Saddle machining equipment and machining process

A technology of processing equipment and processing technology, which is applied in the field of saddle processing equipment and processing technology, can solve the problems of low saddle comfort, many working hours, waste of resources, etc., and achieve the effect of improving the comfort of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]This embodiment provides a saddle processing equipment to increase the production rate of the saddle and improve the comfort of the produced saddle.

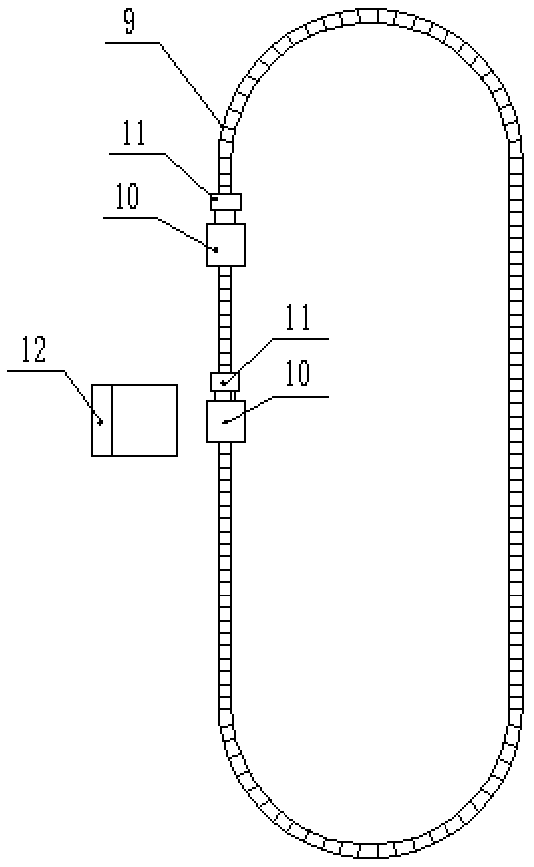

[0037] This embodiment provides a saddle processing equipment, such as figure 1 Shown, comprise: conveying track 9, be provided with formwork 10 and the power system 11 that drives formwork 10 to move on conveying track 9 on conveying track 9, be provided with secondary forming mold on formwork 10, secondary forming mold is used for To install the bottom plate on the foam layer; a 3D printing molding machine 12 is also arranged outside the conveying track 9 .

[0038] Specifically, a cooling system is provided in the 3D printing molding machine 12 .

[0039] Specifically, the mold base 10 is provided with an air suction device, the mold base 10 includes an upper mold and a lower mold, the lower mold includes a cavity for placing the leather layer 1 and the foam layer, and a number of air suction holes are arranged and dis...

