Anti-segregation raw sand silo

A technology for preventing segregation and sand bins, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of affecting the mixing uniformity, difficulty in meeting high-precision production requirements, and low mixing uniformity, and achieve the effect of preventing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

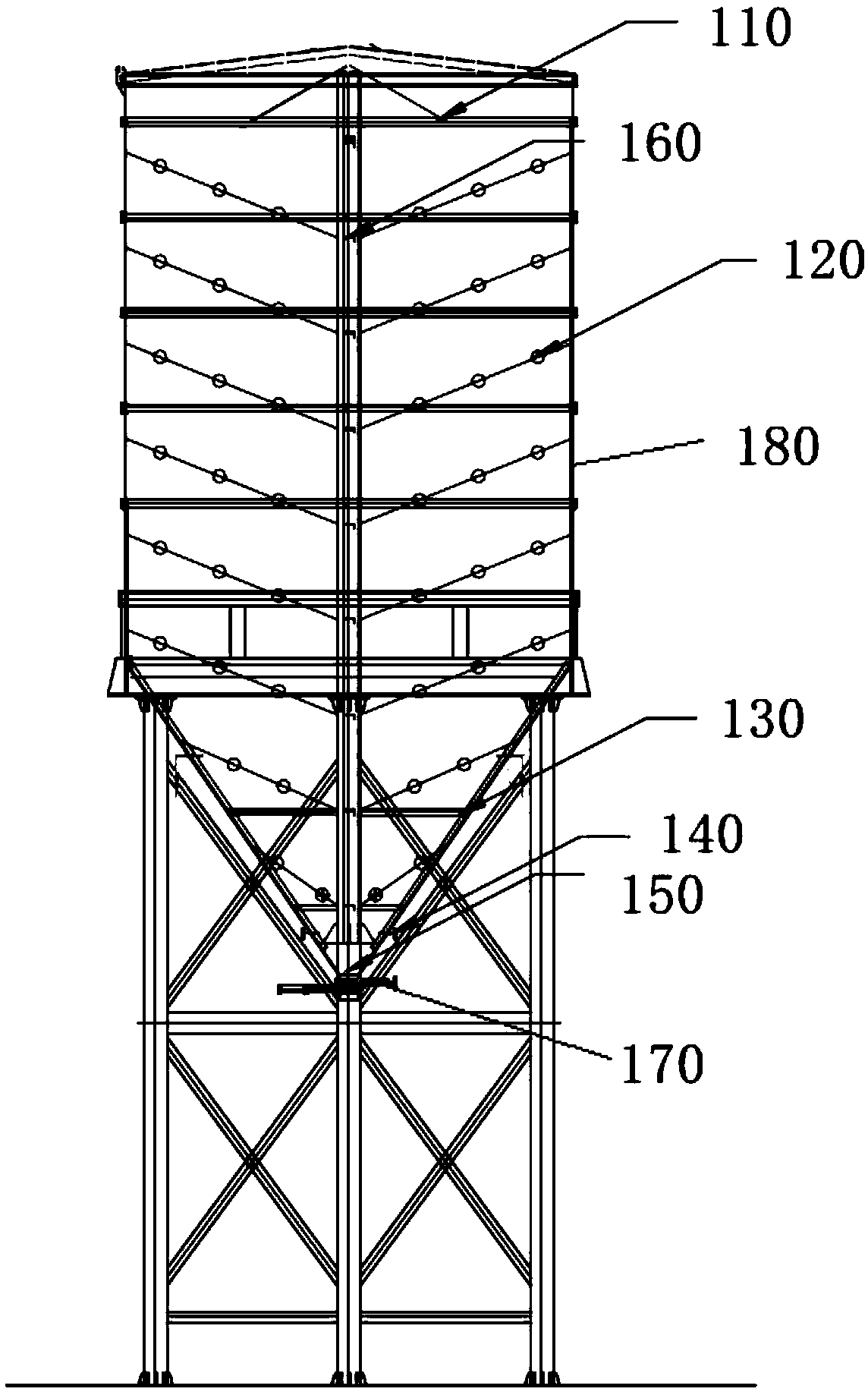

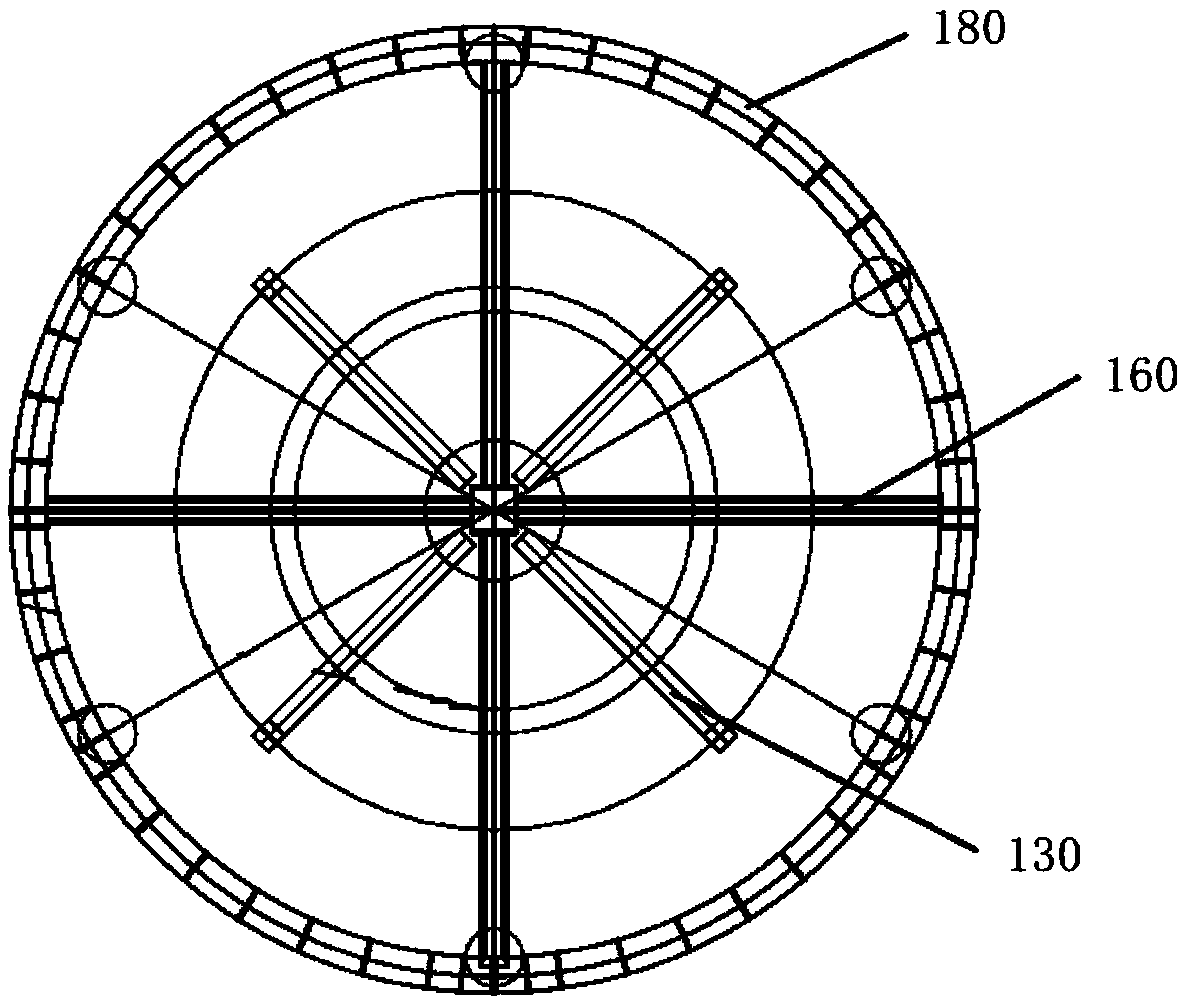

[0031] This embodiment provides a kind of anti-segregation raw sand bin, please refer to Figure 1 to Figure 3 , this anti-segregation raw sand bin includes a bin 180 , a partition plate 160 , a material guide pipe 130 and a flow valve 140 .

