Patents

Literature

55results about How to "Reduce output time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

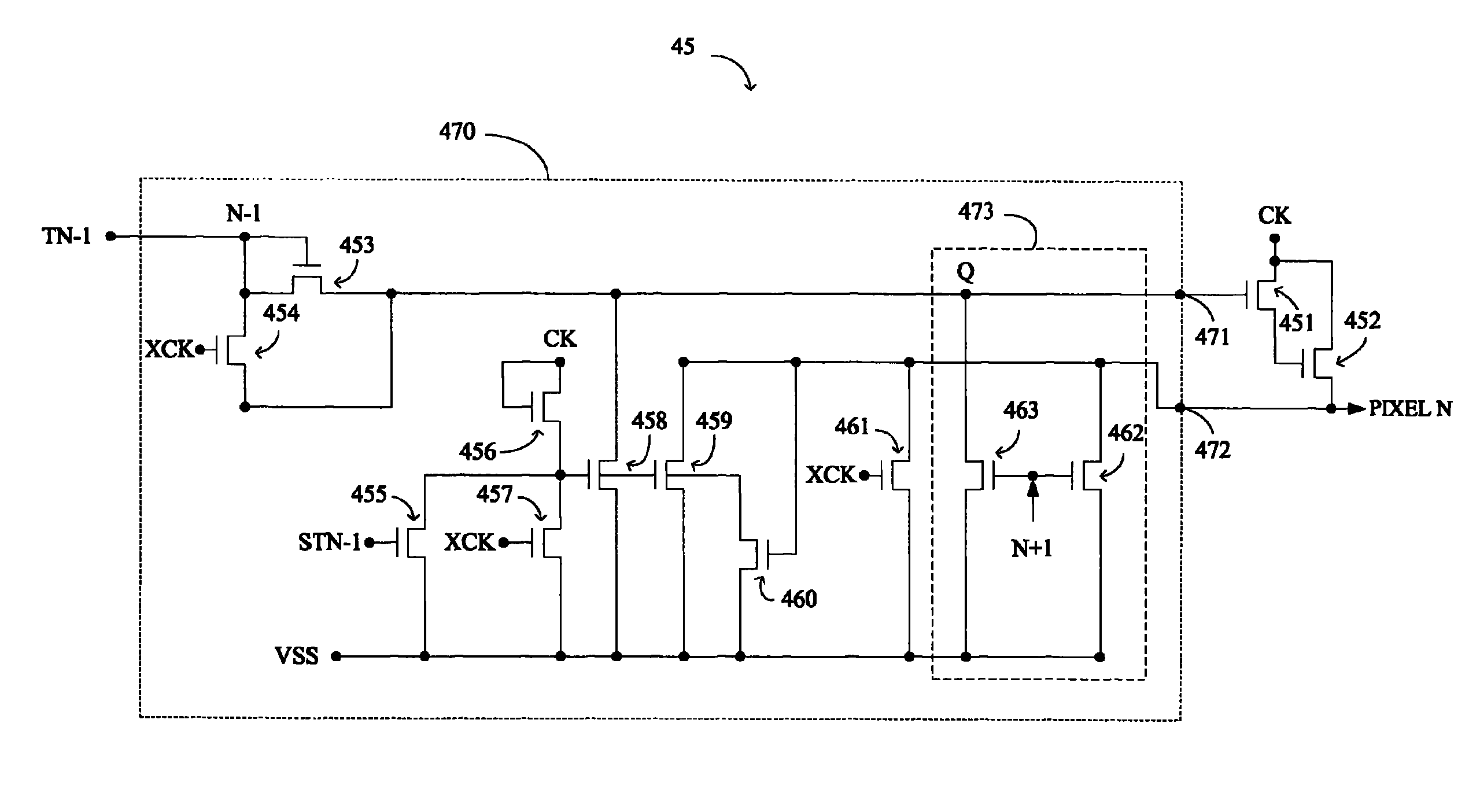

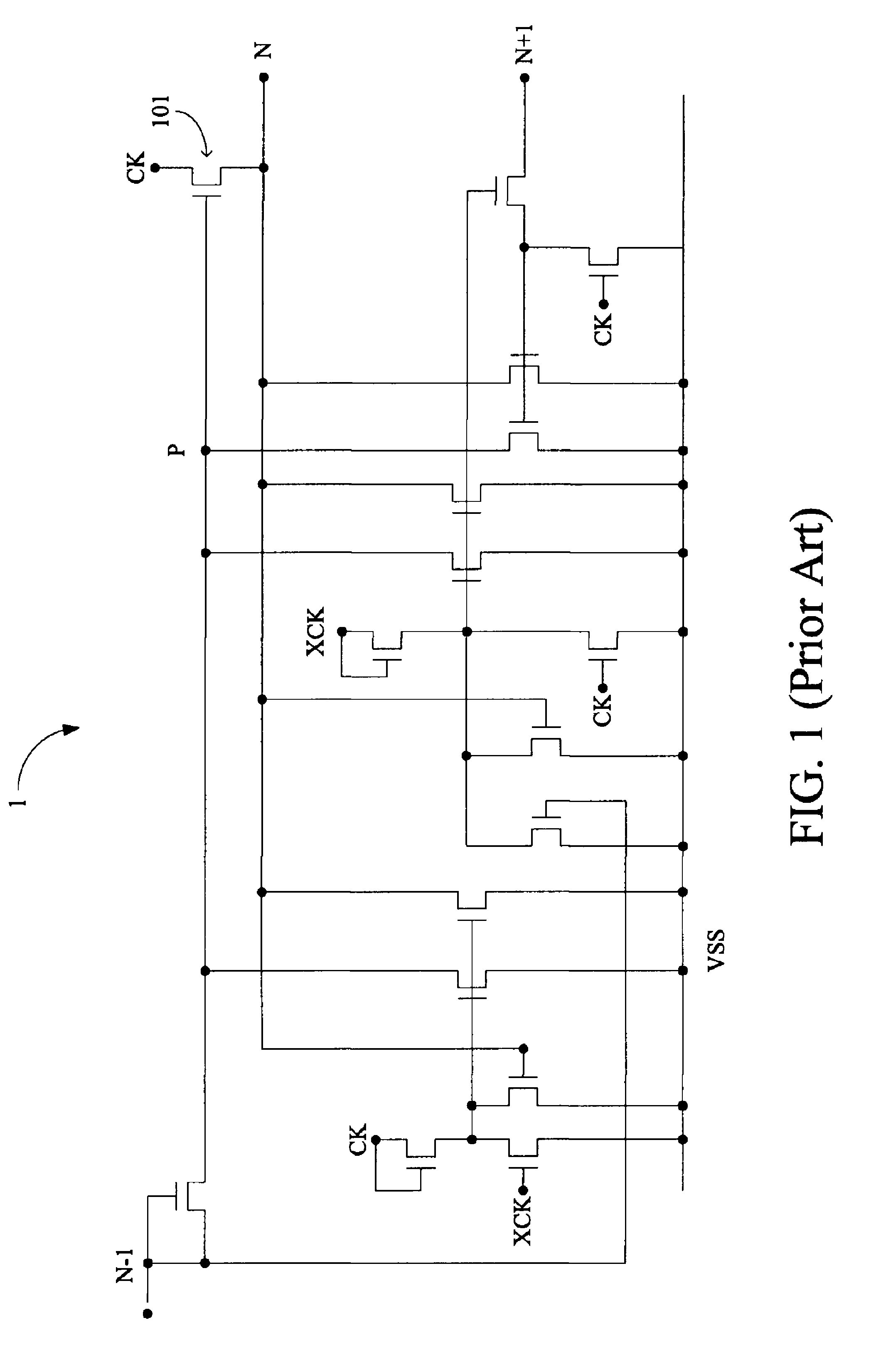

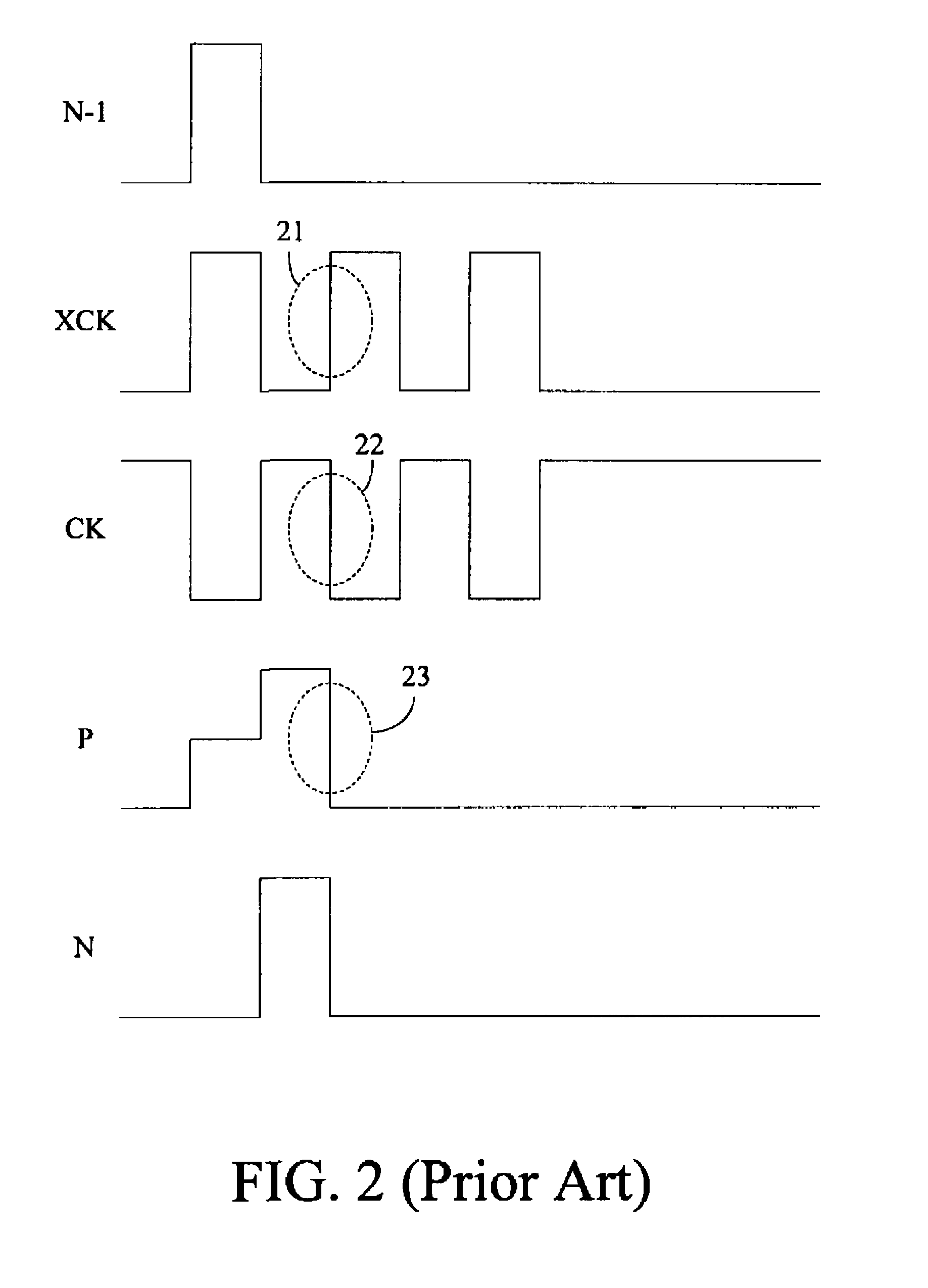

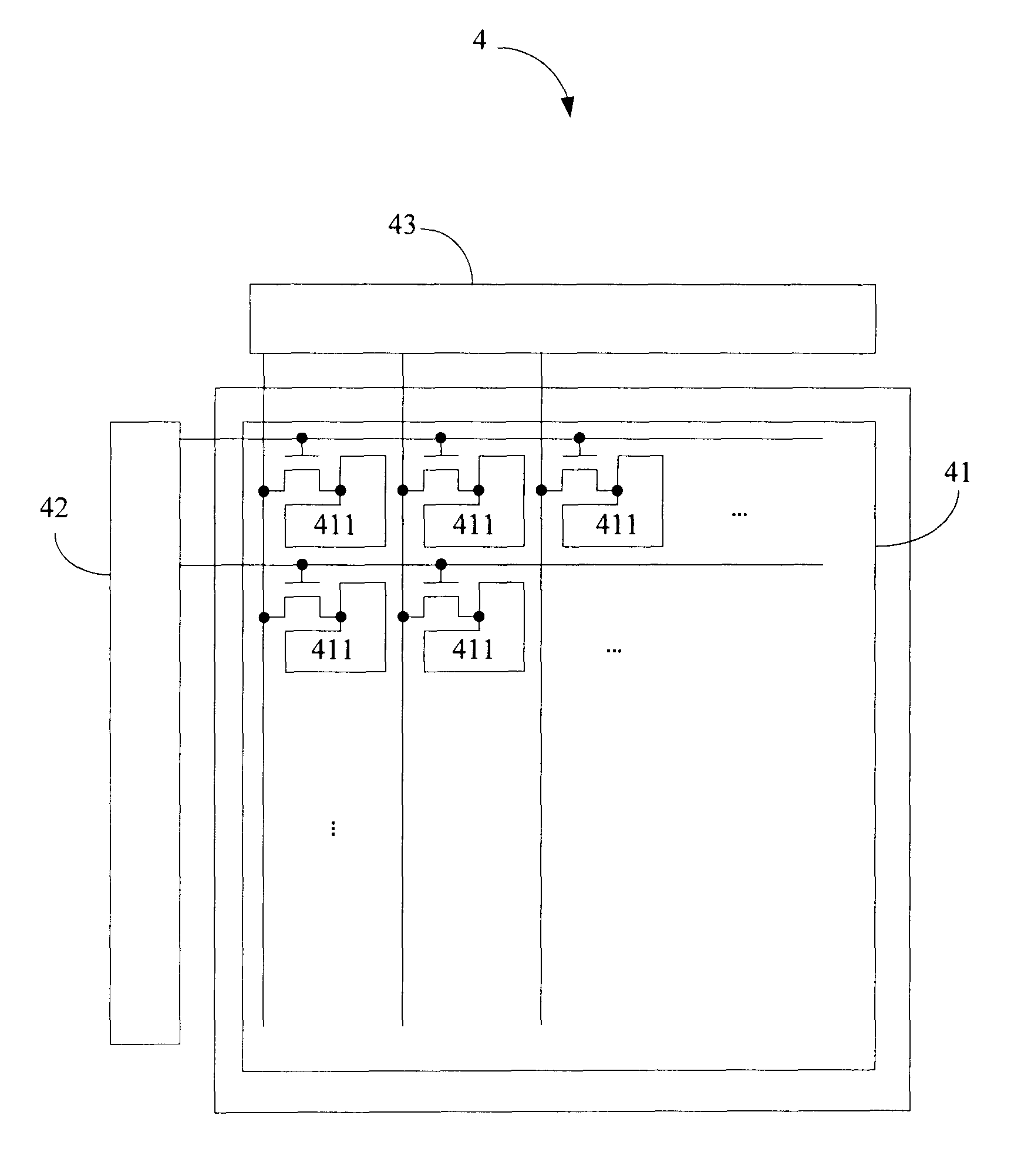

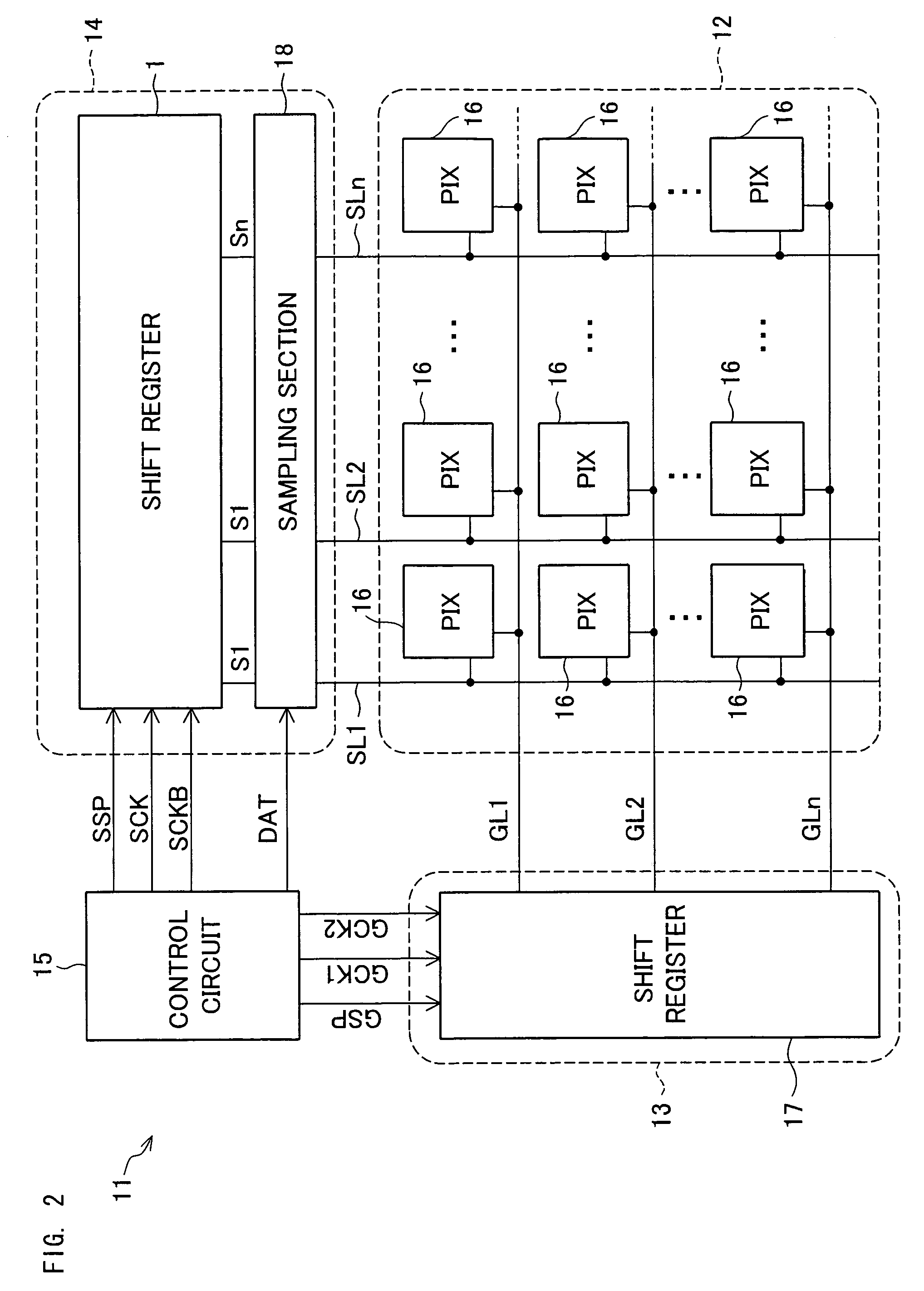

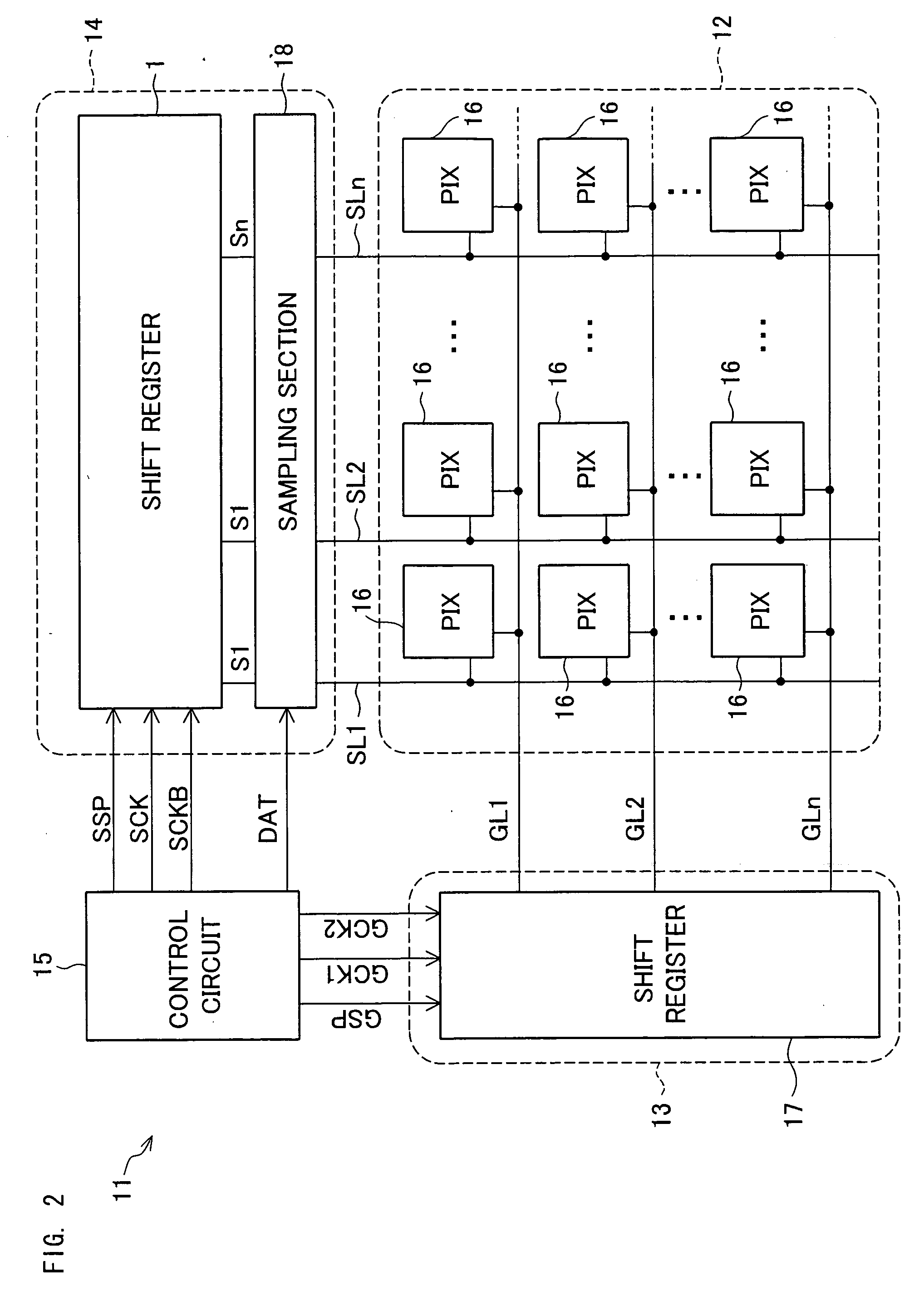

Shift register, shift register array, and flat display apparatus

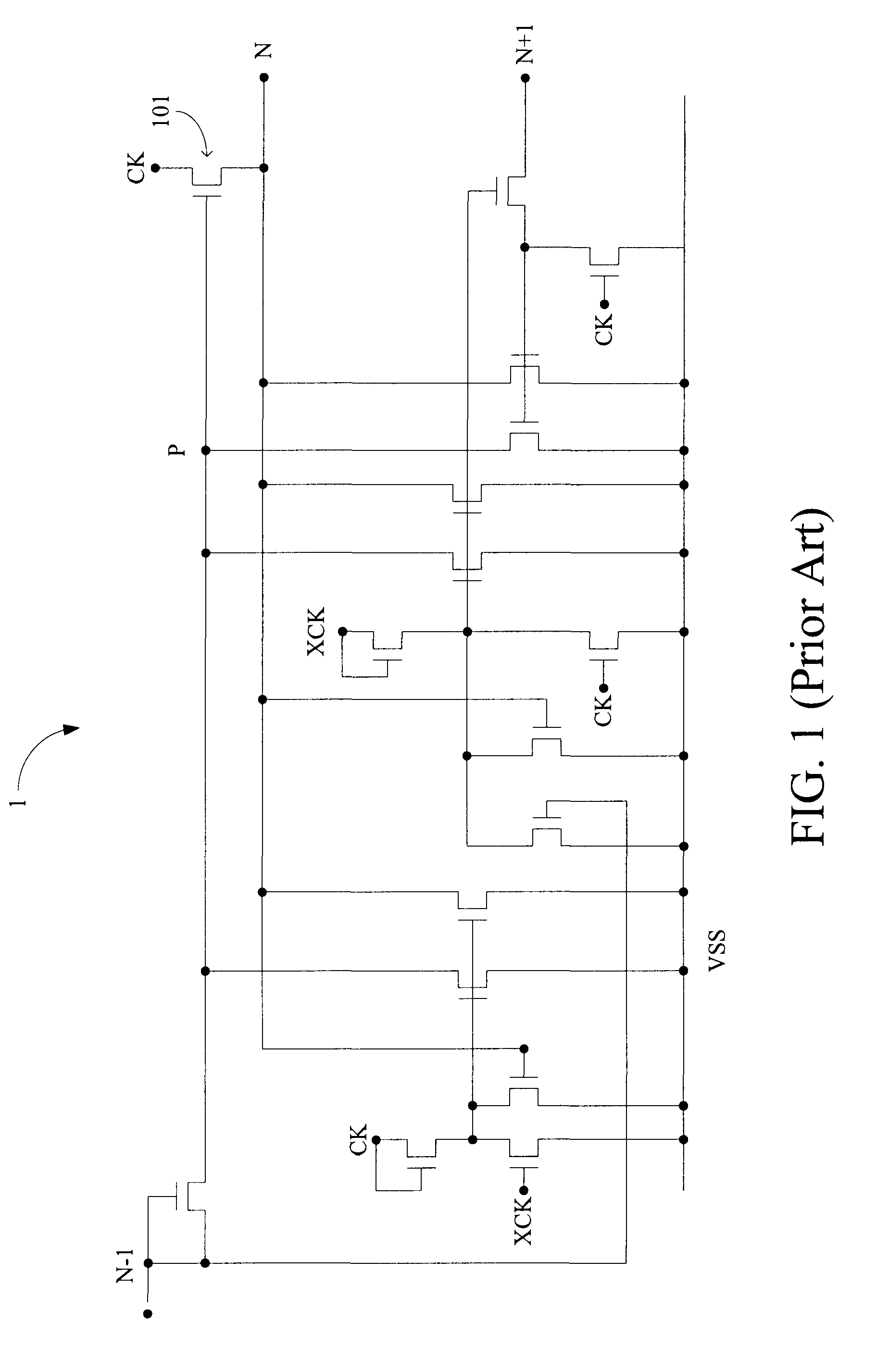

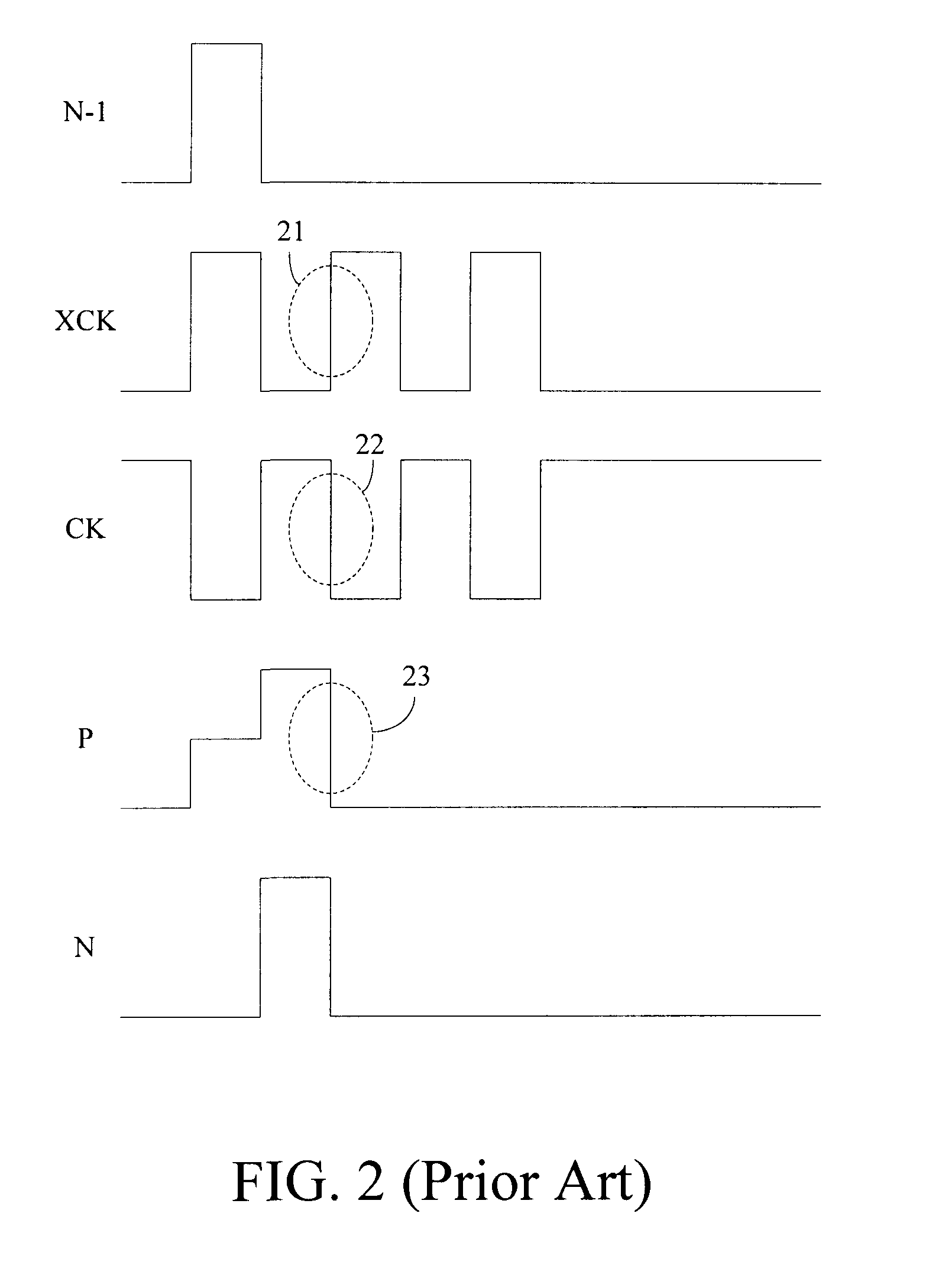

ActiveUS8031160B2Reduce coupling effectReduce output timeStatic indicating devicesDigital storageShift registerEngineering

A flat display apparatus comprising a shift register array is provided. The shift register array comprises a plurality of shift registers. At least one of these shift registers comprises a shift register unit, a first TFT, and a second TFT. The shift register unit is configured to receive an activation signal and comprises a first output terminal and a second output terminal. The gate of the first TFT is coupled to the first output terminal. The second electrode of the first TFT receives a clock signal. The gate of the second TFT is coupled to the first electrode of the first TFT. The second electrode of the second TFT is coupled to the second electrode of the first TFT. The first electrode of the second TFT is coupled to the second output terminal.

Owner:OPTRONIC SCI LLC

Shift register, shift register array, and flat display apparatus

ActiveUS20080068326A1Reduce coupling effectReduce output timeStatic indicating devicesDigital storageFlat panelClock signal

A flat display apparatus comprising a shift register array is provided. The shift register array comprises a plurality of shift registers. At least one of these shift registers comprises a shift register unit, a first TFT, and a second TFT. The shift register unit is configured to receive an activation signal and comprises a first output terminal and a second output terminal. The gate of the first TFT is coupled to the first output terminal. The second electrode of the first TFT receives a clock signal. The gate of the second TFT is coupled to the first electrode of the first TFT. The second electrode of the second TFT is coupled to the second electrode of the first TFT. The first electrode of the second TFT is coupled to the second output terminal.

