A new finite element modeling method for insect wings with flexible vein nodes

A modeling method and finite element technology, applied in instrumentation, design optimization/simulation, calculation, etc., can solve problems such as inability to accurately simulate mechanical properties such as the overall stiffness of wings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

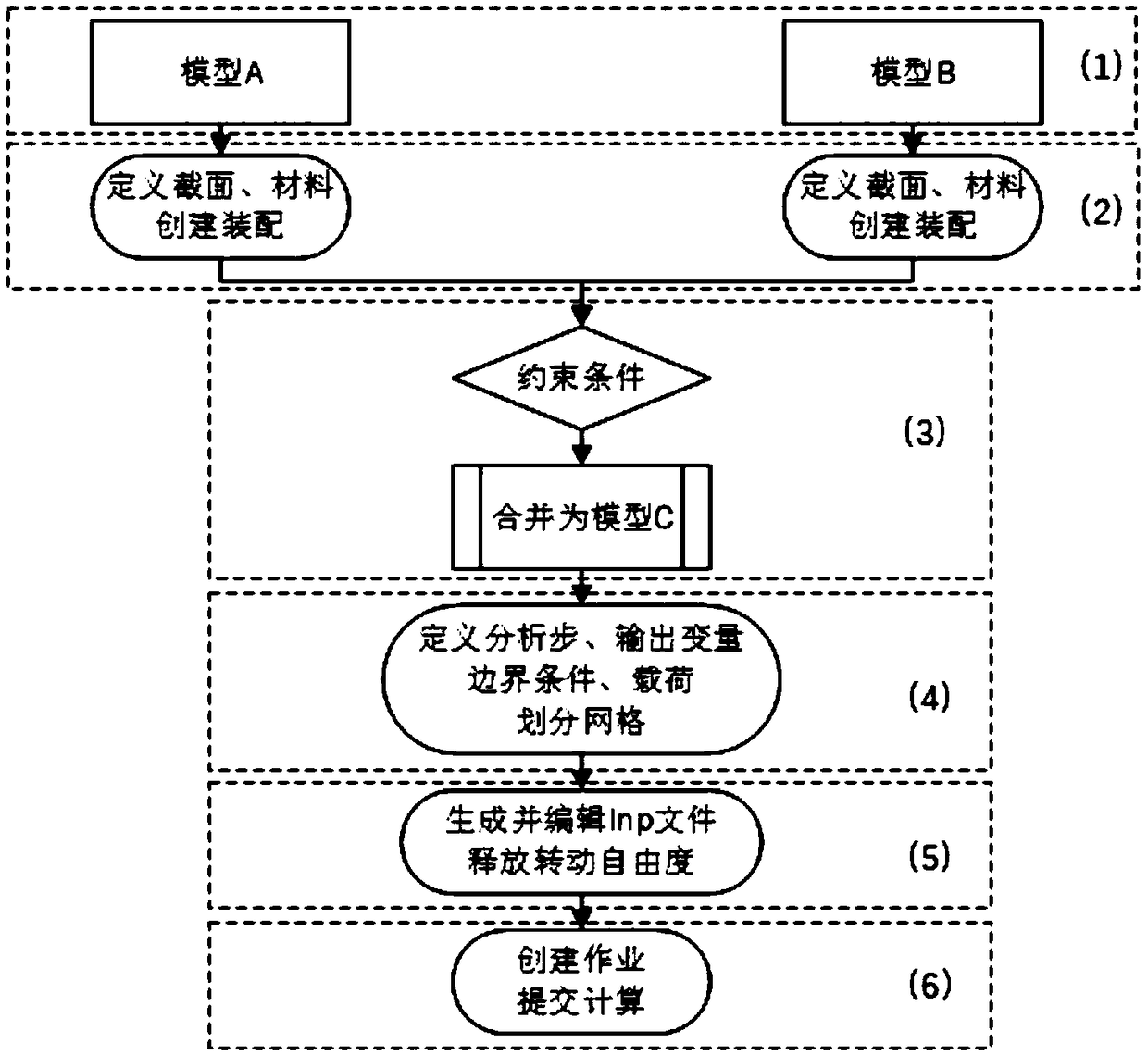

[0046] Such as figure 1 , a new finite element modeling method for insect wings with flexible vein nodes, including the following steps:

[0047](1) Basic modeling, build model A and model B. Model A: wing veins, images of insect wings obtained by scanning, processed by AutoCAD software and imported into Abaqus software to create 3D-deformable-wire type parts; Model B: wing membranes, images of wings obtained by scanning, processed by AutoCAD software After AutoCAD processing, it is imported into Abaqus software to create 3D-deformable-shell type parts.

[0048] (2) Give the component section properties, material parameters, and create an assembly. For model A, assign a circular section, and set the inner diameter and thickness; for model B, assign a uniform thickness shell section, and set the thickness.

[0049] (3) Set constraints, bind model A and model B as model C. Define the binding constraint type to limit the relative displacement and rotation between model A and ...

Embodiment 2

[0061] Such as figure 1 , a new finite element modeling method for insect wings with flexible vein nodes, including the following steps:

[0062] (1) Basic modeling, build model A and model B. Model A: wing veins, images of insect wings obtained by scanning, processed by AutoCAD software and imported into Abaqus software to create 3D-deformable-wire type parts; Model B: wing membranes, images of wings obtained by scanning, processed by AutoCAD software After AutoCAD processing, it is imported into Abaqus software to create 3D-deformable-shell type parts.

[0063] (2) Give the component section properties, material parameters, and create an assembly. For model A, assign a circular section, and set the inner diameter and thickness; for model B, assign a uniform thickness shell section, and set the thickness.

[0064] (3) Set constraints, bind model A and model B as model C. Define the binding constraint type to limit the relative displacement and rotation between model A and...

Embodiment 3

[0076] Such as figure 1 , a new finite element modeling method for insect wings with flexible vein nodes, including the following steps:

[0077] (1) Basic modeling, build model A and model B. Model A: wing veins, images of insect wings obtained by scanning, processed by AutoCAD software and imported into Abaqus software to create 3D-deformable-wire type parts; Model B: wing membranes, images of wings obtained by scanning, processed by AutoCAD software After AutoCAD processing, it is imported into Abaqus software to create 3D-deformable-shell type parts.

[0078] (2) Give the component section properties, material parameters, and create an assembly. For model A, assign a circular section, and set the inner diameter and thickness; for model B, assign a uniform thickness shell section, and set the thickness.

[0079] (3) Set constraints, bind model A and model B as model C. Define the binding constraint type to limit the relative displacement and rotation between model A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com