Cleaning device of art brushes and palettes

A technology for cleaning devices and paint plates, which is applied to devices for removing pen tips, decorative arts, painting tools, etc., can solve the problems of unsatisfactory cleaning effects of art brushes and paint plates, and cannot achieve cleaning effects, and achieves convenient adjustment. , Improve the scope of adaptation, improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

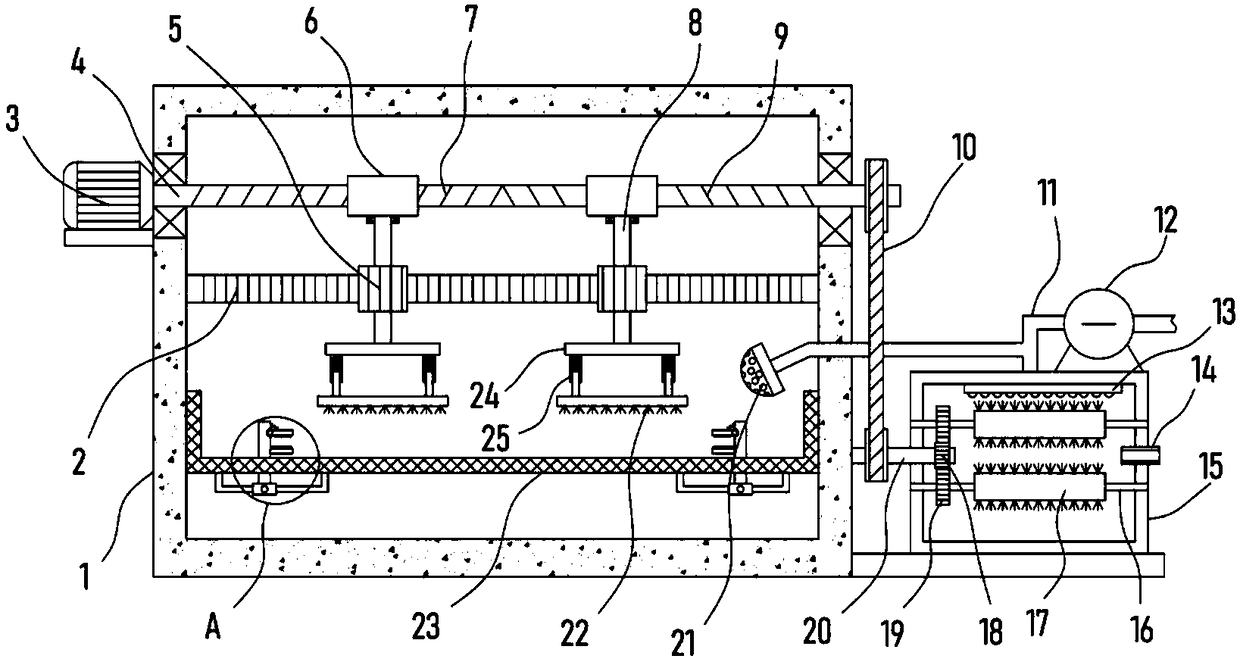

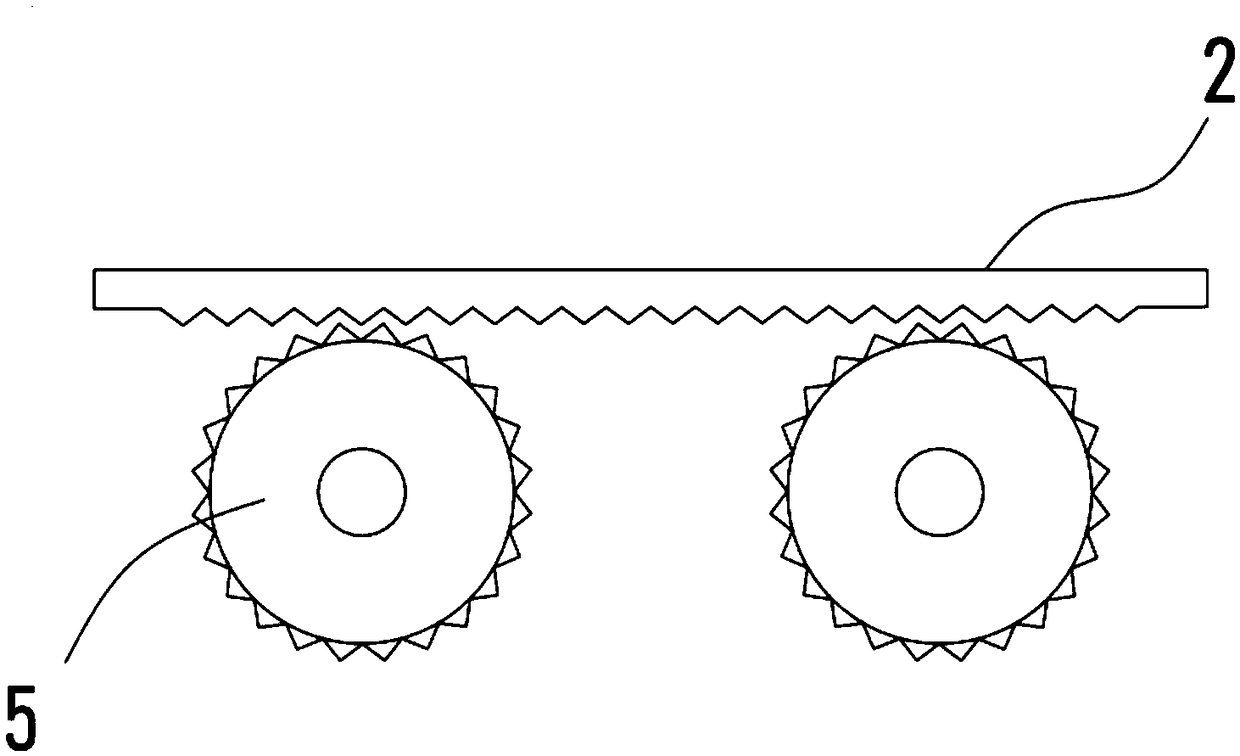

[0021] see Figure 1-3 , a cleaning device for art brushes and paint boards, comprising a board washing box 1 and a brush washing box 15, a rotating drive shaft 4 driven by a drive motor 3 is provided in the washing board box 1, and a drive shaft 4 is symmetrically tapped on the drive shaft 4 The external thread I7 and the external thread II9 opposite to the thread direction are selected, and the threaded connection sleeves on the external thread I7 and the external thread II9 are provided with a threaded sleeve block 6 .

[0022] By starting the drive motor 3, the drive shaft 4 can be driven to rotate, and the drive shaft 4 realizes the lateral sliding of the threaded block 6 on it through the external thread I7 and the external thread II9 on it, and the drive motor 3 can be selected from a servo motor to realize the drive shaft. 4 rotates clockwise or counterclockwise alternately, and at this moment, the threaded sleeve block 6 can carry out lateral relative or opposite move...