Owner:AU OPTRONICS CORP

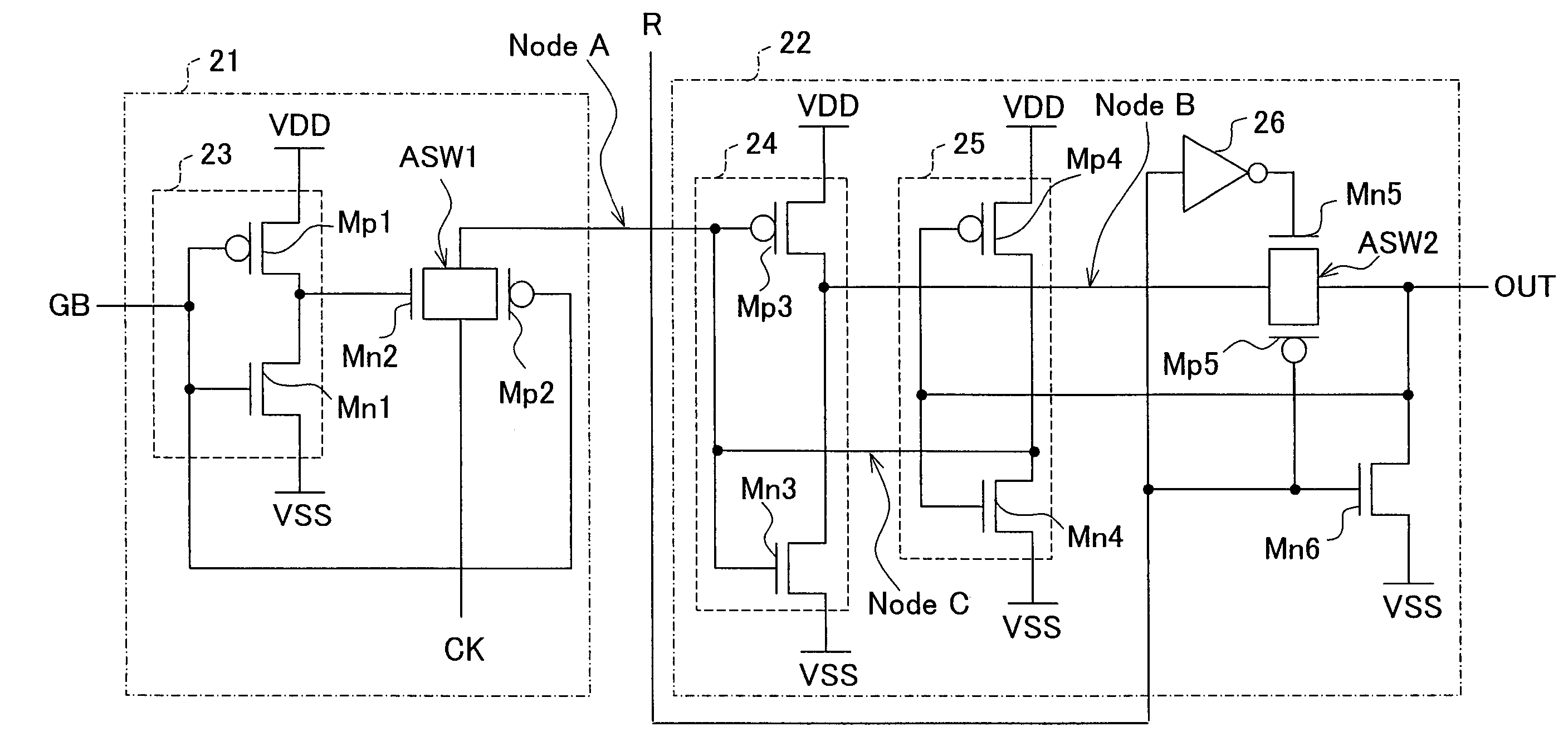

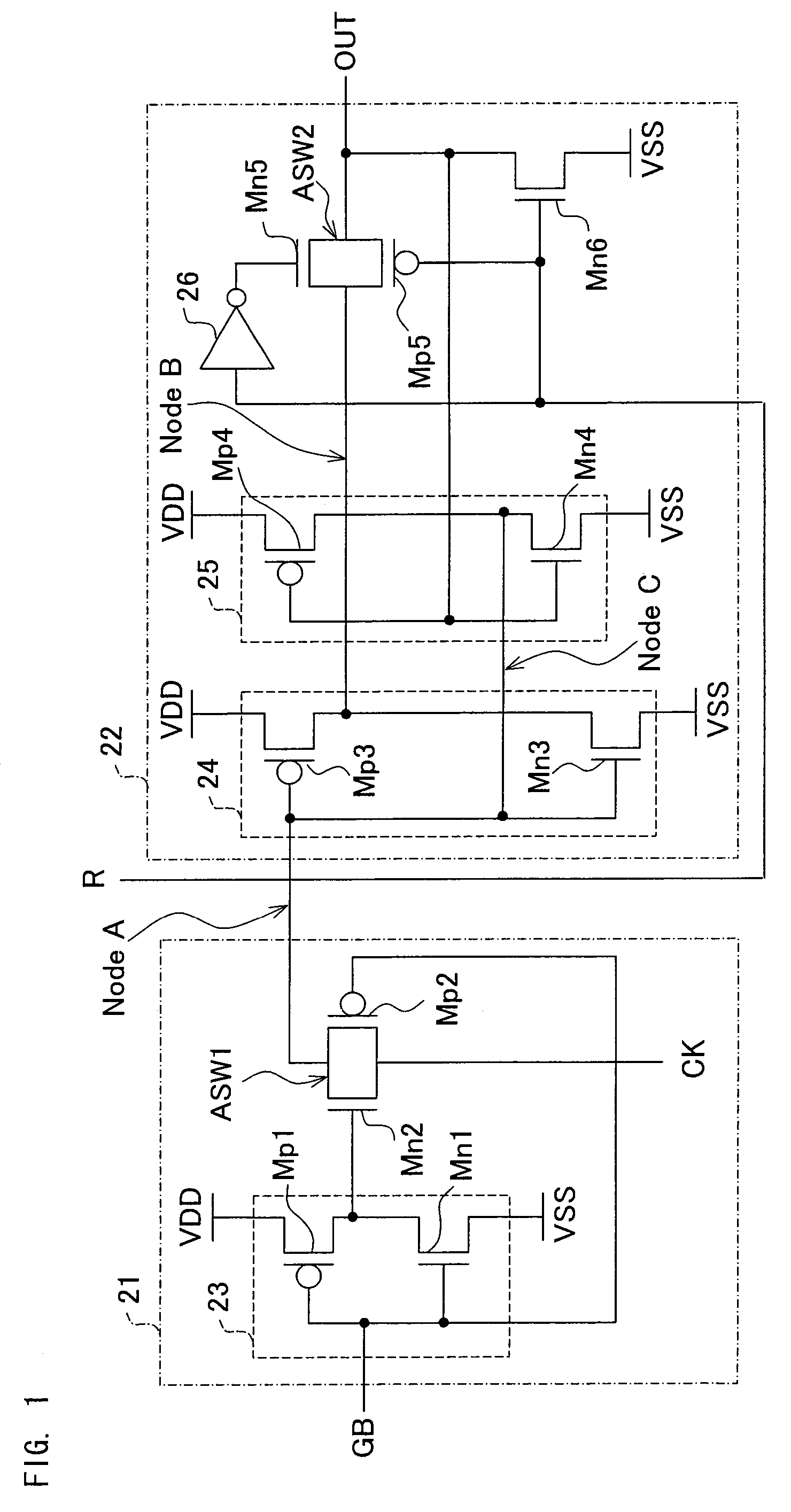

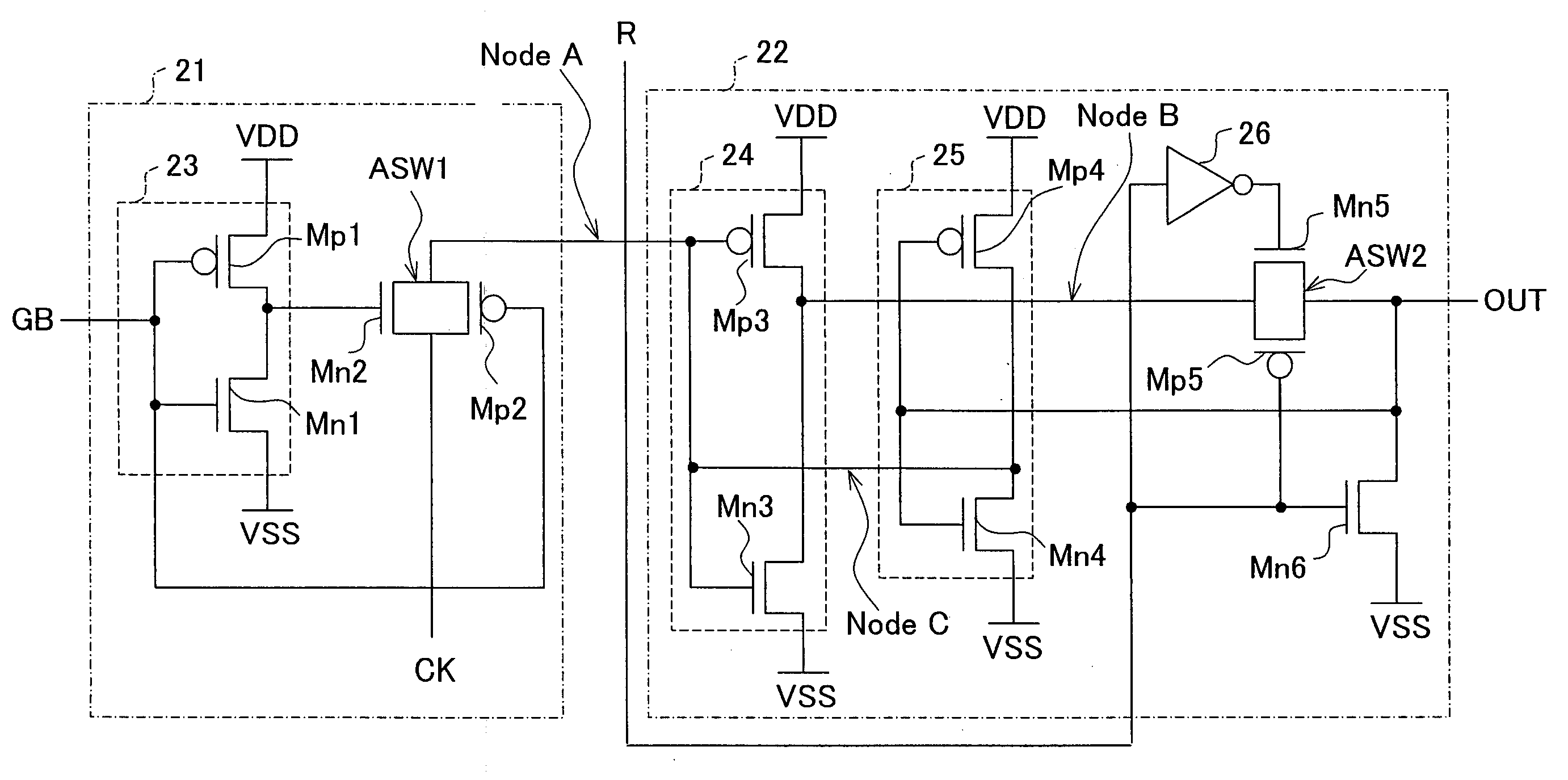

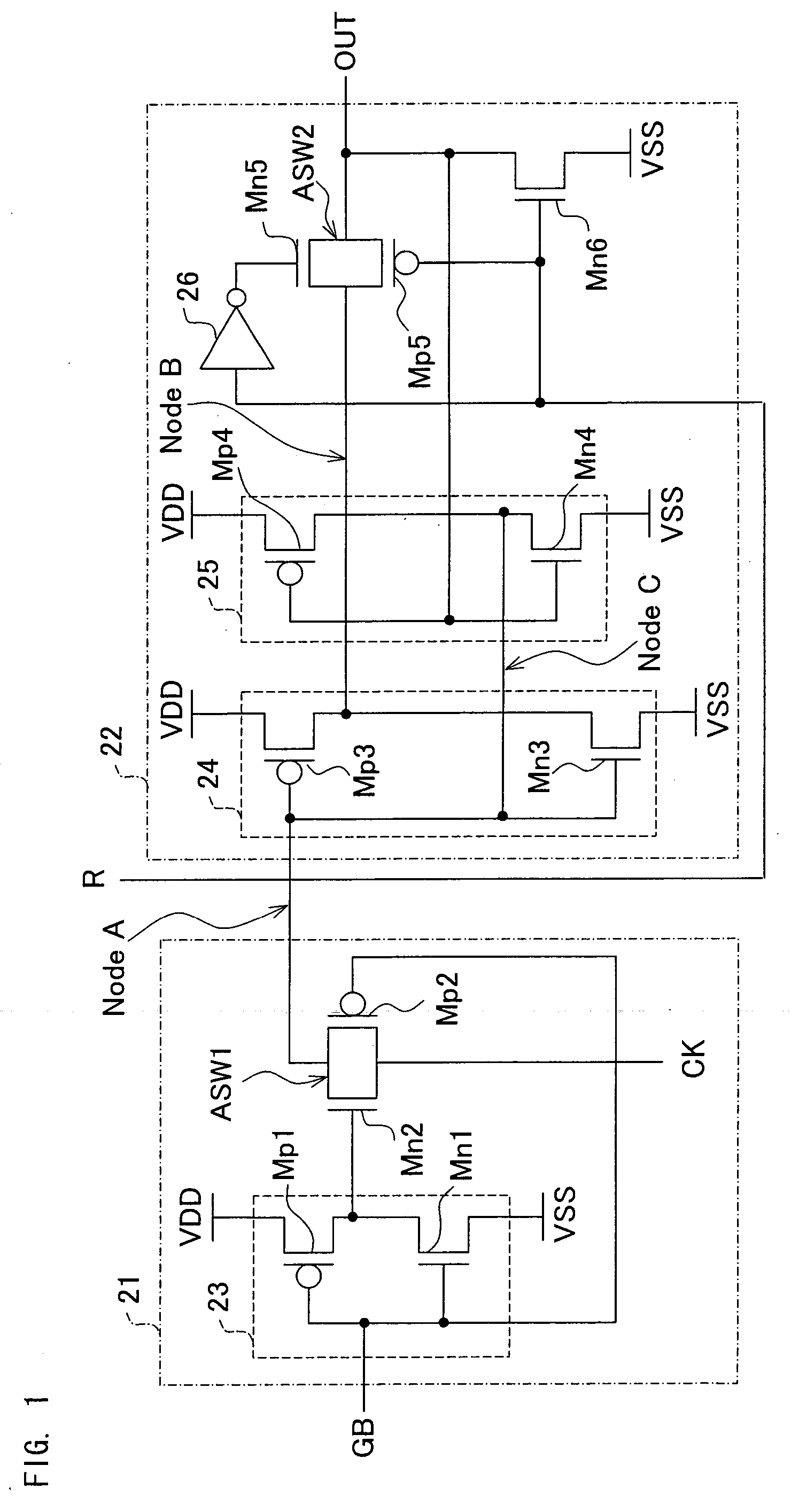

Flip-flops, shift registers, and active-matrix display devices

InactiveUS7420402B2Reduce signal delayImprove featuresStatic indicating devicesCounting chain pulse countersShift registerActive matrix

A latch section includes a latch circuit. The latch circuit includes inverters and latches an input signal from a gating section. Between one of the inverters of the latch circuit and the output terminal OUT is disposed an analog switch whose ON / OFF characteristics are switched according to High / Low of a reset signal. Between the output terminal and an input for receiving a low potential as a power supply of a flip-flop is disposed a switching element whose ON / OFF characteristics are switched according to High / Low of the reset signal.

Owner:SHARP KK

Flip-flops, shift registers, and active-matrix display devices

InactiveUS20050184784A1Reduce signal delayImprove featuresStatic indicating devicesCounting chain pulse countersShift registerActive matrix

A latch section includes a latch circuit. The latch circuit includes inverters and latches an input signal from a gating section. Between one of the inverters of the latch circuit and the output terminal OUT is disposed an analog switch whose ON / OFF characteristics are switched according to High / Low of a reset signal. Between the output terminal and an input for receiving a low potential as a power supply of a flip-flop is disposed a switching element whose ON / OFF characteristics are switched according to High / Low of the reset signal.

Owner:SHARP KK

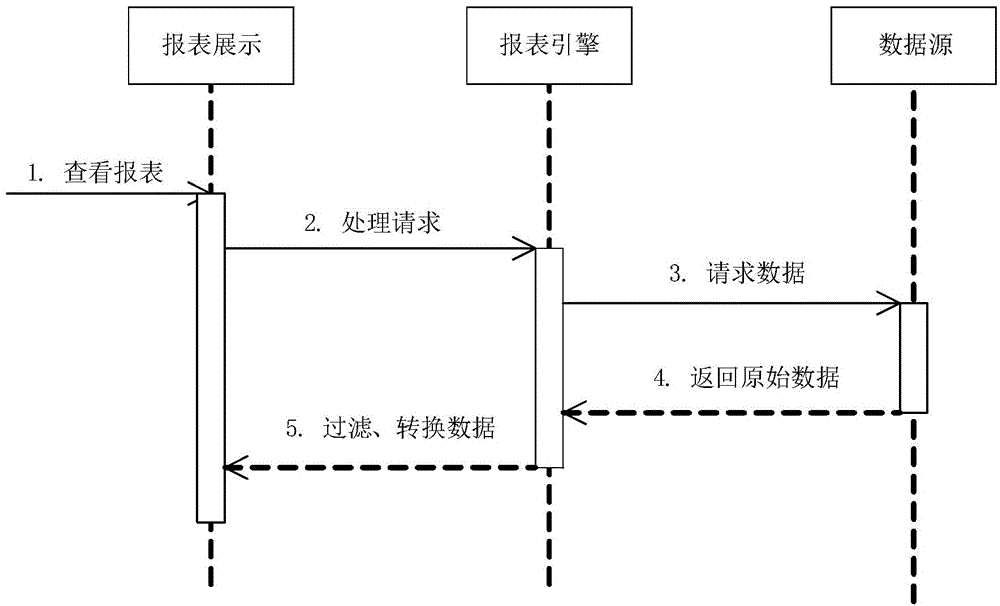

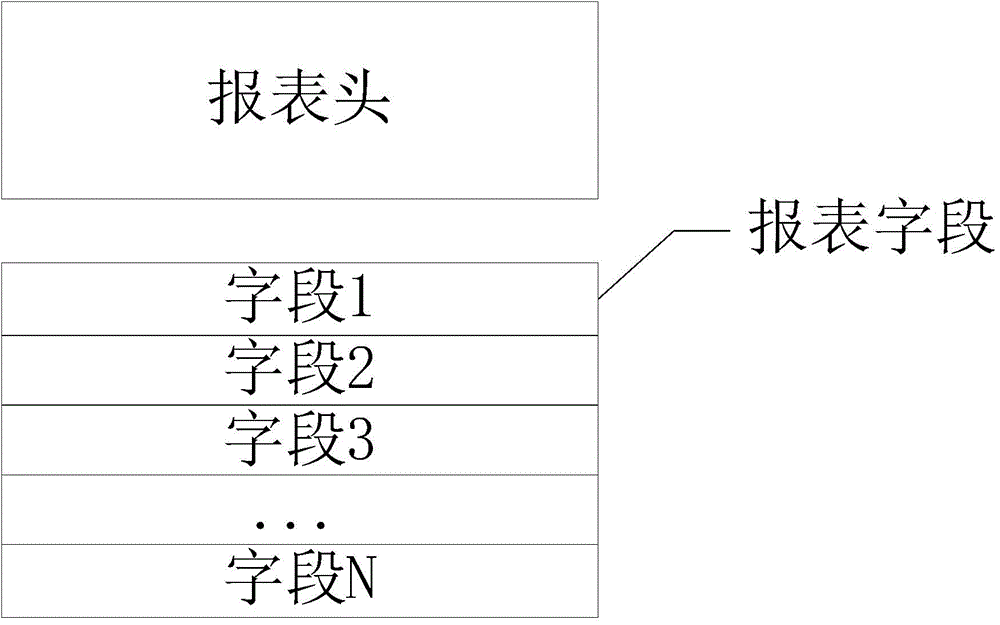

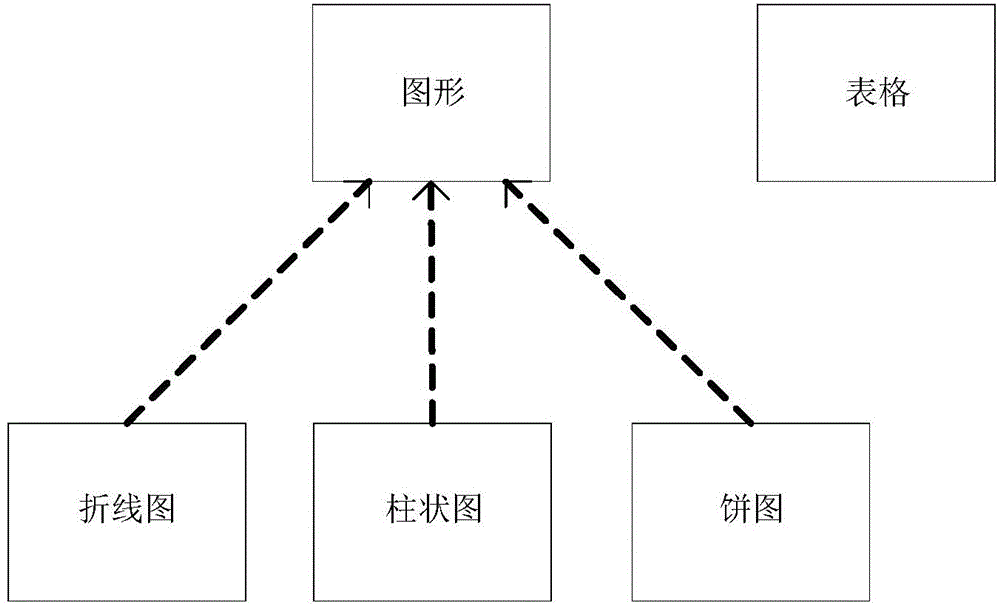

Report display engine based on metadata

InactiveCN104573065AMeet changing needsImprove scalabilityWeb data indexingSpecial data processing applicationsMaintainabilityResult set

The invention discloses a report display engine based on metadata. By defining the metadata, data reading logic, constraint and interface layout during the operation are analyzed. The metadata include a report header and a report field definition. The report engine determines data sources, report titles, the file outputting type and other main information by reading the report header, then integrates the report field definition to search and filter the data during operation and returns to a result set, and finally, based on the report header and the report field definition, determines the report display mode and outputs the same to the clients. The report display engine has the advantages that the standard metadata model is defined, flexible configuration is characterized, and the further metadata expanding is supported; at the premise that the maintainability is guaranteed, the report yield is increased, fast development is supported, and adaptability to the report system requiring frequent changes is achieved.

Owner:GUANGDONG NENGLONG EDUCATION

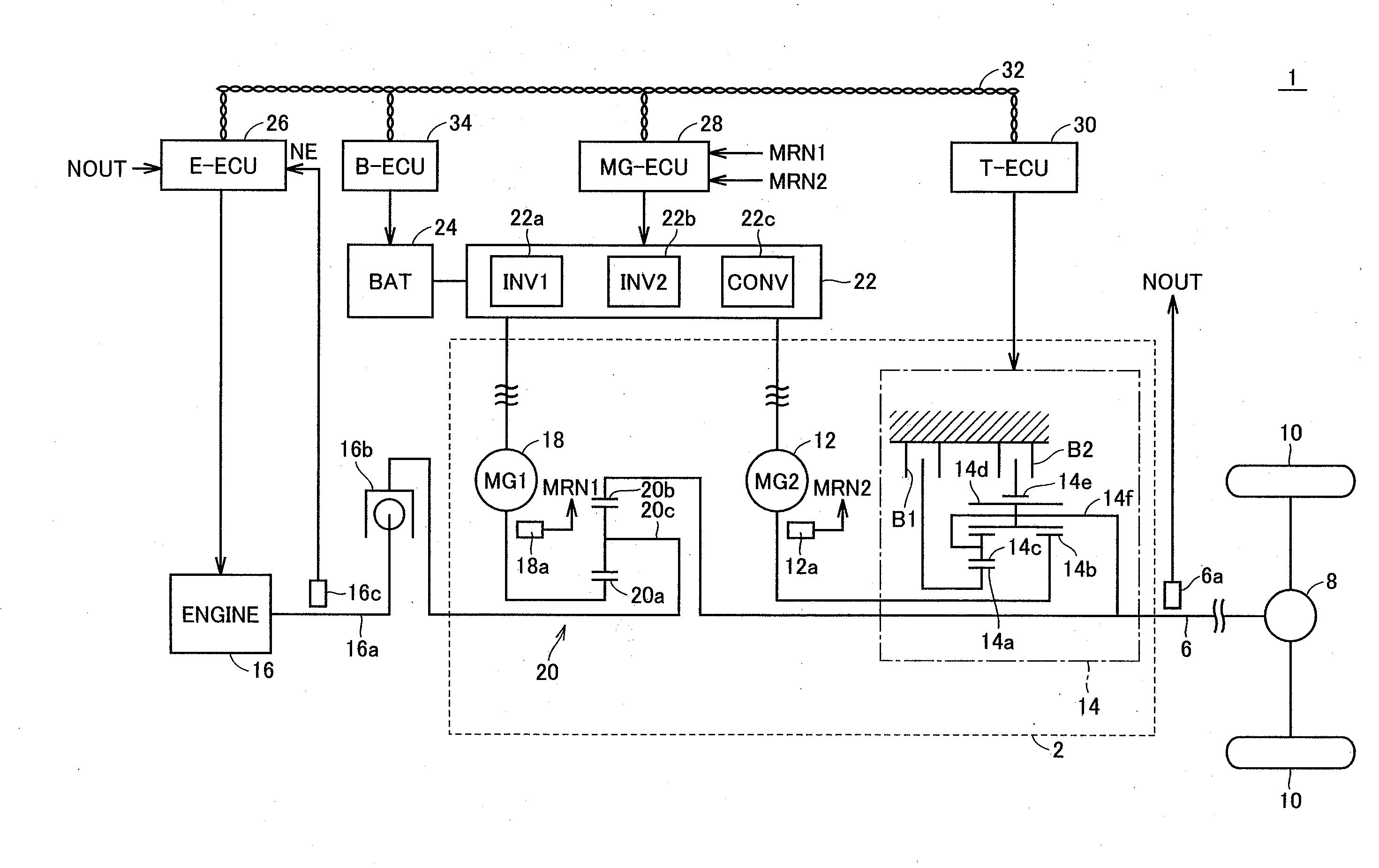

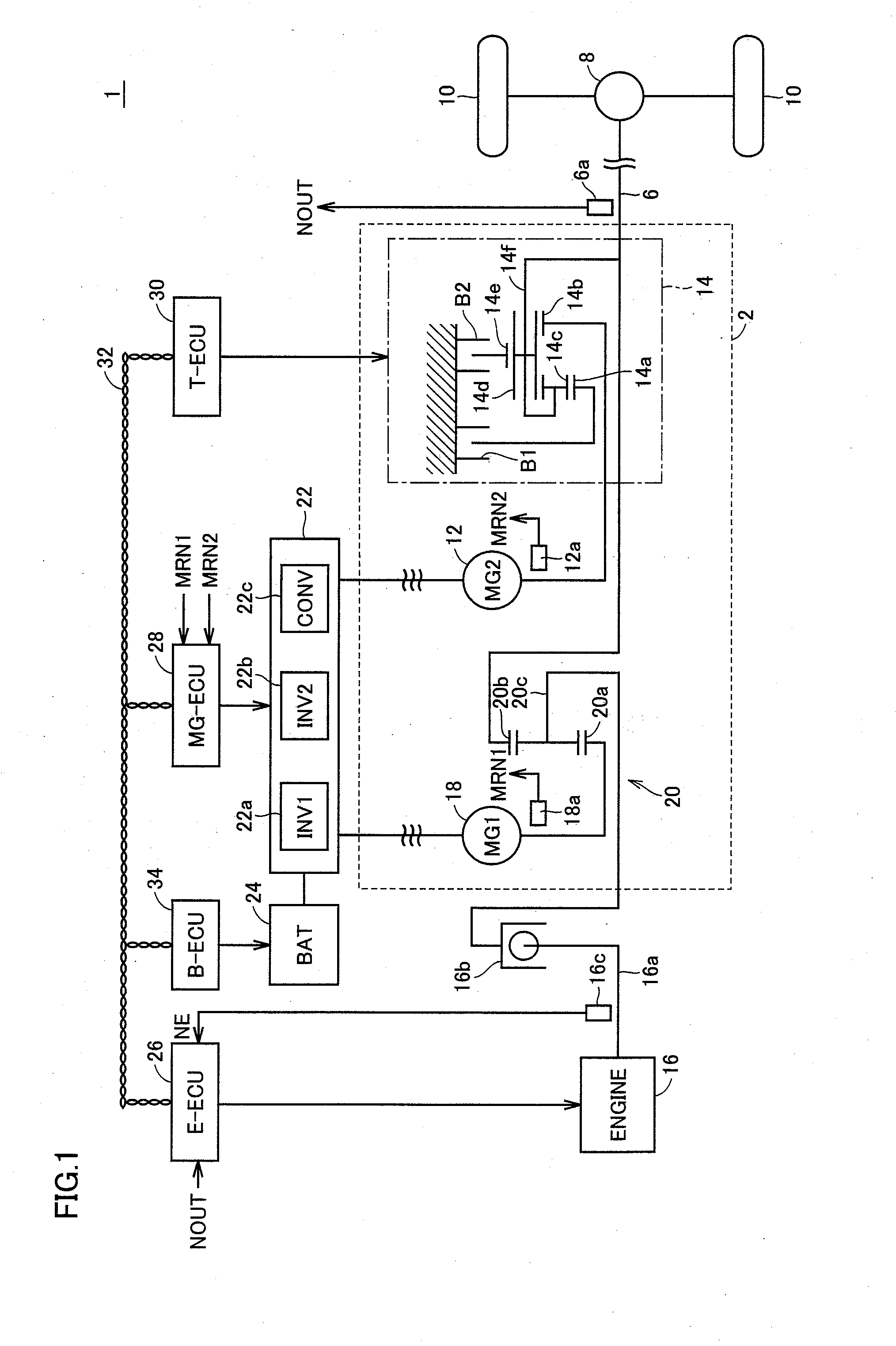

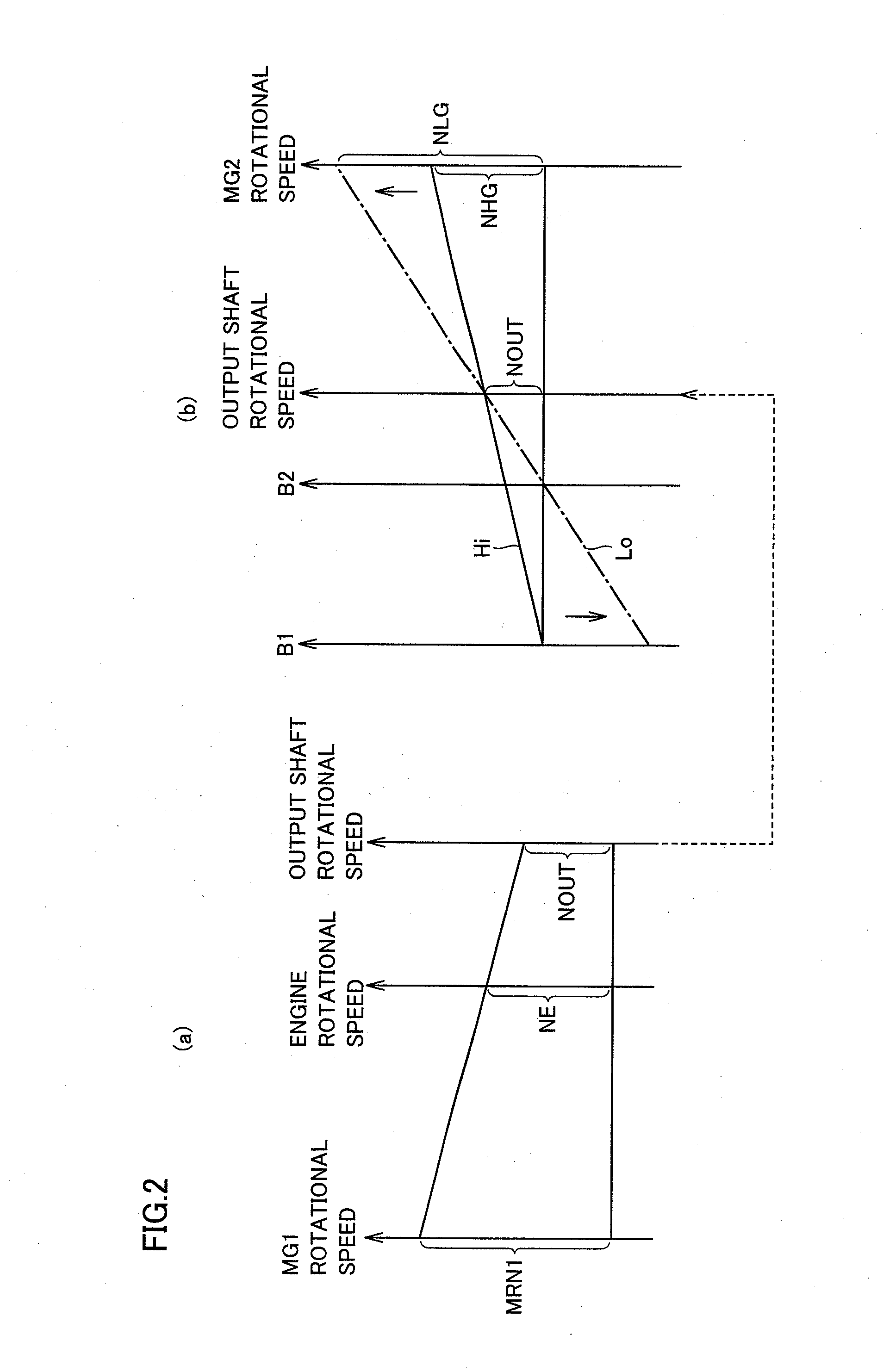

Hybrid driving apparatus, vehicle with the same and control method of the same

For raising an MG2 rotational speed MRN2 to a target rotational speed (low-gear rotational speed NLG), an output torque of an MG2 starts to increase at a time t4. During an inertia phase (period α), the output torque of the MG2 is limited not to exceed a first limit value TLIM1 determined according to a shift progress degree PRG and a second limit value TLIM2 determined according to a rotational speed margin NEmgn. Since the output torque of the MG2 is sufficiently small in a final stage of the inertia phase (period α), output variations occurring at a time t6 when torque down is performed on the MG2 can be small. The torque down of the MG1 and MG2 does not raise engine rotational speed NE.

