High-pressure roller grinding technology workshop

A high-pressure roller mill and high-pressure roller mill technology, which is applied in the field of high-pressure roller mill technology, can solve problems such as affecting production efficiency, inconvenient execution of high-pressure roller mill maintenance work, and insufficient plant layout optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

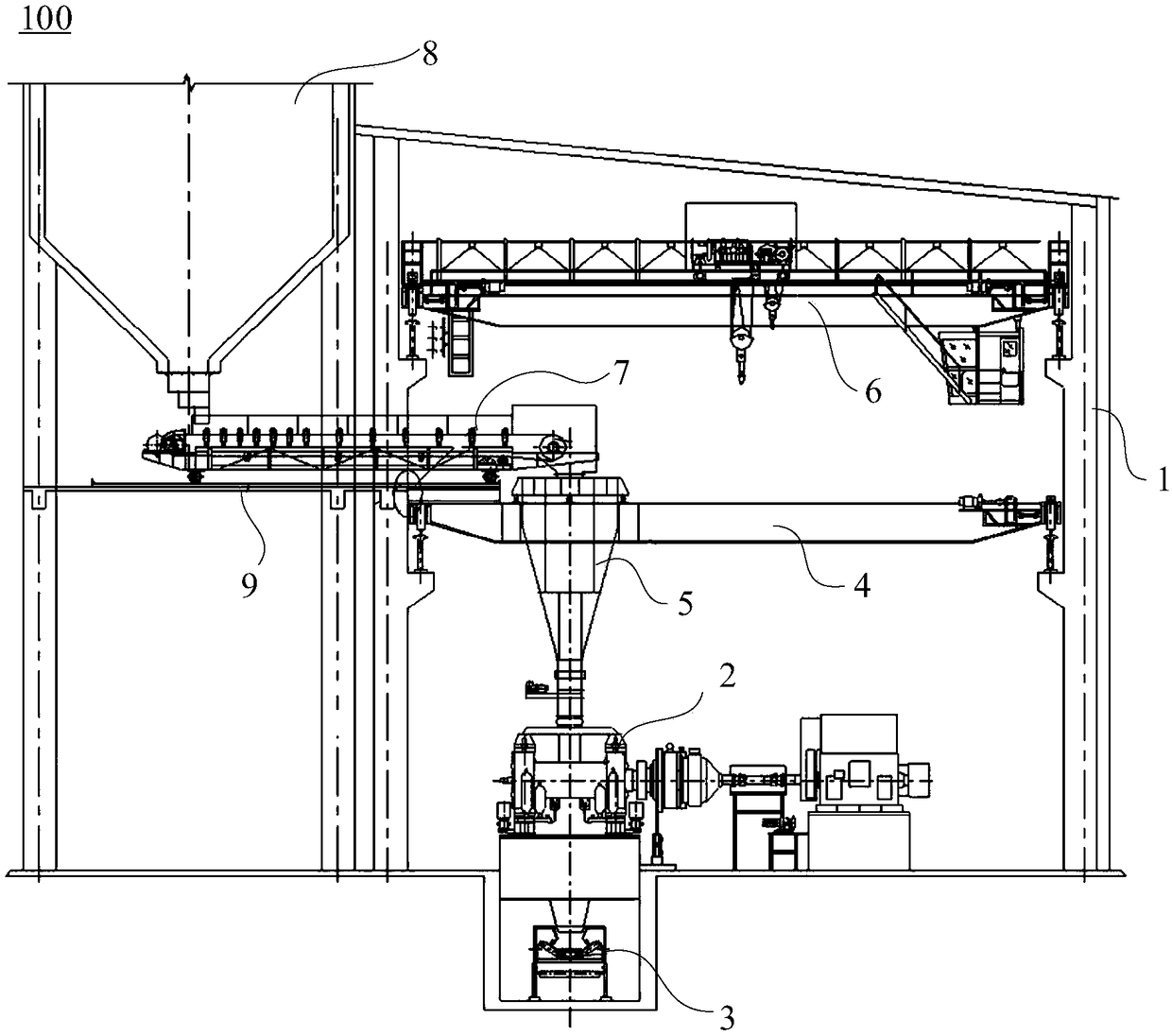

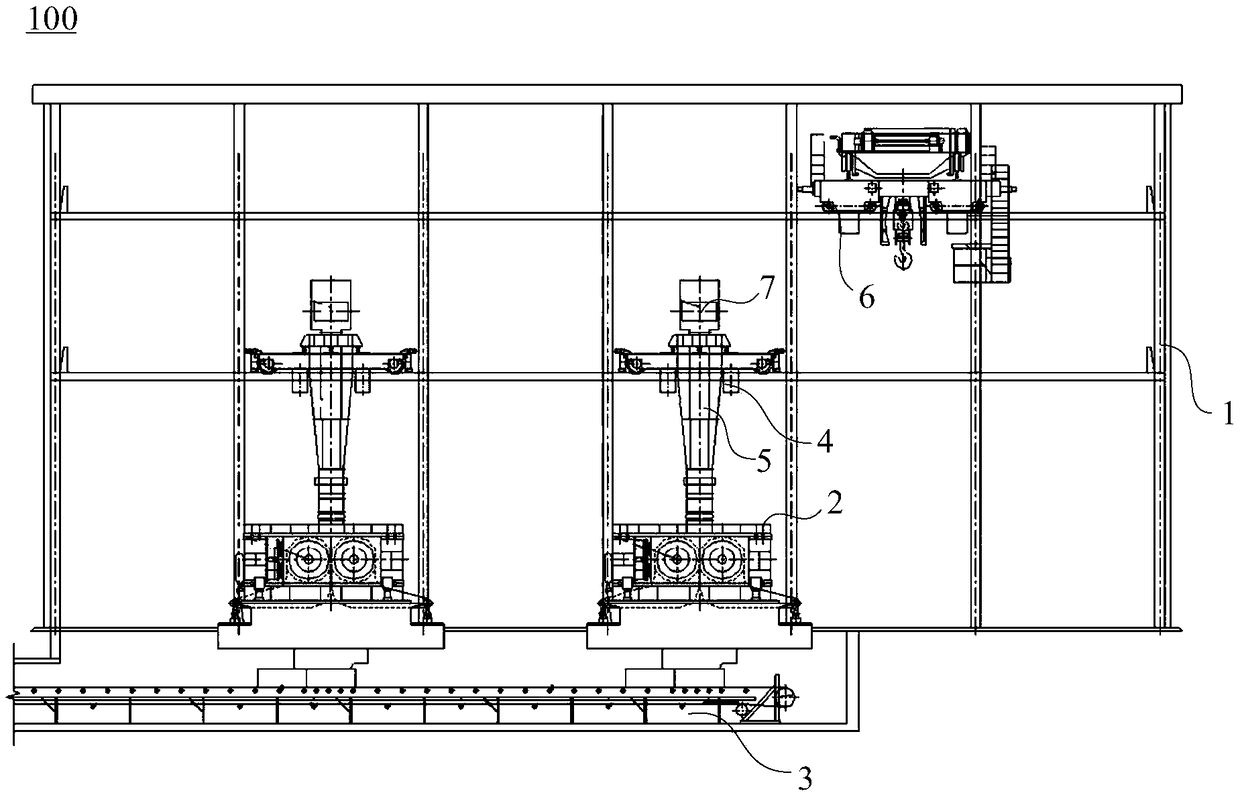

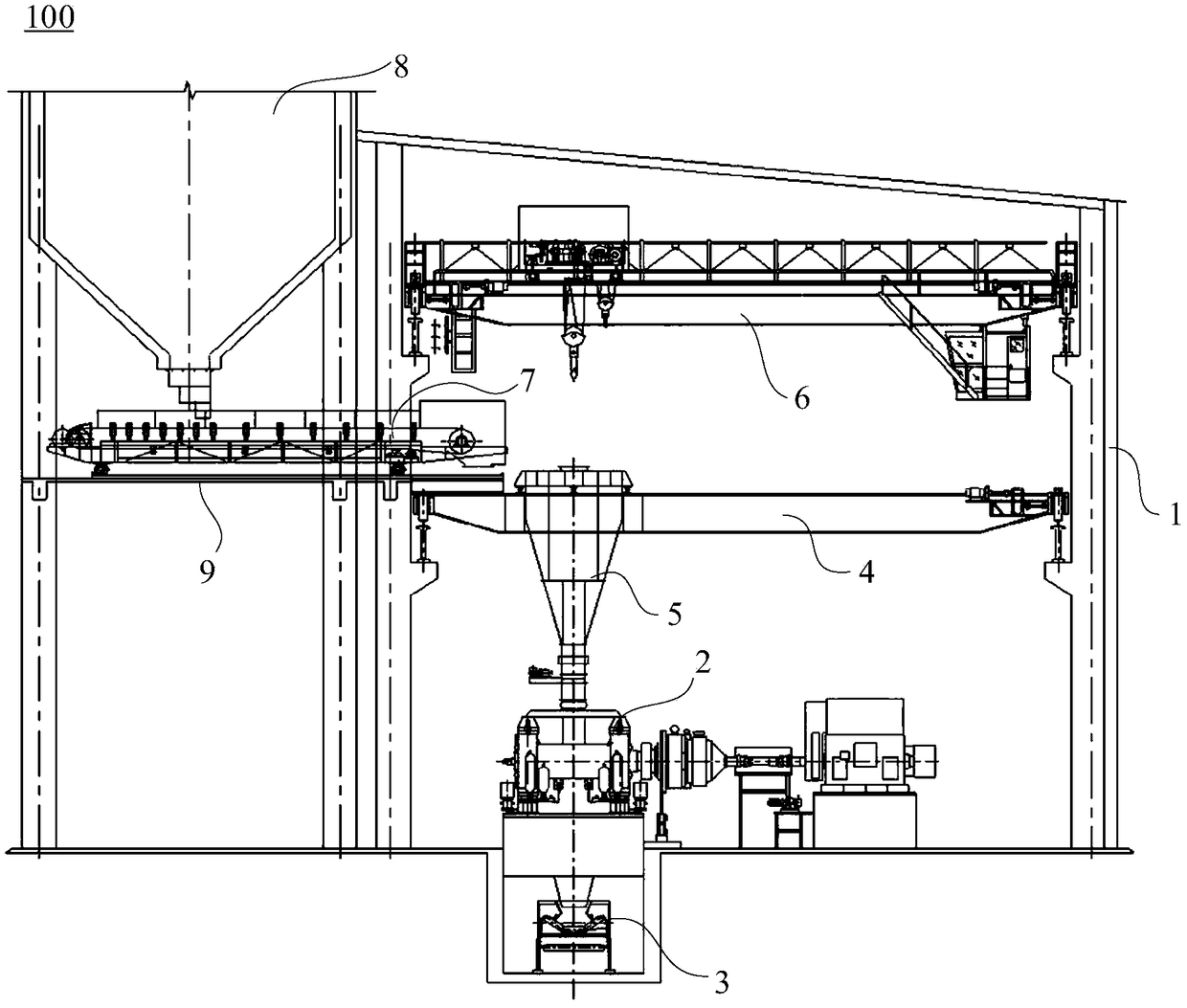

[0035] Please refer to Figure 1 to Figure 6 , This embodiment provides a high-pressure roller mill process workshop 100, the high-pressure roller mill process workshop 100 includes a workshop body 1, a high-pressure roller mill 2, a discharge belt conveyor 3, a steady flow bin supporting the crane 4, a steady flow constant weight bin 5. Overhaul the crane 6, the belt feeder 7 and the silo 8.

[0036] The factory building body 1 is a factory building with a frame structure with an accommodating space inside, which is generally rectangular, the internal space is empty, and the walls are generally brick walls.

[0037] The high-pressure roller mill 2 is installed on the ground of the plant body 1, and the high-pressure roller mill 2 has a roller mill feeding port and a roller mill discharging port. The number of high pressure roller mills 2 can be freely selected according to actual needs. In this implementation, the number of high pressure roller mills 2 is two, and the two hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com