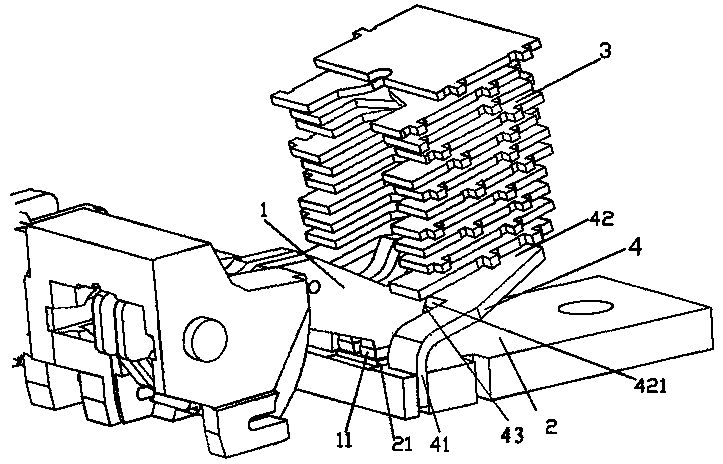

Circuit breaker contact arc extinguishing device and circuit breaker thereof

A technology of arc extinguishing device and circuit breaker, which is applied to high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc. It can solve the problems of different transfer arc effects, achieve good arc extinguishing effect, simple overall structure, and improve electrical life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

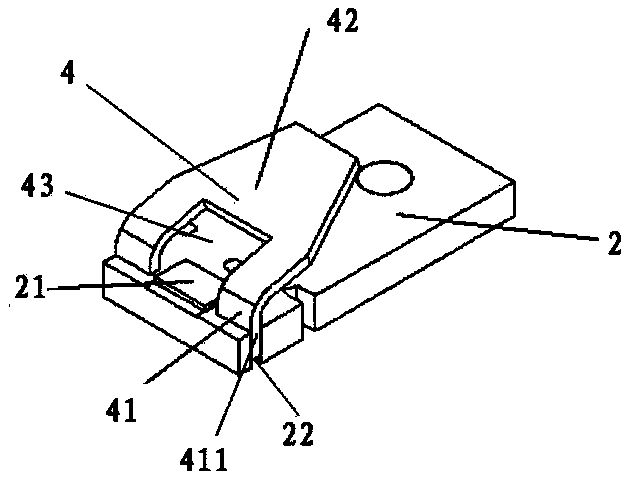

[0026] Such as figure 2 As shown, the arc runner 4 and the static guide rod 2 described in this embodiment are fixedly installed by riveting. Specifically, the static guide rod 2 is provided with grooves 22 on both sides of the static contact point 21 in a direction parallel to the rotation centerline of the movable guide rod, and the supporting leg 41 has a support portion 411 perpendicular to the static guide rod 2. The support part 411 is inserted into the groove 22 of the static guide rod 2, and the fixed installation of the arc runner 4 and the static guide rod 2 is realized by riveting connection.

Embodiment 2

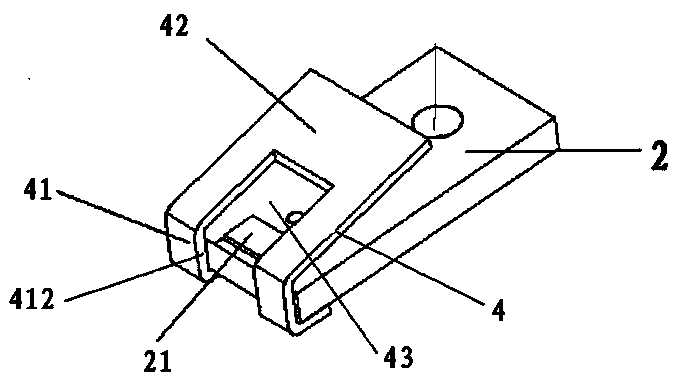

[0028] Such as image 3As shown, the arc striker 4 and the static guide rod 2 described in this embodiment are fixedly installed by welding. Specifically, the support leg 41 has a welded part 412 perpendicular to the static guide rod 2, and the welded part 412 cooperates with the end of the static guide rod 2 to realize the connection between the arc runner 4 and the static guide rod 2 through welding. Fixed installation.

[0029] see Figure 4-Figure 5 , describe the specific arc extinguishing principle of the contact arc extinguishing device of the circuit breaker of the present invention:

[0030] When a short-circuit large current passes through the circuit, the movable contact 11 and the static contact 21 repel each other due to the effect of electrodynamic repulsion, and an arc is formed between the movable contact 11 and the static contact 21. The side is electrically connected with the supporting leg 41 of the arc striker 4, Figure 4 It is the state when the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com