Owner:TOYOTA JIDOSHA KK

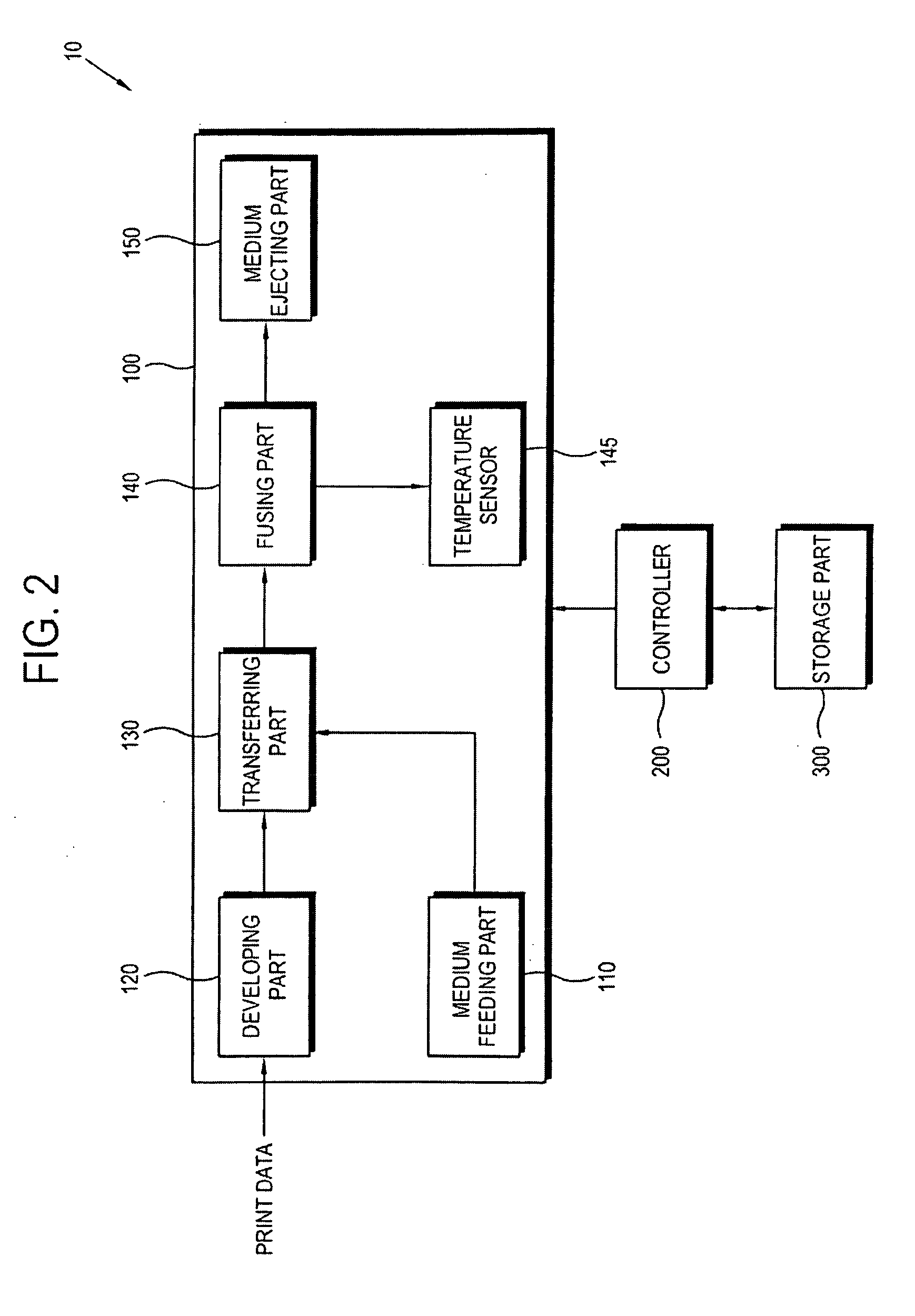

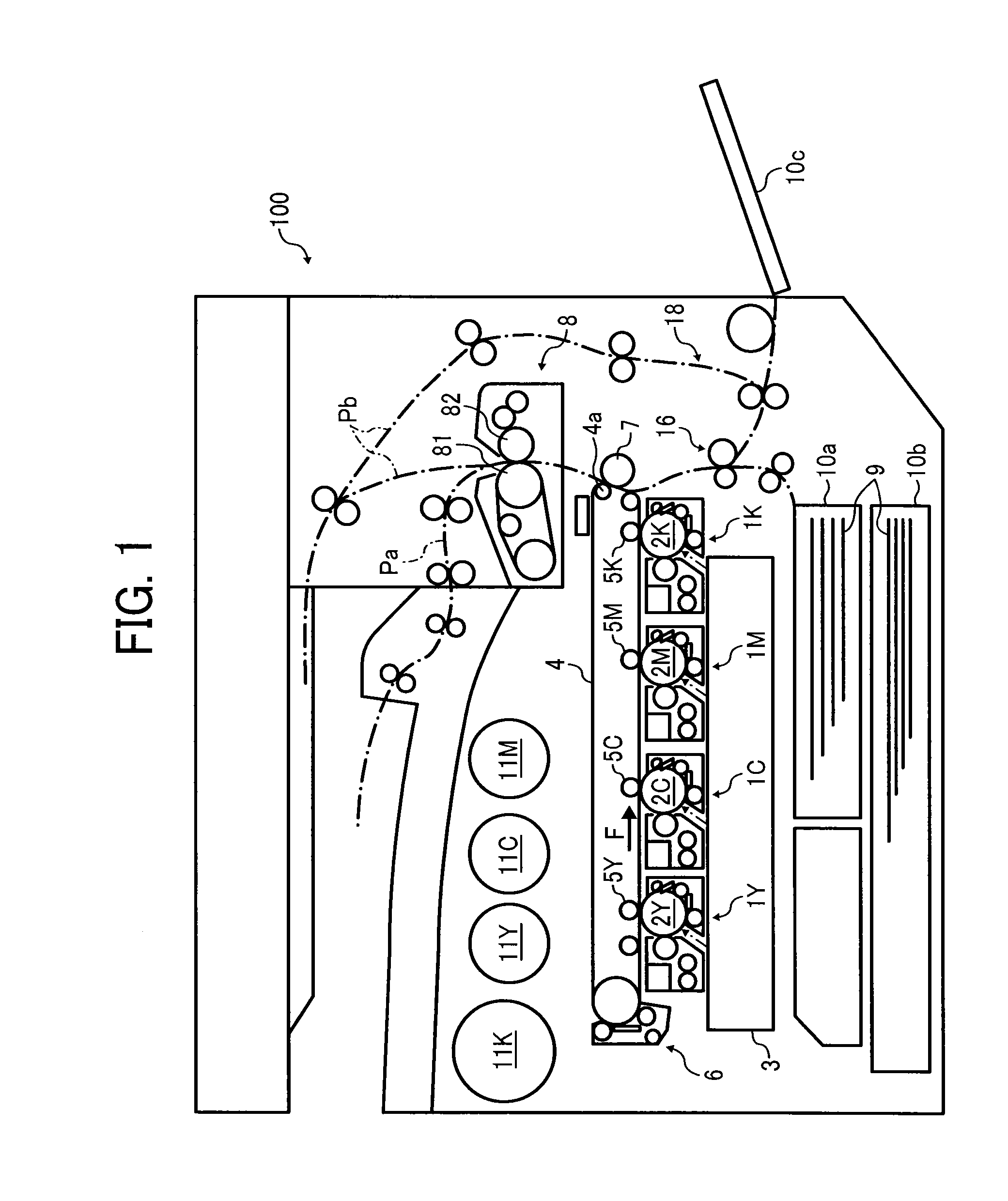

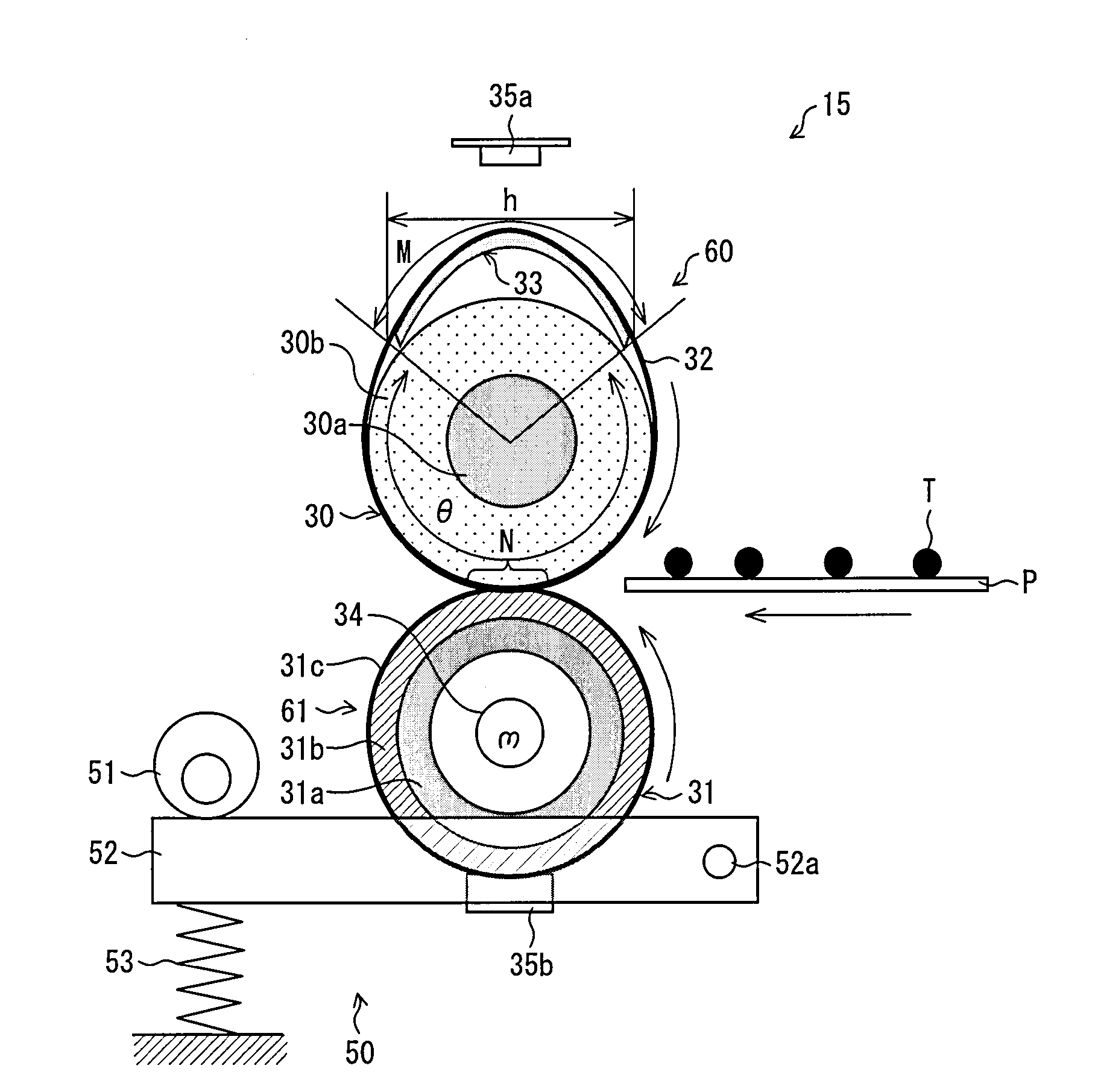

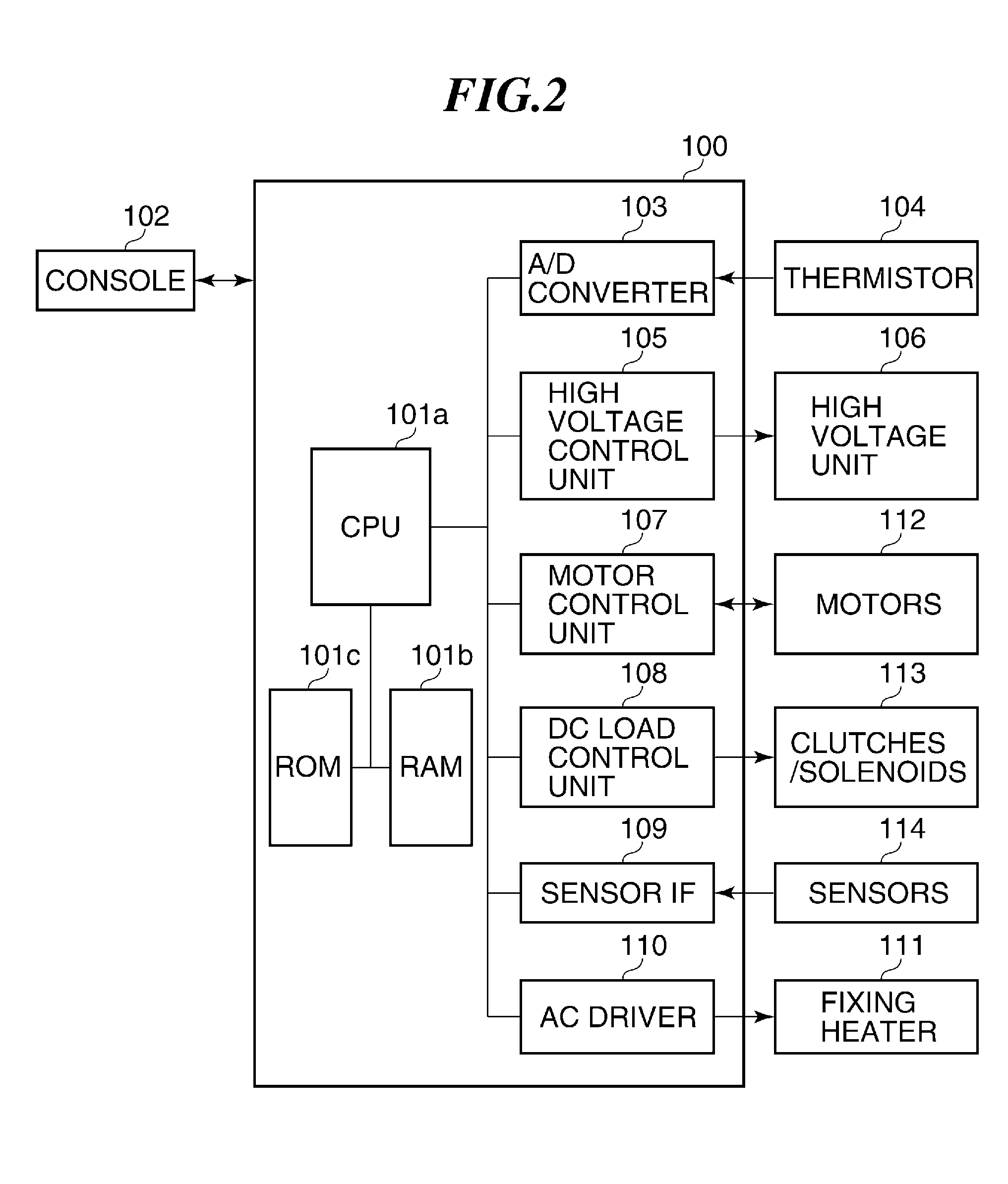

Image forming apparatus and control method thereof

ActiveUS20090174888A1Securing fixability of an image on a recording mediumReduce output timeDigitally marking record carriersDigital computer detailsEngineeringElectrical and Electronics engineering

An image forming apparatus includes: an image forming part which picks up a recording medium at a predetermined pickup timing and forms an image at a predetermined printing speed; and a controller which accelerates the timing for picking up the recording medium in advance of the predetermined pickup timing, and which lowers the printing speed so as to allow the printing operation to take place at a lower fusing temperature during warming up from a cold start in order to shorten the first print output time (FPOT).

Owner:HEWLETT PACKARD DEV CO LP

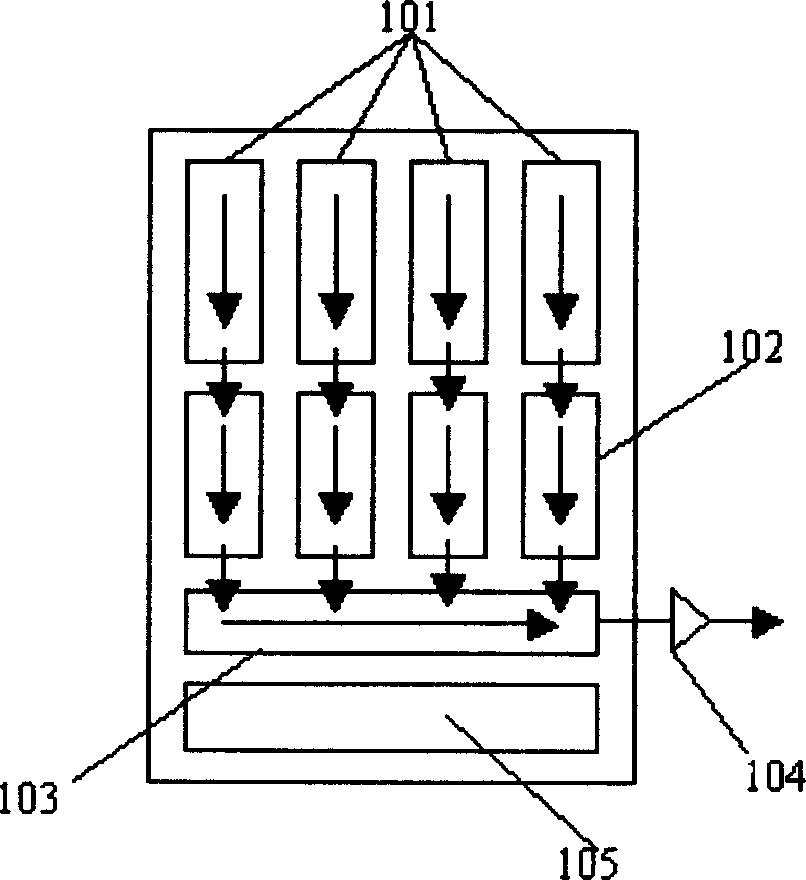

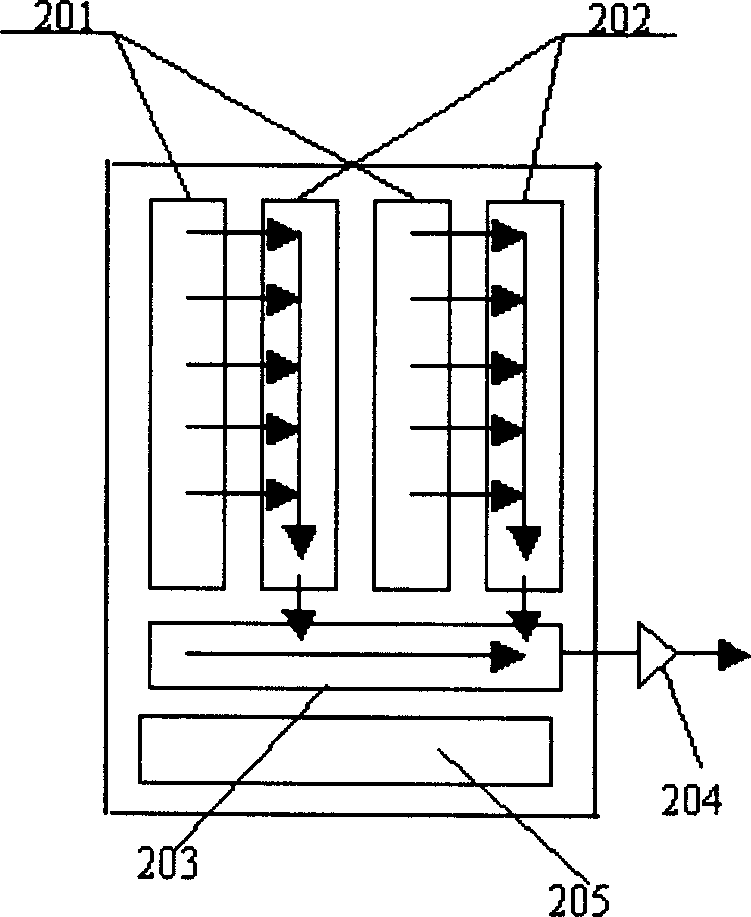

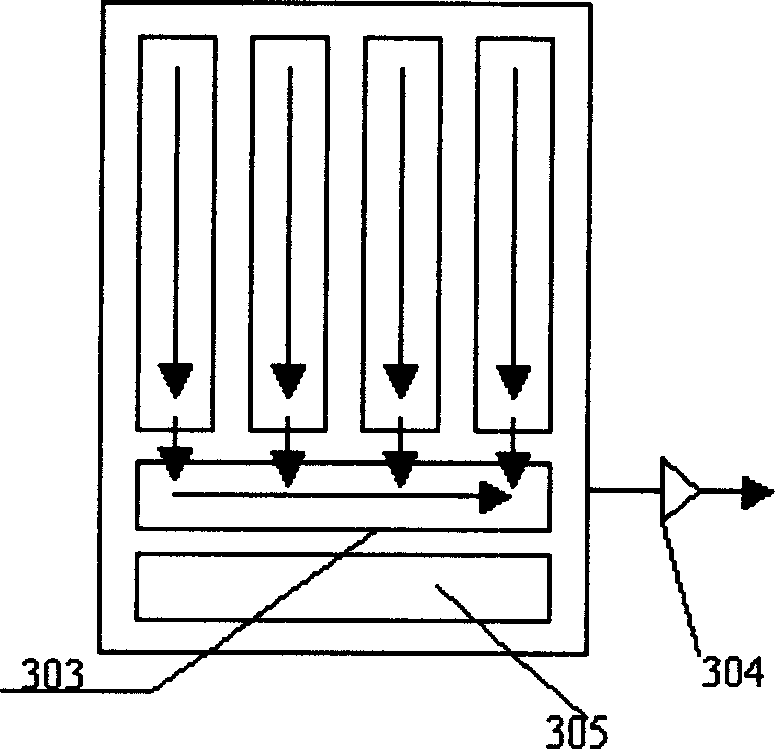

Method for increasing CCD image collection system frame rate

InactiveCN1738356AReduce output timeHigh acquisition rateTelevision system detailsTelevision system scanning detailsWork patternRegion of interest

The invention relates to a method for improving the frame rate of CCD image collecting system. The invention sets the interested region of CCD imaging region as the sub-window according to the need of user, which comprises the first pixel coordinate (I, j) and the its size (m rows X n lines); the invention drives the CCD operate in the sub-window operational mode as only outputting the pixels of said sub-window from the CCD while the pixels outside the sub-window are distinguished inside the CCD chip. So the processing time of each frame image is reduced, and the frame rate is improved. In addition, since the size and the position coordinate of said interested region can be adjusted freely according to the need of user, the adaptability of CCD image collecting device is increased.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

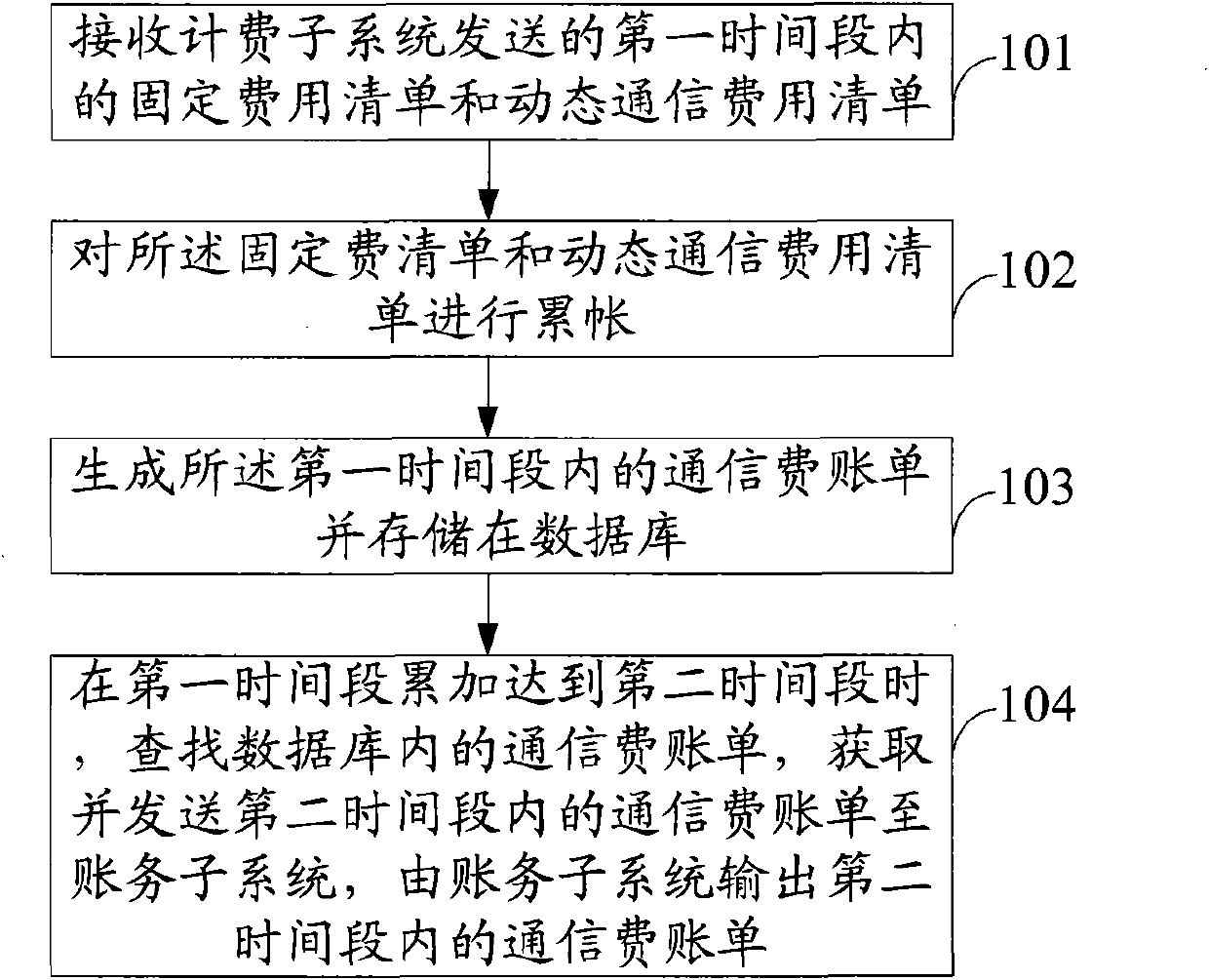

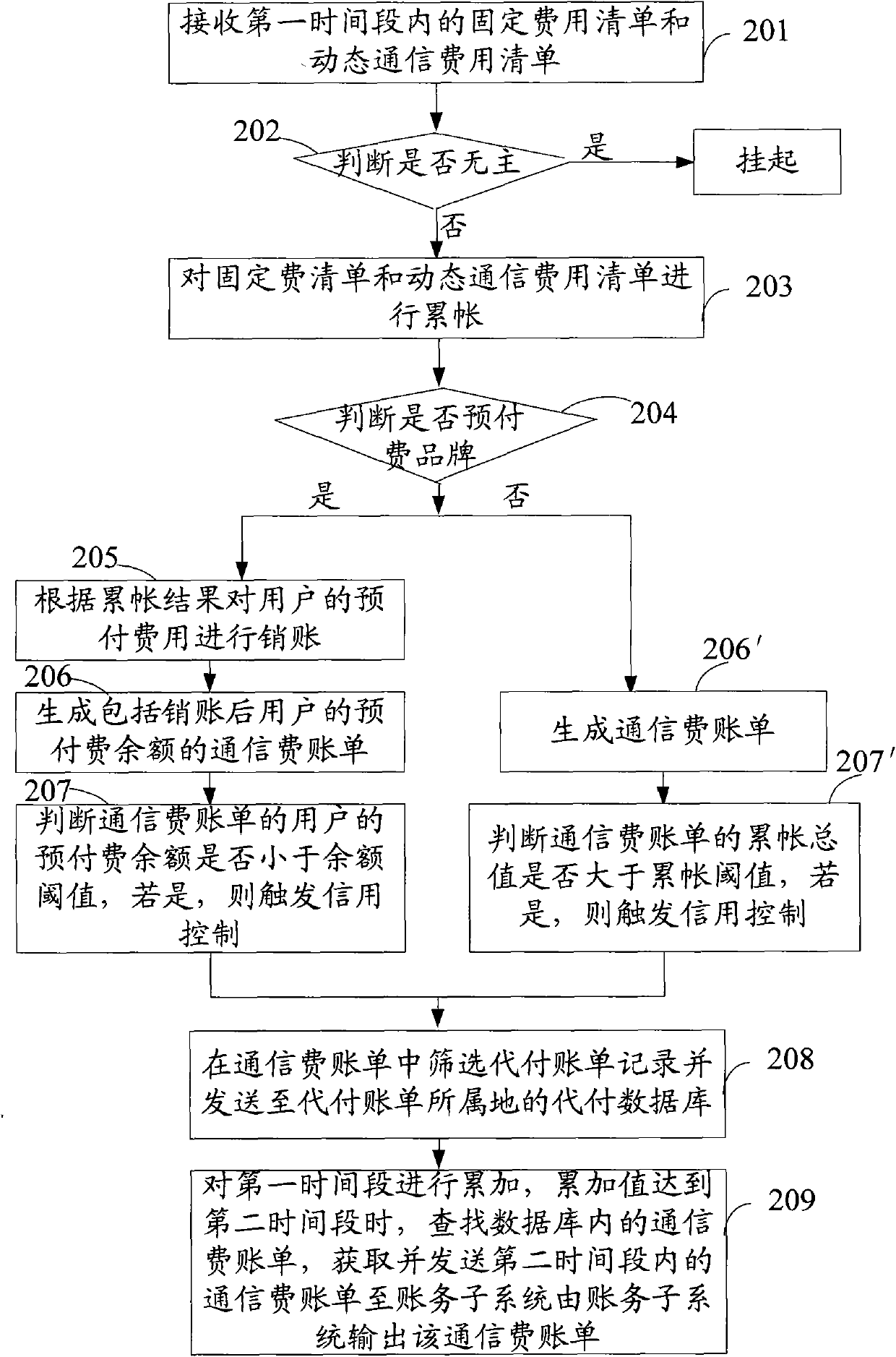

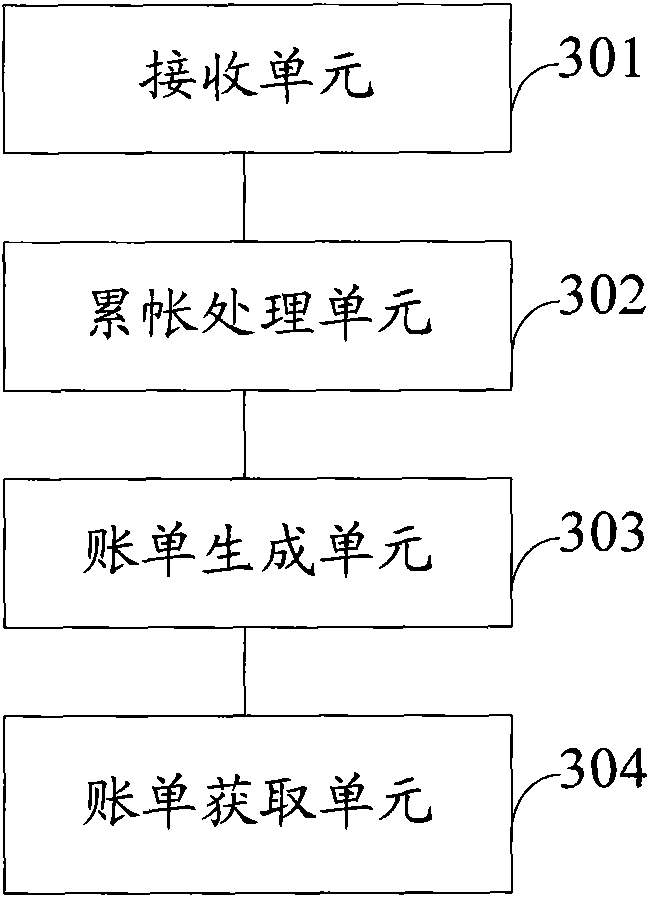

Communication fee bill output method and system

InactiveCN102026138AReduce output timeImprove output efficiencyAccounting/billing servicesPrepayment telephone systemsReal-time computingTime quantum

The invention provides a communication fee bill output method and system. The communication fee bill output method comprises the following steps of: receiving a fixed fee list and a mobile communication fee bill in a first time quantum, which are sent by a charging subsystem; adding up the fixed fee list and the mobile communication fee bill; generating a communication fee bill in the first time quantum and storing in a database; and searching the communication fee bill in the database when the first time quantum is added up to a second time quantum, acquiring a communication fee bill in the second time quantum , sending to an accounting subsystem and outputting the communication fee bill in the second time quantum by the accounting subsystem. The embodiment of the invention proportions the calculation and the accounting treatment of the fixed fee in each first time quantum, balances the bill output load at the end of a month and can call a needed bill from the database and output the needed bill, greatly shorten the output time of the bill at the end of the month and improve the output efficiency of the bill.

