A double eccentric ring self-aligning refueling gun

A self-aligning, double-eccentric technology, applied in engine components, engine lubrication, lighting and heating equipment, etc., can solve the problem of difficult positioning of automatic refueling gun, can not always be in the center position, etc., achieve light weight and compact structure. , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

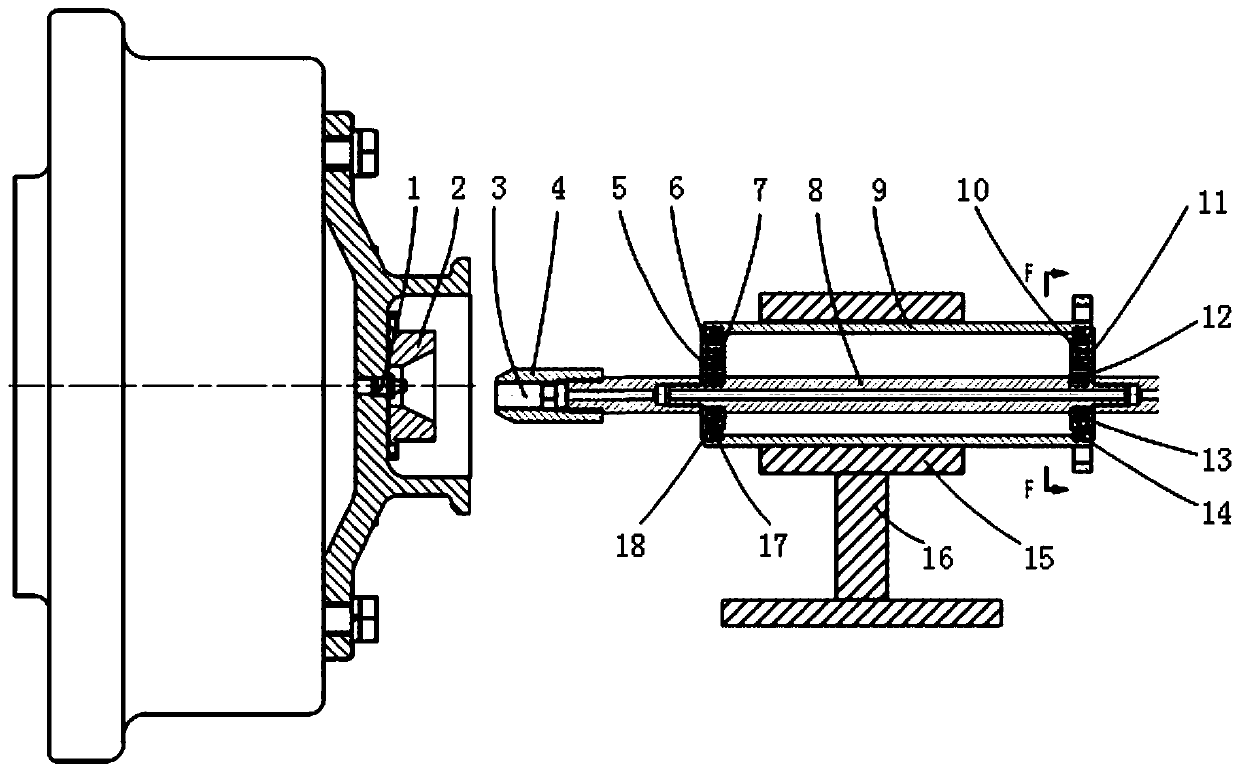

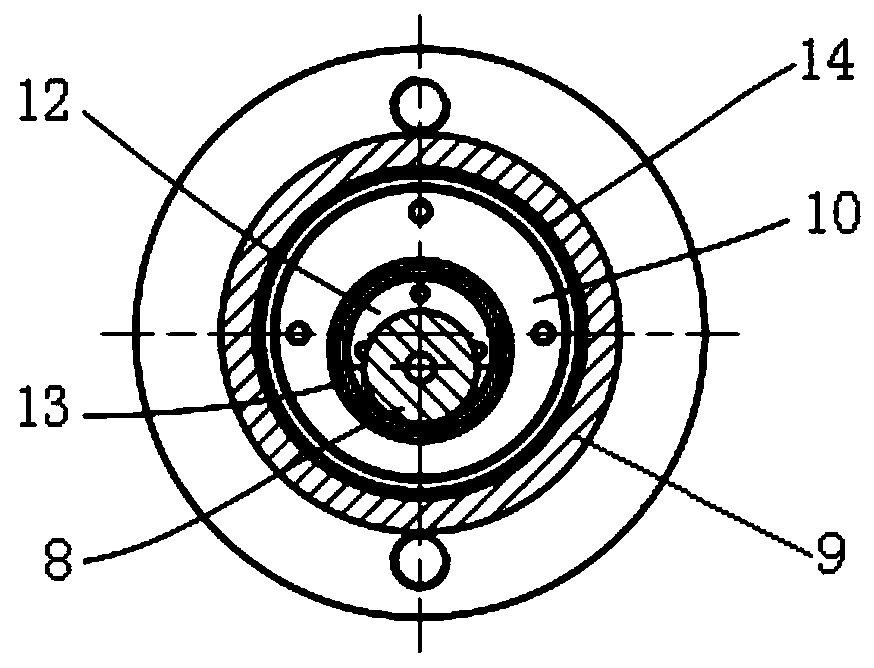

[0022] From Figure 1-2 It can be seen that the double eccentric ring automatic self-aligning fueling gun of this embodiment includes a lubricating oil pipe 8. One end of the lubricating oil pipe 8 is provided with a grease gun guide sleeve 4, and the inner side of the grease gun guide sleeve 4 is provided with a grease nozzle 3 , The input end of the oil nozzle 3 is in communication with the lubricating oil pipe 8, and a grease gun sleeve 9 is provided on the outer side of the lubricating oil pipe 8.

[0023] A first inner eccentric ring 5, a first inner bearing 18, a first outer eccentric ring 7 and a first outer bearing 17 are sequentially arranged between the left end of the lubricating oil pipe 8 and the inner wall of the oil gun sleeve 9, and the lubricating oil pipe 8 penetrates Passing the eccentric hole of the first inner eccentric ring 5, the outer ring of the first inner eccentric ring 5 is equipped with a first inner bearing 18, and the outer ring of the first inner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com