Double-thread clamping device with grabbing positioning function

A technology of grasping positioning and clamping device, applied in the field of machinery, can solve the problems of inability to clamp workpieces of various shapes, inability to be used as an automatic reclaiming device, single function of the clamp, etc., to achieve convenient operation, high use value, The effect of simple transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

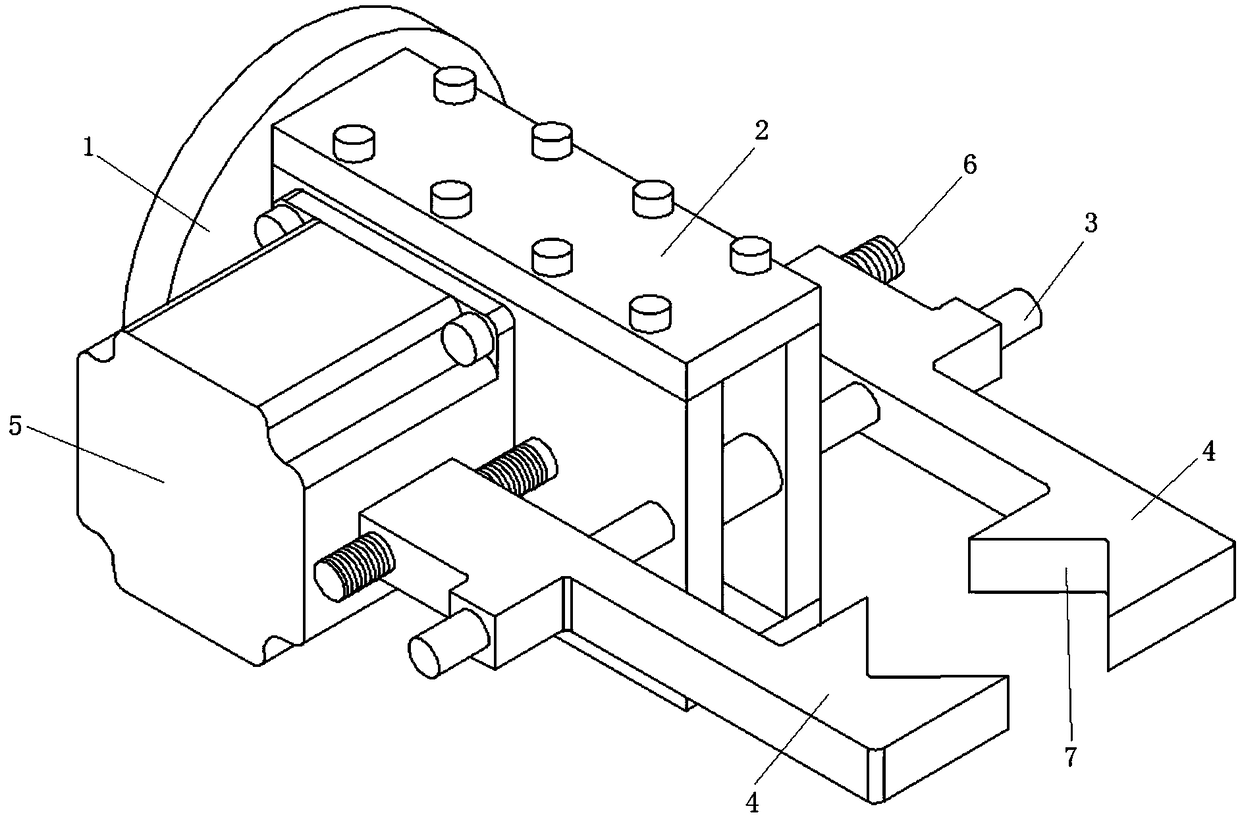

[0012] Attached below figure 1 An embodiment of the present invention is described.

[0013] The double-thread clamping device with the function of grasping and positioning has a mounting plate 1, a frame seat plate 2 is arranged on the outside of the mounting plate 1, and one end of the frame seat plate 2 is fixedly connected to the outside of the mounting plate 1, and the frame seat plate 2 is in addition One end is fixed with two ends protruding from the guide rod 3 on the frame seat plate 2 and the frame plate seat 2 is provided with a power drive device. The mounting end of the claw 4 is sleeved on the guide rod 3 and connected to the power drive device, which drives the two positioning clamping claws 4 to move toward each other or oppositely to realize the workpiece located between the clamping ends of the positioning clamping claws 4 Specifically, the power drive device includes a motor 5, a driving gear, a driven gear and a two-way screw 6, the motor 5 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com