Owner:GUANGZHOU SUNRISE ELECTRONICS DEV

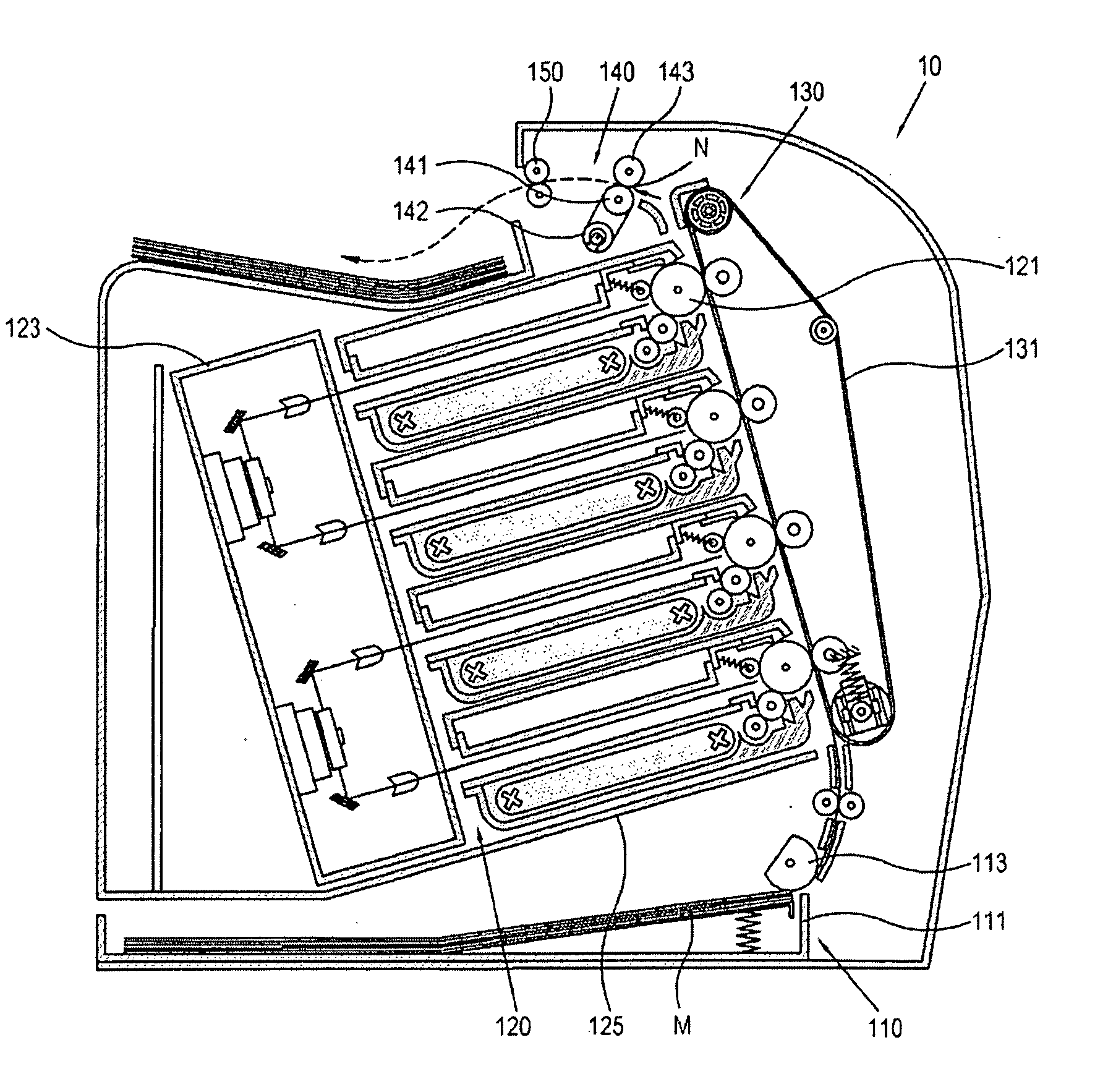

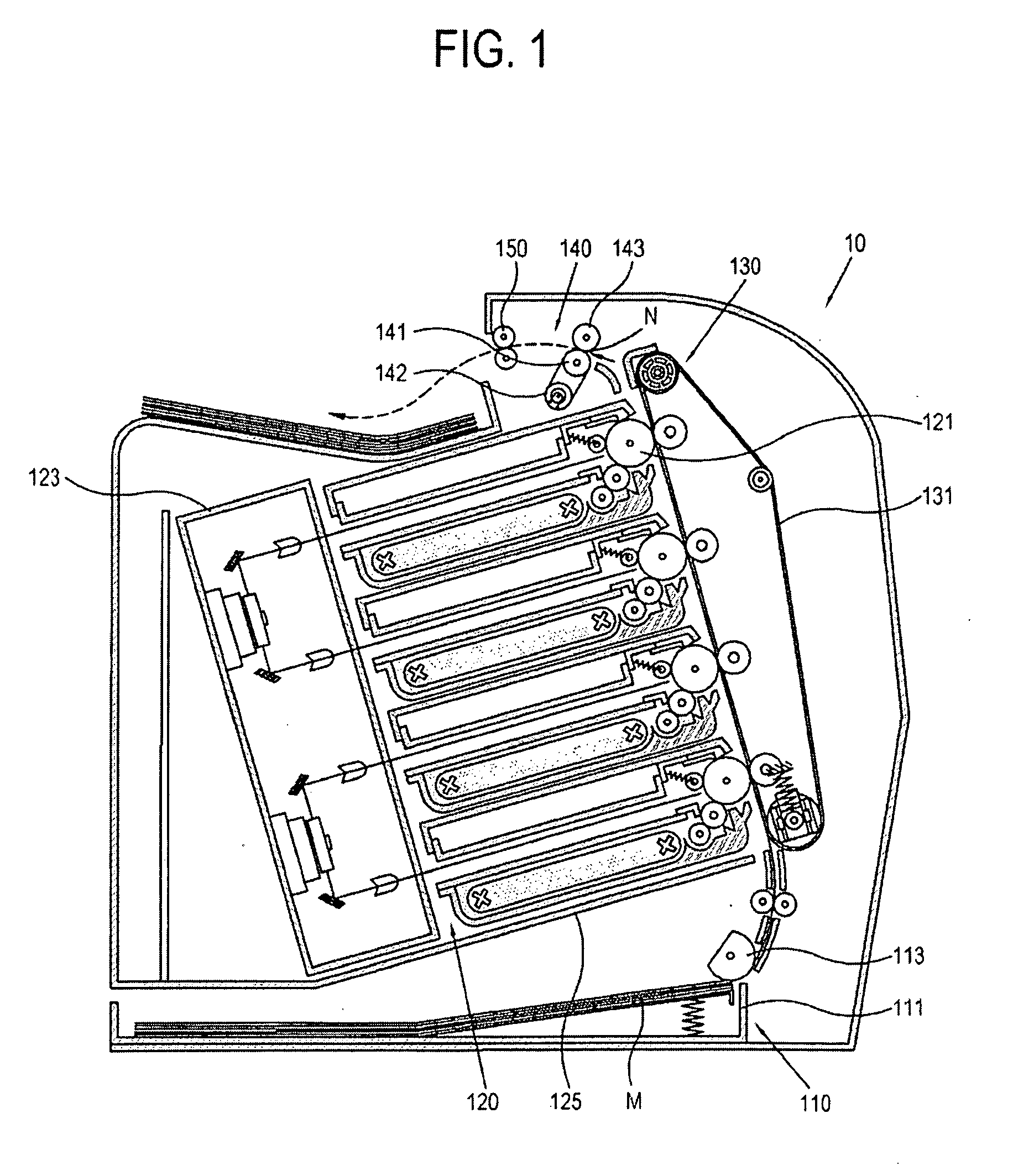

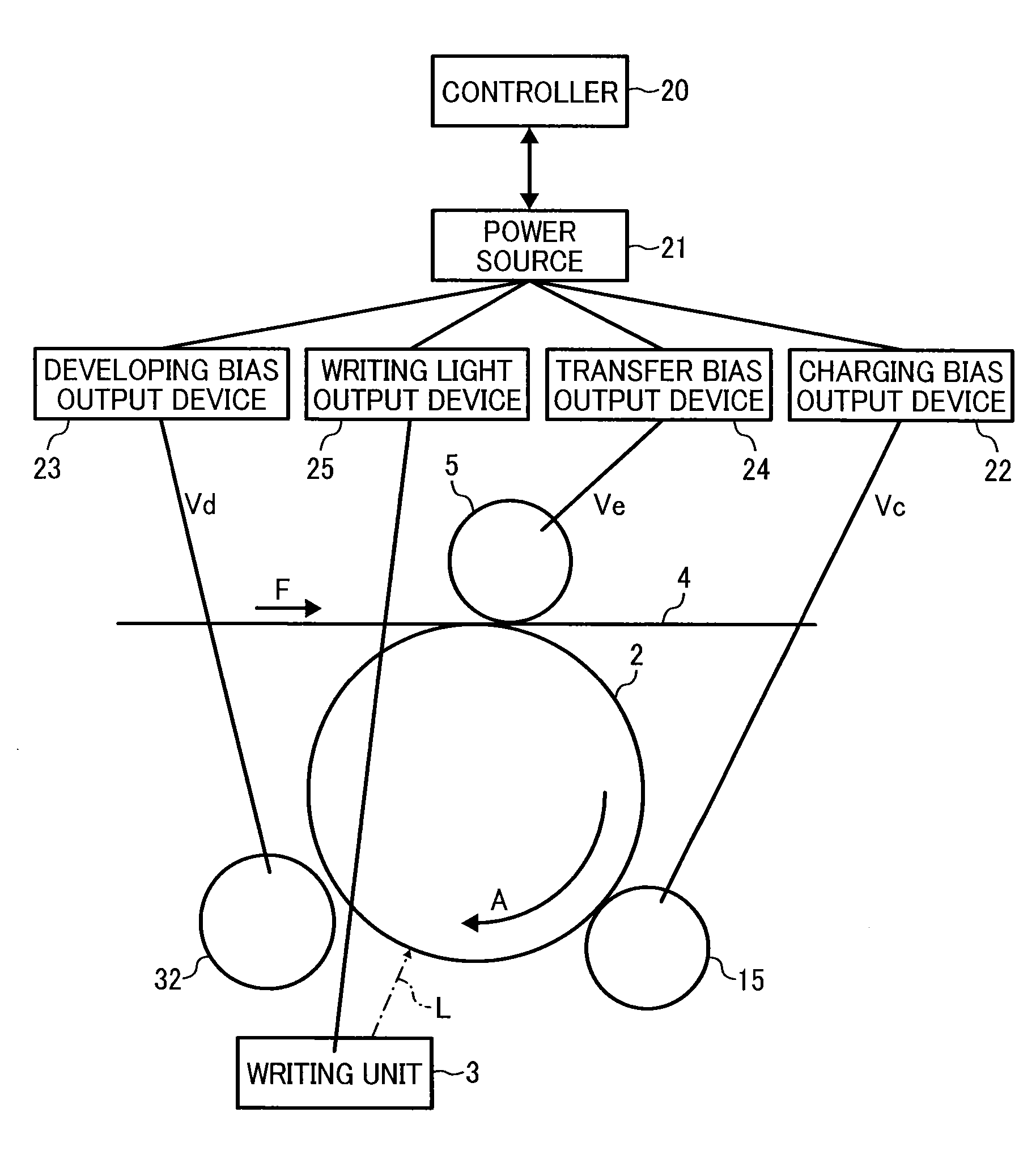

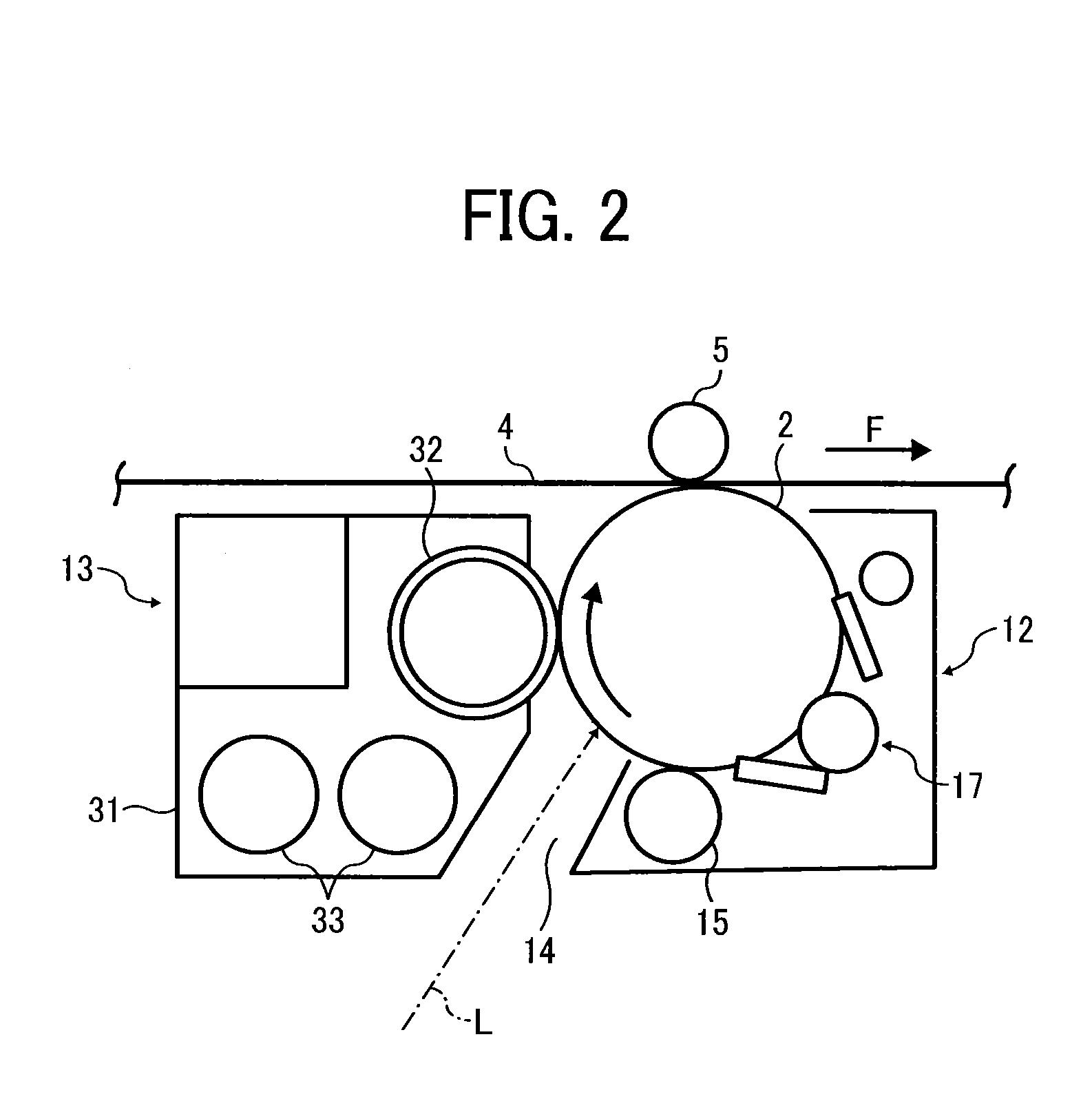

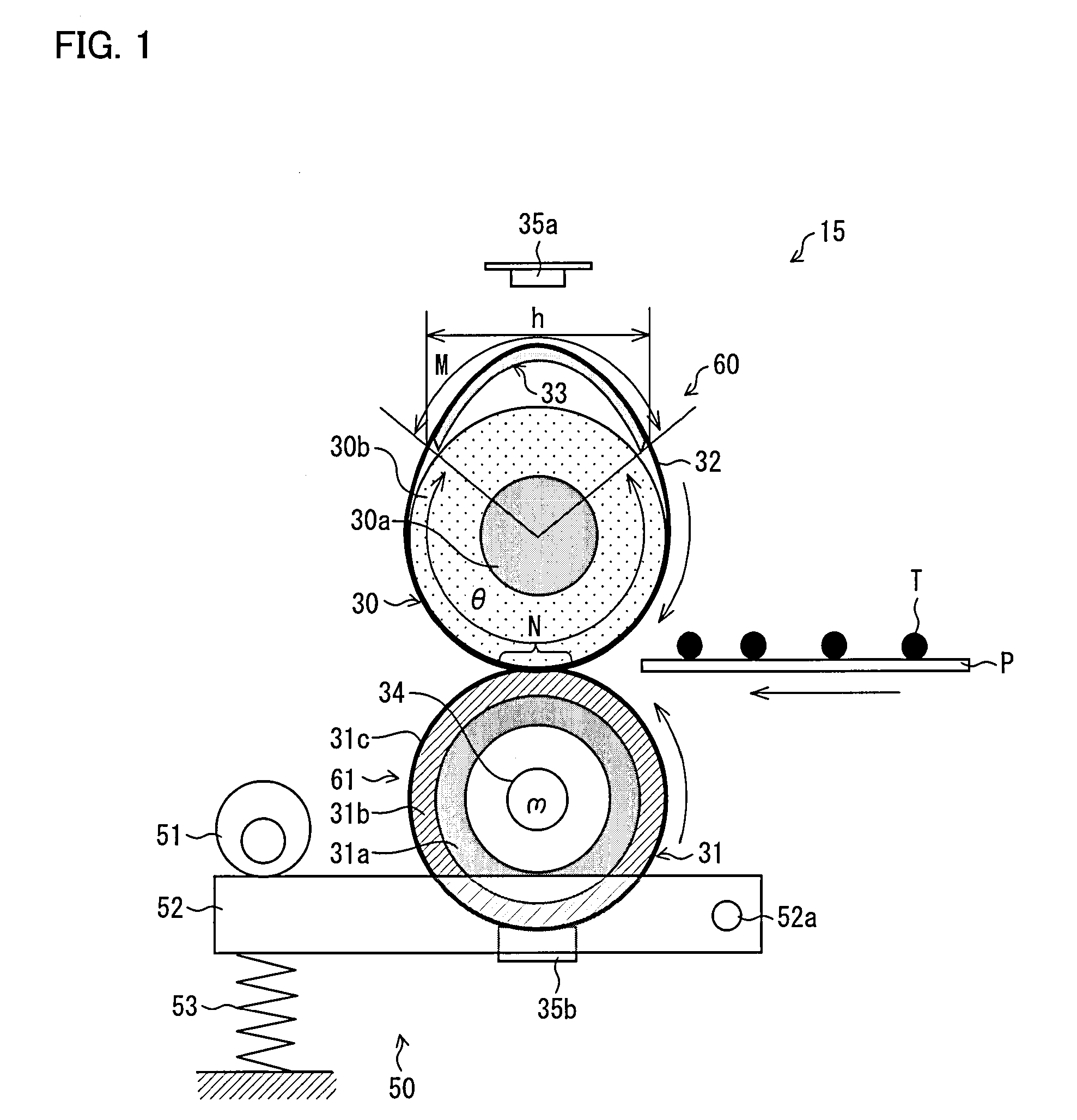

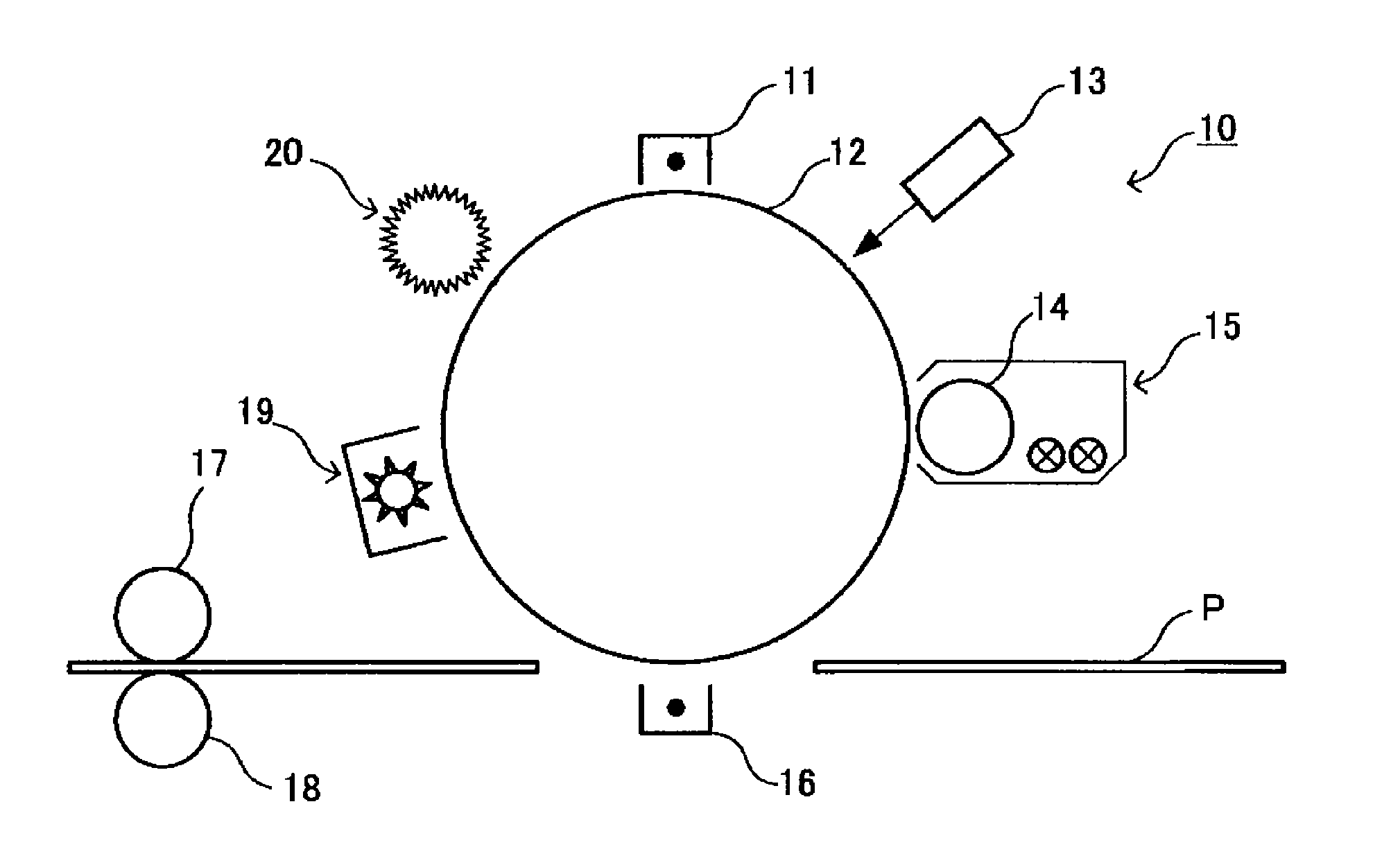

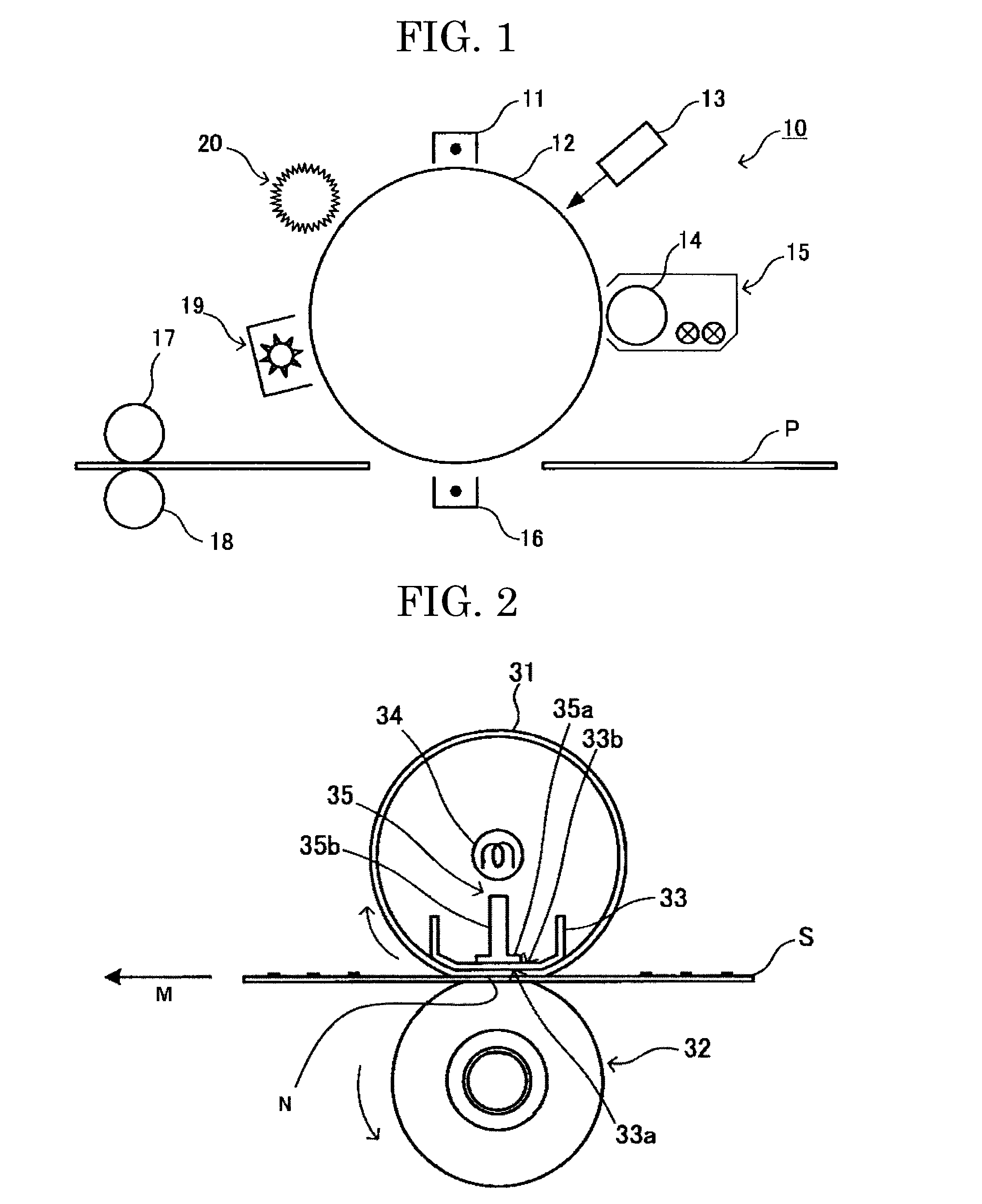

Electrophotographic image forming apparatus

ActiveUS20140255050A1Reduce output timeElectrographic process apparatusCorona dischargeImage formationOutput device

An image forming apparatus includes a charging bias output device, a developing bias output device, a transfer bias output device, and a controller. The controller controls the transfer bias output device to supply a transfer bias from a time at which a first position of a photosensitive member arrives at a transfer position after the charging bias output device starts supplying a charging bias. An initial value of the transfer bias is controlled to be smaller than a normal set value for a predetermined time period (Tc) which is a time after the transfer bias starts to be supplied and within a time corresponding to a rise time (Ta) during which a surface potential of the photosensitive member reaches a predetermined potential after the charging bias starts to be output. The first position of the photosensitive member is a position at which the charging device start charging the photosensitive member.

Owner:RICOH KK

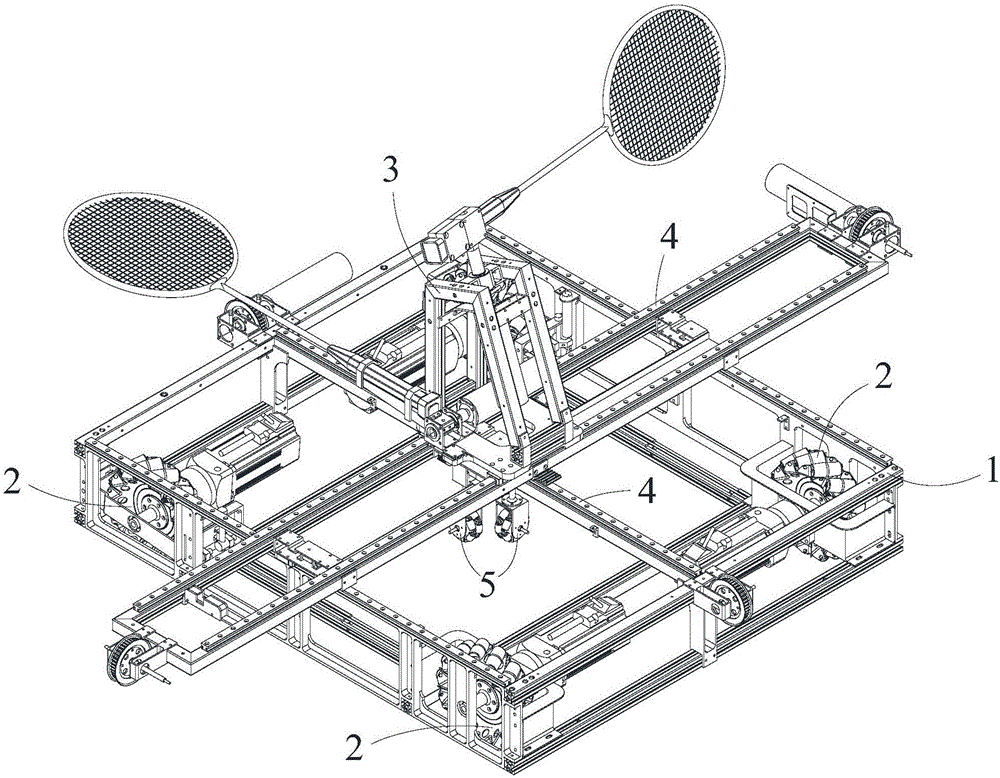

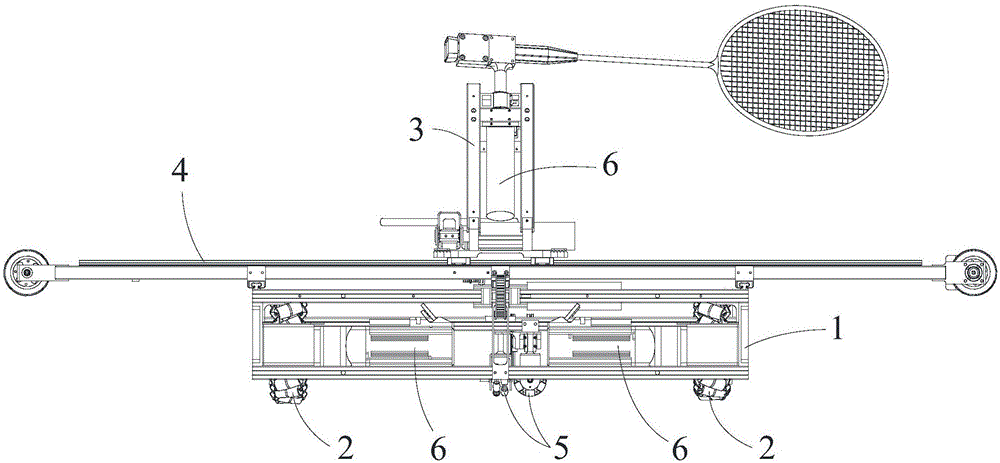

Capturing device with position compensation and method

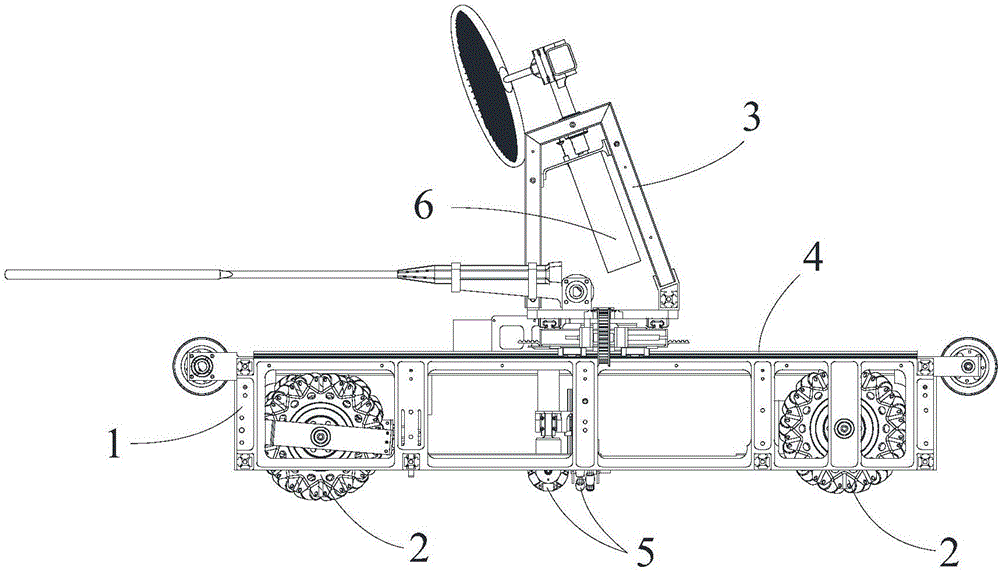

PendingCN106695740ACompact structureReal-time feedbackProgramme-controlled manipulatorSport apparatusControl systemEngineering

The invention discloses a capturing device with position compensation. The capturing device comprises a drive system, a control system and a bottom plate provided with at least one walking wheel. The capturing device further comprises a target mechanism used for intercepting a target, a moving mechanism arranged on the bottom plate and connected with the target mechanism, and a feedback mechanism. The moving mechanism is used for driving the target mechanism to move on the bottom plate. The feedback mechanism is arranged on the bottom plate and comprises a movement detection part and an orthogonal omnidirectional wheel part which is connected with the movement detection part, and the feedback mechanism is used for obtaining the deviation value between the bottom plate and the target and feeding back the deviation value to the control system. By adoption of the device, although the device slides in an inertial manner at the target drop point position, the feedback mechanism records and feeds back the sliding path to the control system, meanwhile, the control system makes the target mechanism move on the bottom plate, the target mechanism is static relative to the drop point, and the target is captured. The capturing device is simple and compact in structure and fast in feedback real-time responding, and the target mechanism can be accurately controlled at the target drop point.