Embodiment 2

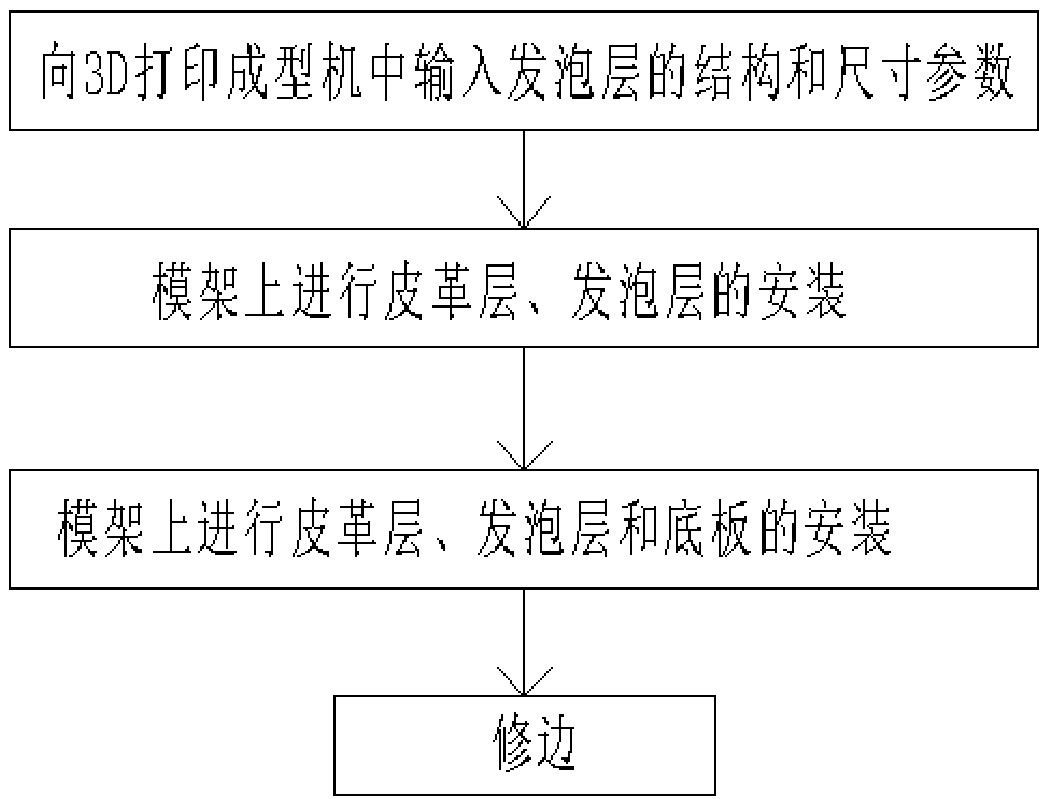

[0044] This embodiment provides a saddle processing technology, including foam molding, input the foamed shape, size and raw material of the saddle to be formed into the 3D printing molding machine 12, and the finished product is directly output by the 3D printing molding machine 12 For the foam layer, according to the requirements of different products, the foam layer of different specifications is output by the 3D printing molding machine 12 .

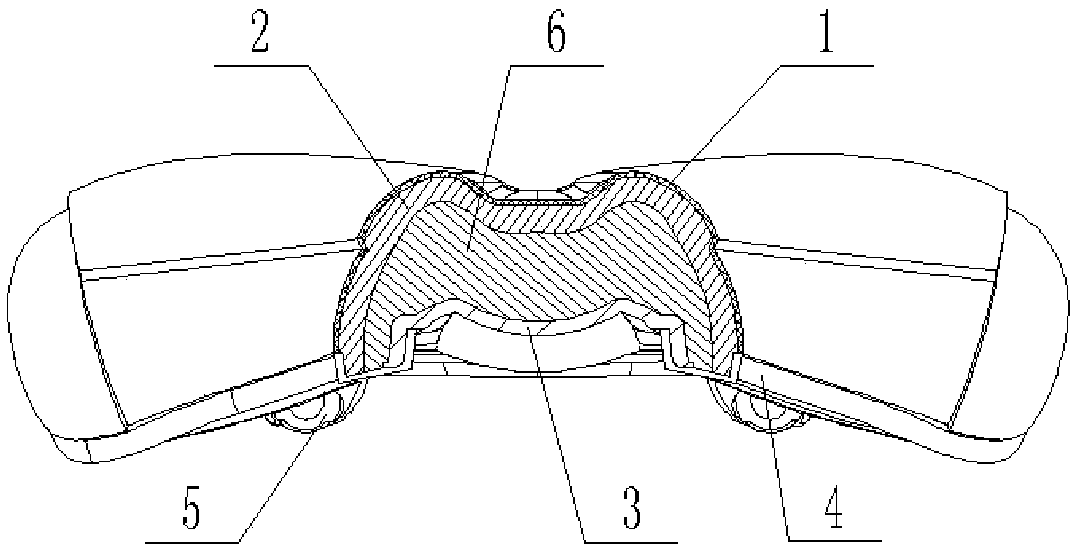

[0045] The leather layer 1 is placed on the bottom of the mold frame 10 lower mold, and then the foamed layer after molding is placed on the top of the leather layer 1, and at the same time, the bottom plate 3 is fixed on the upper mold of the mold frame 10, and the The mold closing of the upper mold and the lower mold realizes bonding of the bottom plate 3, the foam layer and the leather layer 1.

[0046] Trimming, trimming excess edges of the product obtained in the step.

[0047] like figure 2 As shown, the specific process flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com