Submarine drive system

A technology for driving systems and submarines, which can be applied to ships, motor vehicles, underwater ships, etc., can solve problems such as efficiency disadvantages, and achieve the effect of cost-effectiveness and avoiding efficiency disadvantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

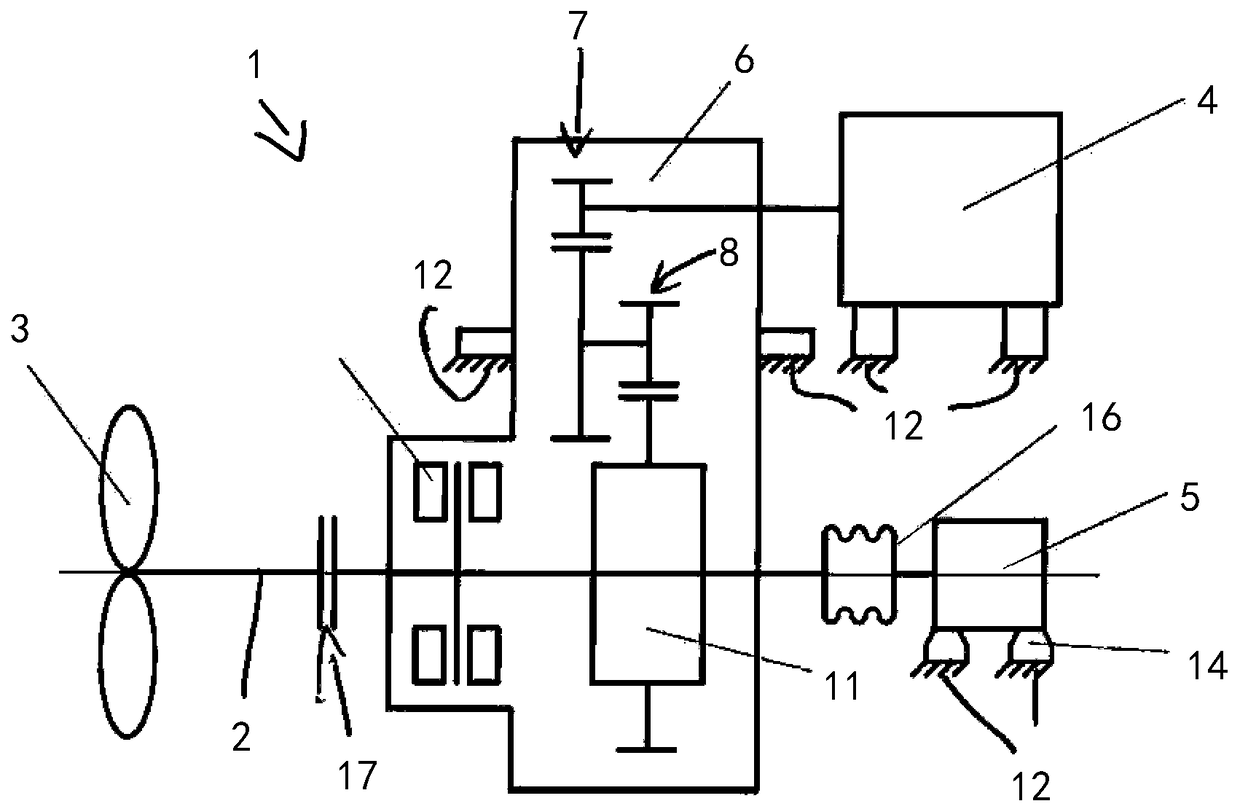

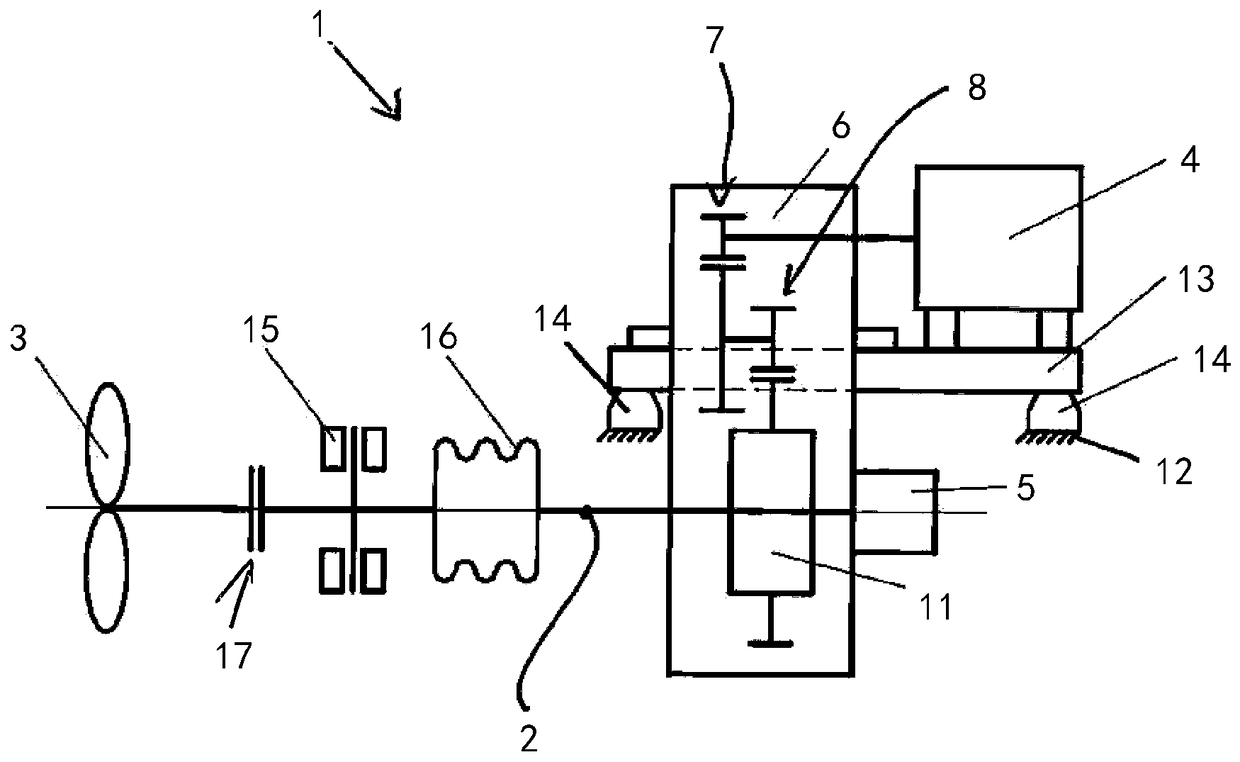

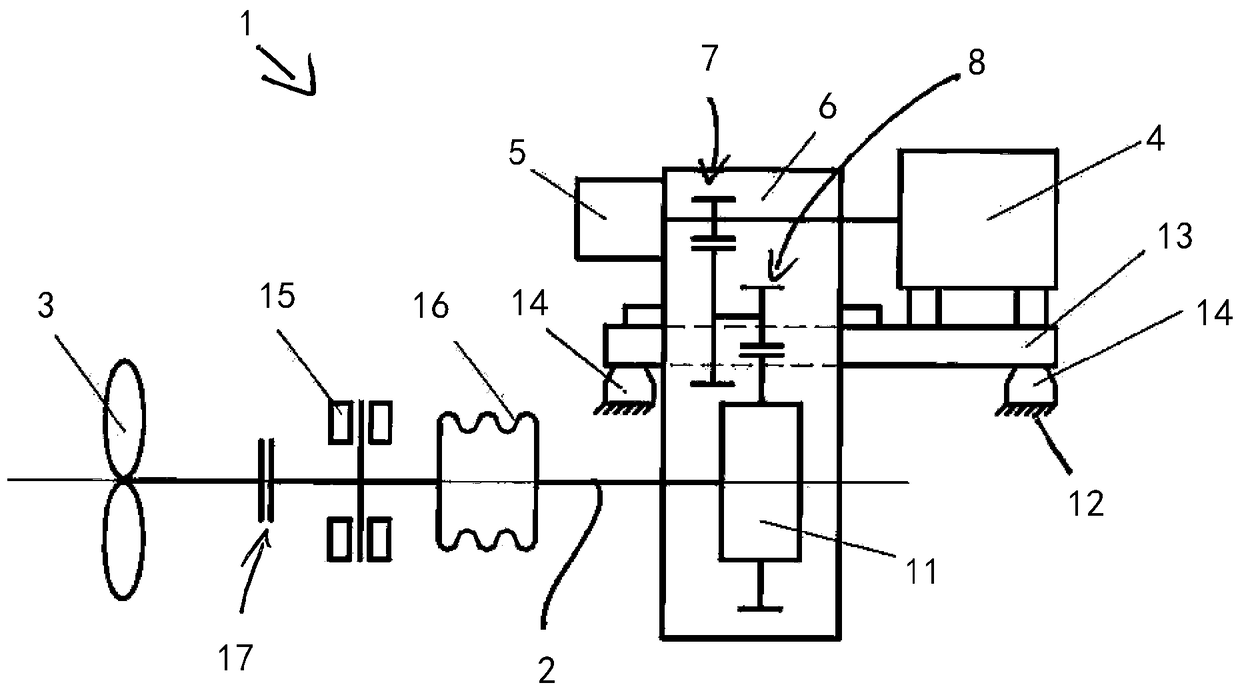

[0017] Figure 1 to Figure 5 Different exemplary embodiments of a submarine drive system 1 according to the invention are shown. Figure 1 to Figure 5 Common to all submarine drive systems 1 is that they include a drive shaft 2, a drive propeller 3 coupled to the drive shaft 2, and a plurality of electric motors 4,5. The at least one first electric motor 4 of the main drive for driving the drive shaft 2 and thus the propeller 3 is designed for full-load operation of the submarine drive system and is coupled or can be coupled to the drive shaft 2 on the drive side . The additionally driven at least one second electric machine 5 is designed for part-load operation of the submarine drive system 1 and is likewise coupled or can be coupled to the drive shaft 2 on the drive side, wherein in the part of the submarine drive system 1 During on-load operations, the submarine typically operates in stealth mode and / or underwater mode.

[0018] Thus, the idea of the submarine drive sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com