Owner:CHENGDU EVENTEC SCI & TECH CO LTD

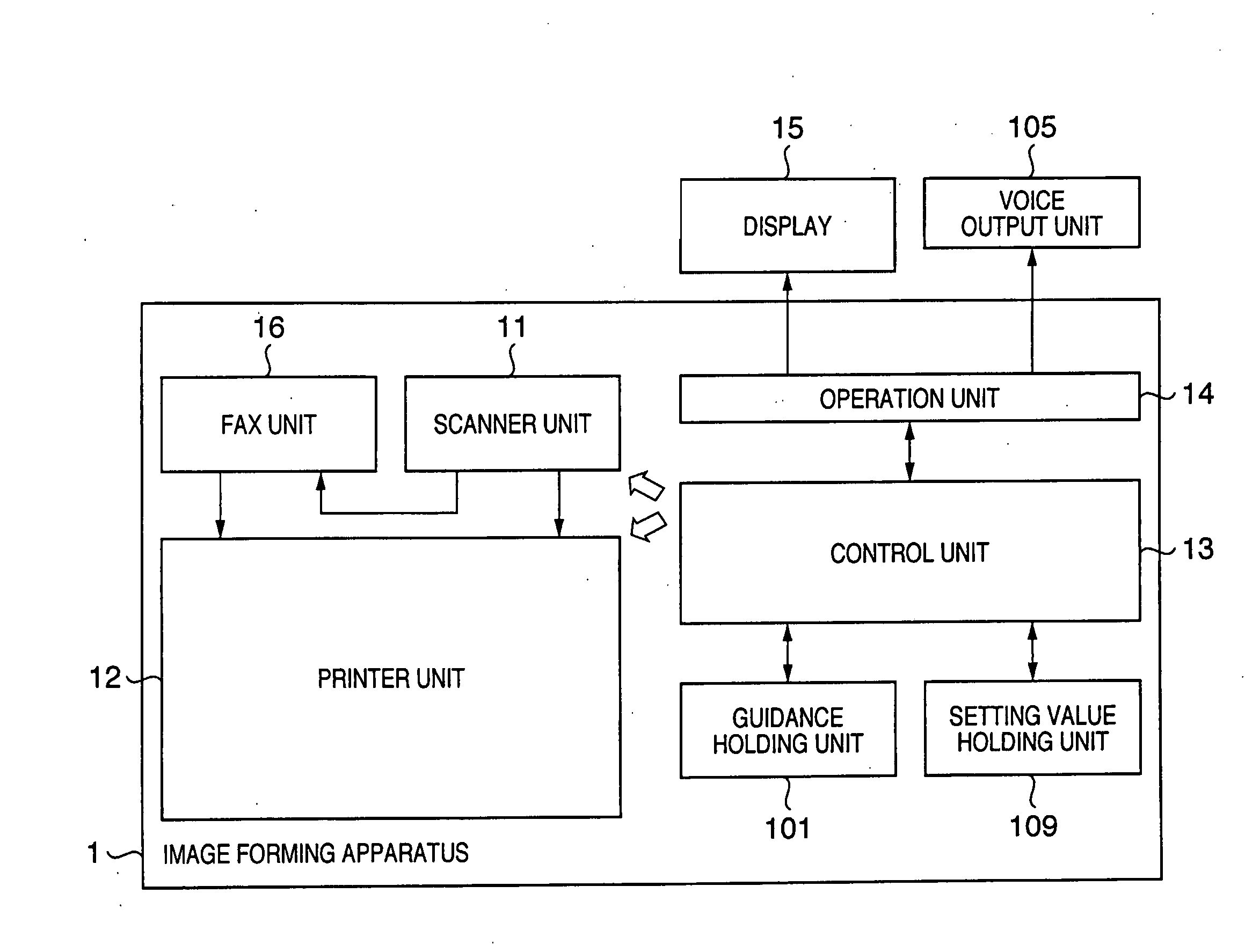

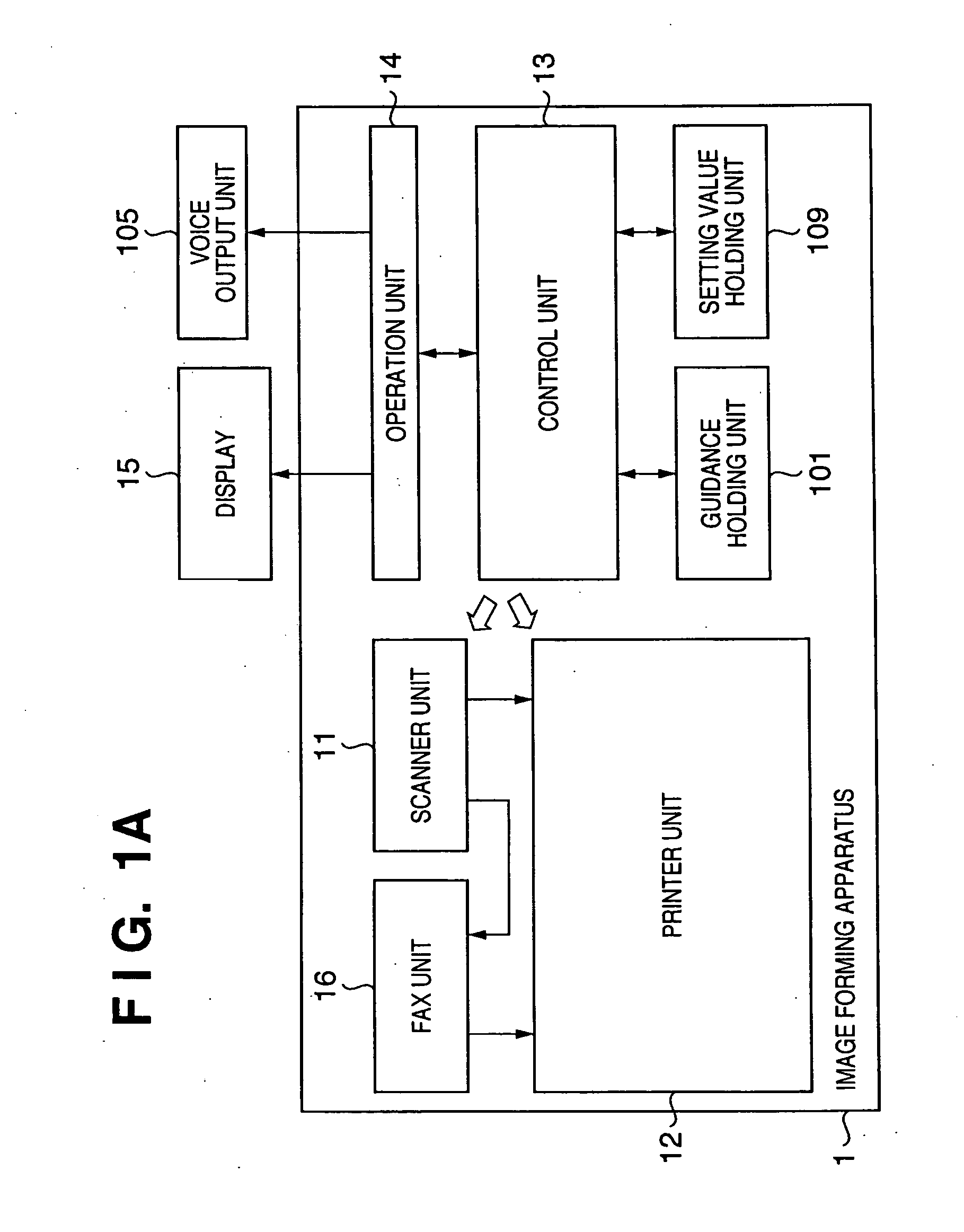

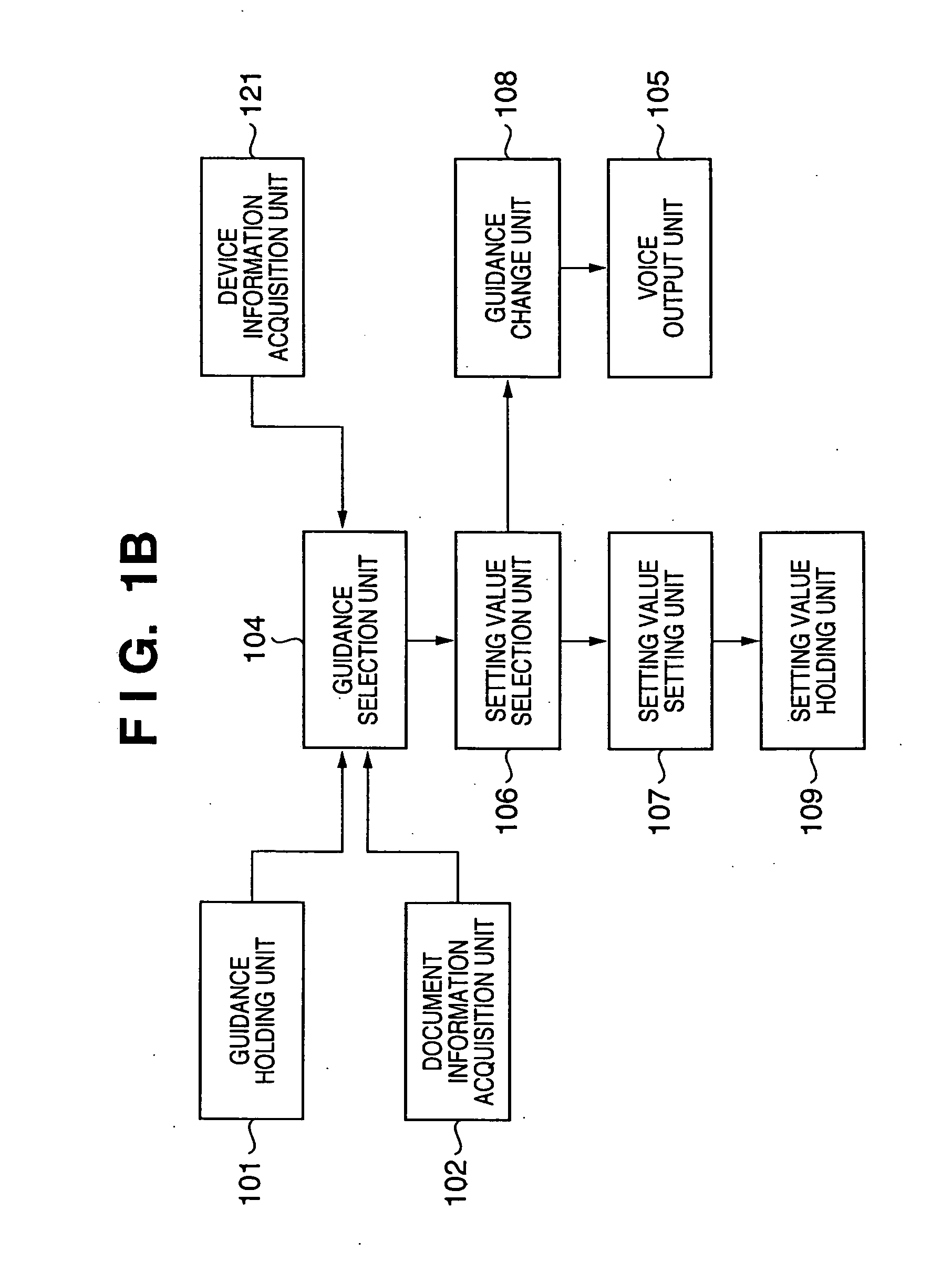

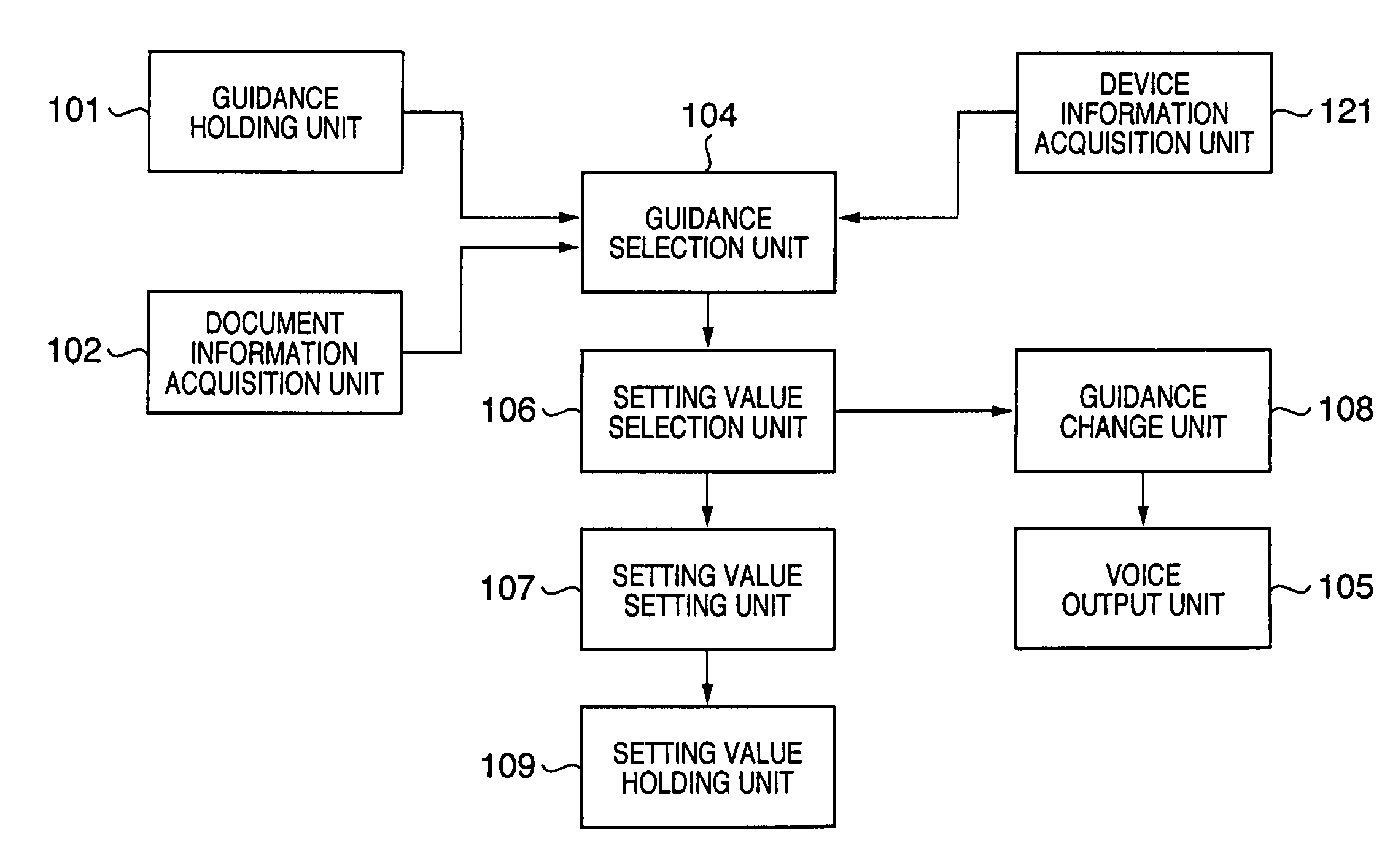

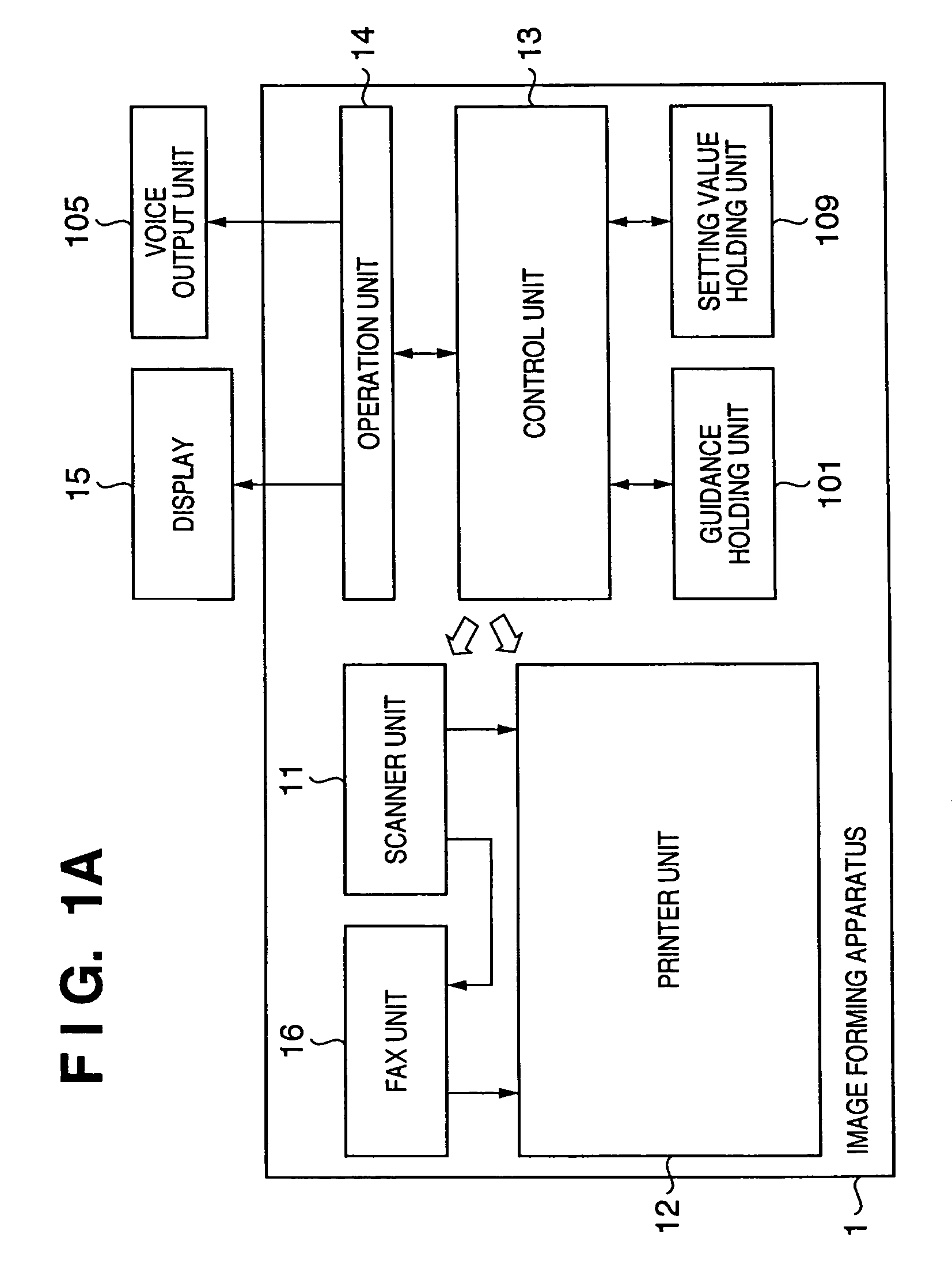

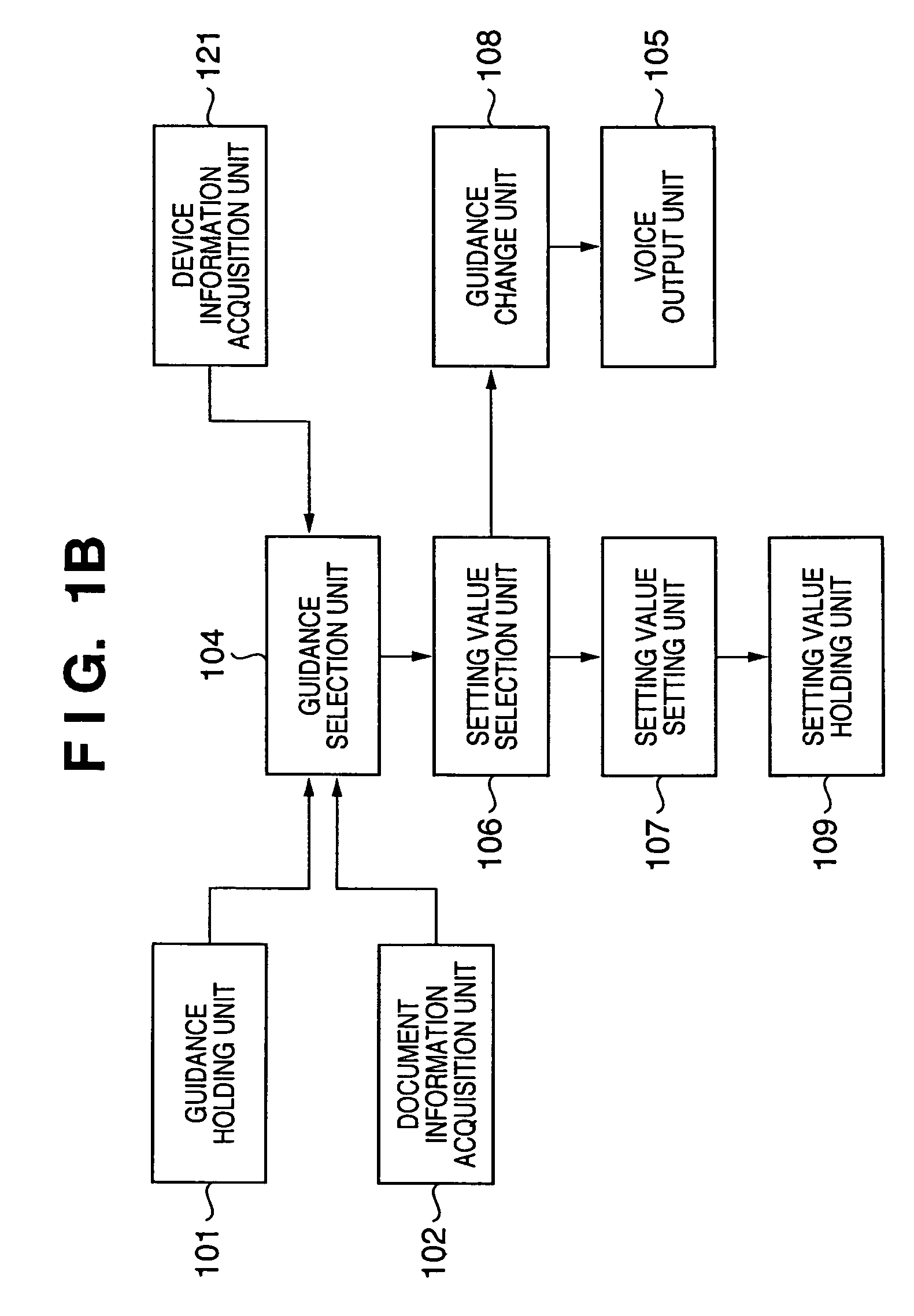

Information processing apparatus and user interface control method

InactiveUS20070016423A1Easy to operateReduce output timeSound input/outputSpeech synthesisInformation processingPaper document

In an information processing apparatus which can set one of a plurality of setting values for a setting item, a guidance holding unit holds guidance information for voice output for each of the plurality of setting values. A document information acquisition unit acquires document information as limiting information which limits a range of a settable setting value. A guidance selection unit and a guidance change unit acquire pieces of guidance information to be output by voice on the basis of the pieces of guidance information corresponding to the plurality of setting values held in the guidance holding unit and the limiting information acquired by the document information acquisition unit. An voice information output unit outputs, by voice, the acquired pieces of guidance information to be output by voice.

Owner:CANON KK

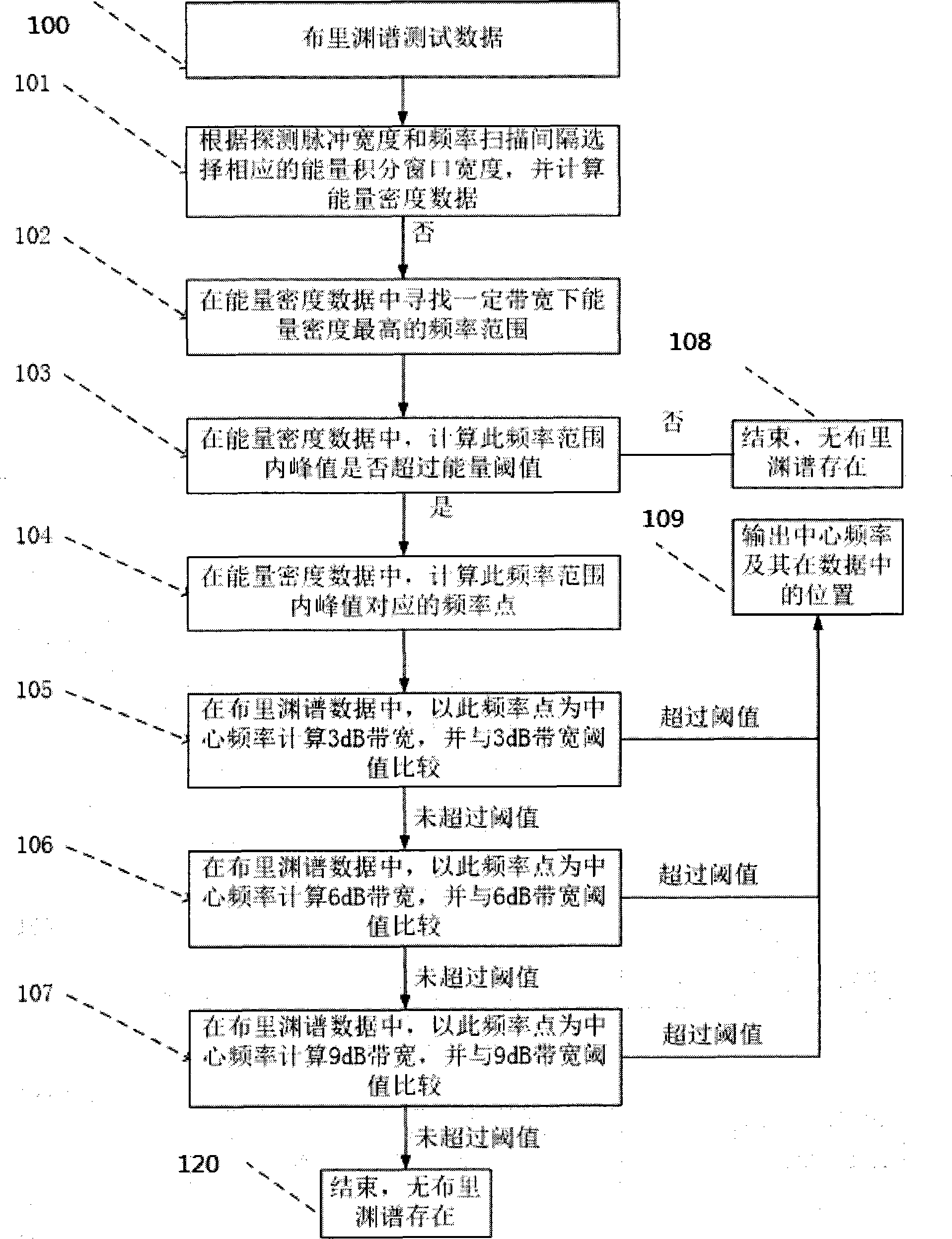

Brillouin spectrum recognition based on energy distribution

ActiveCN103308083AReduce output timeAvoid analysisUsing optical meansConverting sensor output opticallyHigh energyCurve fitting

The invention provides a Brillouin spectrum recognition based on energy distribution. The recognition method comprises the steps of determining Brillouin spectrum test data as L; selecting a corresponding energy integral window width W according to a detection pulse width PW to obtain energy density data P; searching a frequency range SW of the highest energy density from the energy density data P; calculating whether the peak exceeds an energy threshold PT or not in the energy density data P within the frequency range SW of the highest energy density; and searching the frequency point corresponding to the peak in the energy density data P within the highest frequency range. By means of the scheme, on one hand, curve fitting and spectral analysis are performed on data containing Brillouin spectrums only according to judgment results, a lot of meaningless Brillouin spectrum analysis processes are avoided, overall data output time is saved, and the overall test speed is increased; and on the other hand, the analysis accuracy of the Brillouin spectrums is improved under the condition of various signal to noise ratios, and the strain test accuracy is improved.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

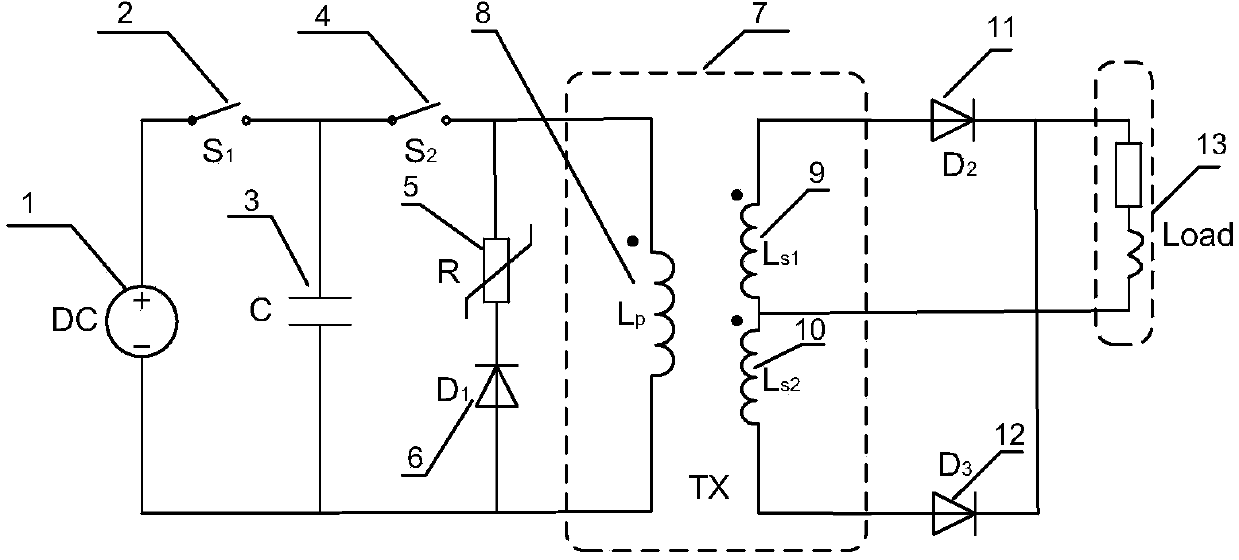

Pulse power supply for converting discharge by utilizing three-winding pulse transformer

InactiveCN104218841AHigh energy storage densityReduce lossNonlinear resistorElectrical resistance and conductance

The invention discloses a pulse power supply for converting discharge by utilizing a three-winding pulse transformer. The pulse power supply comprises a high-voltage DC (Direct Current) power source, an energy storage capacitor, a controllable switch, a diode, a nonlinear resistor, a three-winding pulse transformer and a load. With the adoption of the structure, current in the same direction can be generated on the load no matter any change of the current of a primary winding, and residual current in the winding can be reduced rapidly by utilizing a voltage stabilizing function of the nonlinear resistor. Therefore, the pulse output time can be reduced greatly, and the energy conversion efficiency of the system can be improved.

Owner:SOUTHWEST JIAOTONG UNIV

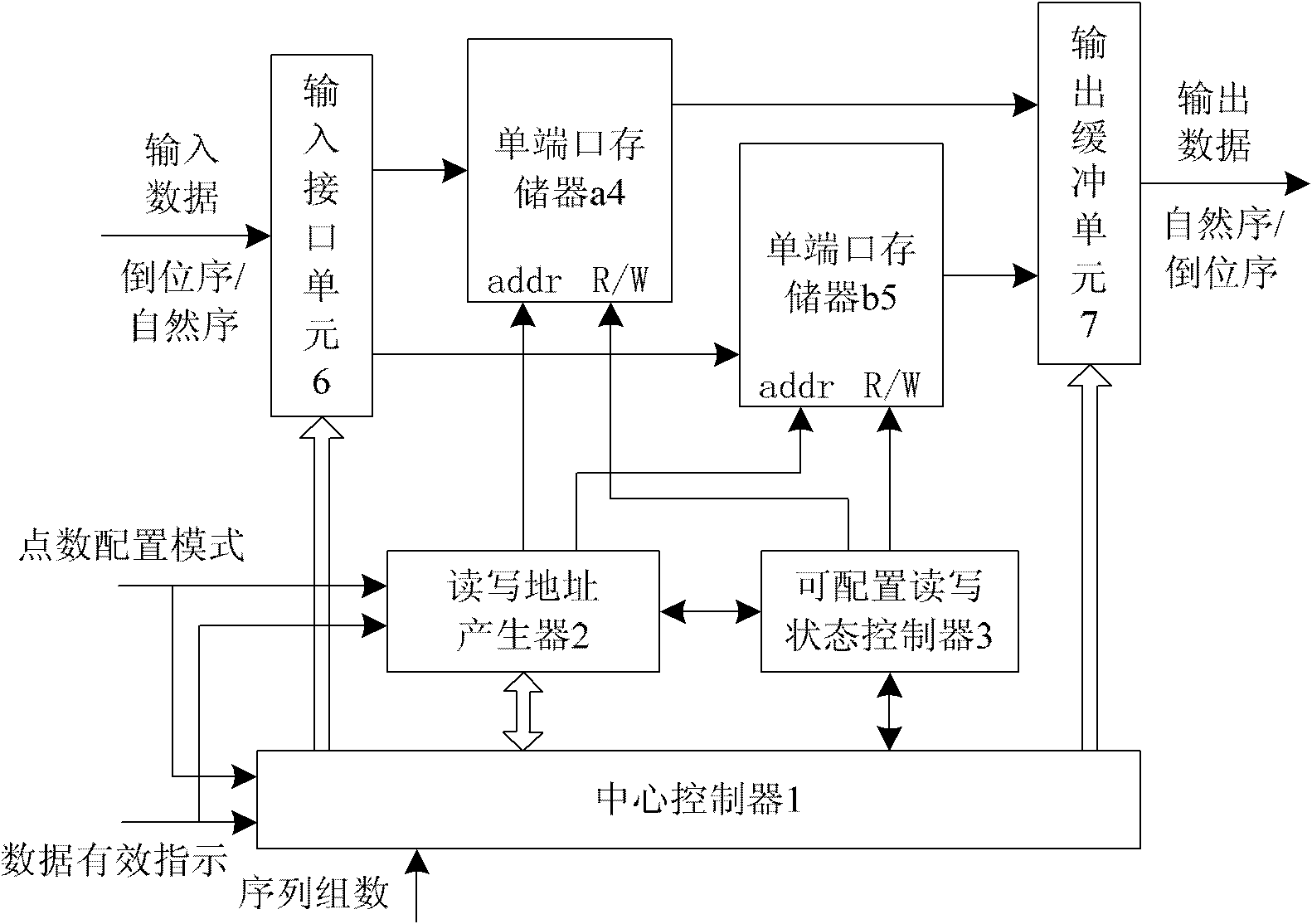

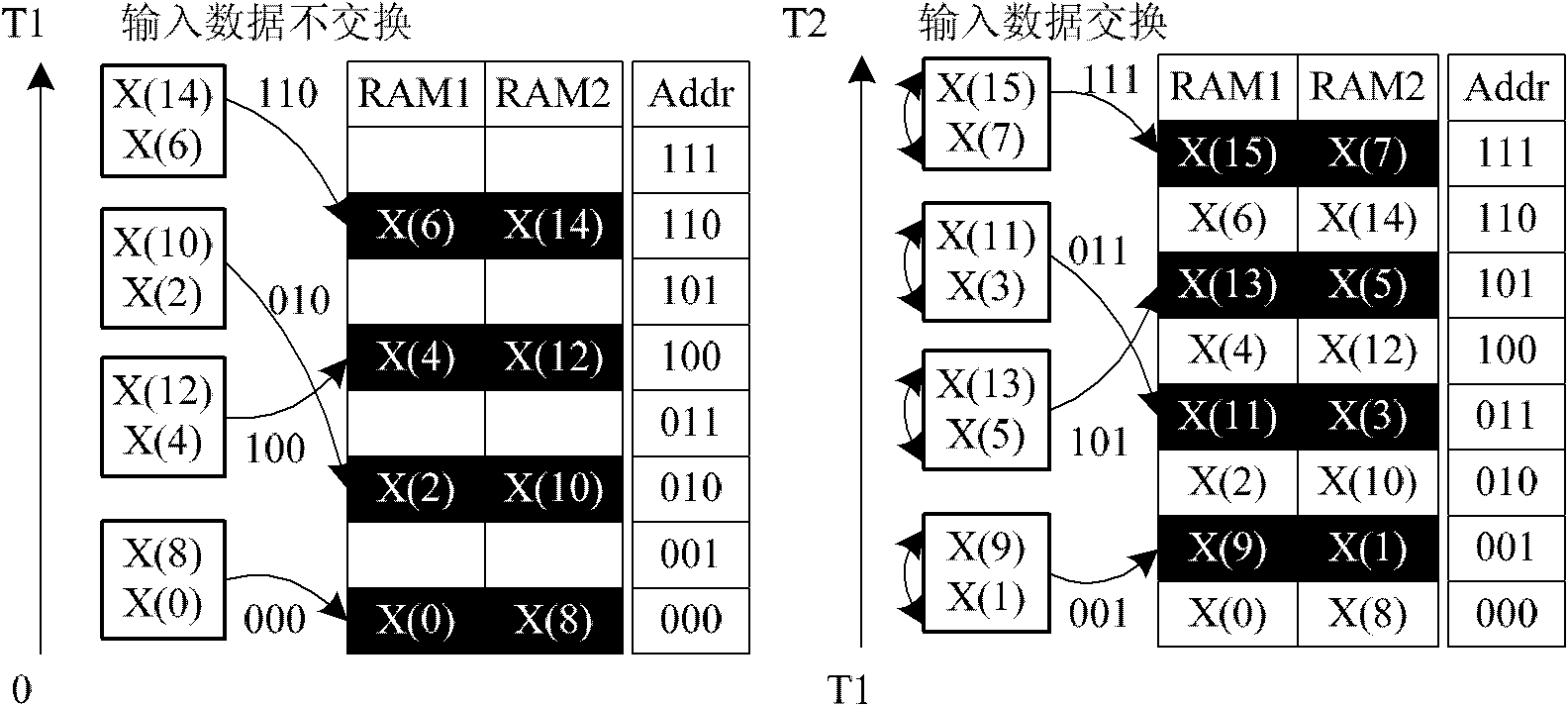

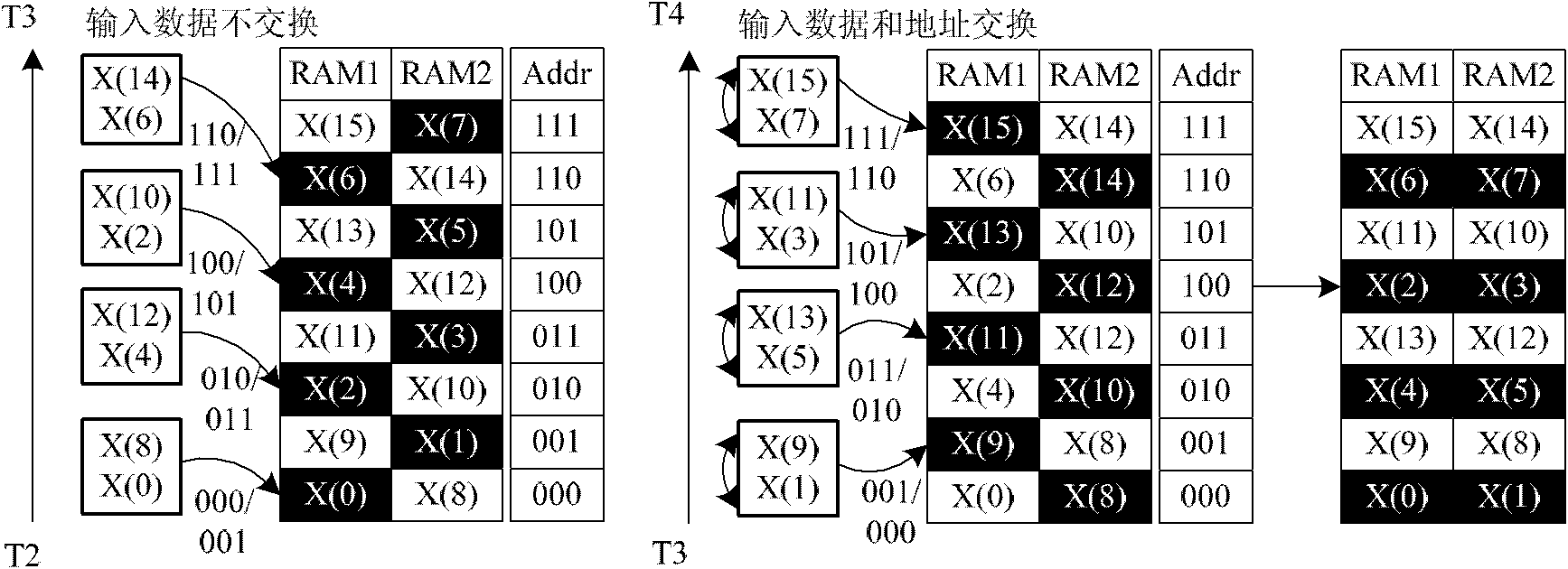

Method and circuit for scheduling data of memory through fast Fourier transform (FFT) reverse operation

ActiveCN102306142AReduce areaEasy to achieve natural order outputEnergy efficient ICTMemory adressing/allocation/relocationExtensibilityFast Fourier transform

The invention discloses a method and a circuit for scheduling the data of a memory through fast Fourier transform (FFT) reverse operation. Two N / 2 depth single-port memories are used for data scheduling, so that the area and power consumption advantages of the single-port memories are fully exerted, and the area of an on-chip memory is effectively reduced; a uniform data pause signal and a direct write after read strategy are adopted, so that the pause of external data can be waited while the data is not lost and a read and write time sequence is not influenced through the design; and N clock data delays with a fixed rule are adopted, so that detection logic that the shortest delay time is realized by a large first in first out (FIFO) memory is effectively avoided. The method and the circuit are high in configurability and expandability, and the dependence of different point numbers on memory capacity and control logic is furthest avoided; and compared with the conventional reverse operation method, the method has the advantages that: a few resources are occupied, configuration flexibility is high, and interrupted and paused continuous data stream can be processed.

Owner:HUAZHONG UNIV OF SCI & TECH

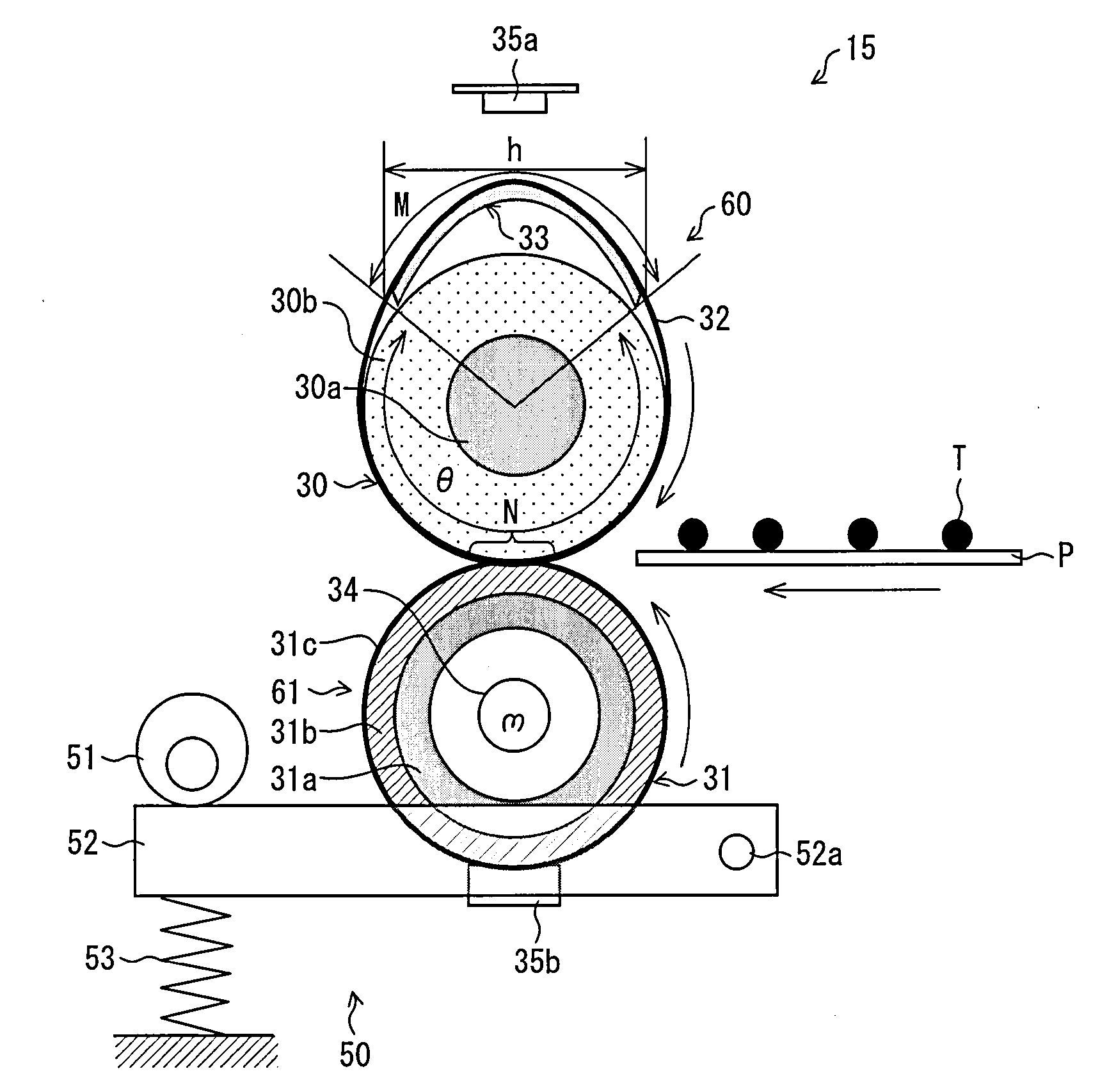

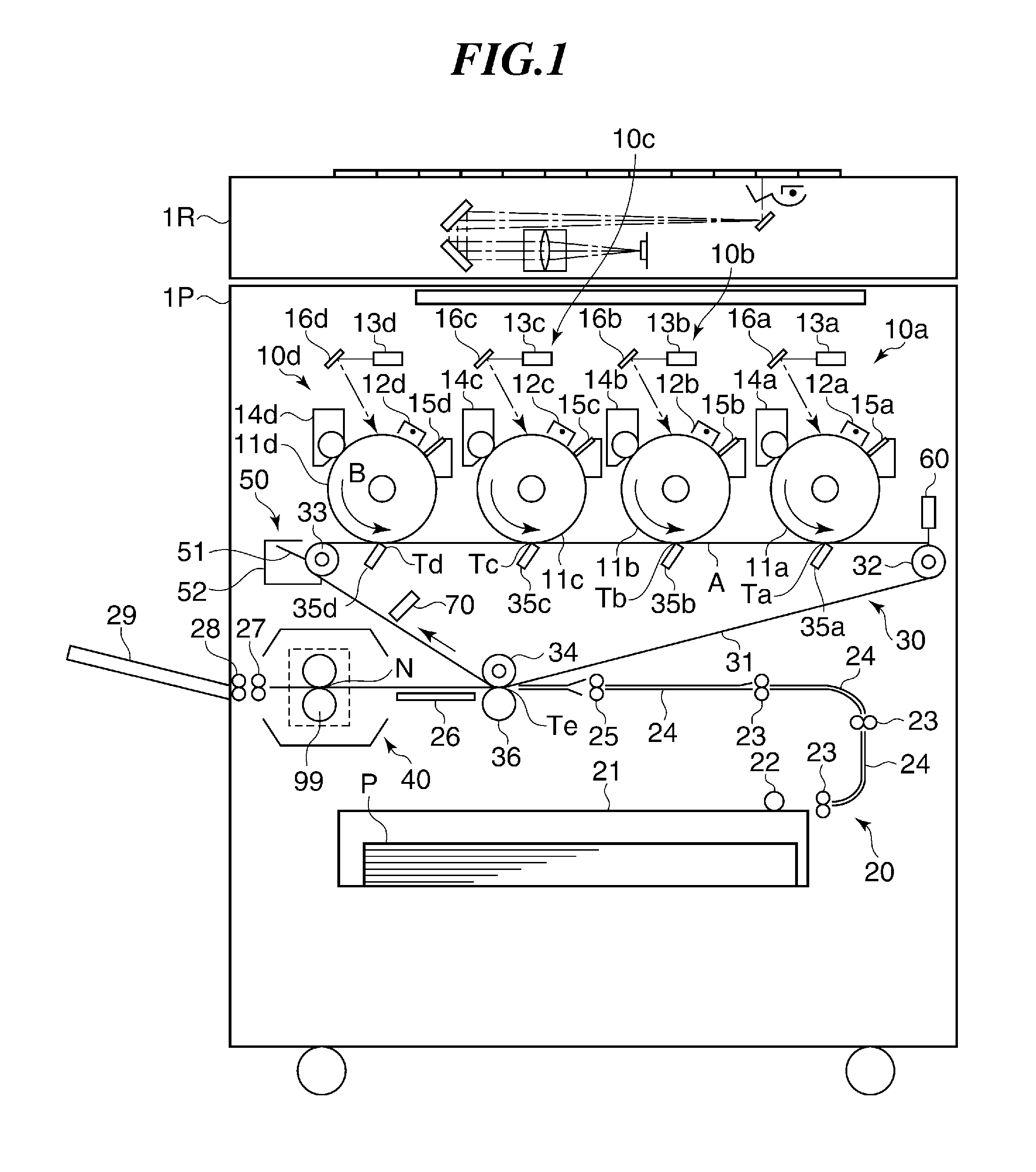

Image forming apparatus

ActiveUS20130195526A1Shorten first print output timeEasy to fixElectrographic process apparatusDevelopersLatent imageImage formation

An image forming apparatus including: image bearing member; latent image forming unit; developing unit; transfer unit; fixing unit, wherein toner in the developing unit contains amorphous polymer, crystalline resin and releasing agent, when the toner is measured for G′ at 40° C. to 210° C. with rheometer at 1 Hz and 1 deg, G′(100) is ≦20,000 and G′(150) is ≧500 Pa, and straight line drawn by connecting points of the G′(100) and G′(110) on curve of the G′ has gradient of ≦0.035, the gradient being “a” expressed by: a=|log10 G′(100)−log10 G′(110)| / 10, and the fixing unit includes: heating member containing flexible endless belt; heat source fixed within the flexible endless belt; and press member in contact with the belt to form nip portion, and the fixing unit is configured to heat / press the medium passing through the nip portion to fix the image on the medium.

