Non-contact angular displacement sensor

An angular displacement sensor, non-contact technology, applied in the sensor field, can solve the problems of complex installation, large volume, complex structure of the non-contact displacement sensor, etc., to save installation space, improve processing and assembly efficiency, and avoid magnetic sensors. The effect of chip damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

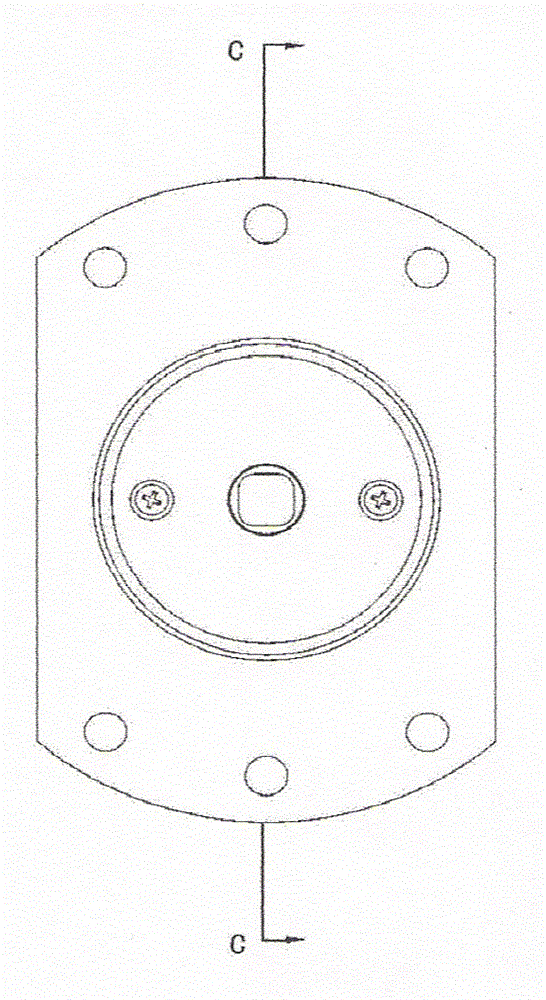

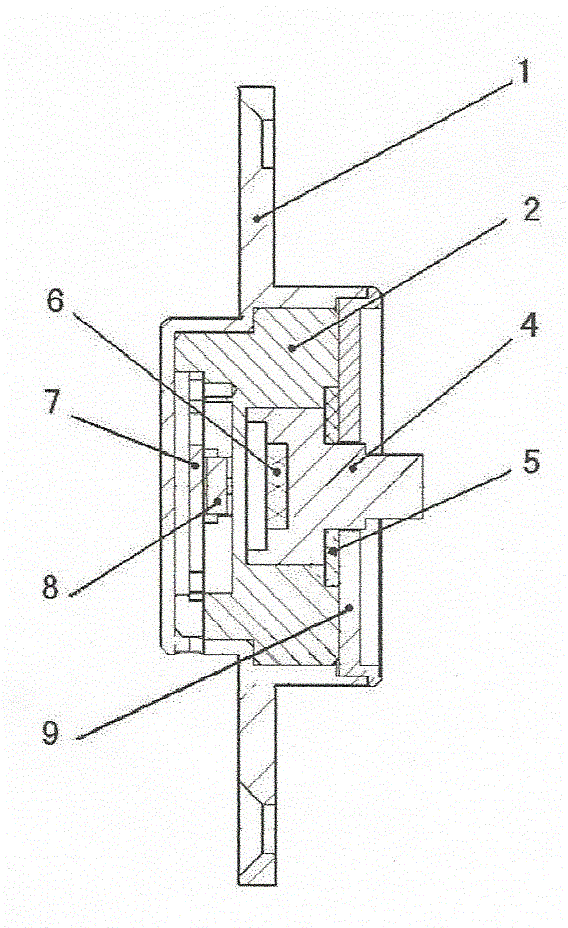

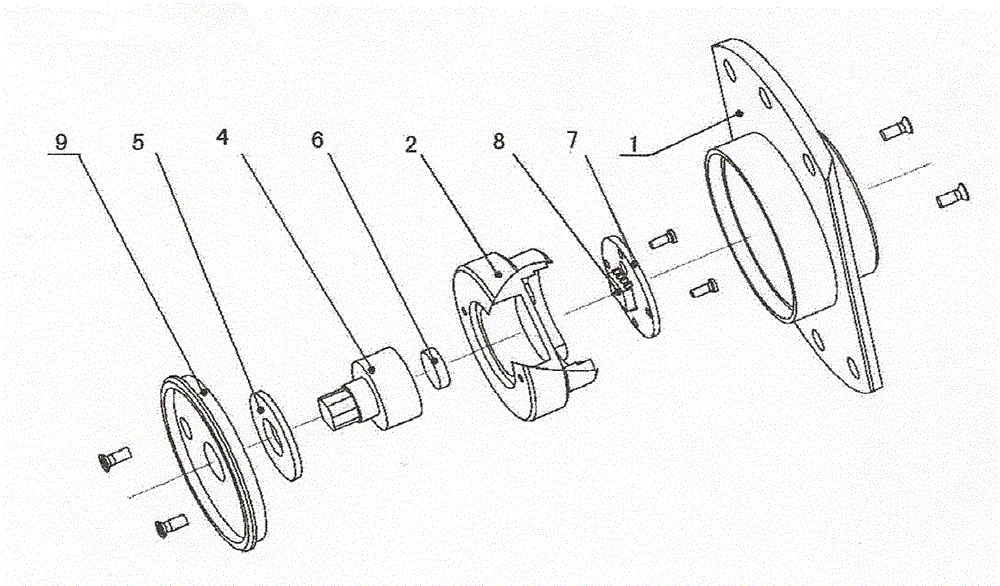

[0026] figure 1 with figure 2 It is the front view and c-c sectional view of the non-contact angular displacement sensor of this embodiment. The angular displacement sensor of this embodiment includes: outer shielding shell (1), inner shell (2), rotating shaft (4), and sealing elastic gasket (5) , magnet (6), wiring substrate (7), magnetic sensitive sensor (8) and front-end shielding cover (9). The outer shielding shell (1) with the flange surface and the front shielding cover (9) are matched and connected to form a complete magnetic shielding system. There is an outlet hole at the end of the outer shielding shell close to the wiring board to facilitate the extraction of sensor power and signal wires. The rotating shaft (4) made of stainless steel has a larger diameter end with a magnet concentrically bonded to the end face; the smaller diameter end shaft is processed into a connection structure with a certain length and a square section after extending out of the front shi...

Embodiment 2

[0031] Figure 4 with Figure 5It is the front view and c-c sectional view of the non-contact angular displacement sensor of this embodiment. The angular displacement sensor of this embodiment includes: outer shielding shell (1), inner shell (2), retaining ring (3), rotating shaft (4), Magnet (6), wiring substrate (7), magnetic sensitive sensor (8) and front-end shielding cover (9). The outer shielding case (1) with the flange surface includes all internal structures such as the inner case (2) as a whole, and is connected with the front shielding cover (9) to form a complete magnetic shielding system. There is an outlet hole at the end of the outer shielding shell close to the wiring board to facilitate the extraction of sensor power and signal wires. The rotating shaft (4) made of stainless steel has a larger diameter end with a magnet concentrically bonded to the end face; the smaller diameter end shaft is processed into a connection structure with a certain length and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com