Insulated operating rod for charged operation

An insulating operating rod and live operation technology, applied in the direction of contact operating parts, etc., can solve the problems of corona discharge, prone to corona discharge, and inability to effectively remove corona discharge, and achieve flexible installation and disassembly, easy transportation and effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

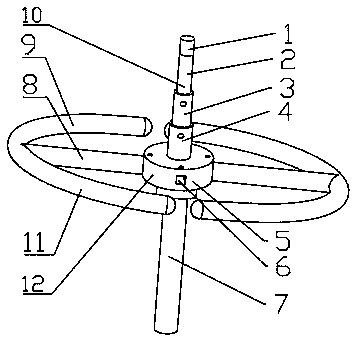

[0024] Such as figure 1 As shown, an insulating operating rod for live work includes a metal joint 1 , a telescopic part 10 , an insulating rod 7 , an installation and fixing part 12 and a protective part 11 .

[0025] Such as figure 1 As shown, the insulating rod 7 is a circular rod-shaped structure, and the insulating rod 7 is mainly used for holding. The metal joint 1 is used for live work, and the metal joint 1 can be set in different shapes according to the application occasion. In this embodiment, the metal joint 1 is cylindrical.

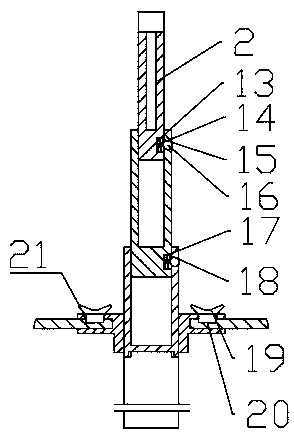

[0026] Such as figure 1 with figure 2 As shown, the telescopic part 10 includes a first telescopic rod 2 , a second telescopic rod 3 , a third telescopic rod 4 , a spring 16 and a steel ball 16 . One end of the telescopic part 10 is connected to the metal joint 1 , and the other end of the telescopic part 10 is connected to the insulating rod 7 . The first telescopic rod 2 is a cylindrical structure with one end closed and one end open,...

Embodiment 2

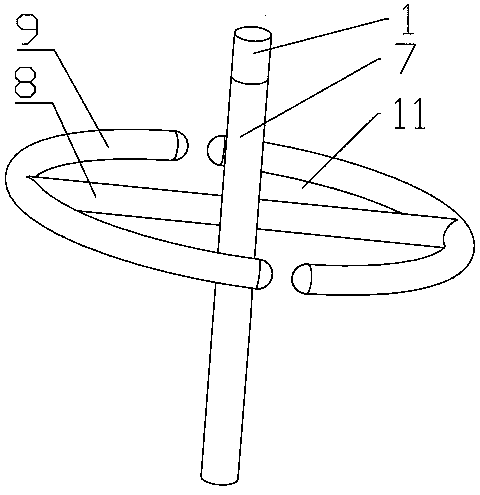

[0030] Such as image 3 As shown, an insulating operating rod for live work includes a metal joint 1, an insulating rod 7 and a protective part 11. The insulating rod 7 is a circular rod-shaped structure, and the insulating rod 7 is mainly used for hand-holding. The metal joint 1 is used for live work, and the metal joint 1 can be set in different shapes according to the application occasion. In this embodiment, the metal joint 1 is cylindrical. The protection part 11 includes a ring body 9 and a connecting rod 8, the ring body 9 is a circular ring structure with a circular cross section, and the connecting rod 8 is a rod-shaped structure with a circular cross section. The protection part 11 includes more than two ring bodies 9 , and in this embodiment the protection part 11 includes two ring bodies 9 . A gap is provided between the ring bodies 9 , and the gaps between the ring bodies 9 are equal. The gap between the ring bodies 9 is less than five times the ring width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com