Owner:RICOH KK

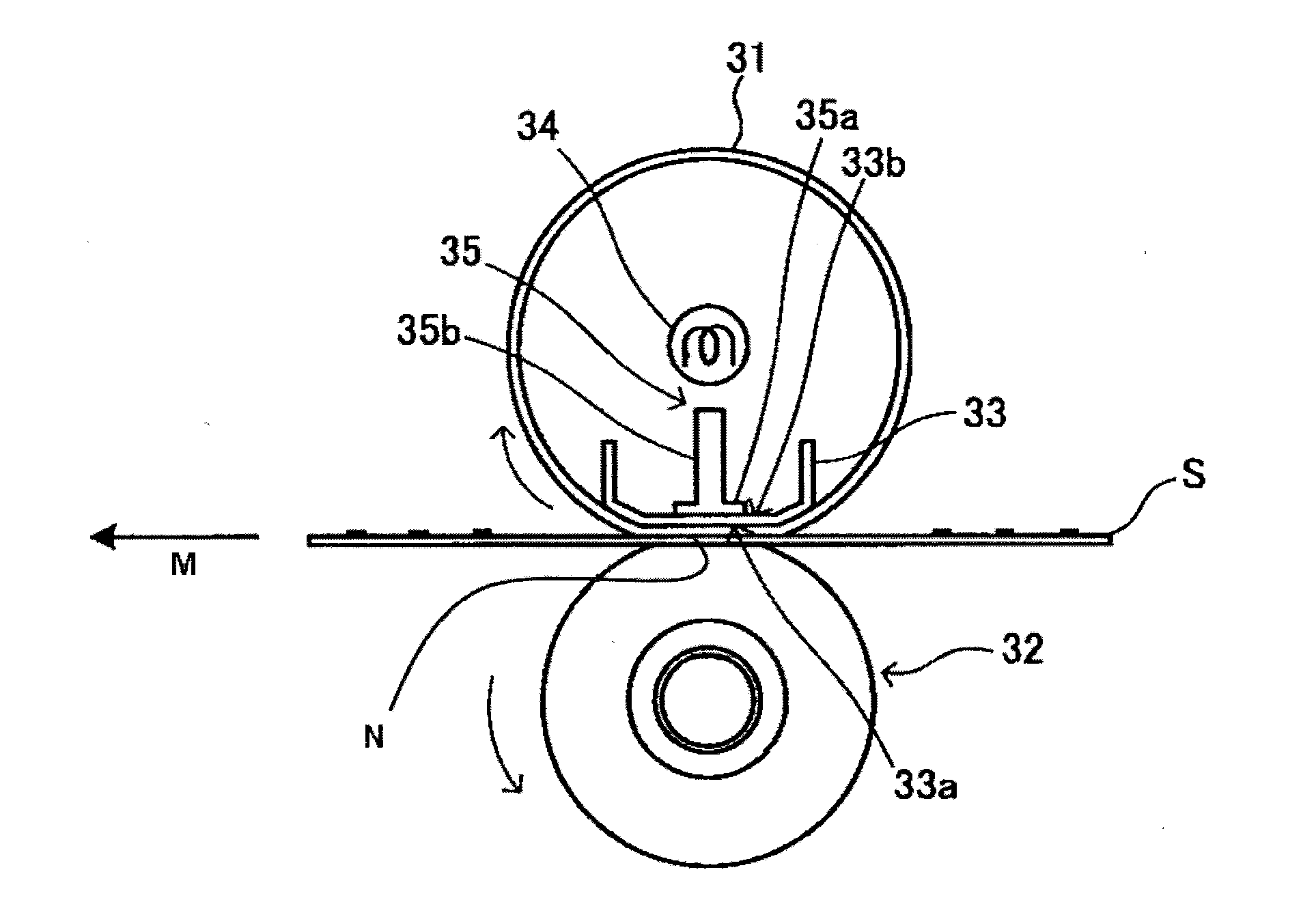

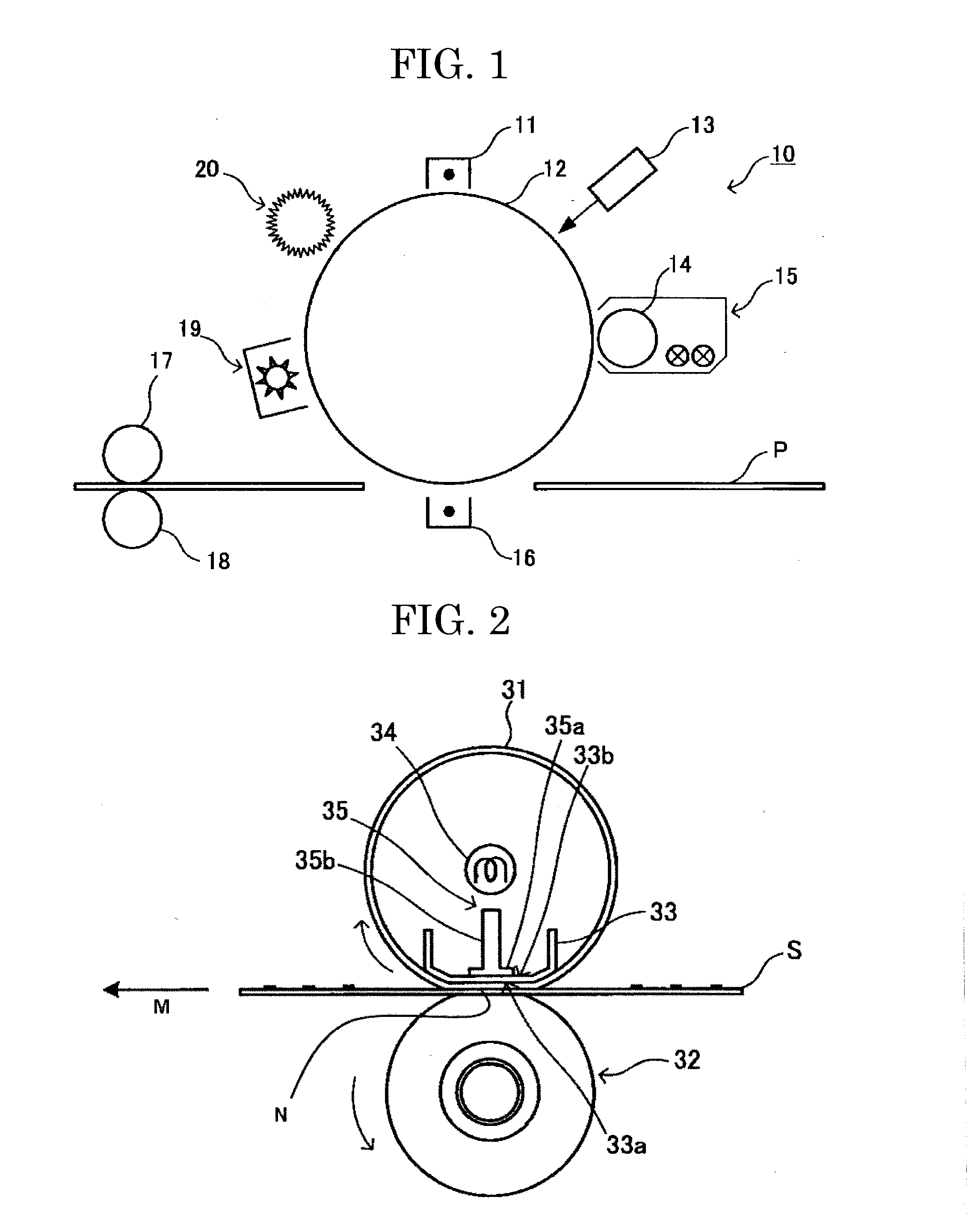

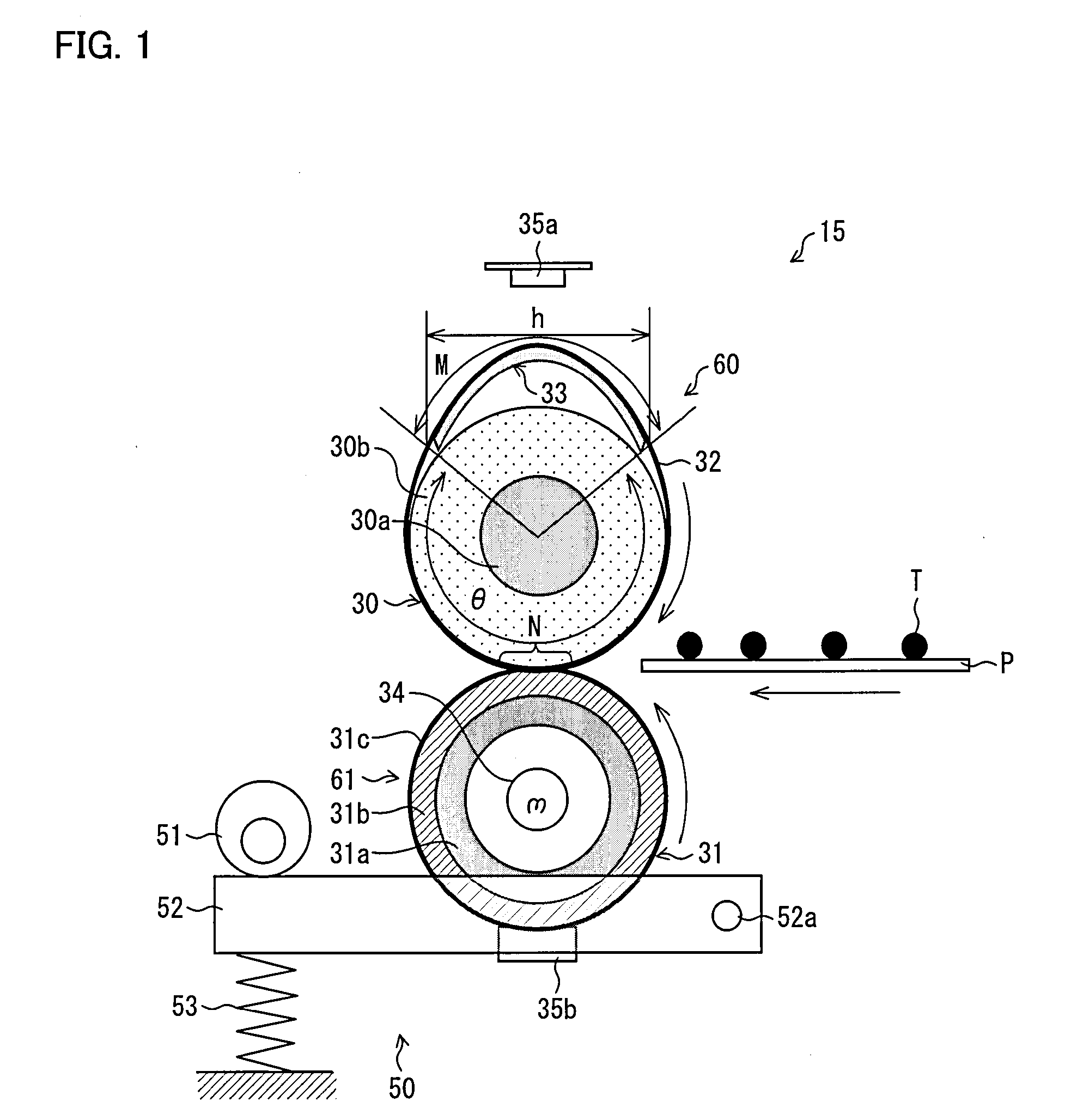

Fixing device and image forming apparatus including the same

ActiveUS20090180821A1Short warm-up timeImprove heating efficiencyOhmic-resistance heatingElectrographic process apparatusImage formationEngineering

Owner:SHARP KK

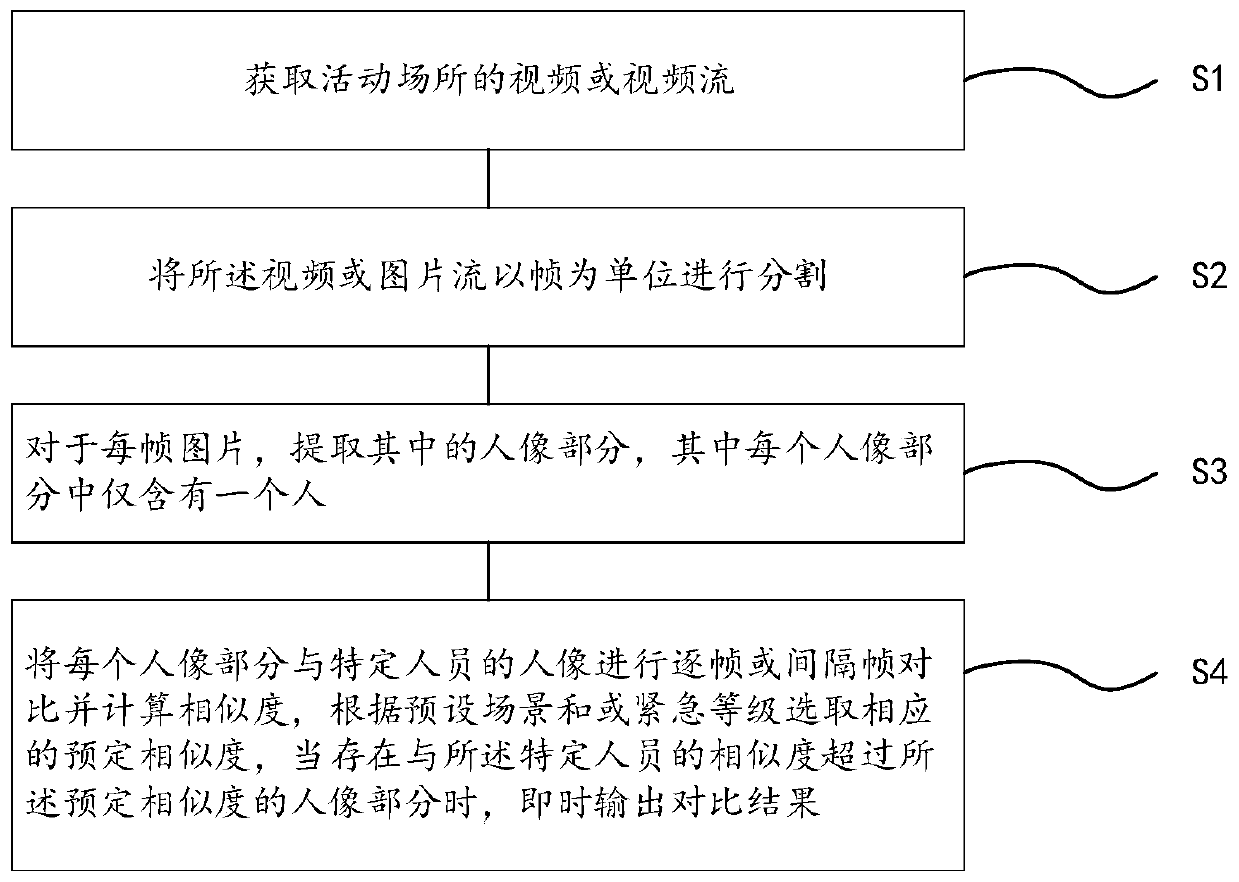

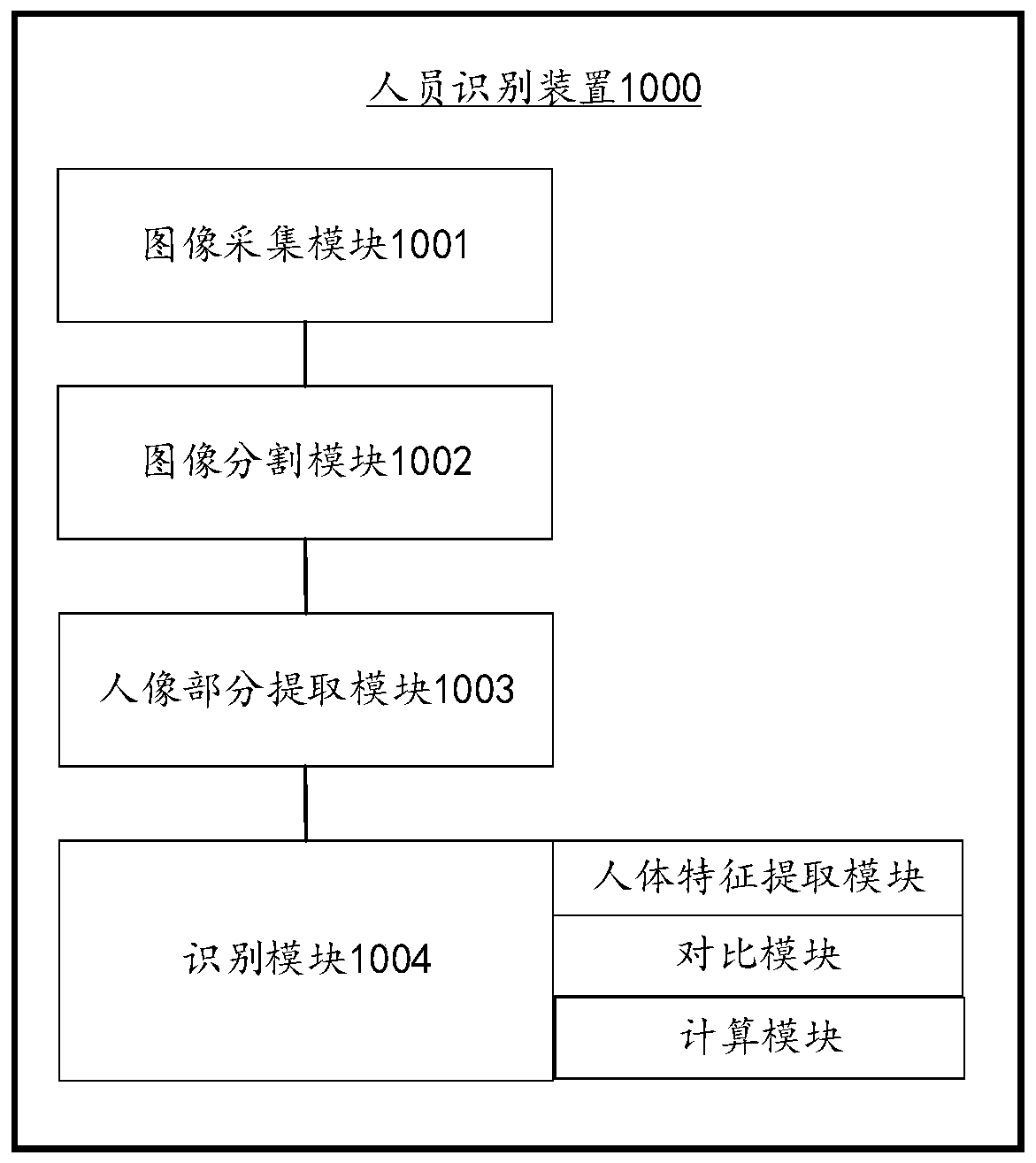

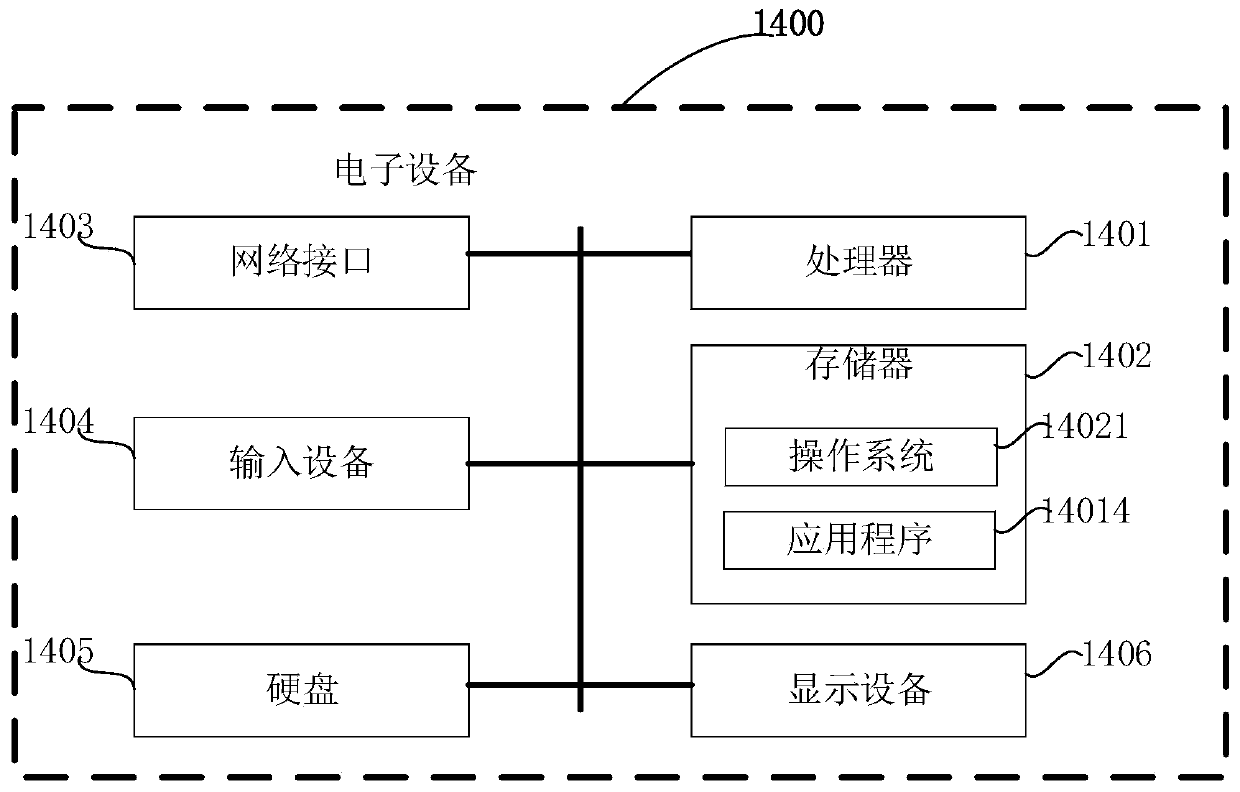

Personnel identification method and device, electronic equipment and computer readable storage medium

PendingCN111444849AReduce output timeFacilitate real-time transaction processingBiometric pattern recognitionVideo streamingComputer graphics (images)

The invention provides a personnel identification method and device, electronic equipment and a computer readable storage medium, and the method comprises the following steps: obtaining a video or video stream of an activity place; segmenting the video or the video stream by taking a frame as a unit; for each frame of picture, extracting a portrait part is extracted, wherein each portrait part only contains one person; comparing each portrait part with a portrait of a specific person frame by frame or at intervals, calculating similarity, selecting corresponding preset similarity according toa preset scene and / or an emergency level, and outputting a comparison result immediately when the portrait part of which the similarity with the specific person exceeds the preset similarity exists. According to the personnel identification method provided by the invention, the comparison result output time can be shortened under emergency and / or dangerous conditions, so that related personnel canquickly process affairs.

Owner:SHANGHAI YITU NETWORK SCI & TECH

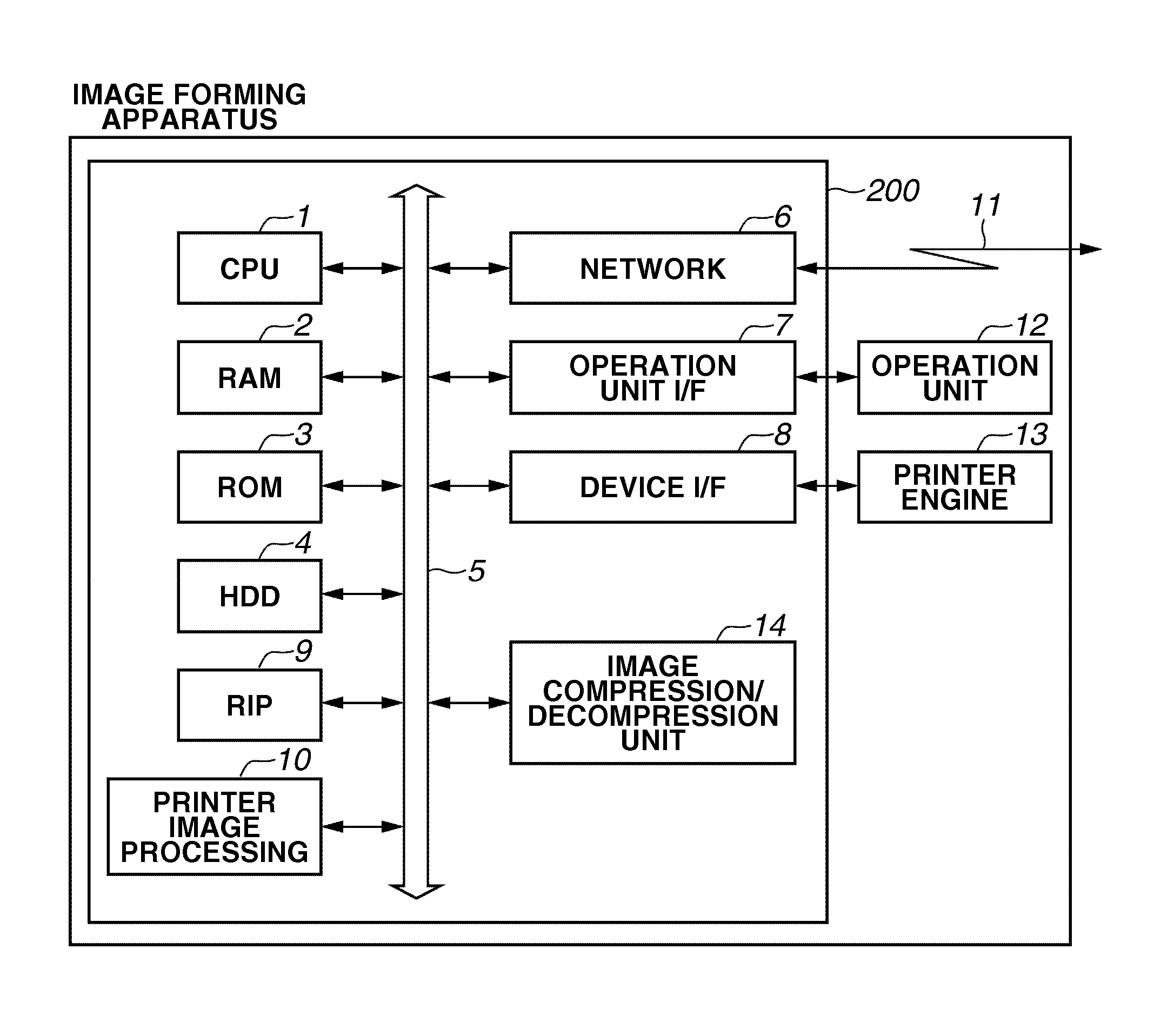

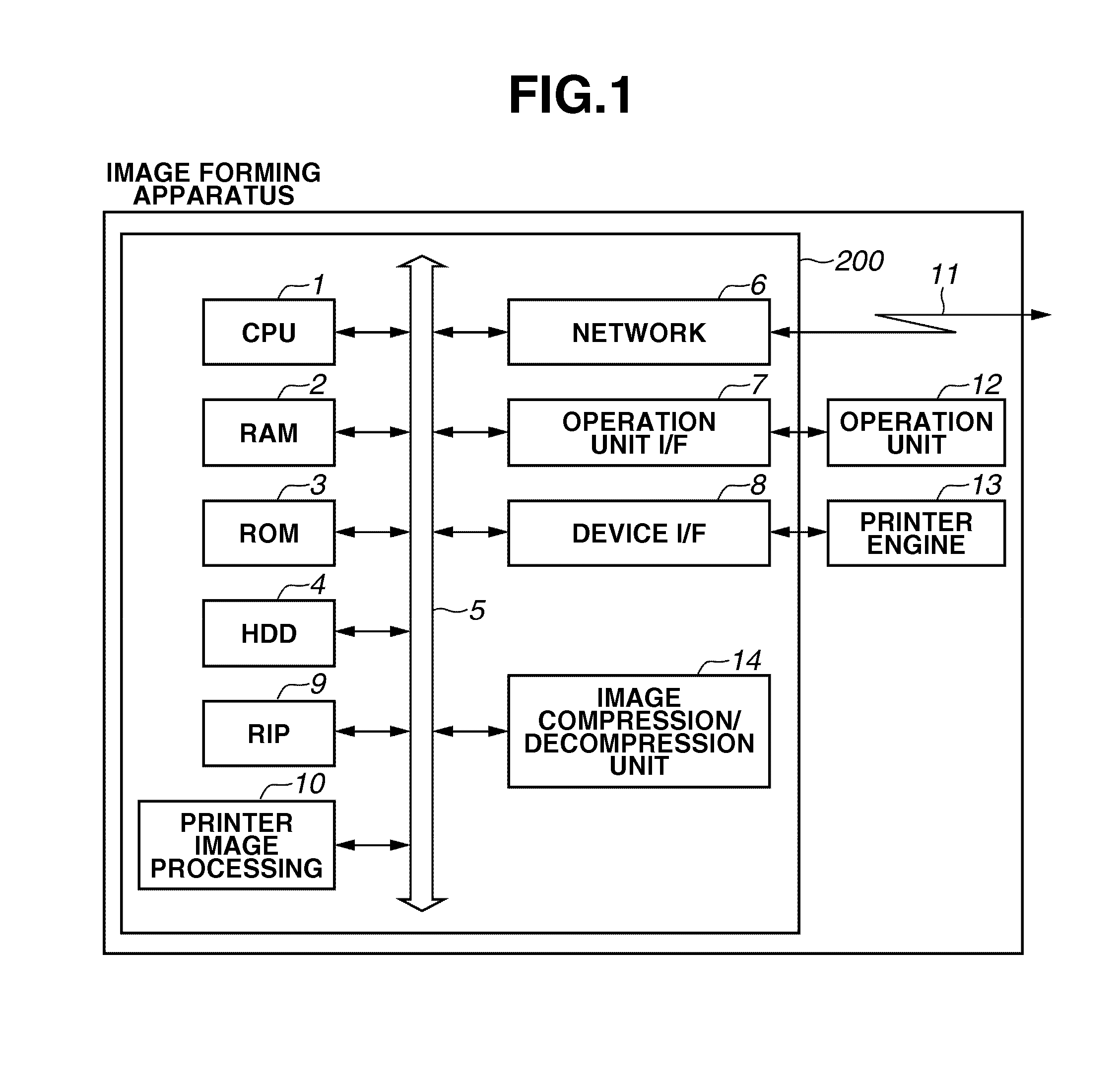

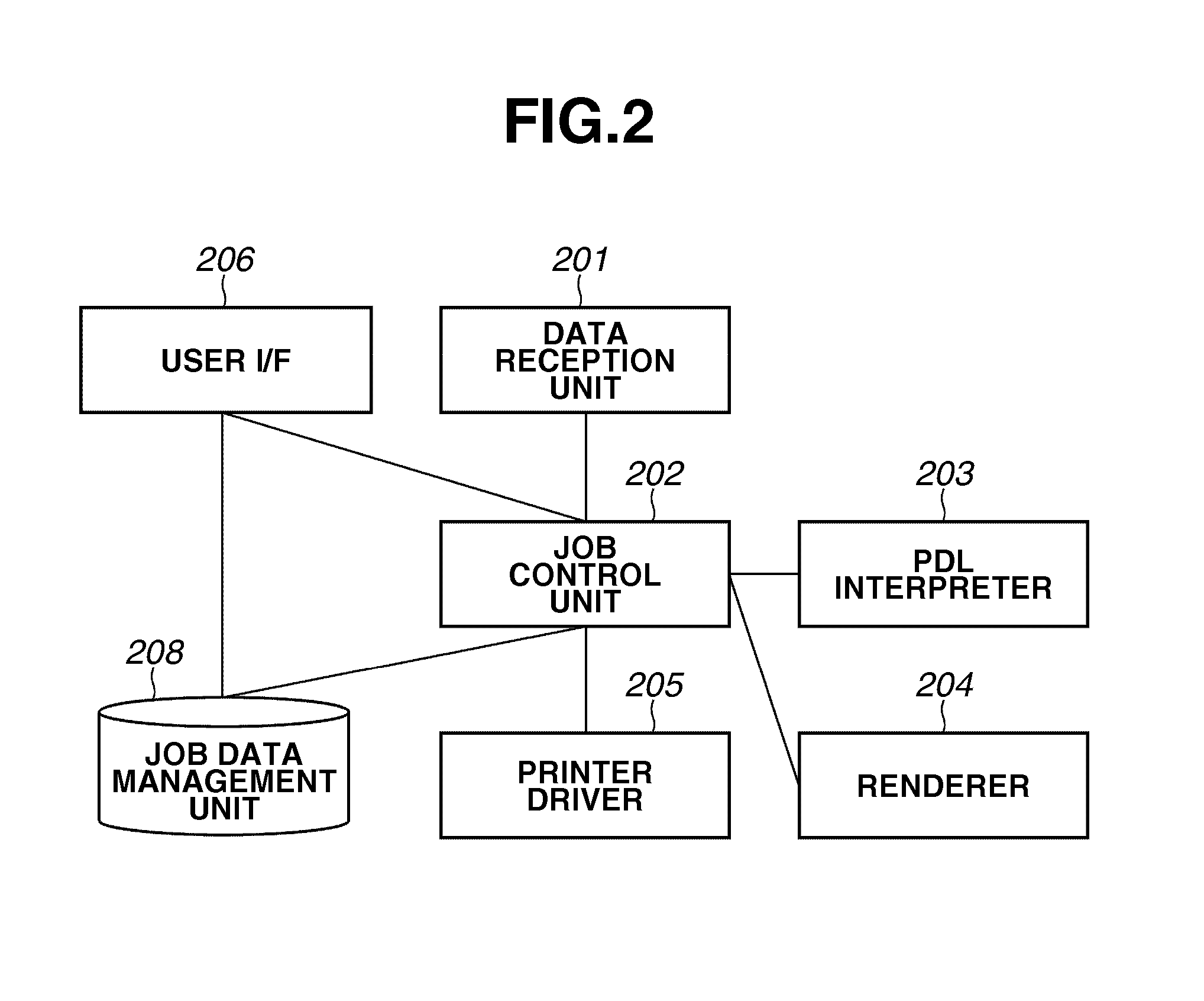

Image processing apparatus, information processing method, and storage medium

InactiveUS8928914B2Reduce output timeVisual presentation using printersDigital output to print unitsInformation processingImaging processing

Owner:CANON KK

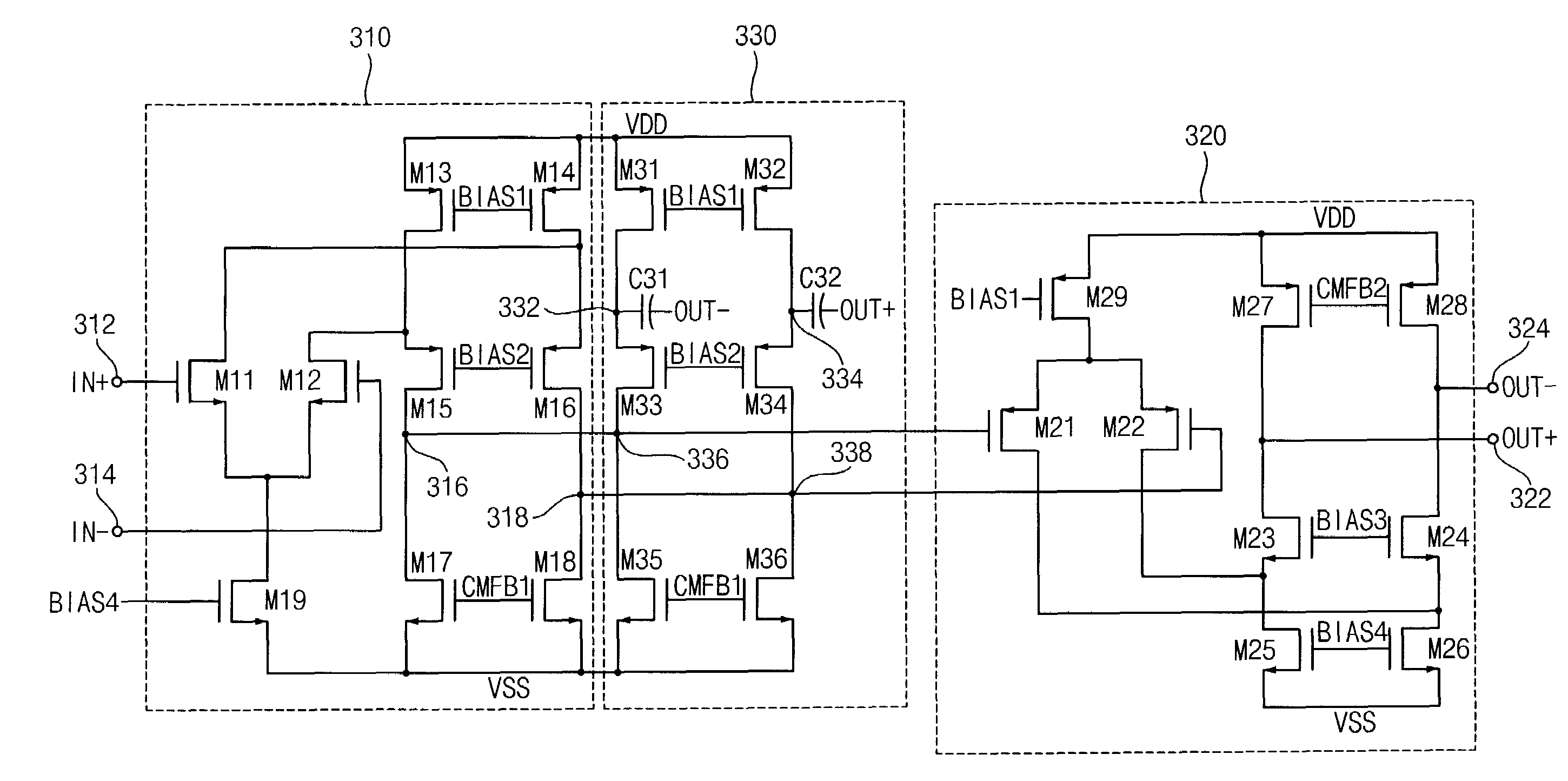

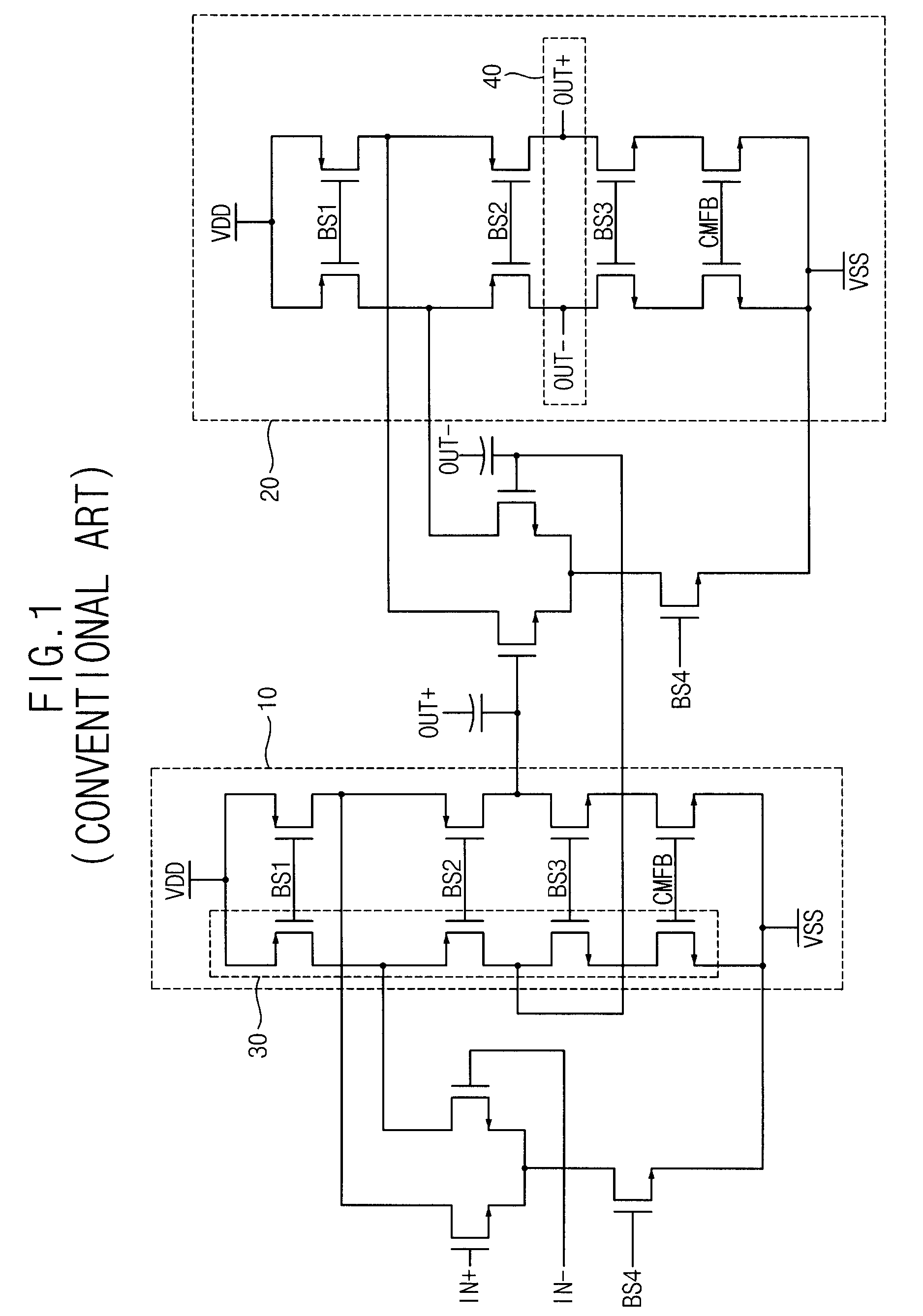

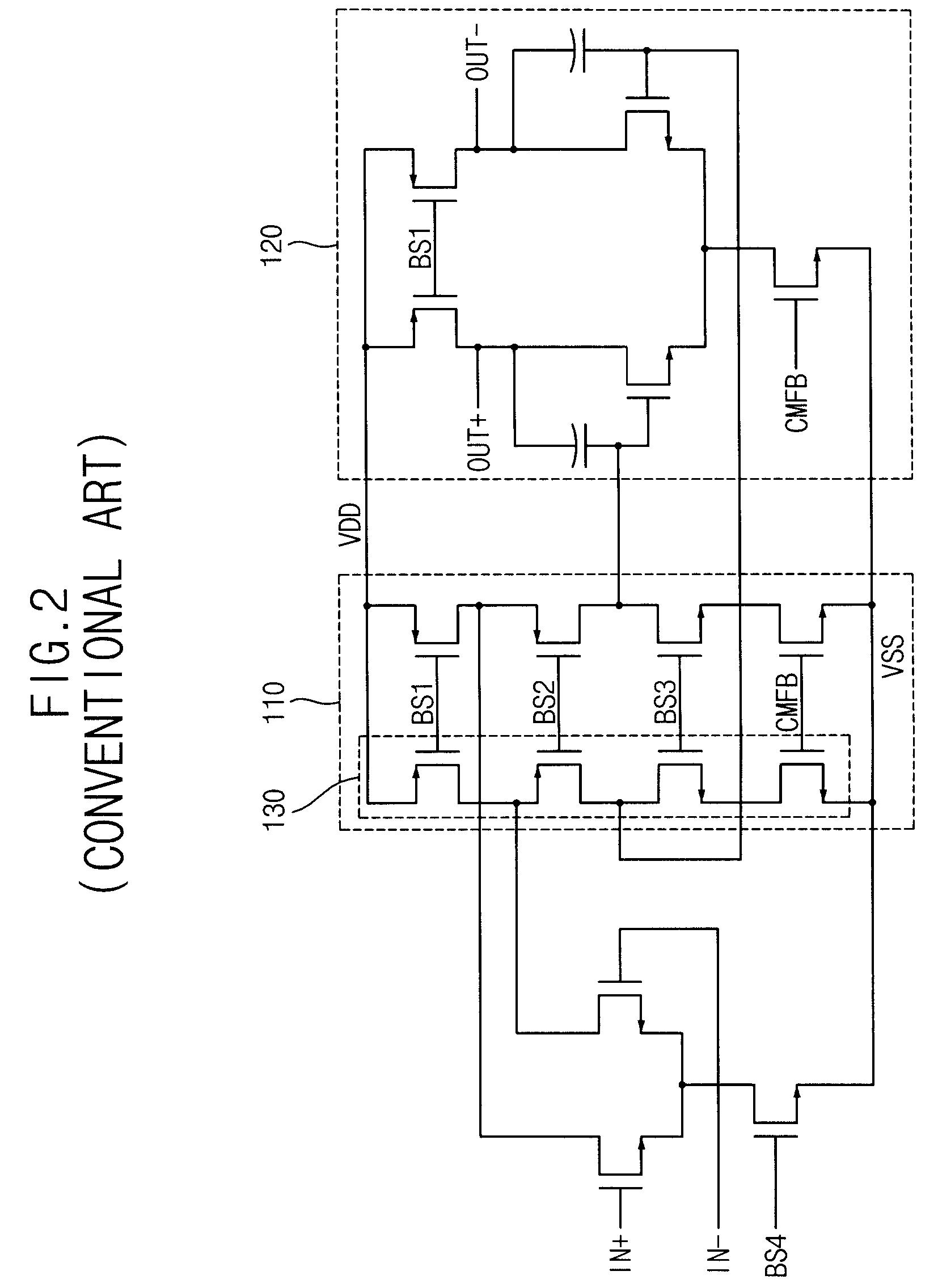

Low-voltage operational amplifier and operational amplifying method

InactiveUS7646241B2Reduce output timeReduced settling timeAmplifier modifications to reduce detrimental impedenceDifferential amplifiersAudio power amplifierLow voltage

A low-voltage operational amplifier includes a differential amplifying stage, an output amplifying stage and a compensation stage. The differential amplifying stage amplifies a difference between a first signal and a second signal that constitute a differential pair using an input pair of NMOS transistors, and outputs an amplified first signal and an amplified second signal. The output amplifying stage amplifies a difference between the amplified first signal and the amplified second signal using an input pair of PMOS transistors, and outputs a first output signal and a second output signal that constitute a differential pair. The compensation stage receives the amplified first signal, the amplified second signal, the first output signal, and the second output signal, and reduces a settling time of the first output signal and the second output signal.

