Electric robot tail end quick change device

A robot and electric technology, applied in the field of electric robot terminal quick change device, can solve the problems of easy damage, limit the range of robot movement, and inapplicability, achieve stable transmission, improve the efficiency of locking and fixing, disassembly and separation, and facilitate The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

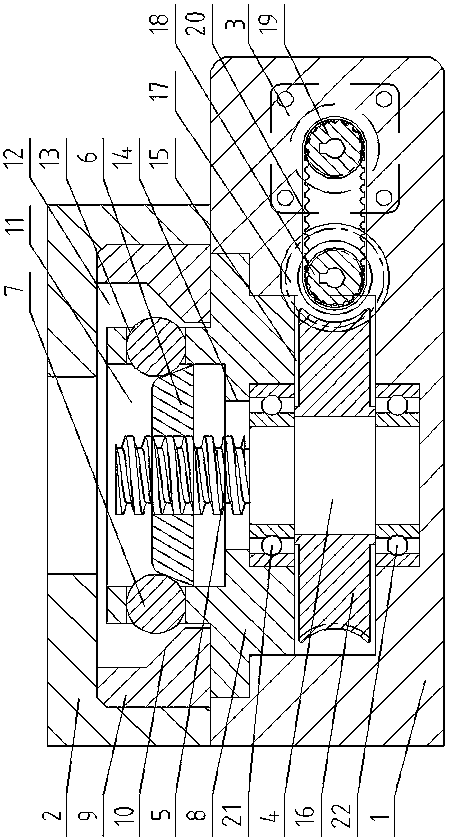

[0039] Such as figure 1 As shown, the electric robot end quick changer includes a robot side disk 1 and a tool side disk 2 which are connected to each other. The end surface of the robot side disk 1 facing the tool side disk 2 is provided with a transmission groove 15 and the tool side disk 2 faces The end surface of the transmission groove 15 is correspondingly provided with a locking groove 12, and the main shaft 4 is rotatably connected in the transmission groove 15, and a transmission mechanism is also provided in the transmission groove 15 to drive and connect the main shaft 4 and the motor 3. The motor 3 is fixed to the robot side disk 1; a locking device is provided in the locking groove 12, and the spindle 4 drives the locking device to control the locking and unlocking of the robot side disk 1 and the tool side disk 2.

[0040] The locking device includes a connecting sleeve 8 located between the transmission groove 15 and the locking groove 12, and the end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com