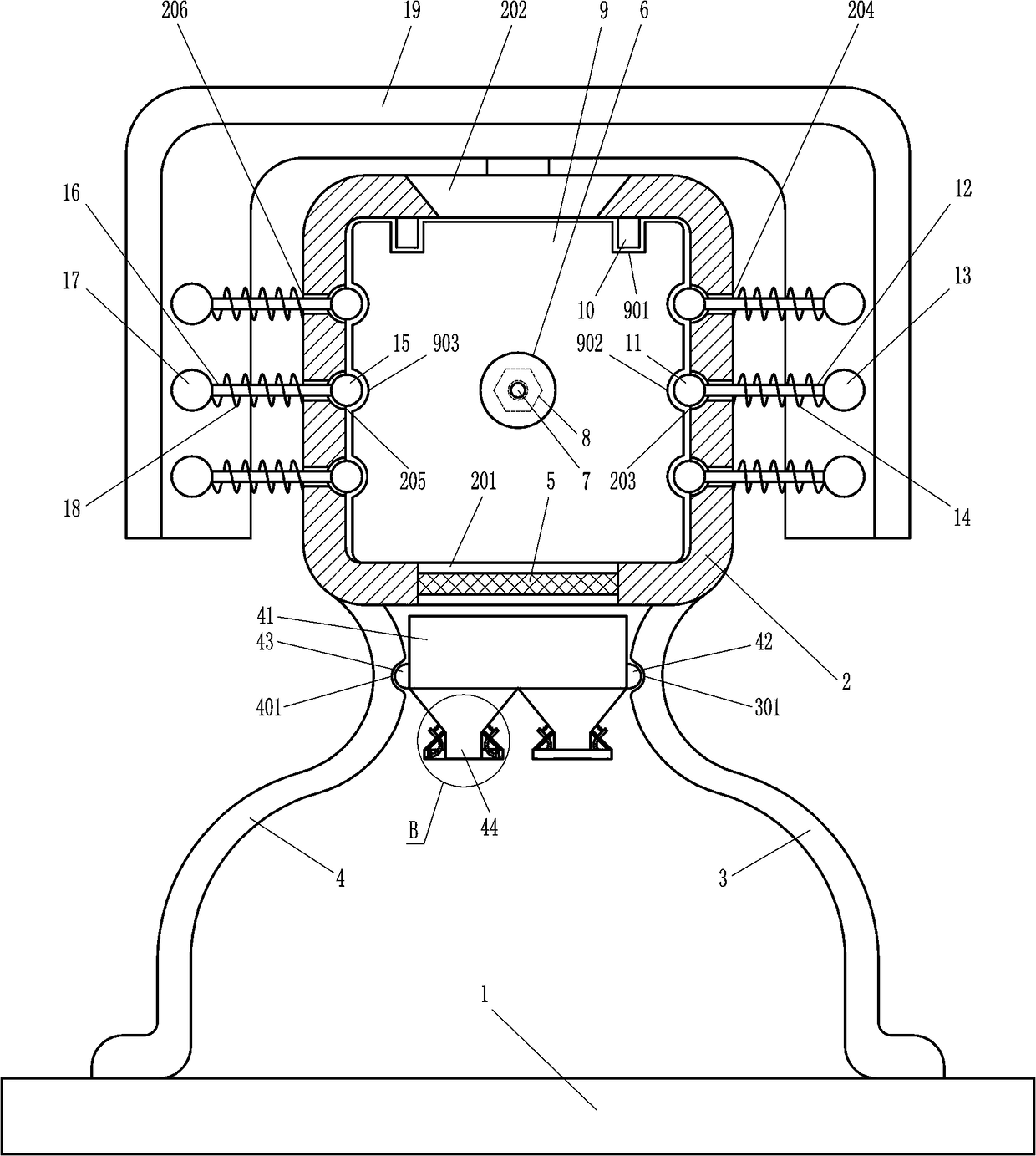

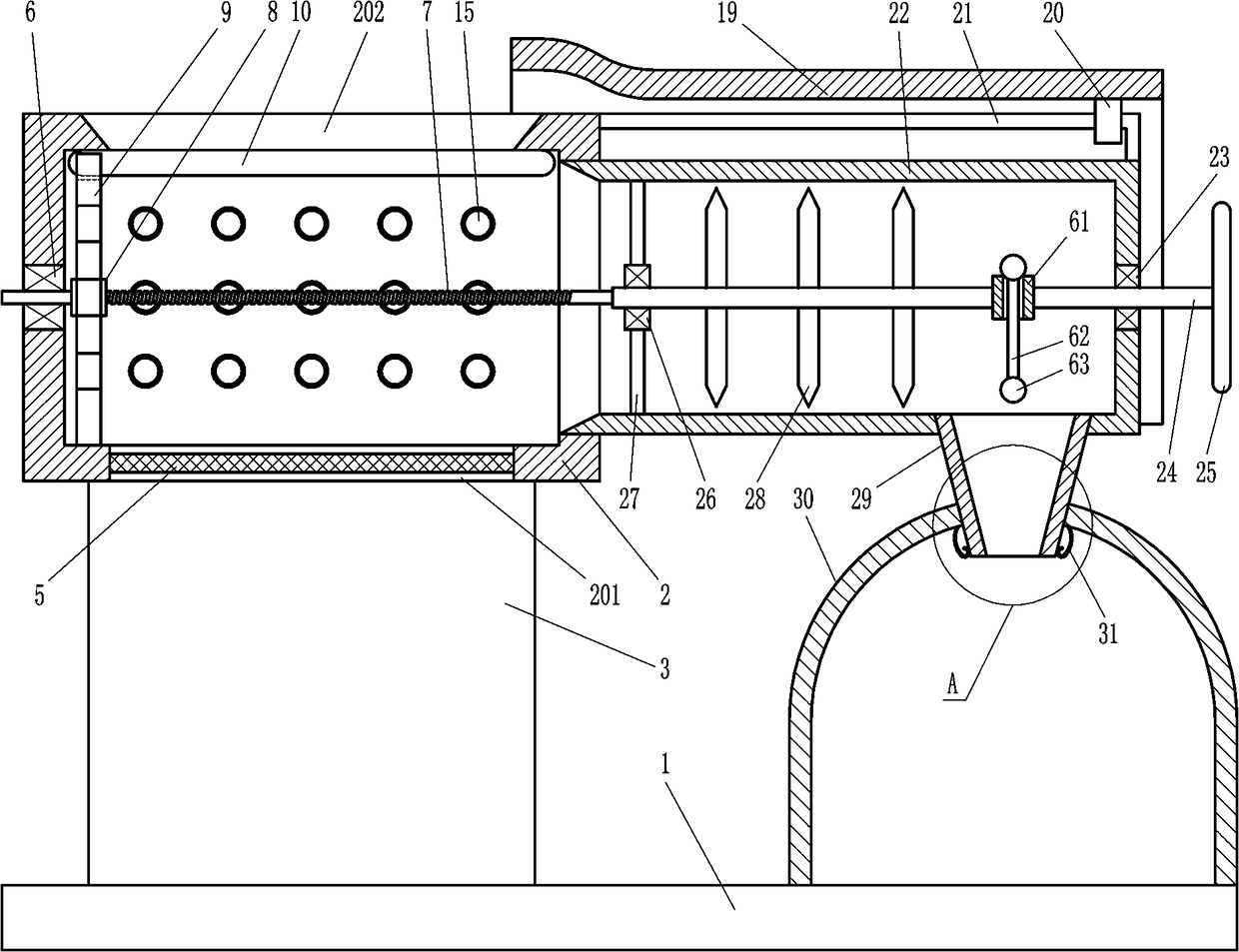

Embodiment 1

[0018] A dehusker for soybeans, such as Figure 1-4 As shown, it includes a base 1, a box body 2, a front bracket 3, a rear bracket 4, a filter screen 5, a first bearing 6, a screw rod 7, a nut 8, a push plate 9, a guide strip 10, and a first extrusion ball 11 , the first guide rod 12, the first contact ball 13, the first spring 14, the second extrusion ball 15, the second guide rod 16, the second contact ball 17, the second spring 18, the inverted U-shaped extrusion cover 19, Guide sleeve 20, L-shaped guide rod 21, cylinder body 22, second bearing 23, rotating shaft 24, rotating wheel 25, third bearing 26, fixed rod 27, cutter 28, tapered discharge pipe 29, inverted U-shaped Support plate 30 and arc-shaped elastic hook 31, box body 2 is positioned at the top of base 1, and the bottom of box body 2 is connected with front frame 3 and rear frame 4, and front frame 3 is positioned at the front of rear frame 4, and front frame 3 and rear frame The brackets 4 are all connected to...

Embodiment 2

[0020] A dehusker for soybeans, such as Figure 1-4As shown, it includes a base 1, a box body 2, a front bracket 3, a rear bracket 4, a filter screen 5, a first bearing 6, a screw rod 7, a nut 8, a push plate 9, a guide strip 10, and a first extrusion ball 11 , the first guide rod 12, the first contact ball 13, the first spring 14, the second extrusion ball 15, the second guide rod 16, the second contact ball 17, the second spring 18, the inverted U-shaped extrusion