Owner:SAMSUNG ELECTRONICS CO LTD

Fixing device and image forming apparatus including the same

ActiveUS8068765B2Short warm-up timeImprove heating efficiencyOhmic-resistance heatingElectrographic process apparatusImage formationEngineering

Owner:SHARP KK

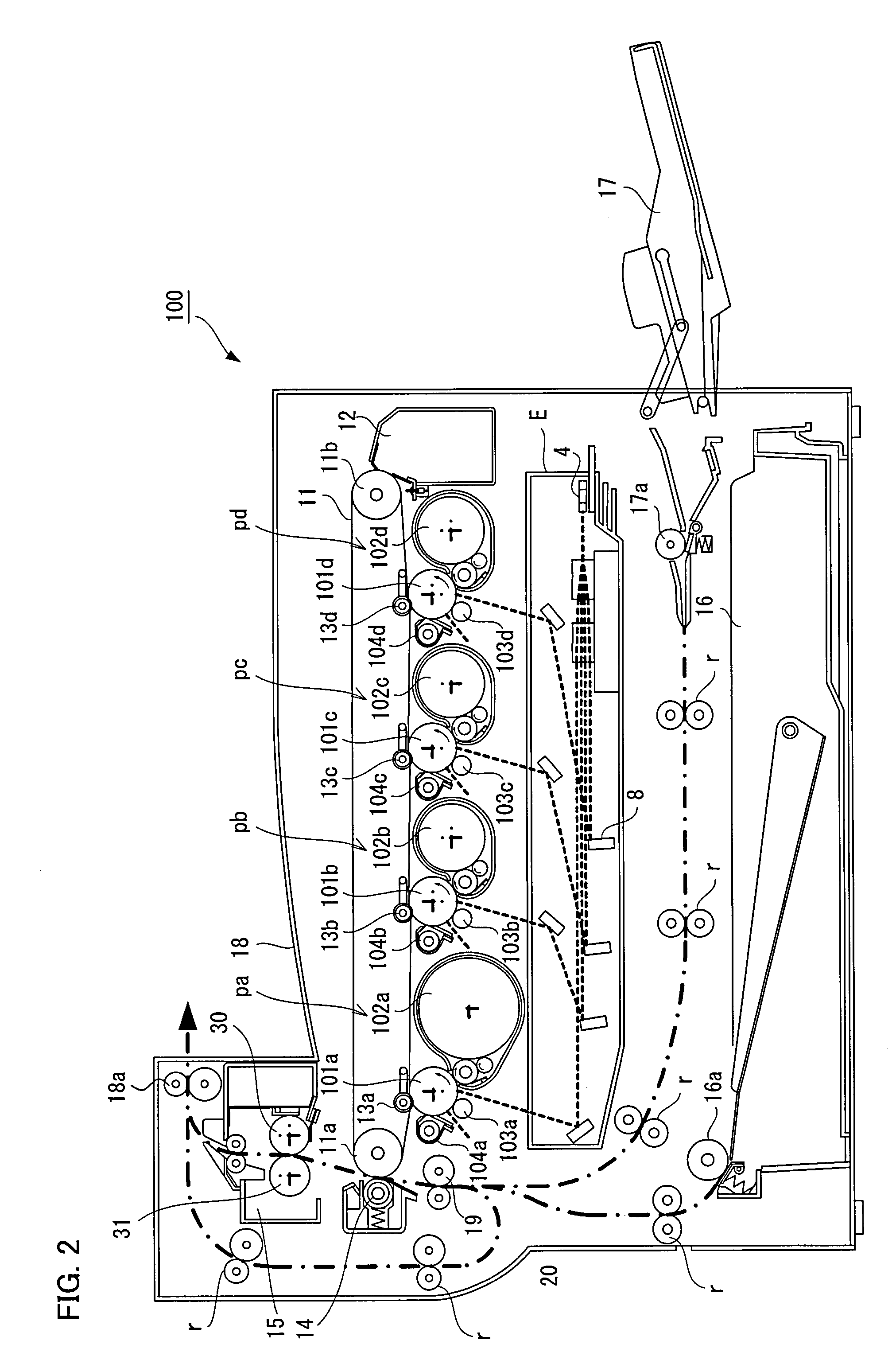

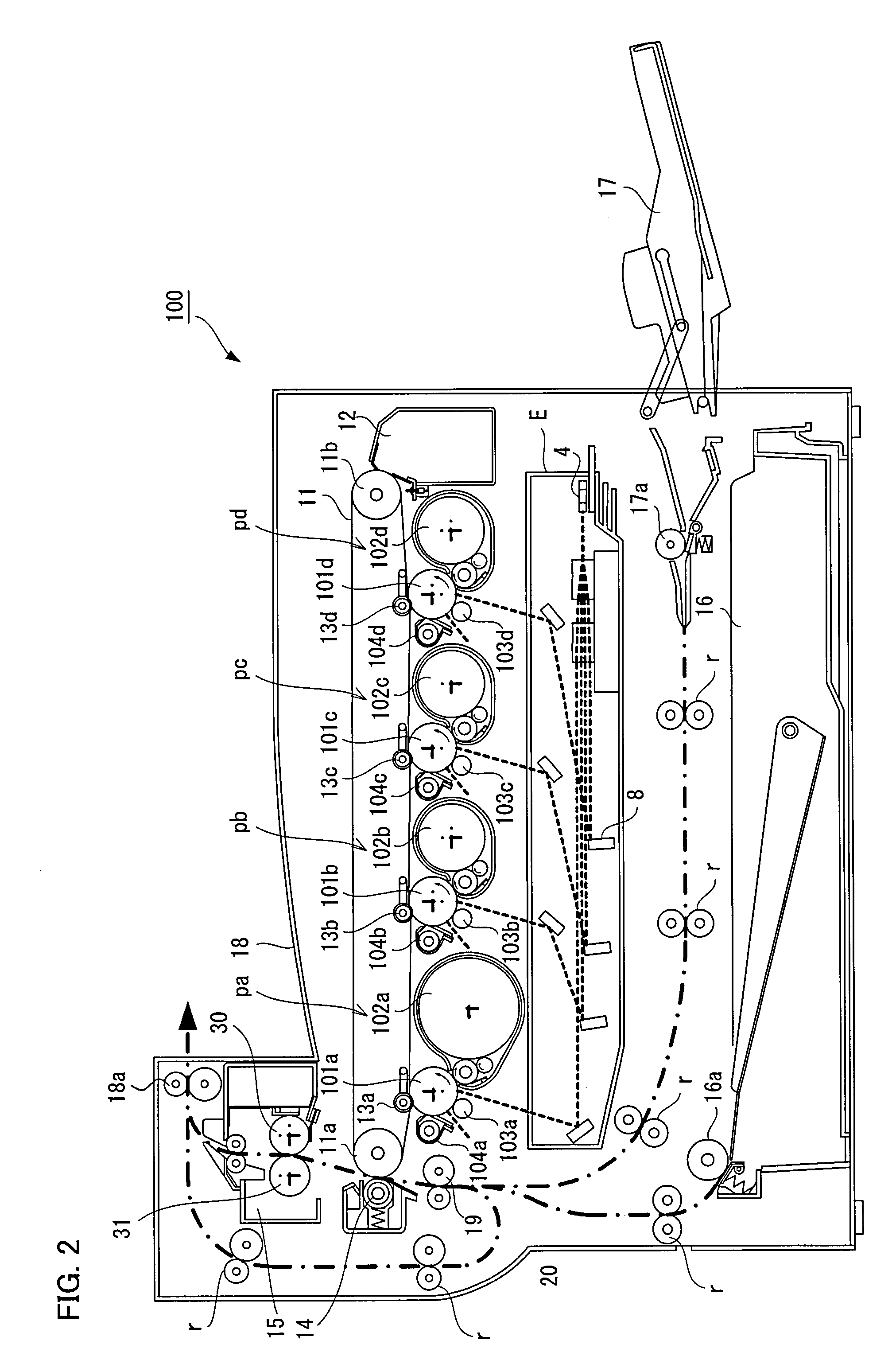

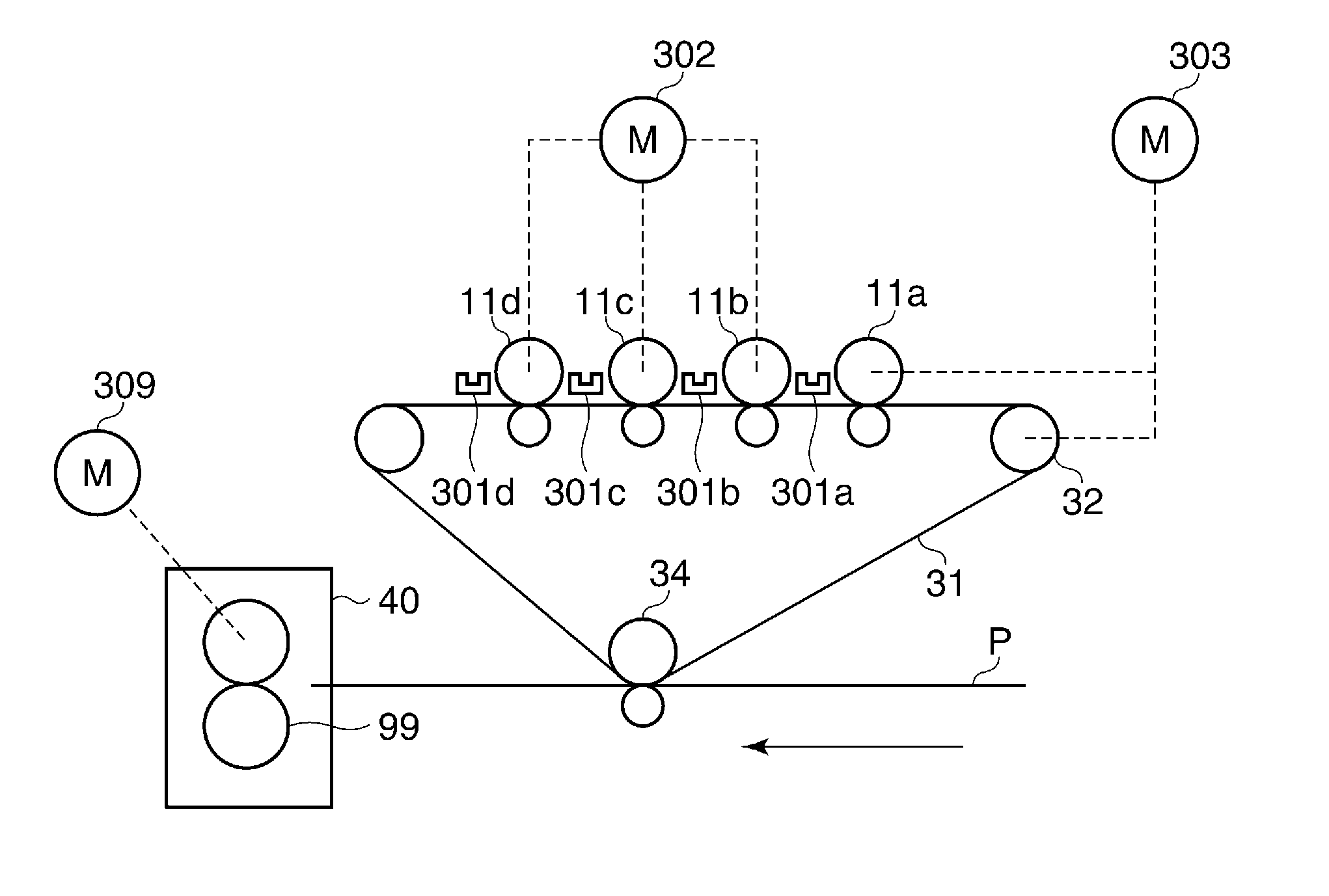

Image forming apparatus using electrophotographic process

InactiveUS20110229203A1Prevent transferAvoid slackElectrographic process apparatusUnit/actuationImage transfer

An image forming apparatus which is capable of reducing first print output time and preventing slack of an intermediate transfer belt in a monochrome mode. Surfaces of photosensitive drums are electrically charged and exposed to light, thereby allowing electrostatic latent images to be formed thereon. Developers are attached to the electrostatic latent images to form visible images transferred to the intermediate transfer belt. Among the photosensitive drums, a photosensitive drum used in the monochrome mode and the intermediate transfer belt are rotatably driven by a first rotatably driving unit, and photosensitive drums other than the photosensitive drum used in the monochrome mode are driven by a second rotatably driving unit. In the monochrome mode, the rotational speed of the second rotatably driving unit is controlled so as to be equal to or less than that of the first rotatably driving unit without adjusting rotation phases of the photosensitive drums.

Owner:CANON KK

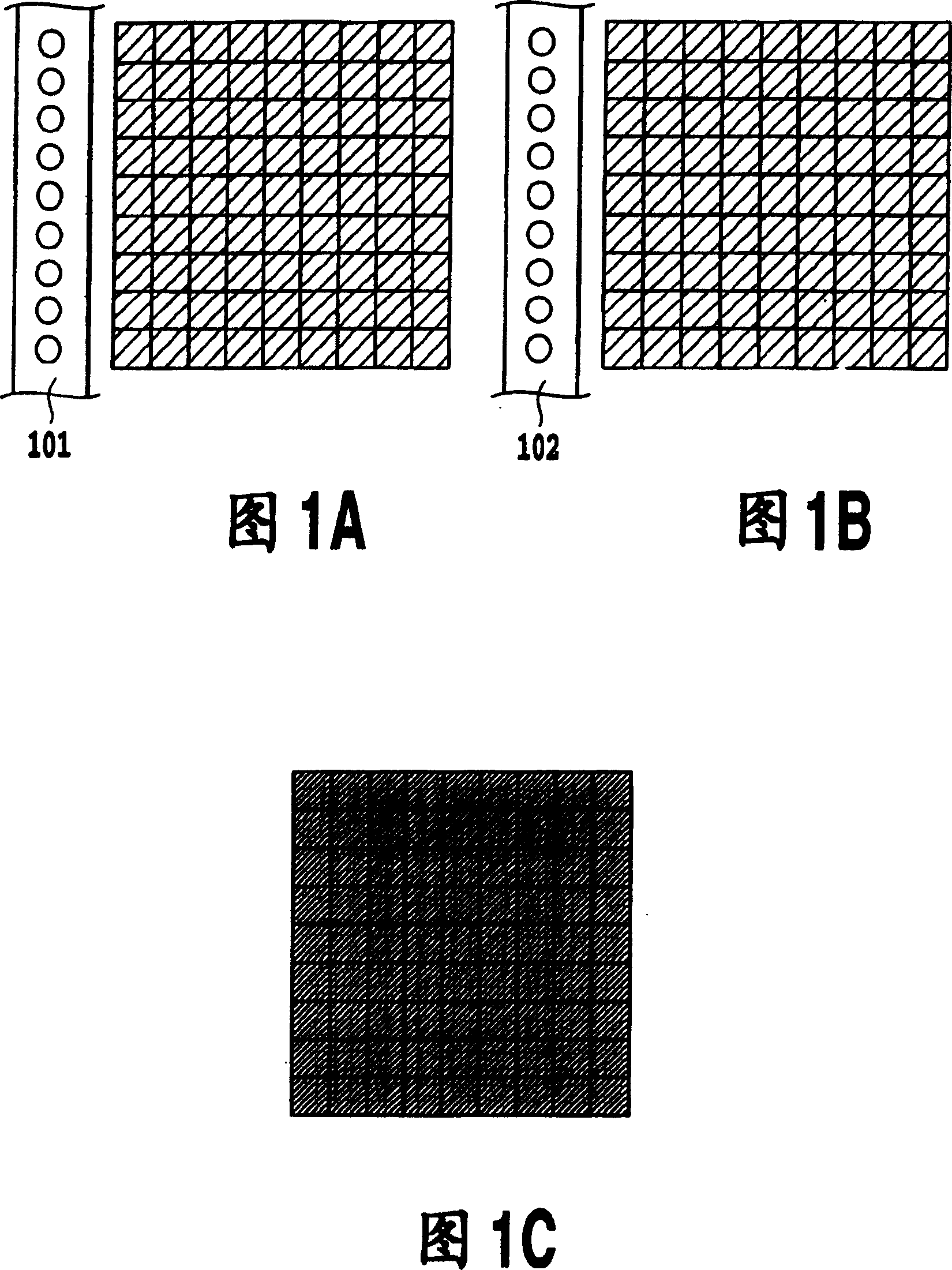

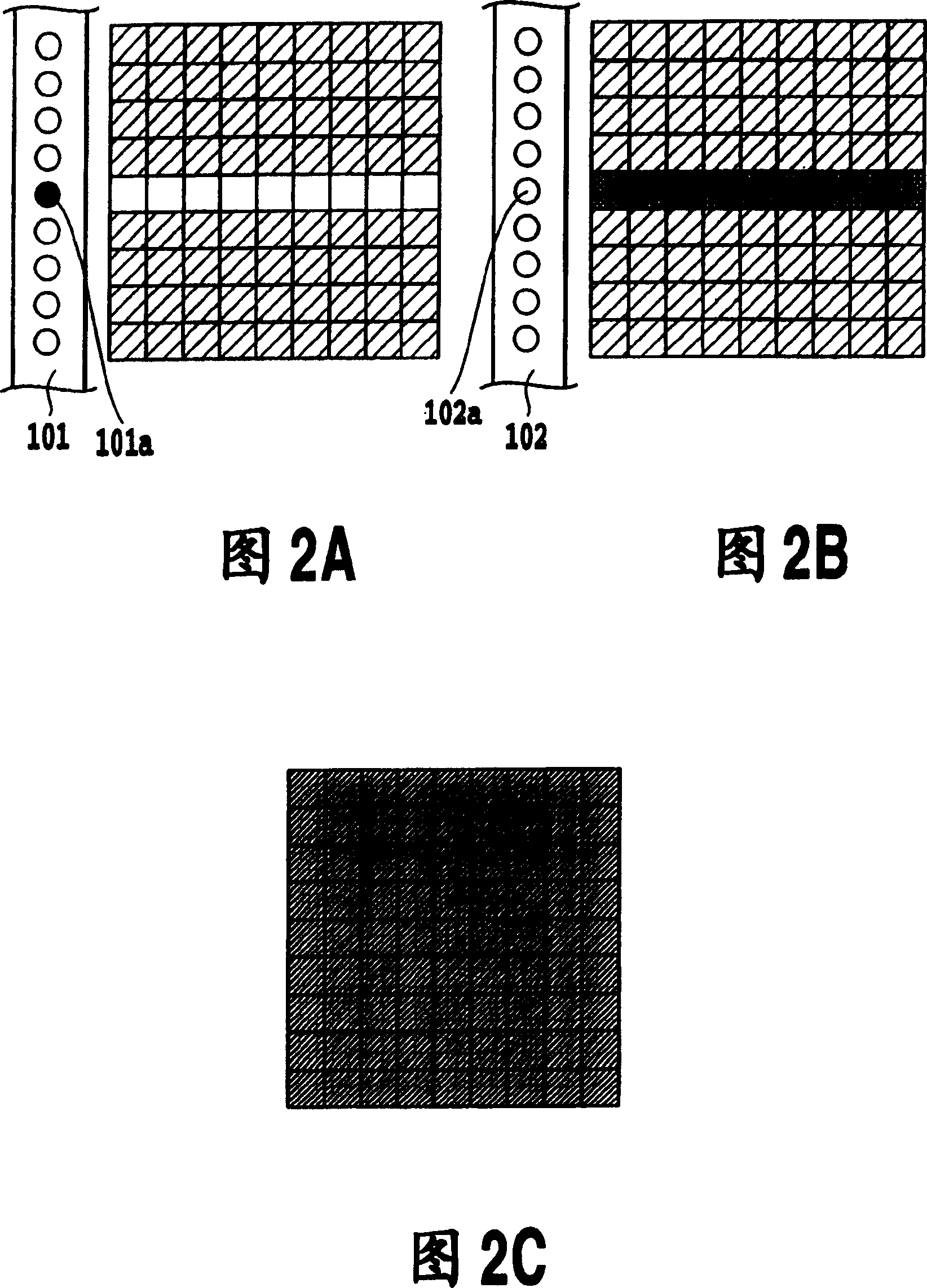

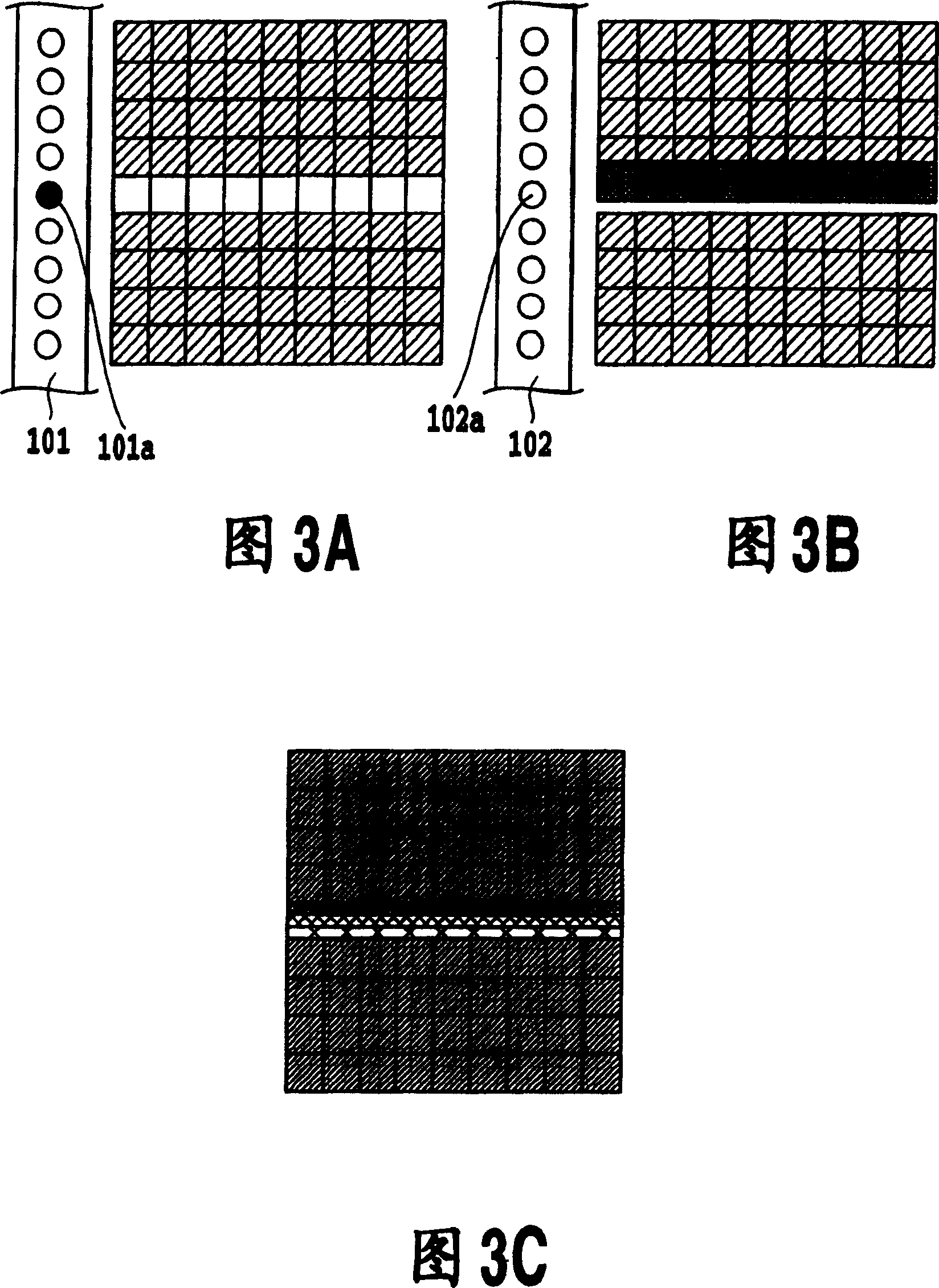

Ink jet print apparatus and ink jet print method

InactiveCN1326699CReduce output timeOther printing apparatusSpecial data processing applicationsEngineeringImage area

In an image area printed by a nozzle group including a defective nozzle, pixels printed by the defective nozzle and part of pixels located in the vicinity of the same are printed by another nozzle group. As a result, since printing is performed not only at the pixels printed by the defective nozzle but also at the pixels in the neighborhood thereof simultaneously by separate nozzles, irregularities of printing attributable to interpolation are distributed even when there is a relative misalignment between the nozzle groups. It is therefore possible to obtain a preferable image without any decrease in output time even when a printing head including a defective nozzle is used.

Owner:CANON KK

Information processing apparatus and user interface control method

InactiveUS7890332B2Easy to operateReduce output timeElectrographic process apparatusSound input/outputInformation processingPaper document

An information processing apparatus can set one of a plurality of setting values for a setting item. A guidance holding unit holds guidance information for voice output for each of the plurality of setting values. A document information acquisition unit acquires document information as limiting information which limits a range of a settable setting value. A guidance selection unit and a guidance change unit acquire pieces of guidance information to be output by voice on the basis of the pieces of guidance information corresponding to the plurality of setting values held in the guidance holding unit and the limiting information acquired by the document information acquisition unit. A voice information output unit outputs, by voice, the acquired pieces of guidance information to be output by voice.

Owner:CANON KK

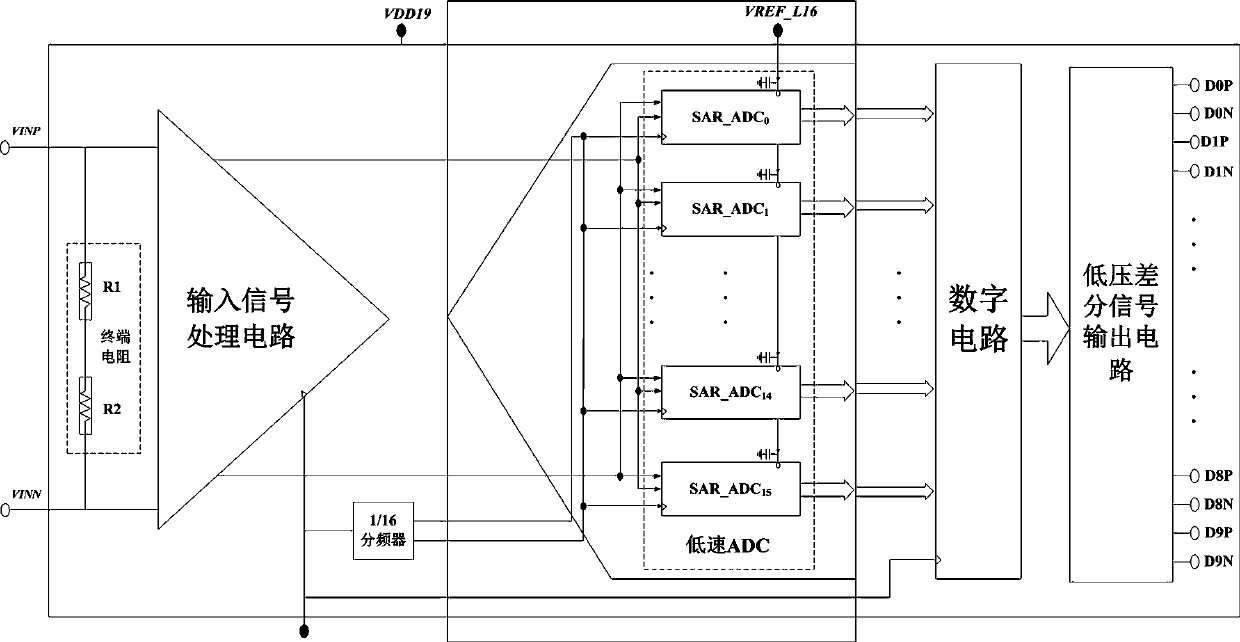

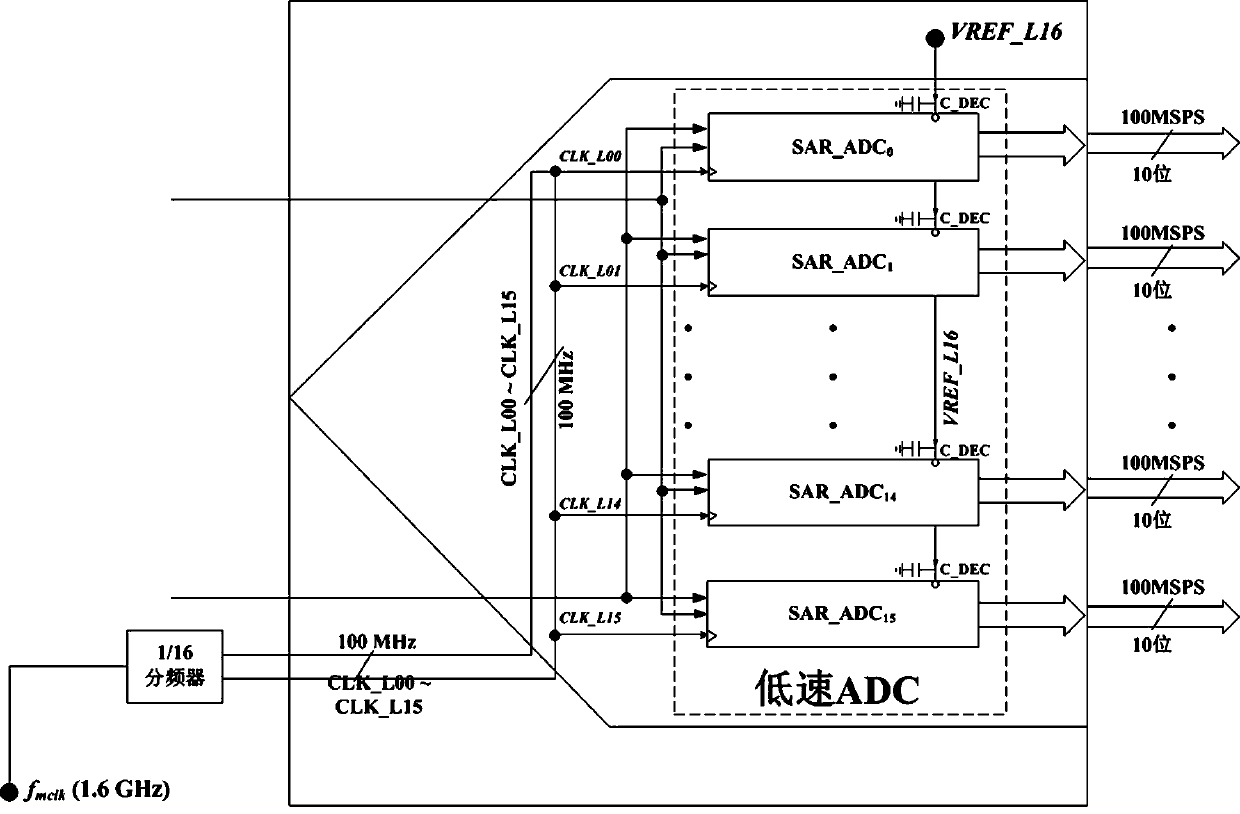

Low-power-consumption ultra-high-speed high-precision analog-to-digital converter

ActiveCN110299919AMitigating Mismatch EffectsImprove performancePower saving provisionsElectric signal transmission systemsUltra high speedLow speed

The invention discloses a low-power-consumption ultra-high-speed high-precision analog-to-digital converter. The analog-to-digital converter comprises an input circuit, a low-speed ADC, a 1 / 16 frequency divider and an output circuit, the input circuit is connected with the low-speed ADC, the low-speed ADC is connected with the output circuit, and the 1 / 16 frequency divider is connected with the input circuit and the low-speed ADC; the input circuit samples an input signal by adopting the frequency of 1.6 GHz. The low-speed ADC is used for acquiring signals from the input circuit at the frequency of 100MHz; the low-power-consumption ADC circuit architecture with the 10-bit resolution gigahertz sampling frequency is constructed in an IC chip.

