Heat management method for new energy automobile power electric source system

A new energy vehicle, power supply technology, applied in electric vehicles, circuits, electrical components, etc., can solve problems such as thermal runaway, inability to predict dynamic trends in advance, and achieve the effect of simple and effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

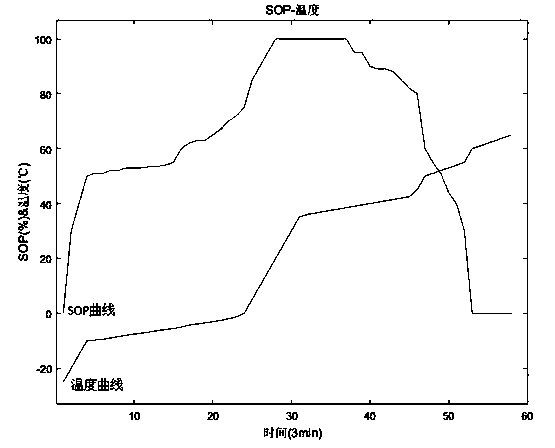

[0111] image 3 It is the relationship curve between the output SOP of the battery pack and the temperature trend. When the temperature is -20°C to 20°C, the output SOP of the battery pack gradually increases with the rise of the temperature. When the temperature rises to 20°C to 35°C, the battery The group outputs full power (SOP=100%), the output power starts to drop when the temperature exceeds 35°C, and drops to 0 when the temperature is 60°C and above.

Embodiment 2

[0113] Figure 4It is a graph of the relationship between the output SOP of the battery pack and the dynamic change of temperature. It can be seen from the curve in the figure that at a temperature of 30°C or below, the SOP gradually increases until 100%. After reaching 30°C but the temperature continues to rise, the SOP begins to fluctuate. showing a downward trend. When the temperature began to drop rapidly, the SOP rose gradually, and finally after 130 minutes, the temperature and SOP fluctuated in a small range and were in a stable state as a whole.

Embodiment 3

[0115] Figure 5 It is a graph of the relationship between the temperature of the battery pack and the auxiliary thermal management components (heating and cooling components). It can be seen from the curve in the figure that at temperatures below 0°C, the heating components work at full load. After reaching 0°C, the heating power gradually decreases, while the temperature It still continues to rise but tends to be slow; when the temperature rises to 5°C, the output power of the heating component is 0, and the heating component is turned off. During this process, the heat dissipation component does not work. When the temperature rises to 30°C and is still rising, the heat dissipation component Start to start, until the cooling part starts to work at full power at 35°C, the temperature shows a downward trend after 100 minutes, and the heat dissipation power also begins to decrease, and it begins to stabilize after 112 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com