cover 19, Guide sleeve 20, L-shaped guide rod 21, cylinder body 22, second bearing 23, rotating shaft 24, rotating wheel 25, third bearing 26, fixed rod 27, cutter 28, tapered discharge pipe 29, inverted U-shaped Support plate 30 and arc-shaped elastic hook 31, box body 2 is positioned at the top of base 1, and the bottom of box body 2 is connected with front frame 3 and rear frame 4, and front frame 3 is positioned at the front of rear frame 4, and front frame 3 and rear frame The brackets 4 are all connected to ...

Embodiment 3

[0023] A dehusker for soybeans, such as Figure 1-4As shown, it includes a base 1, a box body 2, a front bracket 3, a rear bracket 4, a filter screen 5, a first bearing 6, a screw rod 7, a nut 8, a push plate 9, a guide strip 10, and a first extrusion ball 11 , the first guide rod 12, the first contact ball 13, the first spring 14, the second extrusion ball 15, the second guide rod 16, the second contact ball 17, the second spring 18, the inverted U-shaped extrusion cover 19, Guide sleeve 20, L-shaped guide rod 21, cylinder body 22, second bearing 23, rotating shaft 24, rotating wheel 25, third bearing 26, fixed rod 27, cutter 28, tapered discharge pipe 29, inverted U-shaped Support plate 30 and arc-shaped elastic hook 31, box body 2 is positioned at the top of base 1, and the bottom of box body 2 is connected with front frame 3 and rear frame 4, and front frame 3 is positioned at the front of rear frame 4, and front frame 3 and rear frame The brackets 4 are all connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com