Embodiment 2

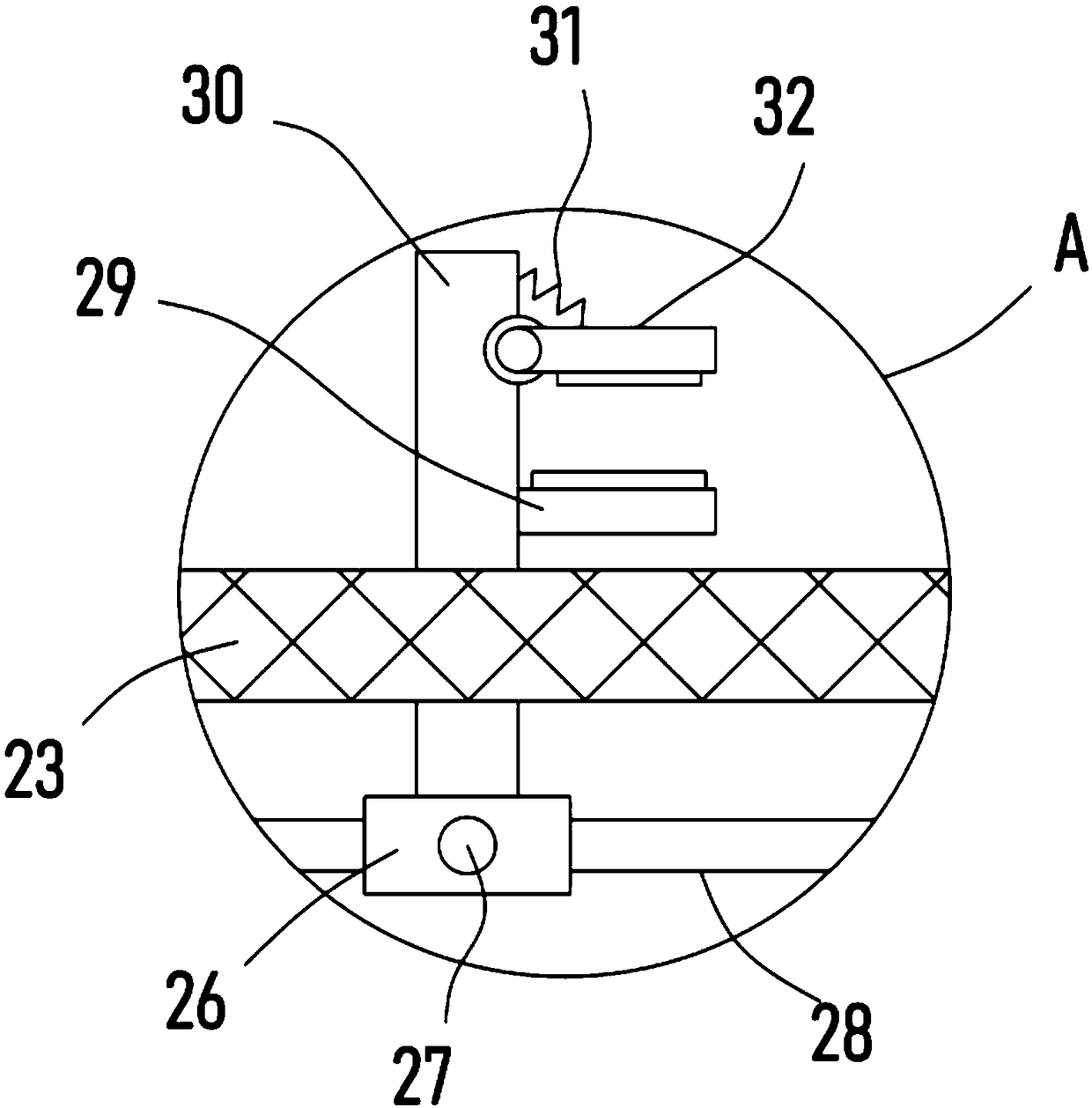

[0027] On the basis of Embodiment 1, in addition, the clamping device includes a guide rod 28 fixed on the load-bearing net plate 23, a sliding sleeve 26 is slidably installed on the guide rod 28, and a sliding sleeve 26 is threaded to abut against the guide rod 28. The locking stud 27, the upper end of the sliding sleeve 26 is vertically fixed with a vertical plate 30 that is slidingly connected with the load-bearing net plate 23.

[0028] The sliding sleeve 26 can slide laterally along the guide rod 28, and the sliding sleeve 26 and the guide rod 28 can be locked to fix the position by rotating the locking stud 27, thereby realizing the adjustment of the lateral spacing between the vertical plates 30. Easily adapts to different sized palettes.

[0029] Further, the side wall of the vertical plate 30 is horizontally fixed with the lower clamping plate 29 and the upper clamping plate 32 which is rotated, the limit spring 31 is hinged between the upper clamping plate 32 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com