[0032] The partition plate 160 is arranged in the feed bin 180, and the partition board 160 divides the feed bin 180 into a plurality of feeding channels;

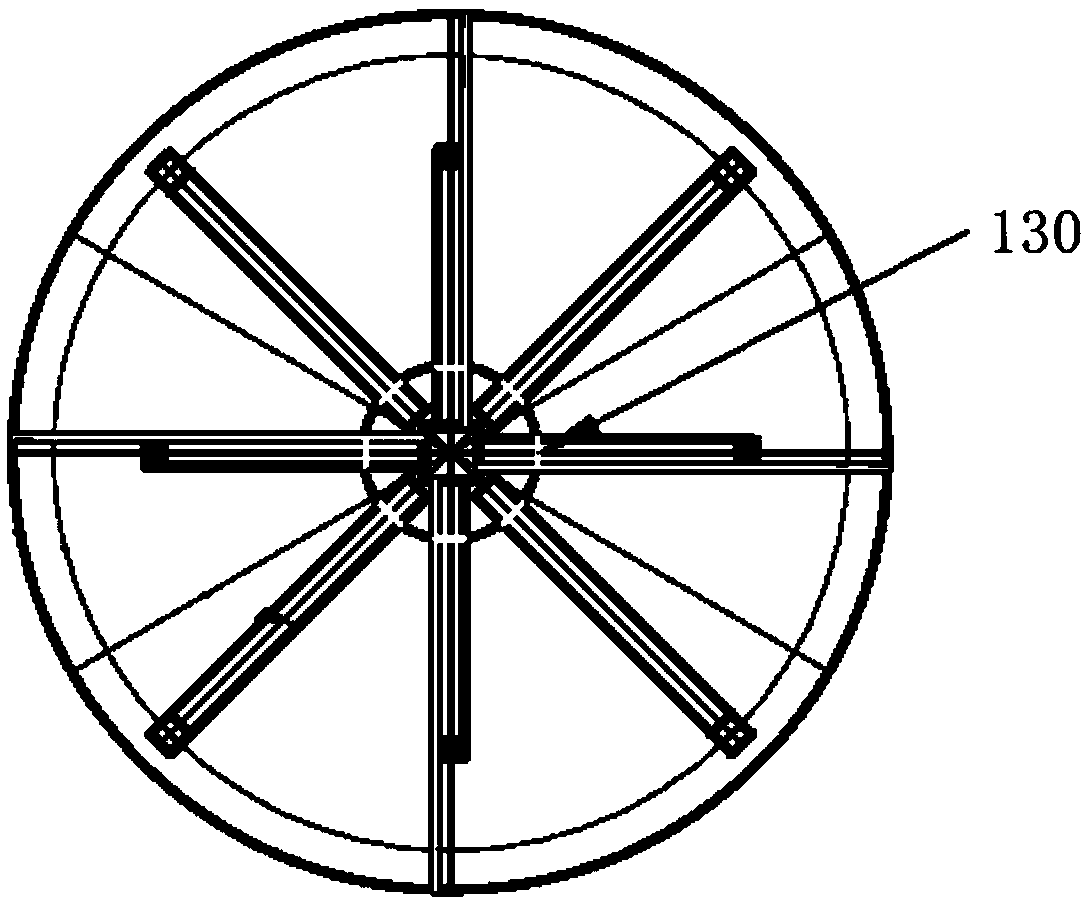

[0033] One end of the material guide pipe 130 communicates with the feeding channel, and the material guide tube 130 is arranged in multiples, and each feeding channel communicates with at least one material guide tube 130, and the end of the feeding channel away from the material guide tube 130 is used for feeding The feeding end of the feed pipe 130 is the discharge end for discharging at the end far away from the discharge channel;

[0034] The flow valve 140 is disposed on the material guide tube 130 , and the flow valve 140 is used to adjust the flow rate of the material guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com