Waterproof high-voltage cabinet

A high-voltage cabinet, waterproof technology, applied in the field of substations, can solve the company's power failure, the inability to recycle the land, the damage of high-voltage cabinet components and other problems, and achieve the effect of preventing electrical components from being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

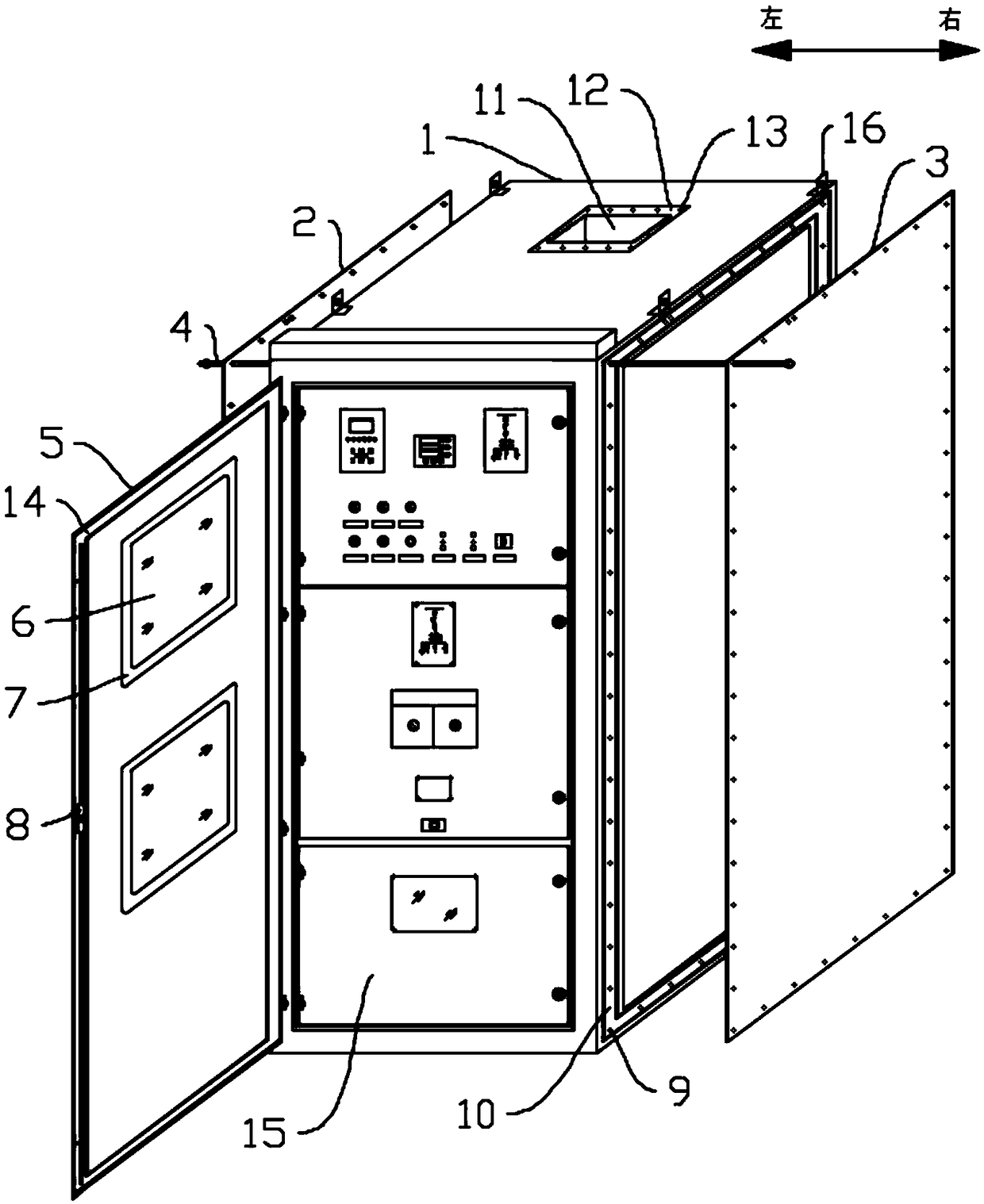

[0034] Such as figure 1 As shown, in this embodiment, the present invention includes:

[0035] Cabinet 1, the front, left and right sides of the cabinet 1 are provided with openings, the cabinet 1 is provided with a cavity for accommodating electrical components and the bottom of the cabinet 1 is provided with a A cable sealing device that achieves a waterproof effect on the cable, a control panel 15 is provided inside the cabinet 1, and the control panel 15 is vertically arranged at the opening on the front side of the cabinet 1, and the control panel 15 The periphery is sealed and fixedly connected with the inner wall of the cabinet body 1; the bottom of the cabinet body 1 is provided with a cable inlet hole, and the cable sealing device is arranged in the cable inlet hole for connecting the cable with the cabinet body 1 to form a seal, the cable sealing device includes a shell, a cover plate and a sealing sleeve, the shell includes a shell main body, an extension body and ...

