Simulation calculation method for a double-face slit coating contact type die head

A slit coating and analog computing technology, applied in the direction of calculation, design optimization/simulation, special data processing applications, etc., can solve the problem of not considering the deformation of the substrate, and cannot guide the design of double-sided slit coating contact die , not applicable to the simulation of double-sided slit coating, etc., to achieve the effect of improving the accuracy and reliability of numerical prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

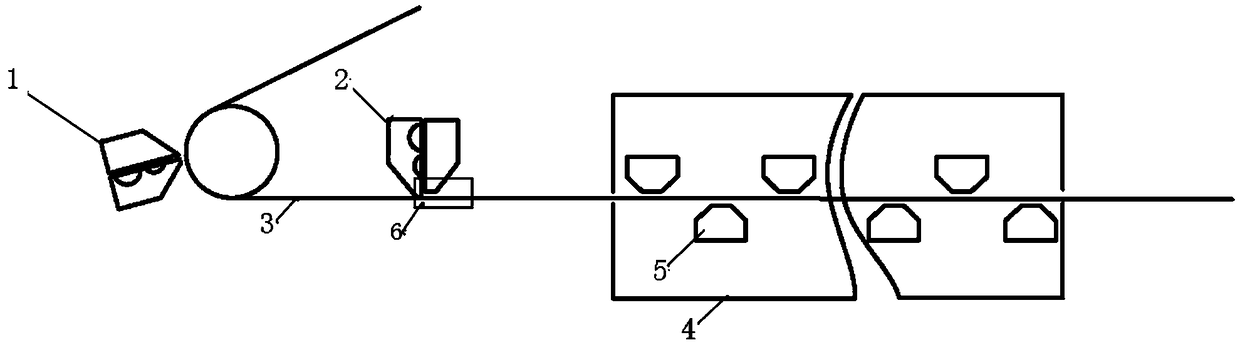

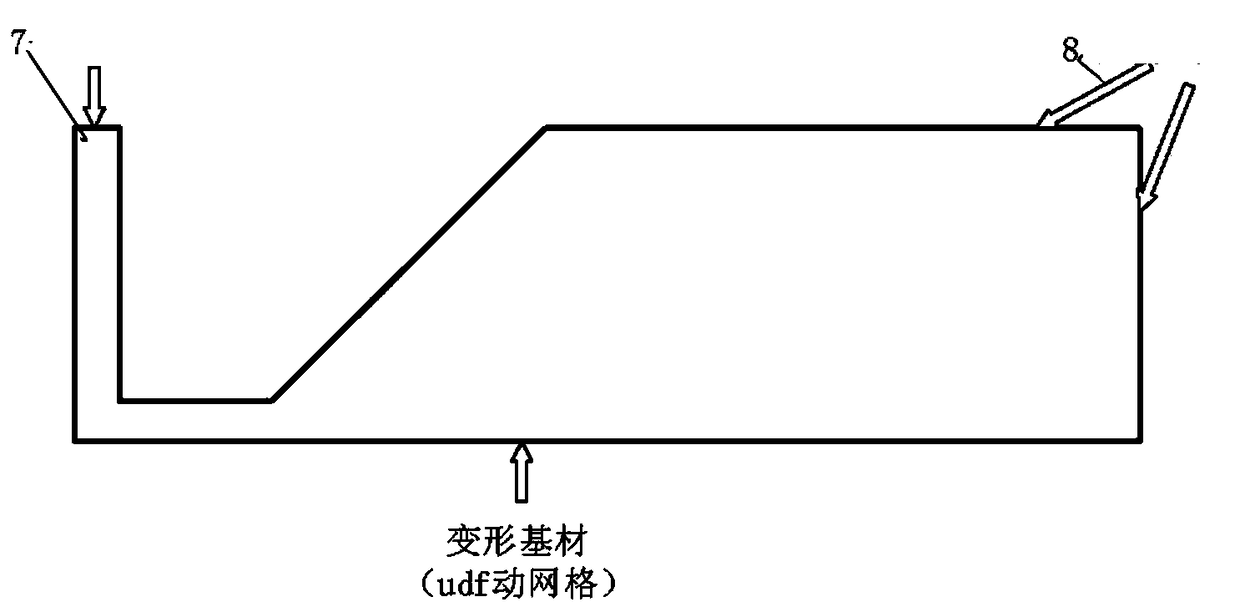

[0040] Step 1: Establish the geometric model of the calculation domain formed by the lip part of the double-sided slot coating contact die and the substrate, such as image 3 shown.

[0041] The base material is copper foil, and the main material properties are: density ρ=8900kg / m 3 , elastic modulus E=121GPa, thickness t=10μm. The flow field medium is lithium battery slurry and air, the slurry properties are: non-Newtonian fluid, density ρ=1340kg / m 3 ,, satisfy the power law model μ=kγ n =59.4*γ 0.37 , the surface tension is 0.05132N / m, and the contact angle with the substrate is 25.6°; the air properties are: density ρ=1.225kg / m 3 , Dynamic viscosity μ=1.7895e-5kg / (m·s).

[0042] Step 2: Grid division of flow field calculation domain.

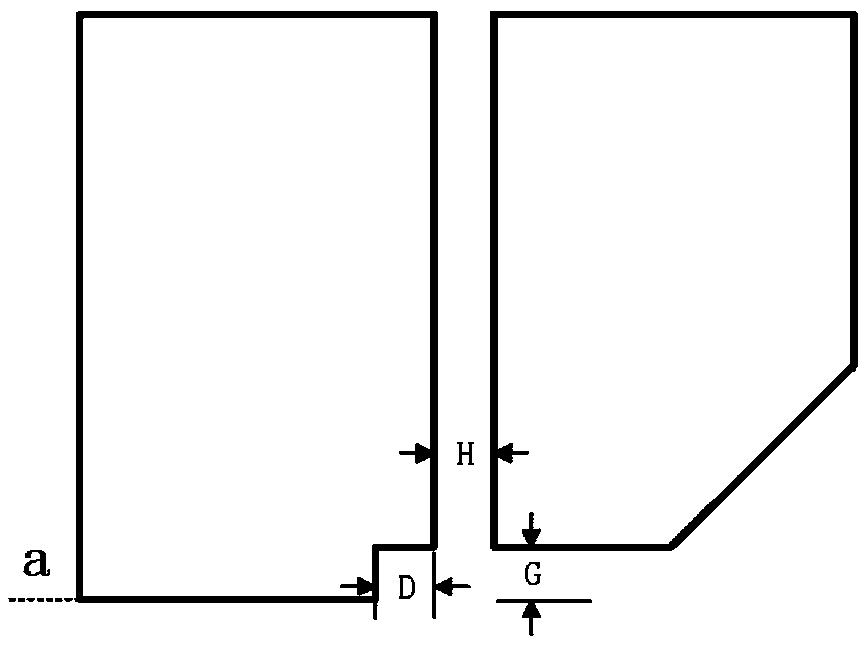

[0043] Mesh the flow field area, such as Figure 4 As shown, here G=0.25mm, H=0.4mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com