Bubble blowing machine

A technology of bubble blowing machine and machine base, applied in the field of glass product manufacturing, which can solve the problems of low processing efficiency, taking out wine glasses, manual clamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

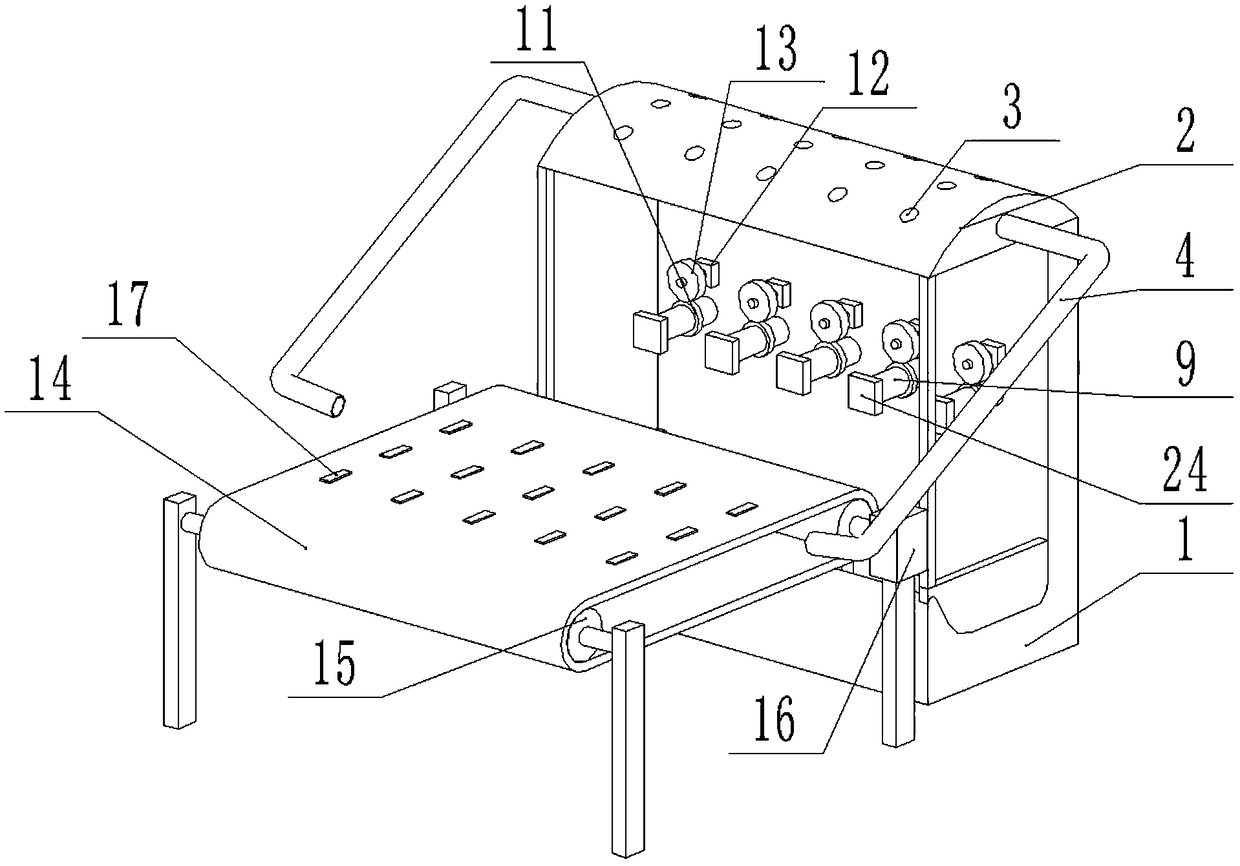

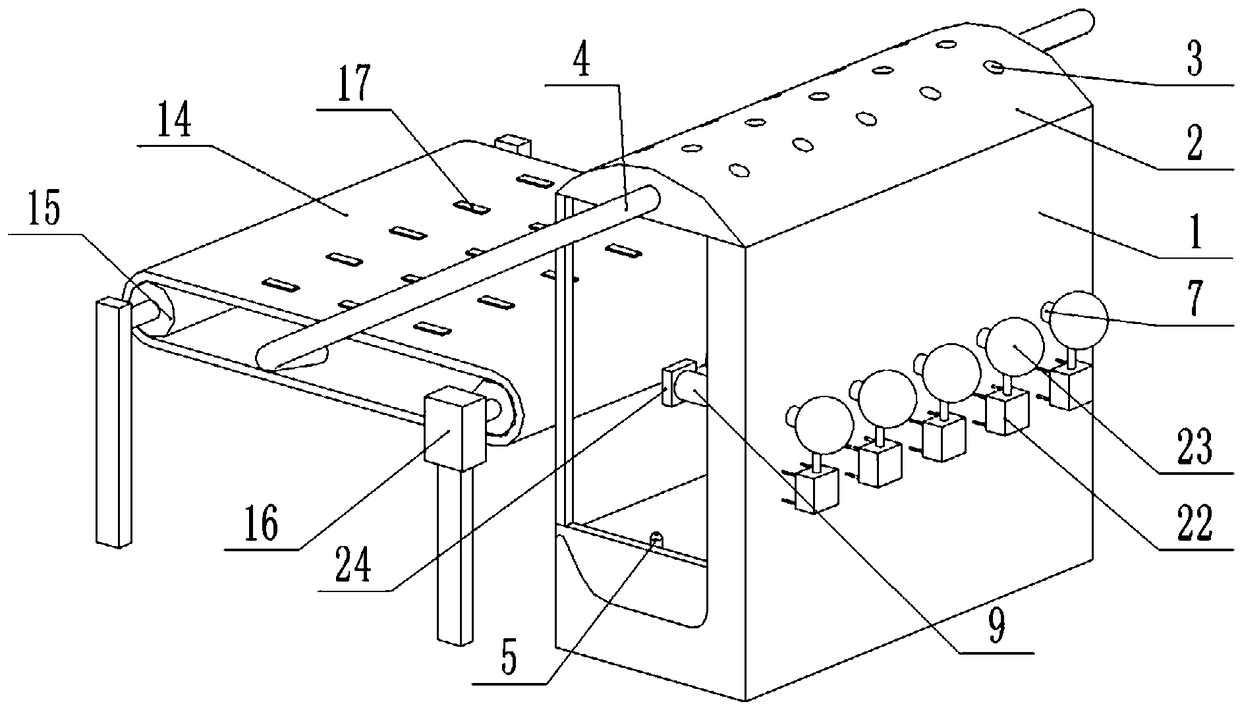

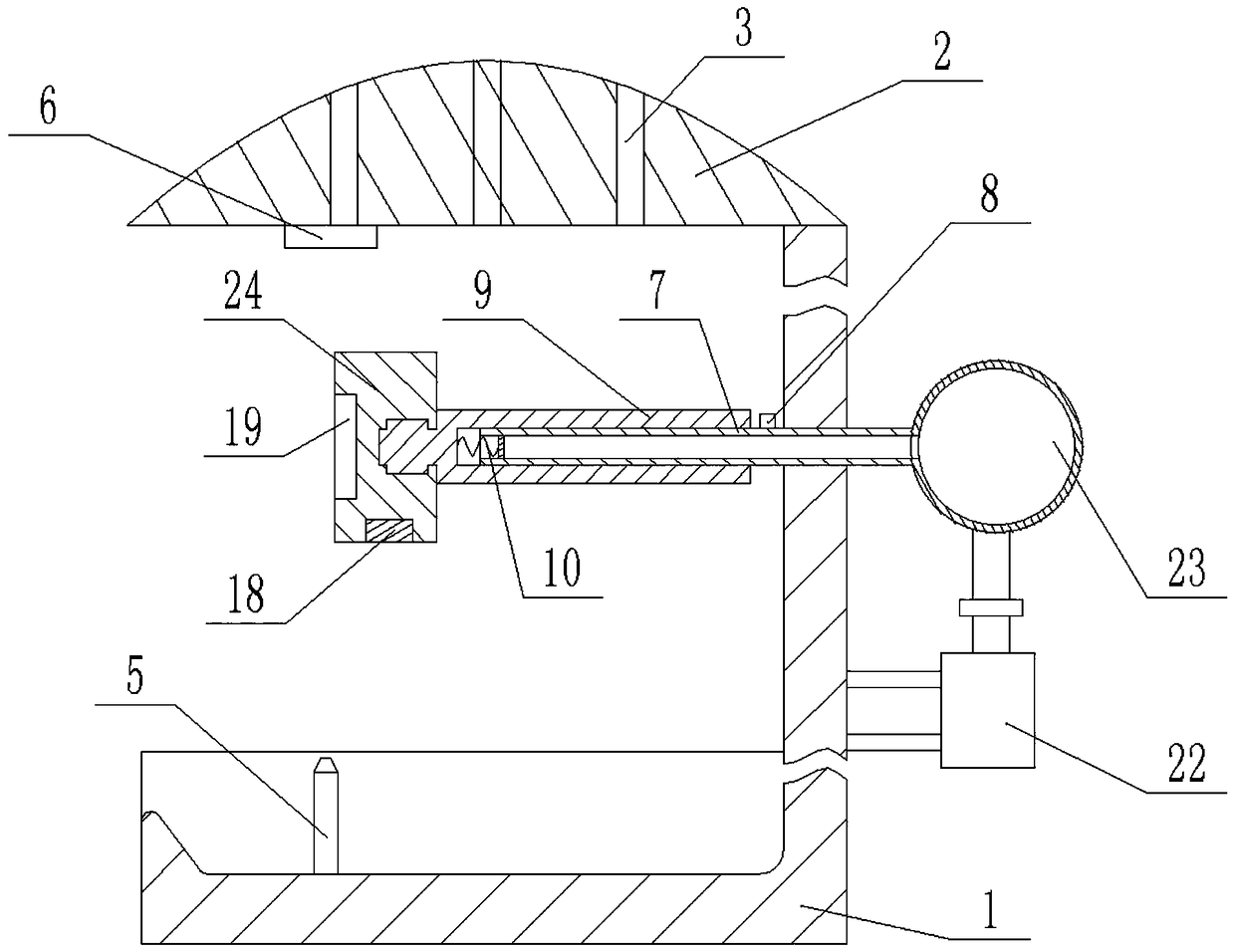

[0016] The following is further described in detail through specific implementation methods:

[0017] The reference signs in the drawings of the description include: machine base 1, top cover 2, air passage 3, air outlet pipe 4, flame spray gun 5, first resistor 6, telescopic rod 7, second solenoid valve 8, clamping rod 9, First spring 10, second friction wheel 11, motor 12, first friction wheel 13, conveyor belt 14, roller 15, driver 16, first magnetic block 17, second magnetic block 18, groove 19, second spring 20 , splint 21, air pump 22, air bag 23, jaw pliers 24.

[0018] The embodiment is basically as attached figure 1 , figure 2 Shown:

[0019] The bubble blowing machine includes a machine base 1, the top of the machine base 1 is provided with a top cover 2, the middle part of the top cover 2 is arched upwards, and the top cover 2 is provided with a hollow accommodation cavity, which is filled with sodium bicarbonate particles. The top cover 2 is provided with seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com