Embodiment 2

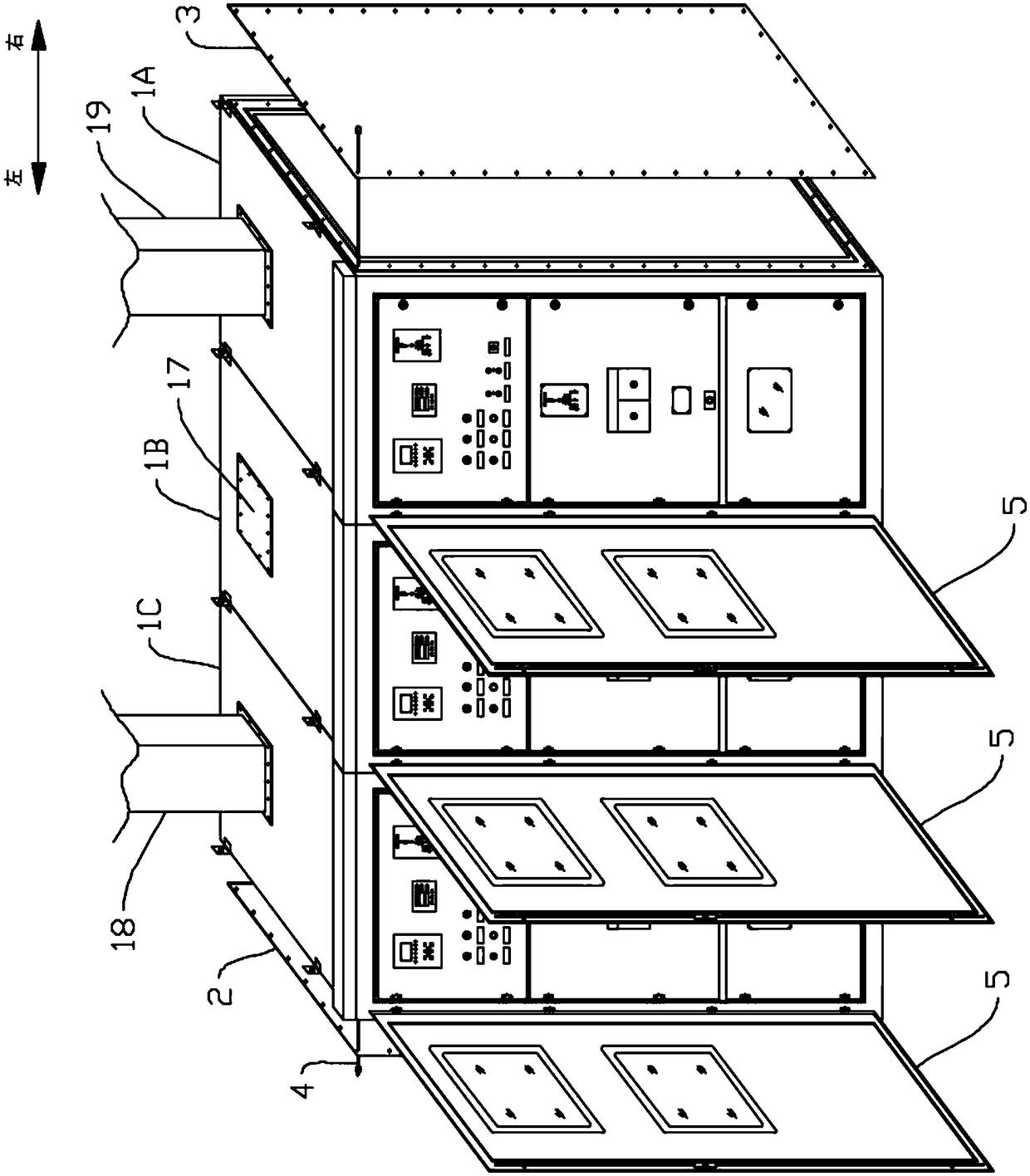

[0041] Such as figure 2As shown, in this embodiment, there are three cabinets 1 of the present invention, and the content is the same as that of the first embodiment. The four cabinets 1 are respectively a cabinet 1A, a cabinet 1B and a cabinet 1C, and the cabinet 1A, the cabinet 1B and the cabinet 1C are sequentially connected in series to form a closed body, and the left sealing plate 2 is fixed by a fixing rod 4 On the left side of the cabinet body 1C, the right sealing plate 3 is fixed on the right side of the cabinet body 1A through a fixing rod 4, and the forced ventilation opening 11 of the cabinet body 1C is fixed with an air intake port by bolts. Pipe 18, the forced ventilation opening 11 of the cabinet body 1A is fixed with an air outlet pipe 19 by bolts, the forced ventilation opening 11 of the cabinet body 1B is fixed with a blind plate 17 through bolts, and the air inlet pipe 18 And the air outlet pipe 19 makes the heat generated by the electrical components in ...

