Geonet Frame and Its Application

A technology of geonet and net frame, applied in artificial islands, water conservancy projects, soil protection, etc., can solve the problems of long production time, unusable, poor mechanical properties, etc., and achieve low manufacturing cost, stable structure, and high load-carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

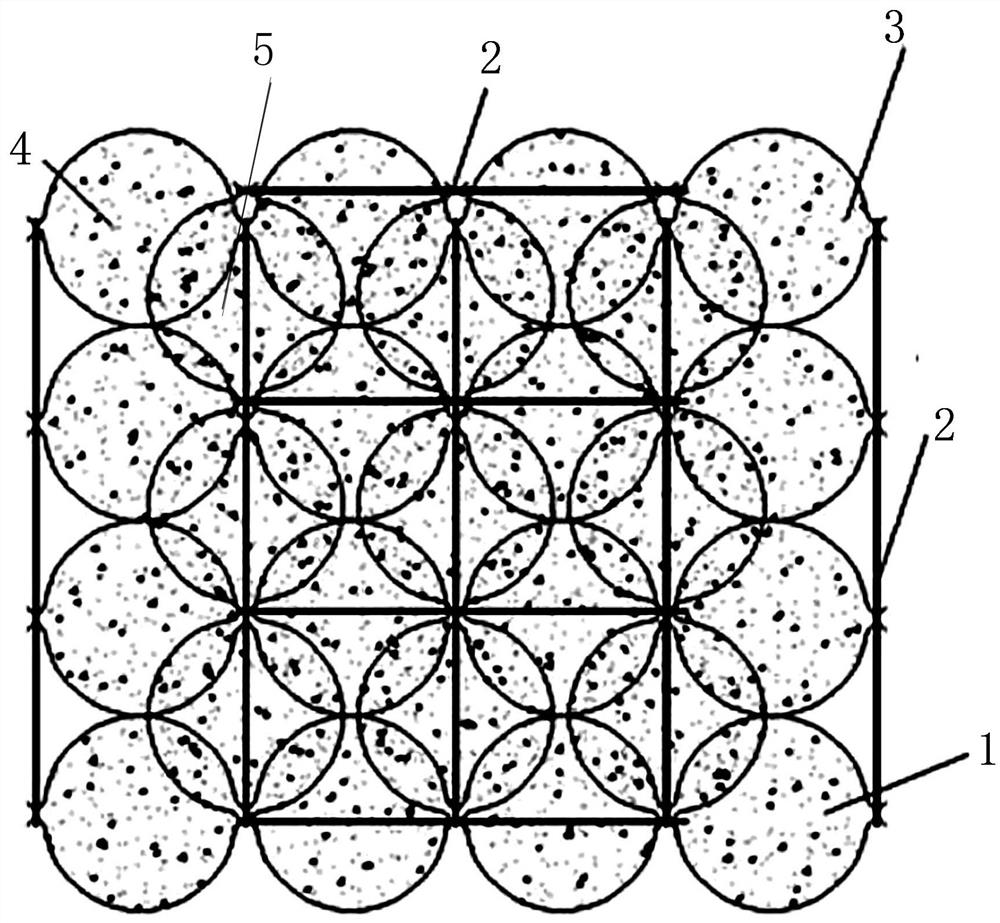

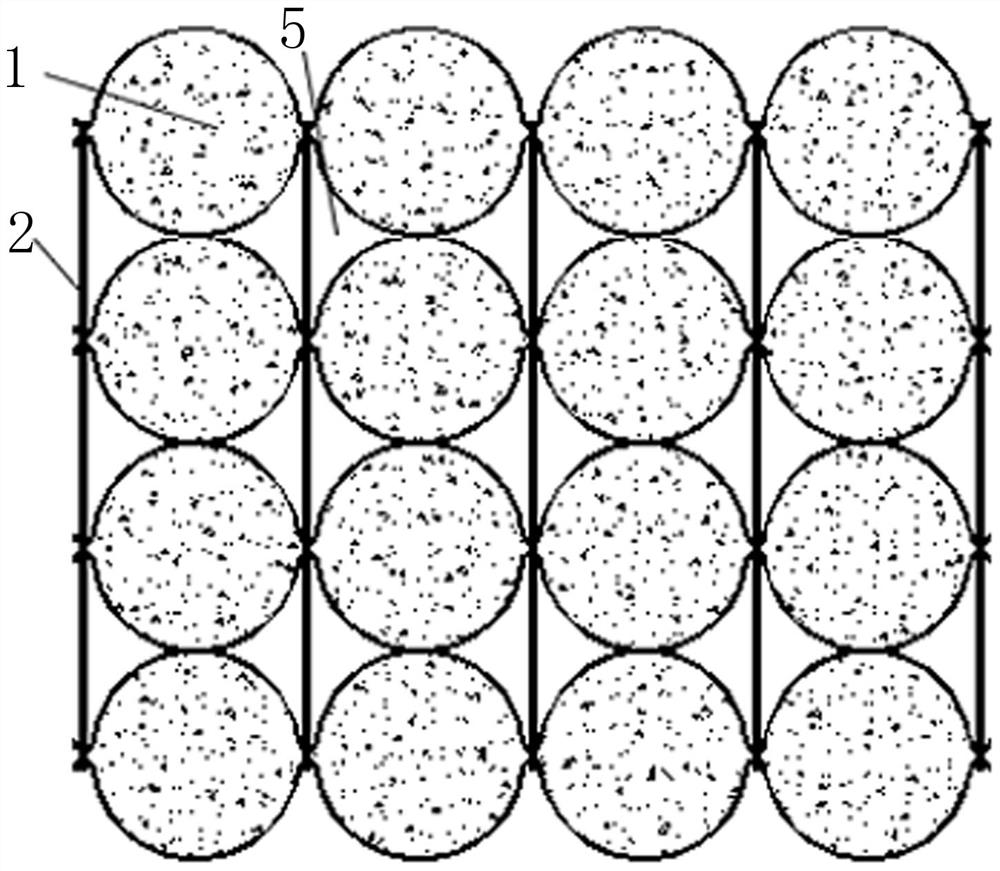

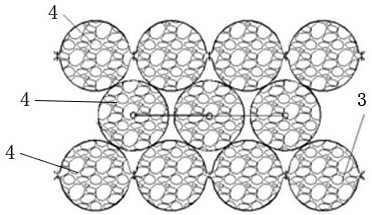

[0028] Such as Figure 1-Figure 3 As shown, a geonet frame includes a geonet layer 4, and several layers of geonet layers 4 are stacked and bound by ropes 2 to form a frame body;

[0029] The geonet layer 4 includes several geotechnical strips 1 , and adjacent geotechnical strips 1 are bound by ropes 2 to form the geonet layer 4 on the same plane.

[0030] The geotechnical strip 1 is composed of a plurality of interconnected similar spherical soil balls 3, and each soil ball 3 is provided with a filler.

[0031] The geostrip 1 includes a long bag, the two ends of which are closed, and the long bag is provided with fillers and bound by several ropes 2 to form several interconnected similar spherical soil balls 3 .

[0032] The long bag is preferably a long PP woven bag (polypropylene woven bag containing TH), which has high strength, and its filling is realized by machine.

[0033] When several layers of geonet layers 4 are stacked, each soil ball 3 in the upper geonet layer ...

Embodiment 2

[0037] An application of the above-mentioned geonetwork frame in foundation reinforcement is as follows:

[0038] Such as Figure 4 as shown,

