Waterproof wire harness sheath of easy fixing type

A fixed, waterproof line technology, applied in the direction of electrical components, etc., can solve the problems of sheath shedding, wear, and easy aging of cable ties, and achieve the effect of preventing sheath from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

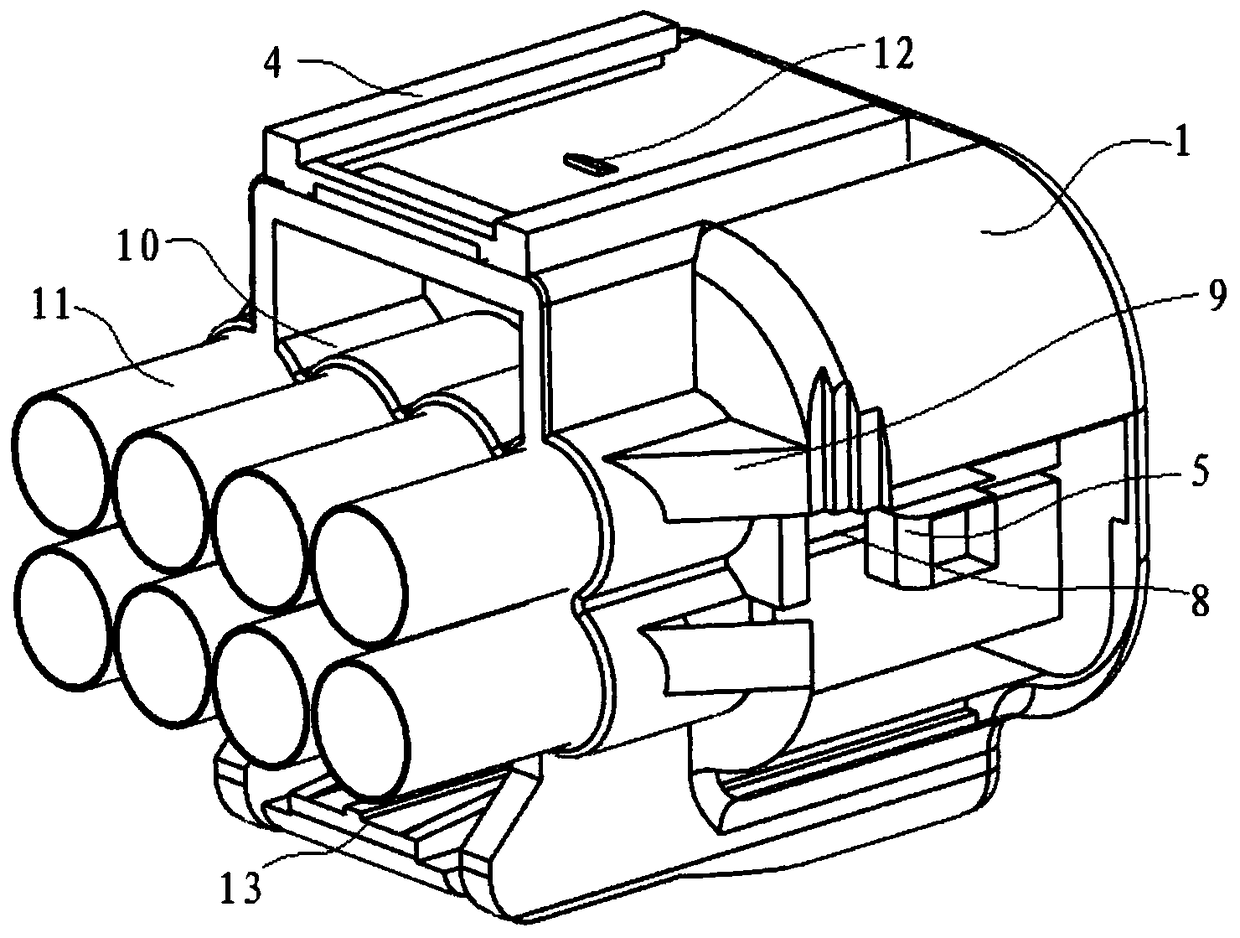

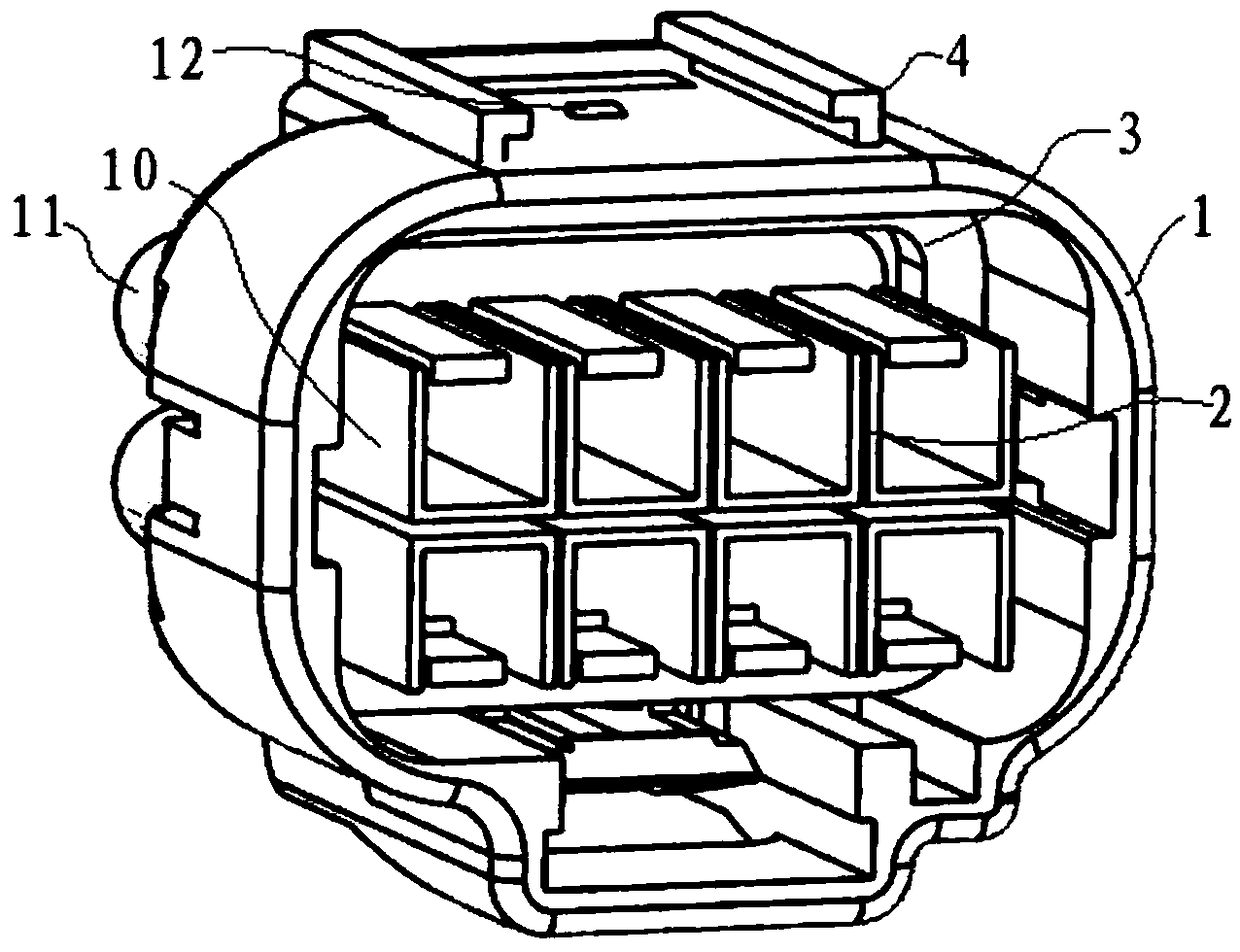

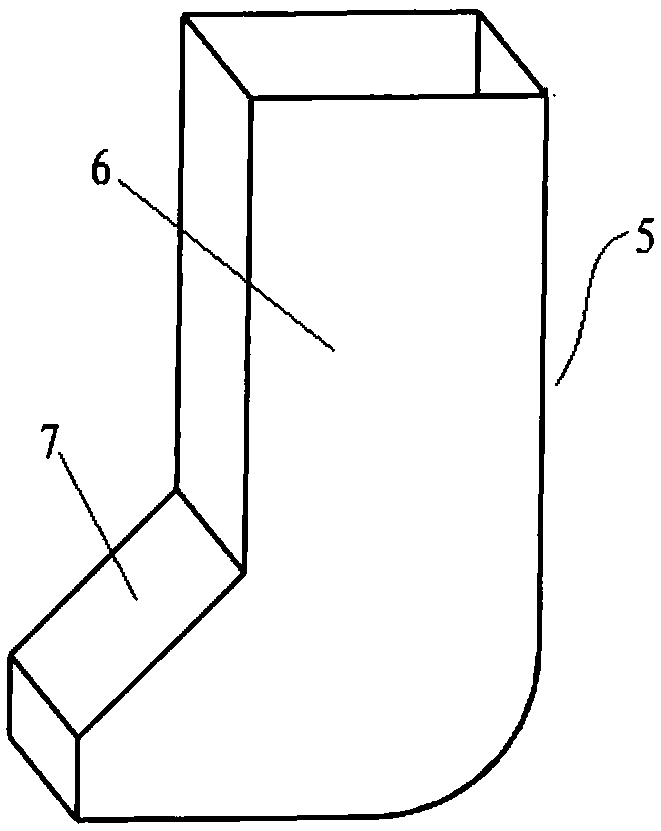

[0022] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides an easy-to-fix waterproof wire harness sheath, including a sheath body 1, and the sheath body 1 has a terminal connection portion 2, wherein:

[0023] The inside of the sheath body 1 is also provided with a waterproof retainer 3, the waterproof retainer 3 is made of rubber, and the waterproof retainer 3 is arranged around the terminal connection portion 2 along the circumferential direction of the terminal connection portion 2 by using the waterproof retainer 3, even if the water in the surrounding environment of the wire harness sheath splashes onto the wire harness sheath, due to the blocking effect of the waterproof retainer 3, the water is not easy to enter the wire harness sheath, and it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com