Embodiment 3

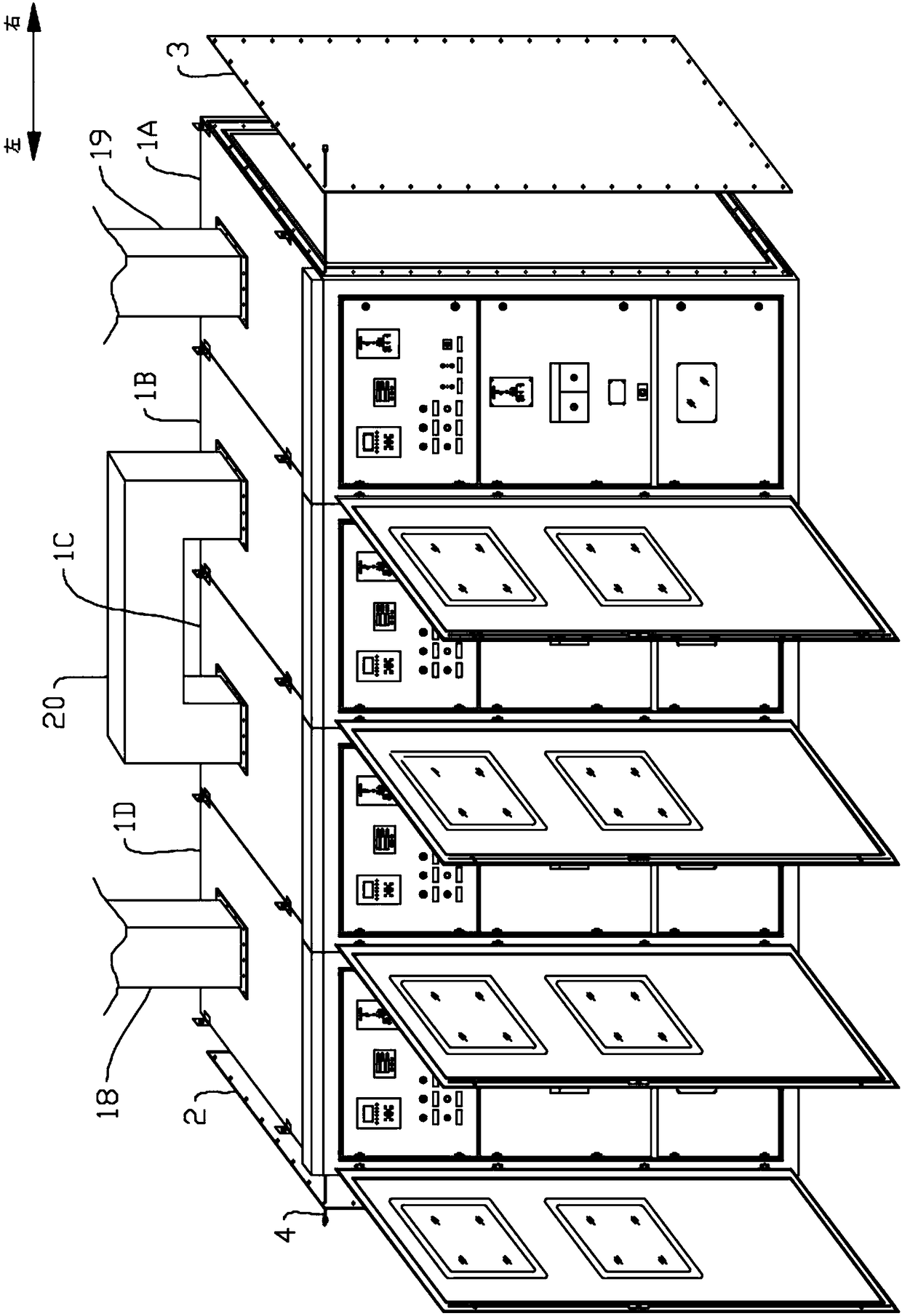

[0043] Such as image 3 As shown, in this embodiment, there are four cabinets 1 of the present invention, and the content is the same as that of the first embodiment. The four cabinets 1 are respectively cabinet 1A, cabinet 1B, cabinet 1C and cabinet 1D, and cabinet 1A, cabinet 1B, cabinet 1C and cabinet 1D are sequentially connected in series to form a closed body, and the left The sealing plate 2 is fixed on the left side of the cabinet 1D through the fixing rod 4, the right sealing plate 3 is fixed on the right side of the cabinet 1A through the fixing rod 4, and the forced ventilation port of the cabinet 1D 11 is fixed with an air inlet pipe 18 by bolts, and the forced ventilation port 11 of the cabinet body 1A is fixed with an air outlet pipe 19 by bolts, and the forced ventilation port 11 of the cabinet body 1B and the cabinet body An air duct 20 is provided between the forced ventilation openings 11 of 1C, and the two ends of the air duct 20 are respectively fixed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com