[0039] According to the geological conditions of the foundation 7 and the load level acting on the foundation, the scope and depth of the foundation pit 6 to be excavated are determined, and then the foundation pit is excavated according to the conventional foundation pit excavation process.

[0040] Fill the excavated soil or other construction waste into the prepared long PP woven bag, and then tie the ropes 2 equidistantly around the outside of the long PP woven bag, so that the fillings inside the long PP woven bag become independent Soil ball 3, that is to complete the production of geostrip 1; put the prepared geostrip 1 into the foundation pit 6, note that the geostrip 1 in the same layer needs to be placed in the same direction, and then connect the layer with the connecting rope 2 The geotechnical strips inside are connected...

Embodiment 3

[0043] An application of the above-mentioned geotechnical network frame in slope reinforcement, specifically:

[0044] Determine the slope surface of the slope according to the geological conditions of the slope and the load level acting on the slope;

[0045]Sequentially close to the slope surface of the slope to form a geogrid with the same slope as the slope, and install it in front of the slope: fill the excavated soil or other construction waste into the prepared long strip PP woven bag, and then place it in the long The outside of the strip-shaped PP woven bag is equidistantly tied with ropes 2, so that the filling inside the long strip-shaped PP woven bag becomes individual soil balls 3, that is, the production of the geostrip 1 is completed; the prepared geostrip 1 is close to the edge Note that the geostrips 1 in the same layer need to be placed in the same direction, and then use the connecting rope 2 to connect and fix the geostrips 1 in the layer to make it a geone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com