Yarn falling spool pipe bank

A bobbin and doffing technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of reduced efficiency of the whole vehicle, skewed bobbins, single-spindle spinning stop, etc., and achieves improved operation. Efficiency, bobbin regularity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and the schematic embodiment of the present invention and illustration are used for explaining the present invention, but not as limiting the present invention

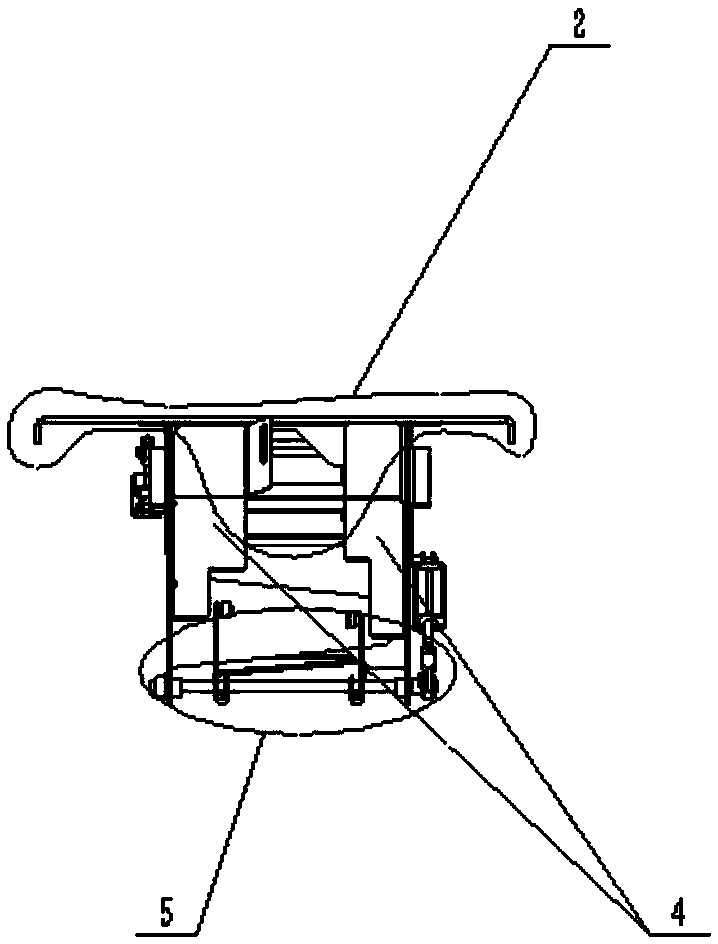

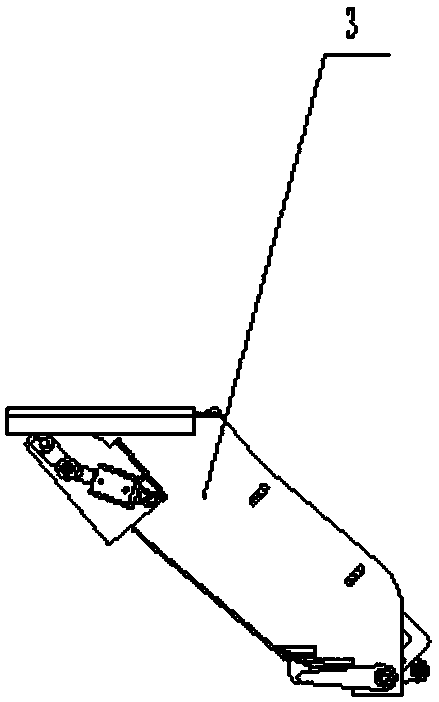

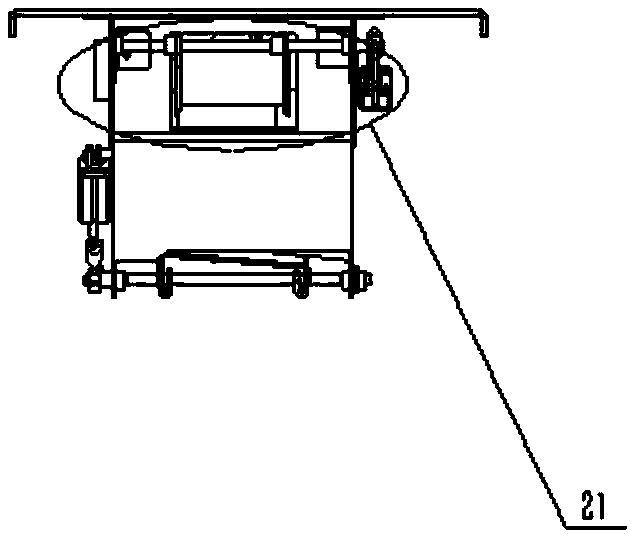

[0035] Such as Figure 1a , Figure 1b , Figure 1c , Figure 2a , Figure 2b , Figure 2c , image 3 as well as Figure 4a and Figure 4b As shown, the present invention specifically discloses a doffing bobbin storehouse, which includes a main body part 3 of a pipe storehouse frame, and a buffer and skew correction part 2 is arranged on the upper end of the main body part 3 of the pipe storehouse frame, and the buffer and skew correction part 2 includes The support plate 22, the corrector 23 arranged at the bottom of the support plate 22, the stop assembly 21 arranged at one end of the corrector 23, the stop assembly 21 is provided with a correction drive cylinder 211, and the main pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com