Owner:成都铭科思微电子技术有限责任公司

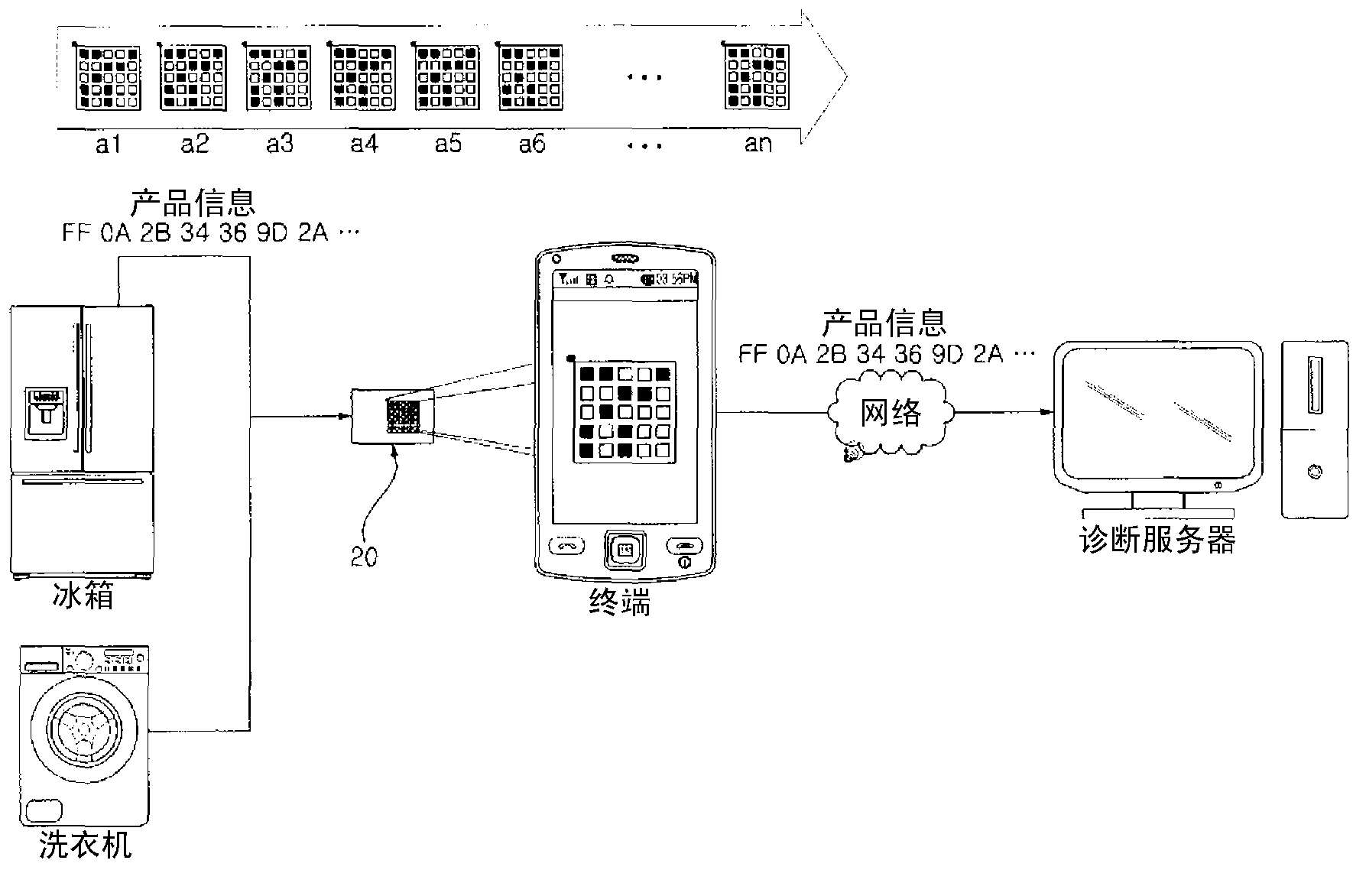

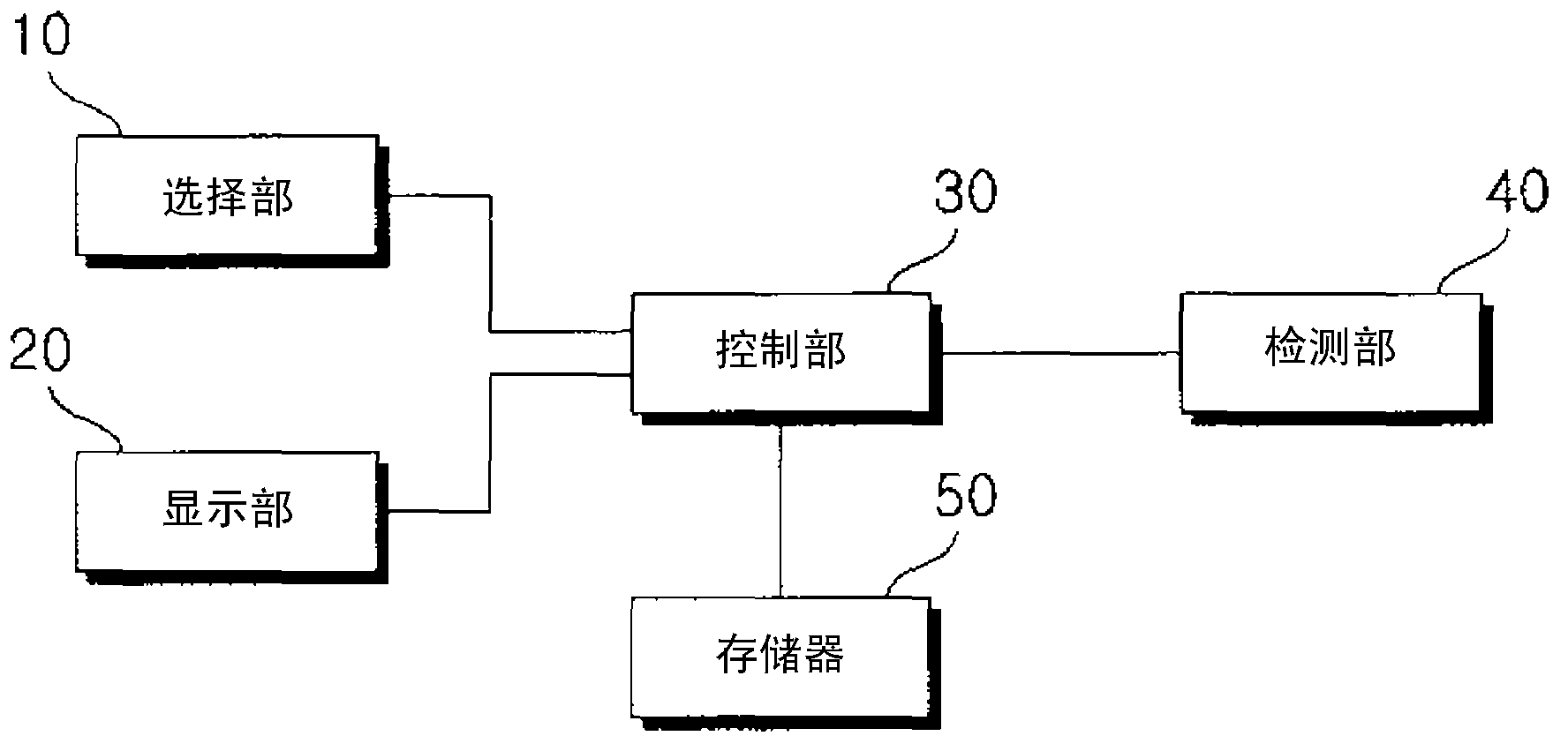

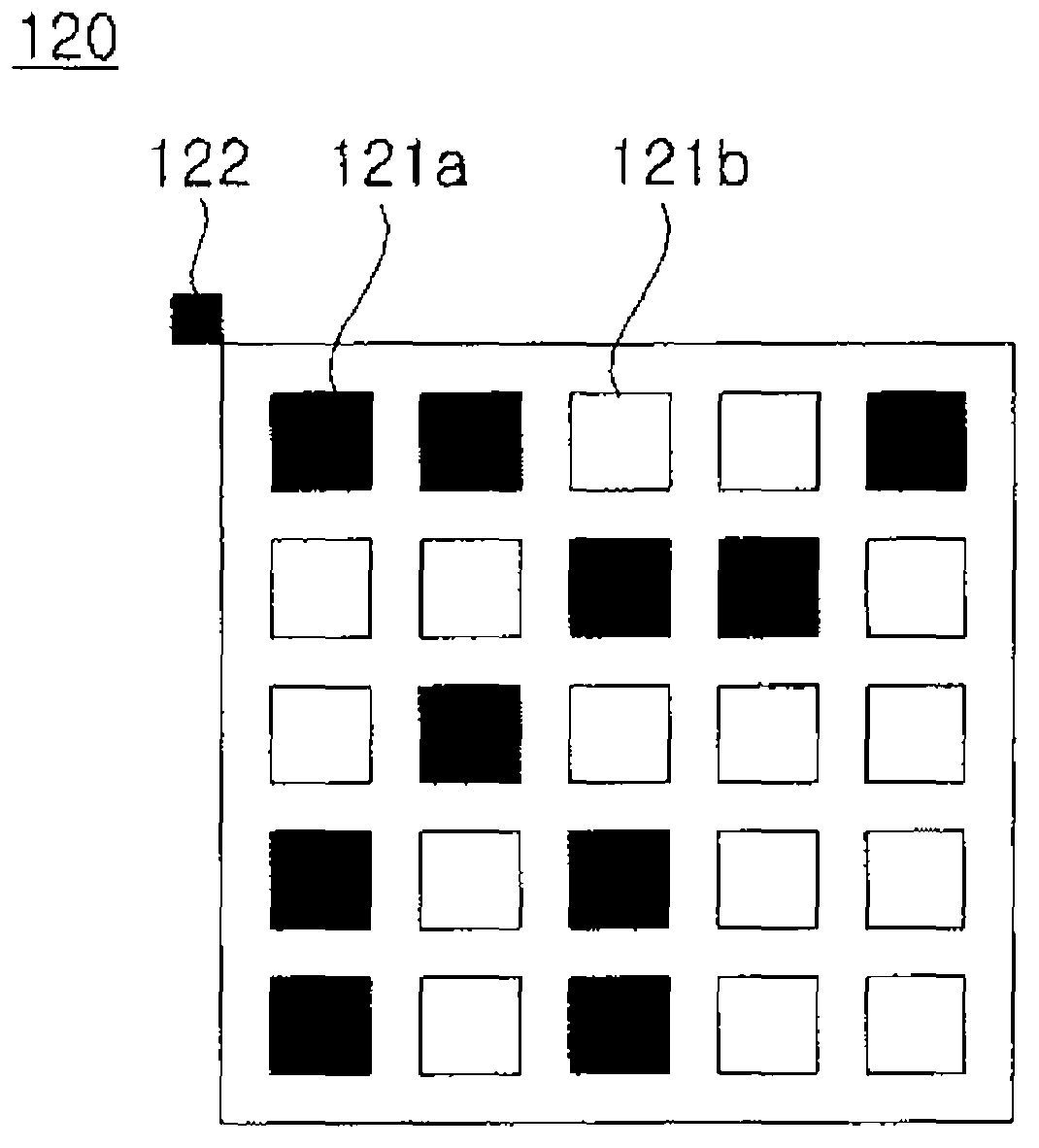

Electronic appliances, diagnostic system for electronic appliances and diagnostic method for electronic appliances

ActiveCN103229455APrecise deliveryFast outputSpecial service provision for substationLighting and heating apparatusPerformed DiagnosisEngineering

The present invention relates to electronic appliances, a diagnostic system for electronic appliances and a diagnostic method for electronic appliances, and performs diagnosis of electronic appliances rapidly and accurately by reversely extracting product information from a plurality of images which include product information outputted from the electronic appliances.

Owner:LG ELECTRONICS INC

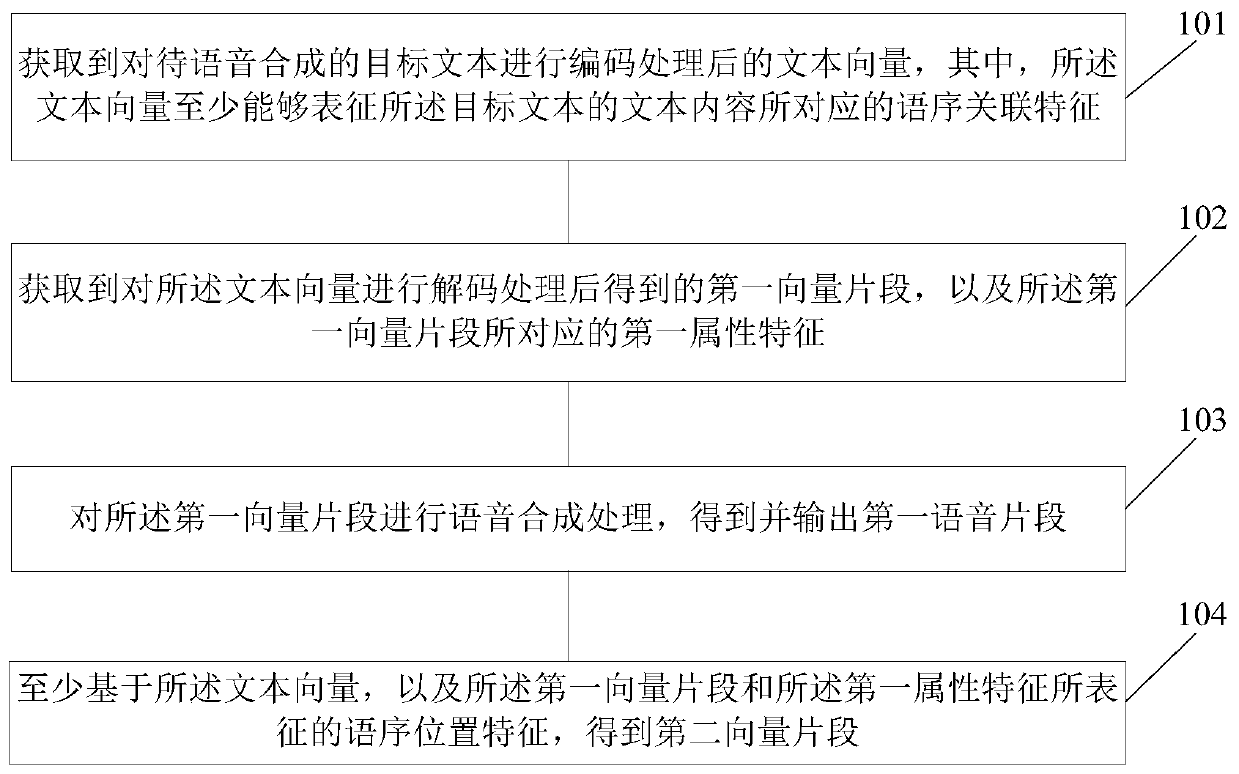

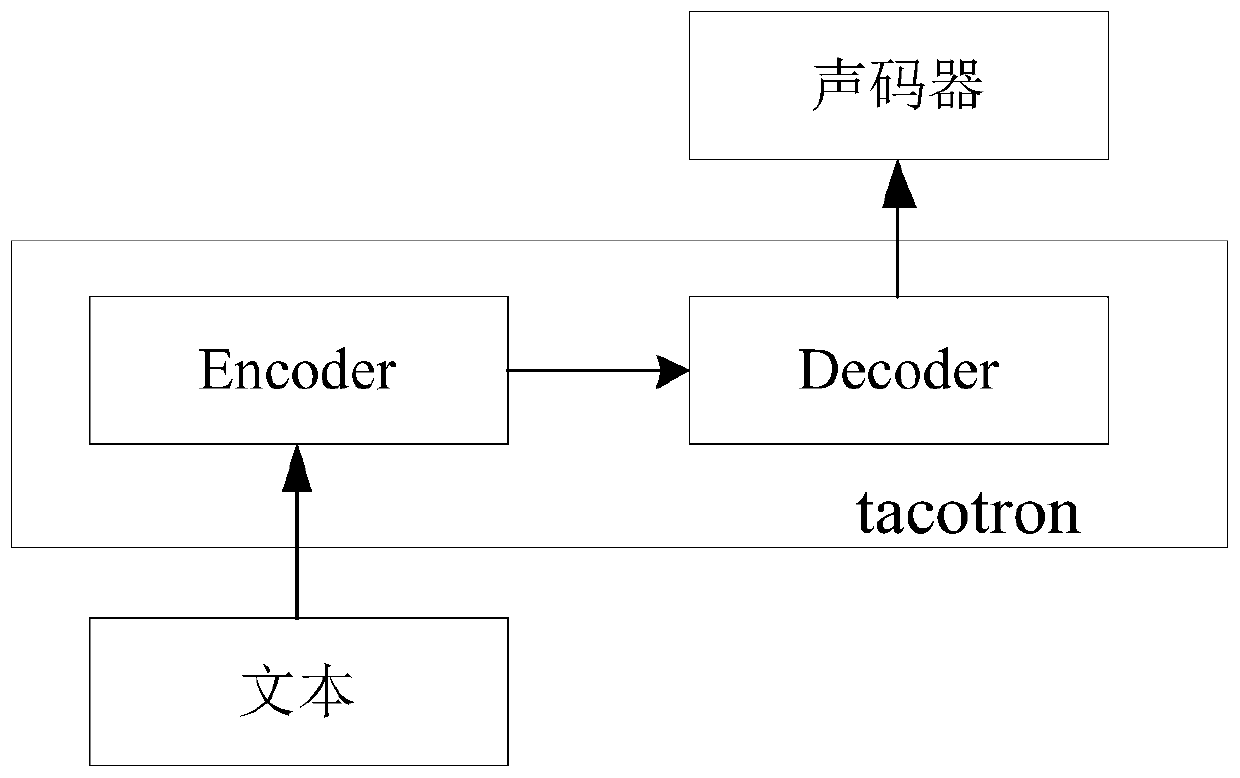

Speech synthesis method and device, equipment and storage medium

The invention relates to a voice synthesis method and device, equipment and a storage medium. The method comprises the following steps: obtaining a text vector after encoding a target text to be subjected to speech synthesis; obtaining a first vector segment obtained by decoding the text vector, and a first attribute feature corresponding to the first vector segment; wherein the first attribute feature at least can represent a word order position feature corresponding to the first vector fragment in the text content of the target text; performing voice synthesis processing on the first vectorsegment to obtain and output a first voice segment; and obtaining a second vector segment at least based on the text vector and the word order position features represented by the first vector segmentand the first attribute features. Thus, the purpose of converting stream output into stream output is achieved, a foundation is laid for reducing the overall output time, and meanwhile a foundation is laid for improving user experience.

Owner:ZHEJIANG TONGHUASHUN INTELLIGENT TECH CO LTD

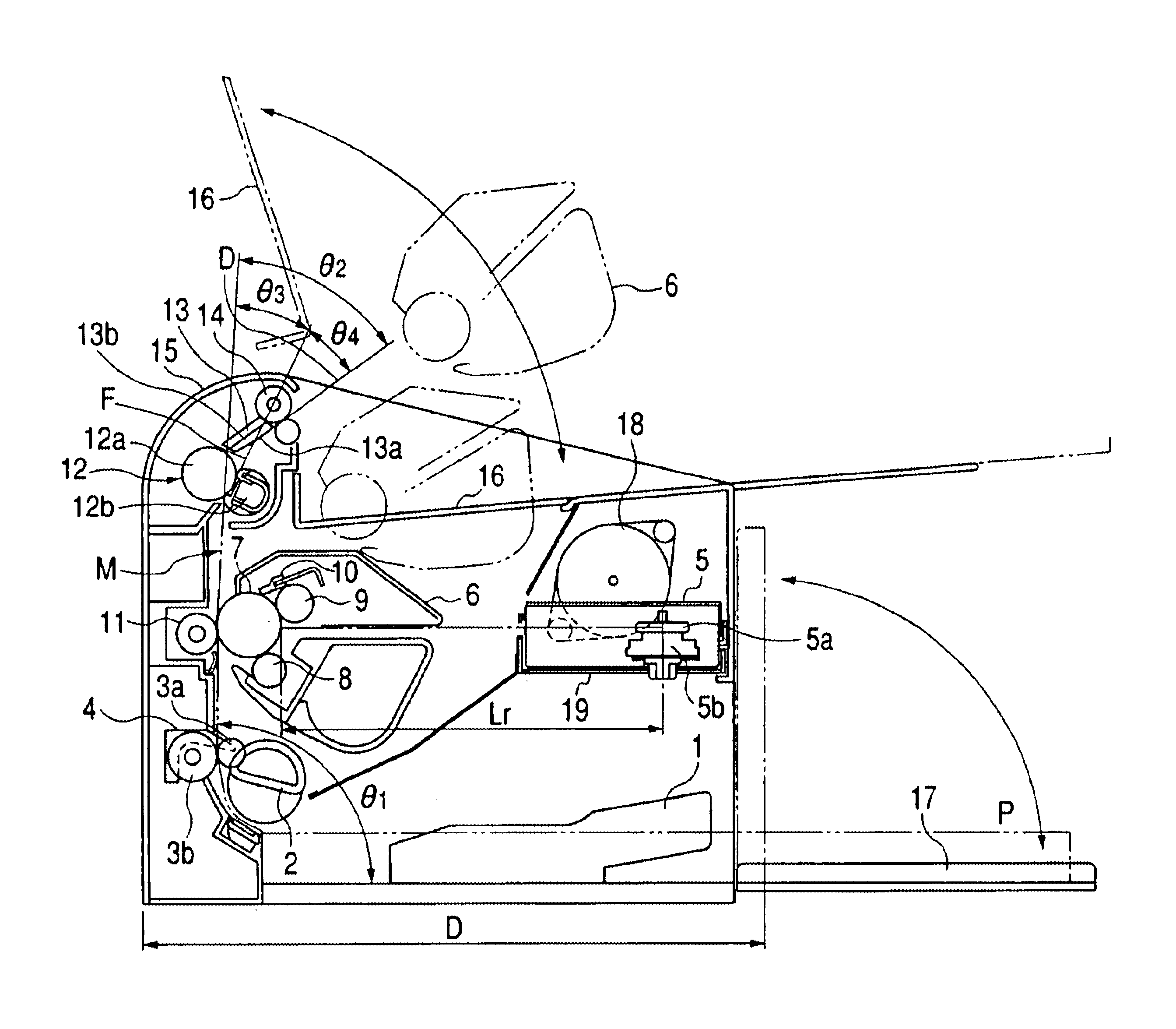

Image forming apparatus

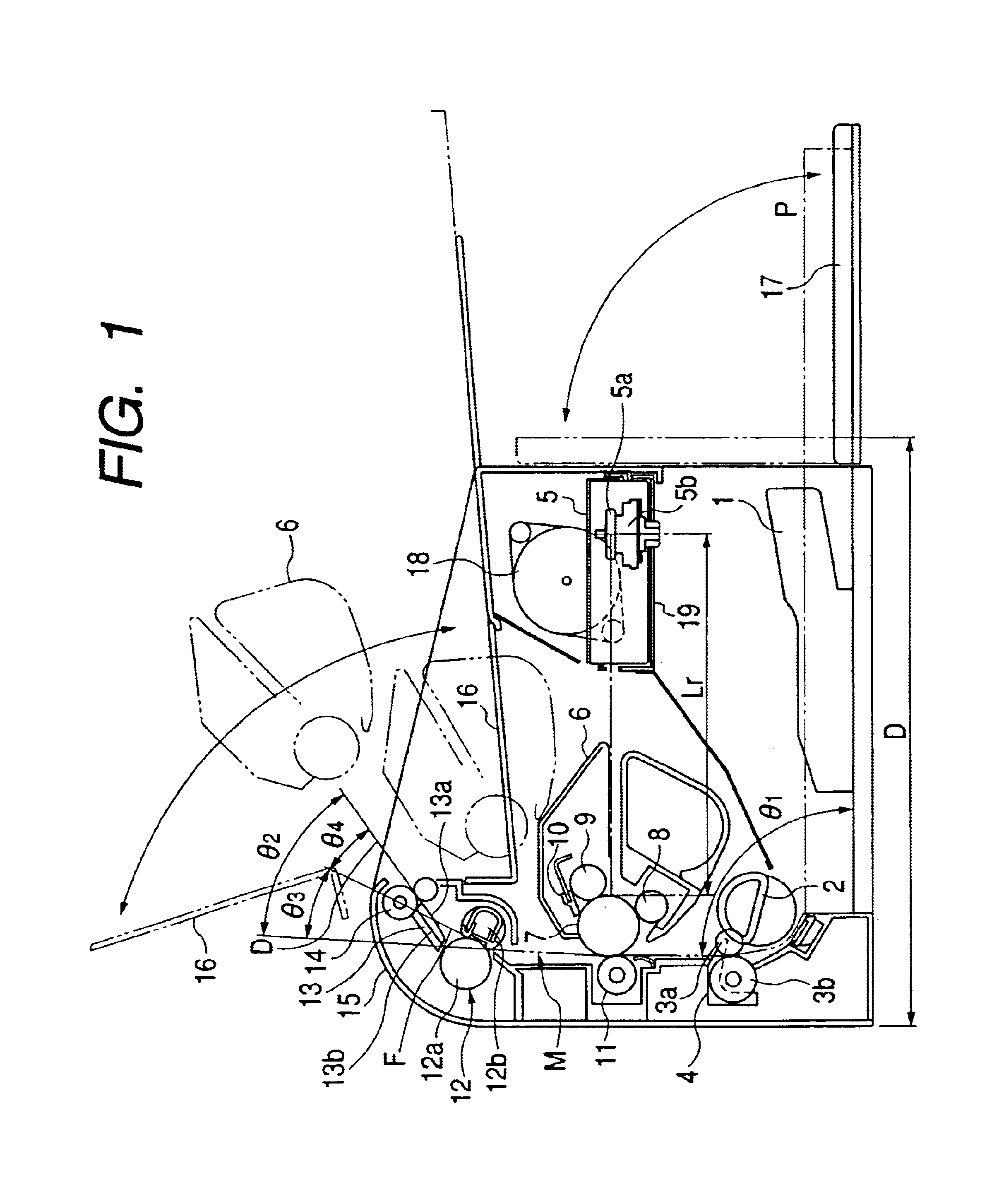

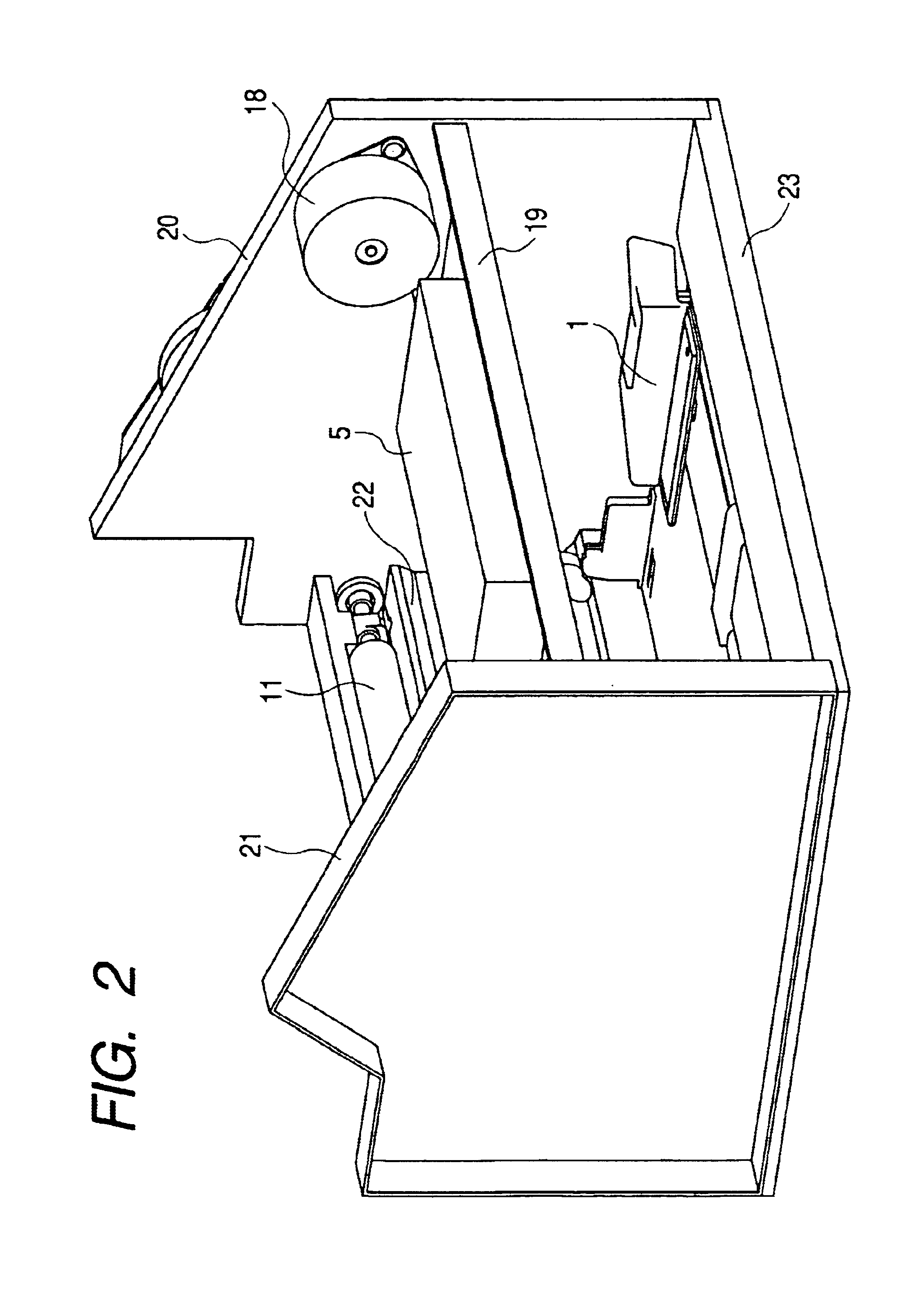

ActiveUS6909494B2Reduce output timePhotographic printingOther printing apparatusImage formationMechanical engineering

Owner:CANON KK

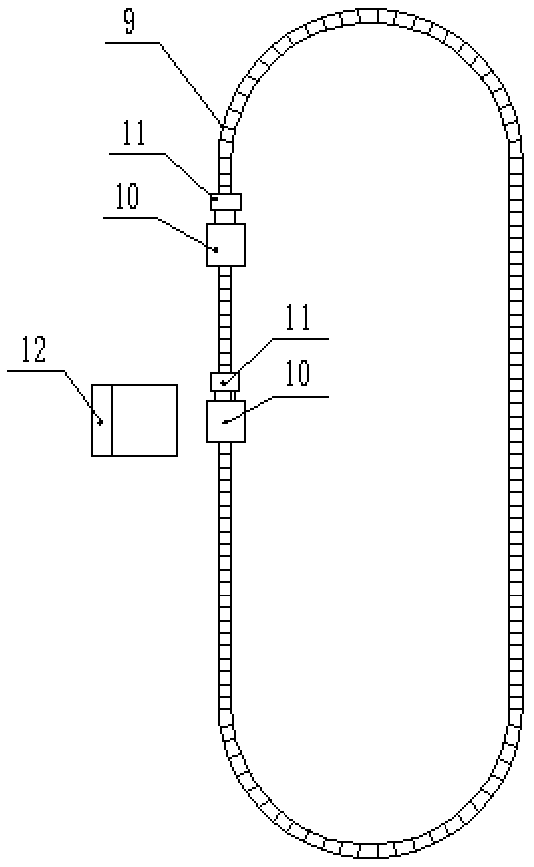

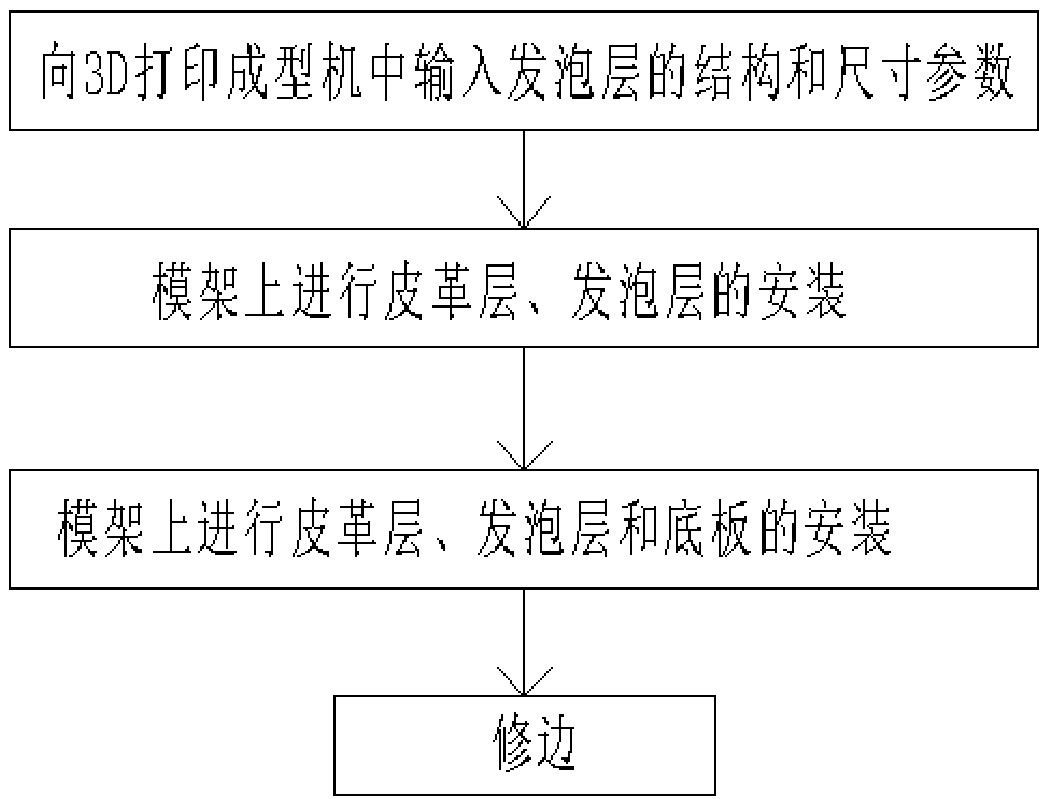

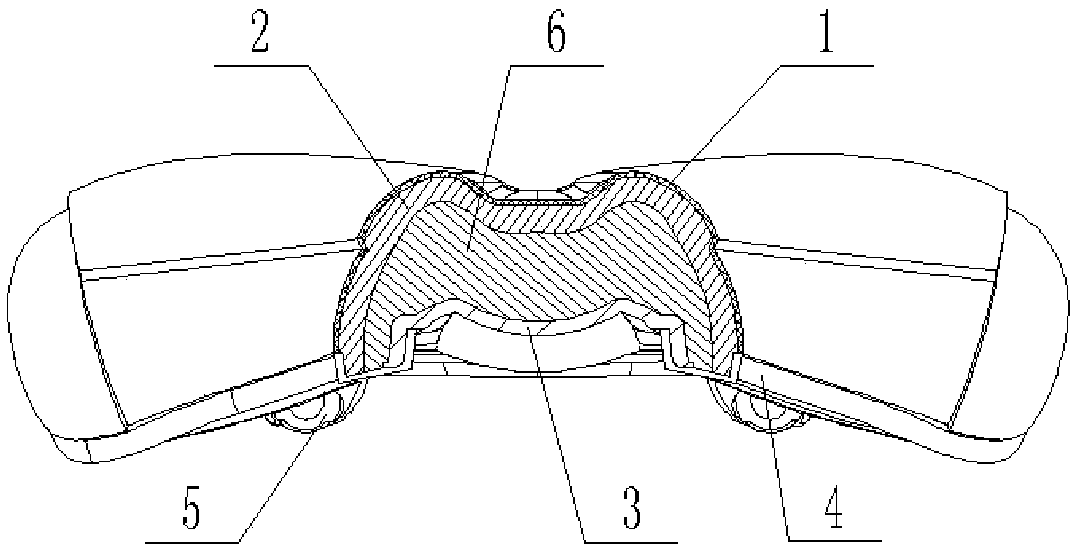

Saddle machining equipment and machining process

ActiveCN109501309AImprove use comfort performanceSpeed up the production processDomestic articlesEngineeringMachining process

The invention provides saddle machining equipment and a machining process, and relates to the field of traffic equipment. The technical problems that the production progress of an saddle and the use comfort degree of the saddle can be solved. The saddle machining equipment comprises a conveying track, the conveying track is provided with a mold frame and a power system for driving the mold frame to move on the conveying track, a secondary forming mold is arranged on the mold frame, and the secondary forming mold is used for installing a bottom plate on a foaming layer; a 3D printing forming machine is further arranged on the outer side of the conveying track; the invention further relates to the machining process, the machining process comprises the following steps that foaming forming iscarried out, a 3D printing forming machine is used for machining, a leather layer is placed on the bottommost layer of a lower mold of the mold frame, then the formed foaming layer is placed on the uppermost part of the leather layer, at the same time, the bottom plate is fixed to an upper mold of the mold frame, through the mold closing of the upper mold and the lower mold of the mold frame, andbonding of the bottom plate, the foaming layer and the leather layer is realized; and finally trimming is carried out. The saddle machining equipment and the machining process are adopted, the production is accelerated, the working procedures are saved, and the comfort degree of the saddle is improved.

Owner:TIANJIN JIASITE VEHICLE IND

Image forming apparatus

ActiveUS9052621B2Reduce output timeEasy to fixDevelopersElectrographic process apparatusLatent imageImage formation

An image forming apparatus including: image bearing member; latent image forming unit; developing unit; transfer unit; fixing unit, wherein toner in the developing unit contains amorphous polymer, crystalline resin and releasing agent, when the toner is measured for G′ at 40° C. to 210° C. with rheometer at 1 Hz and 1 deg, G′(100) is ≦20,000 and G′(150) is ≧500 Pa, and straight line drawn by connecting points of the G′(100) and G′(110) on curve of the G′ has gradient of ≦0.035, the gradient being “a” expressed by: a=|log10G′(100)−log10G′(110)| / 10, and the fixing unit includes: heating member containing flexible endless belt; heat source fixed within the flexible endless belt; and press member in contact with the belt to form nip portion, and the fixing unit is configured to heat / press the medium passing through the nip portion to fix the image on the medium.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com