A kind of foaming material preparation foaming stirring tank

A technology of foaming materials and stirring tanks, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as waste, affecting the mixing and stirring ratio of foaming materials, and low quality of finished foaming materials , to achieve the effect of improving the quality of finished products, good support effect and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

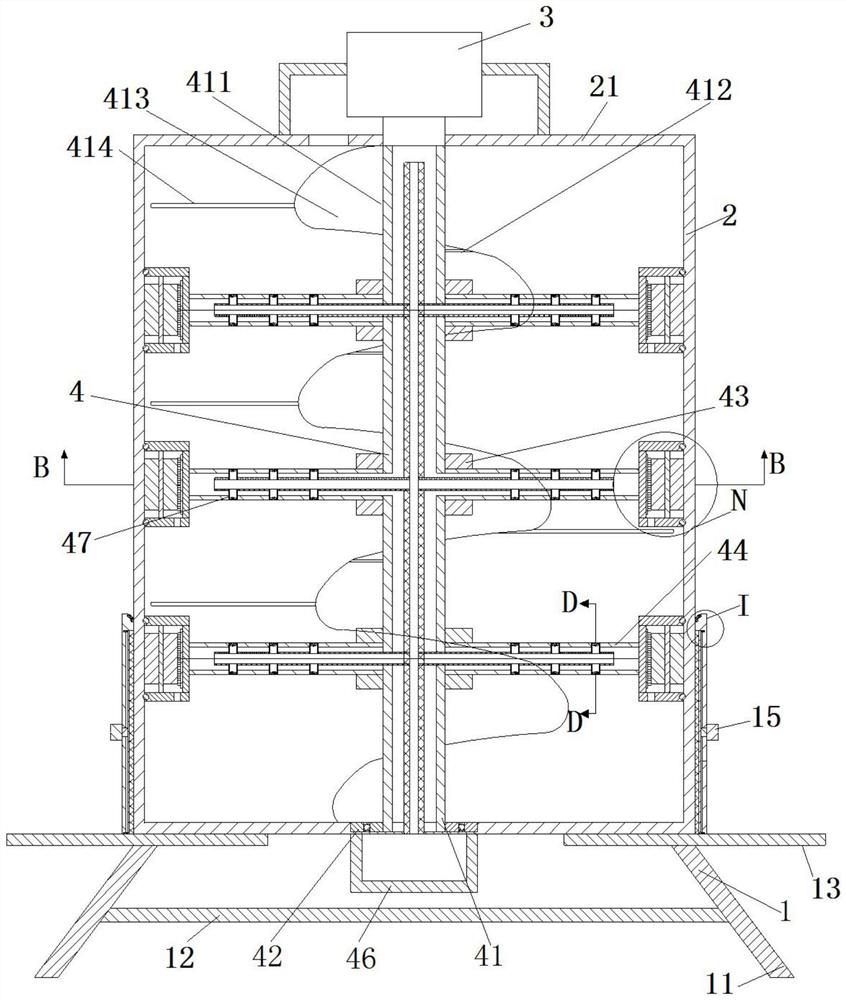

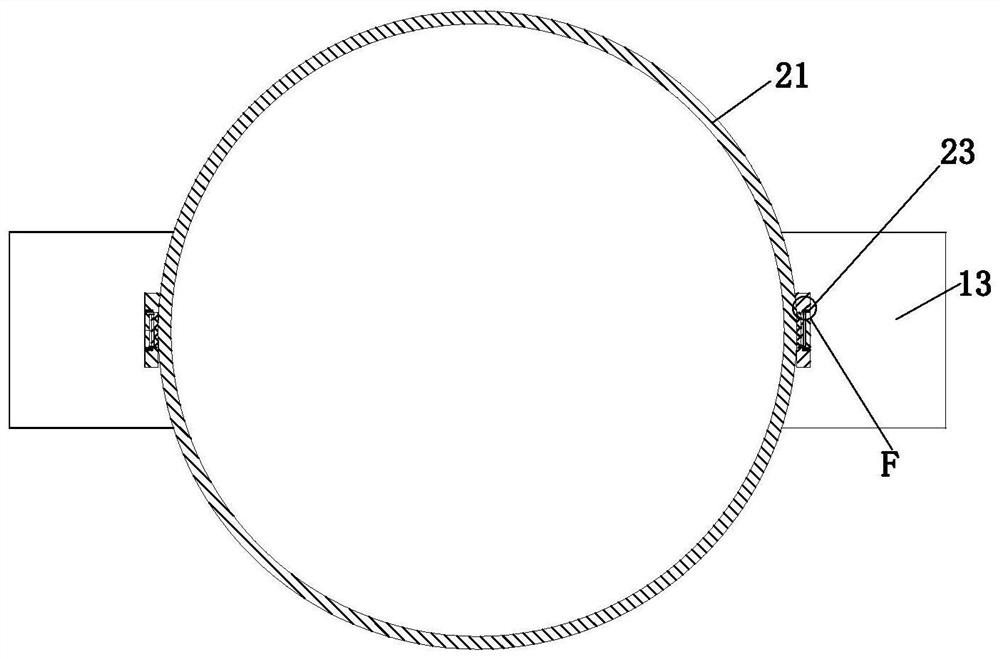

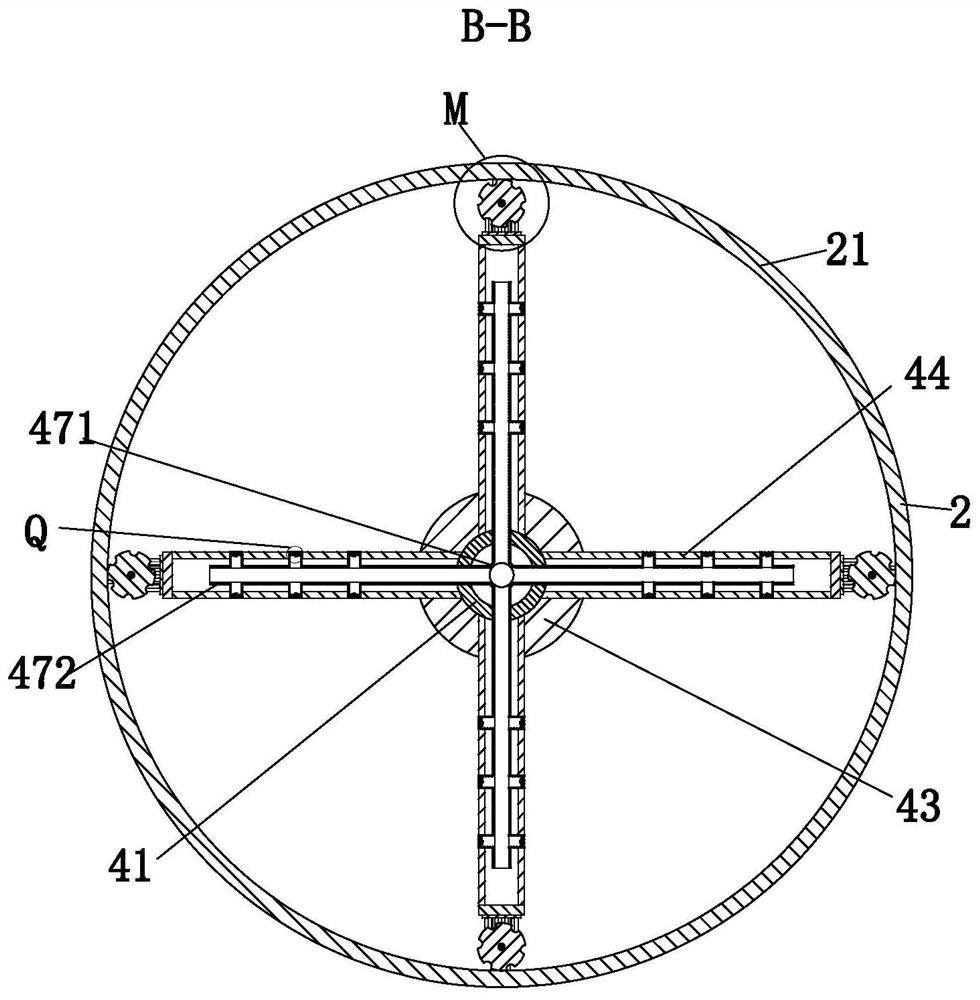

[0036] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 11 , to further elaborate the present invention.

[0037] A foaming stirred tank for preparing foam materials, comprising a fixing device 1, a stirring tank 2, a motor 3, and a stirring device 4, the upper end of the fixing device 1 is equipped with a stirring tank 2, and the upper end of the stirring tank 2 is fixed and installed by a motor base There is a motor 3, and the output shaft of the motor 3 is equipped with a stirring device 4 through a coupling; wherein:

[0038] Described stirring device 4 comprises rotating pipe 41, bearing 42, fixed plate 43, stirring pipe 44, positioning frame 45, air pump 46 and air intake frame 47, and motor 3 lower end output shafts are fixedly installed with rotating pipe 41 by shaft coupling, and rotating The lower end of the tube 41 is equipped with a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com