Anti-collision structure for tail of freight car

A truck and anti-collision technology, which is applied to vehicle components, vehicle safety arrangements, bumpers, etc., can solve the problems of loading efficiency and convenience of maintenance, high strength and rigidity of the anti-collision beam, and cars rushing into the bottom of the truck, etc. , to achieve good cushioning energy absorption effect, high efficiency energy absorption, and avoid harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

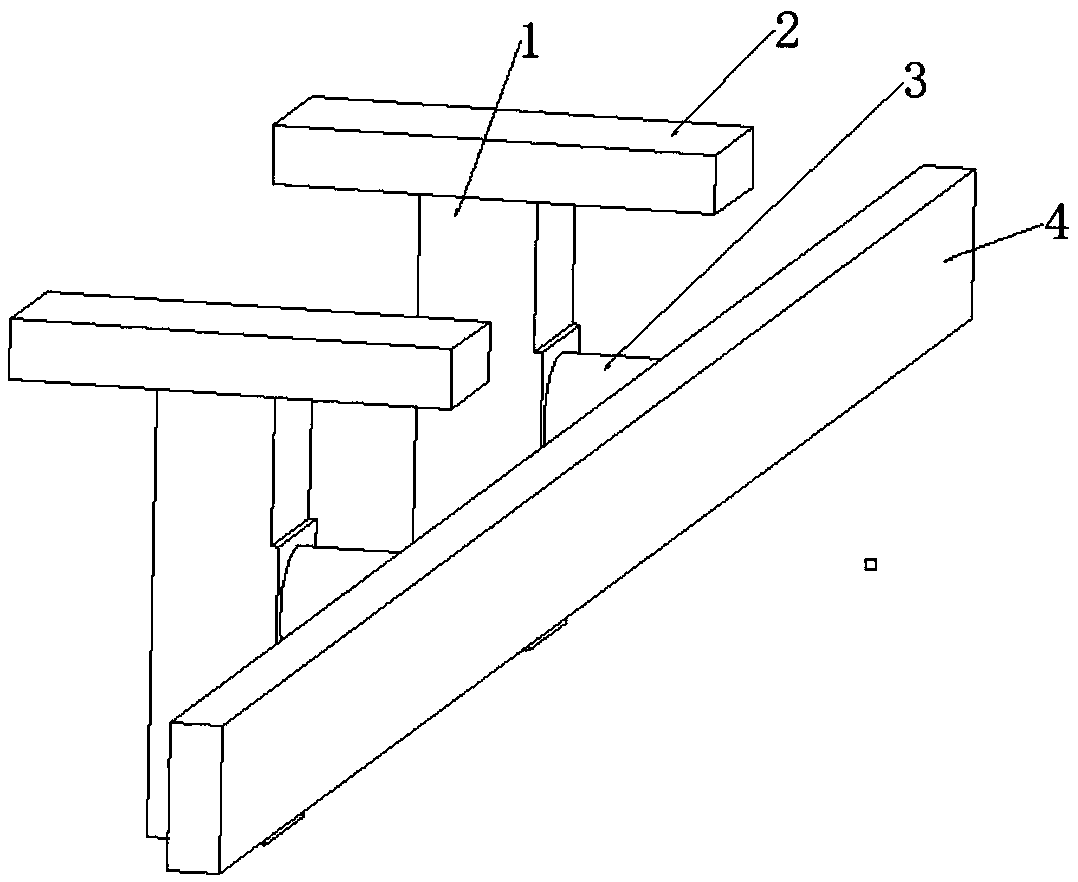

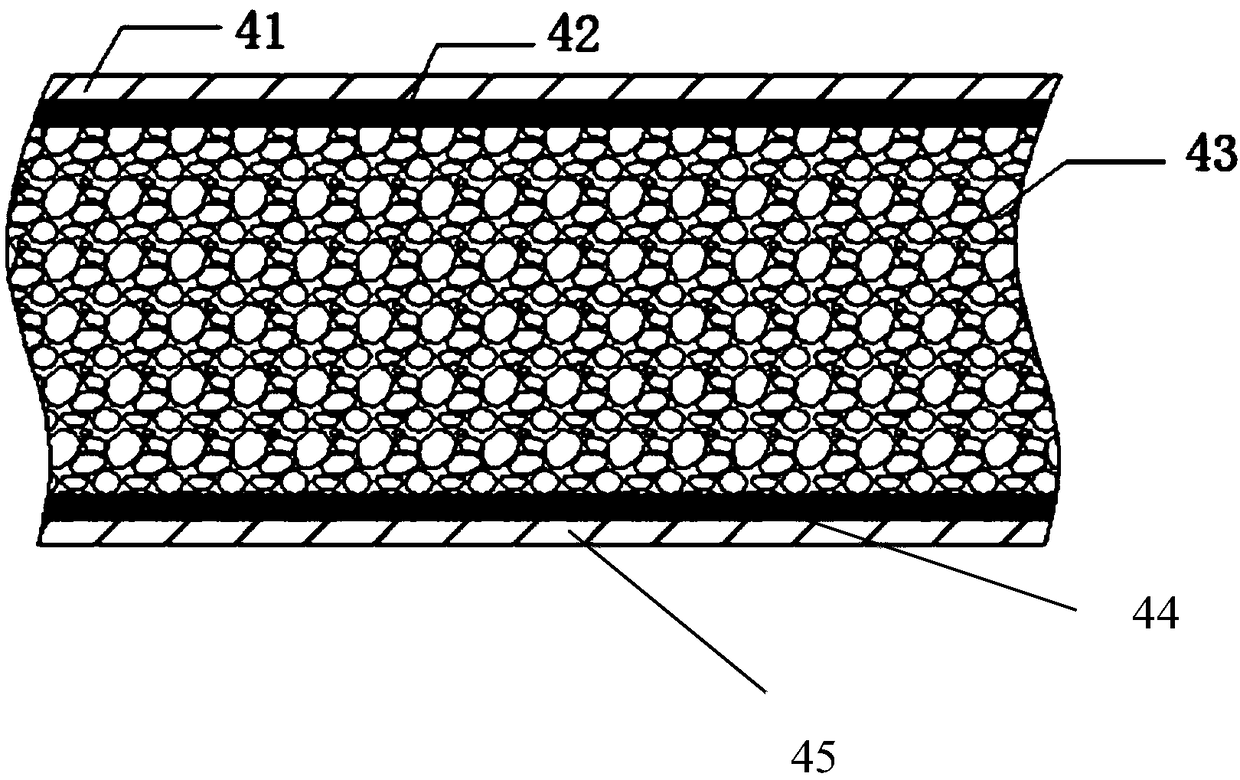

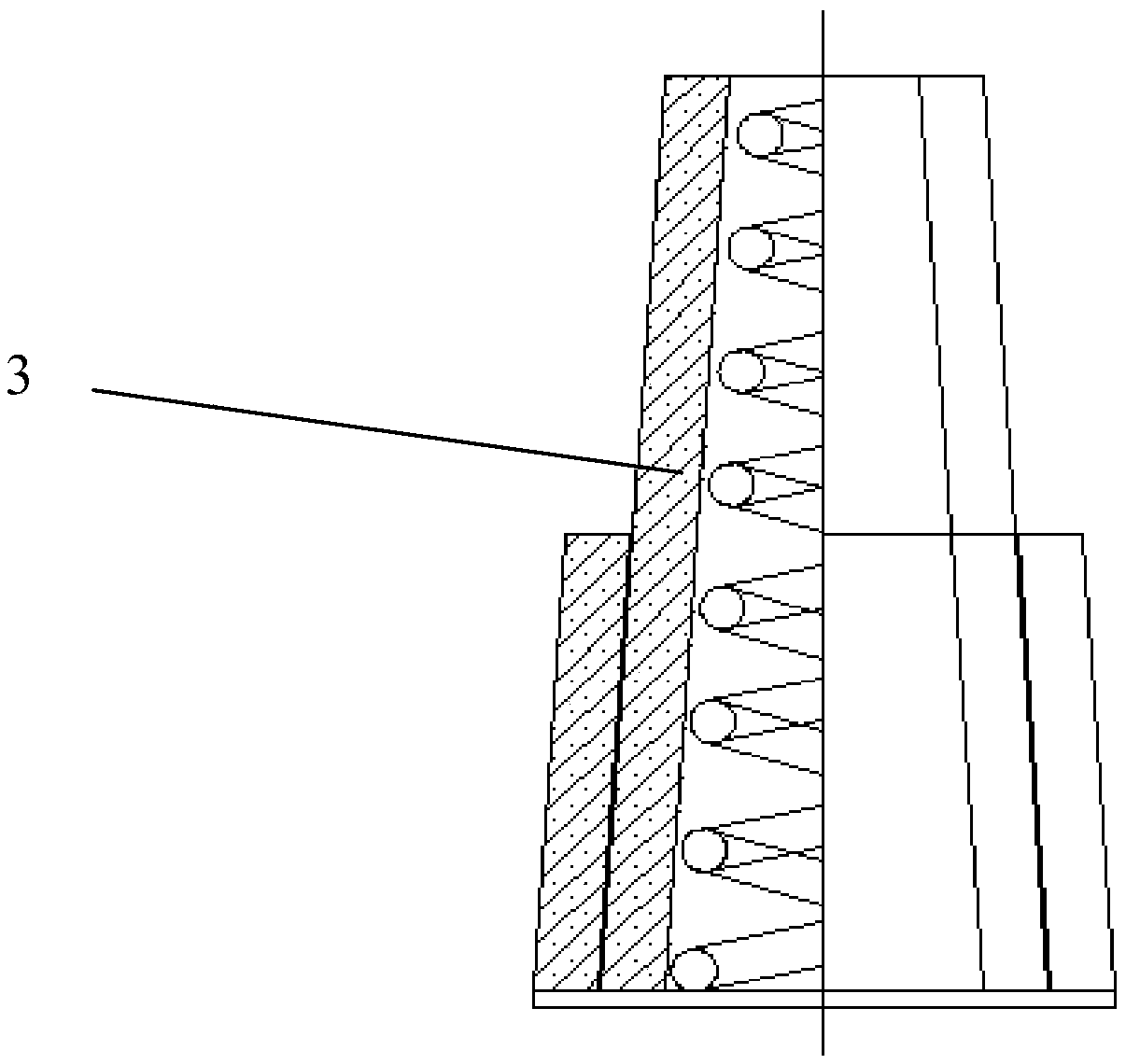

[0025] An anti-collision structure at the rear of a truck, comprising a vehicle longitudinal beam 2, a channel steel 1, an energy-absorbing box 3, and an anti-collision beam 4; the upper end of the channel steel 1 is connected to the vehicle longitudinal beam 2; the anti-collision beam 4 The length is set along the width direction of the car, and the energy-absorbing box 3 is connected to the side of the anti-collision beam 4; the side of the channel-shaped steel 1 close to the energy-absorbing box 3 is provided with a connector, and the energy-absorbing box 3 is connected to a An energy-absorbing box connector 5, which is detachably connected to the energy-absorbing box connector 5; the anti-collision beam 4 is sequentially composed of a first aluminum alloy plate 41, a first carbon fiber composite material 42, and foamed aluminum along its thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com