Proportioning structure in recycled concrete processing process

A recycled concrete and processing technology, which is applied in the direction of batching and batching equipment, mixing operation control, clay preparation equipment, etc., can solve the problems of concrete not meeting the standard, reducing the compressive strength of concrete, and reducing product quality, so as to improve concrete products. Improvement of quality, improvement of compressive strength, and improvement of manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

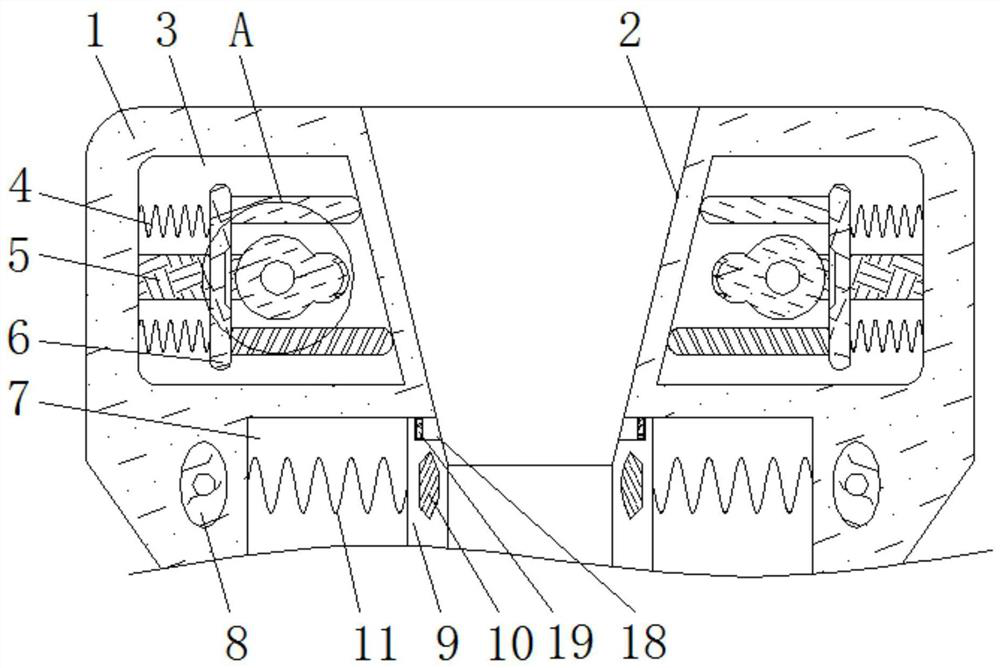

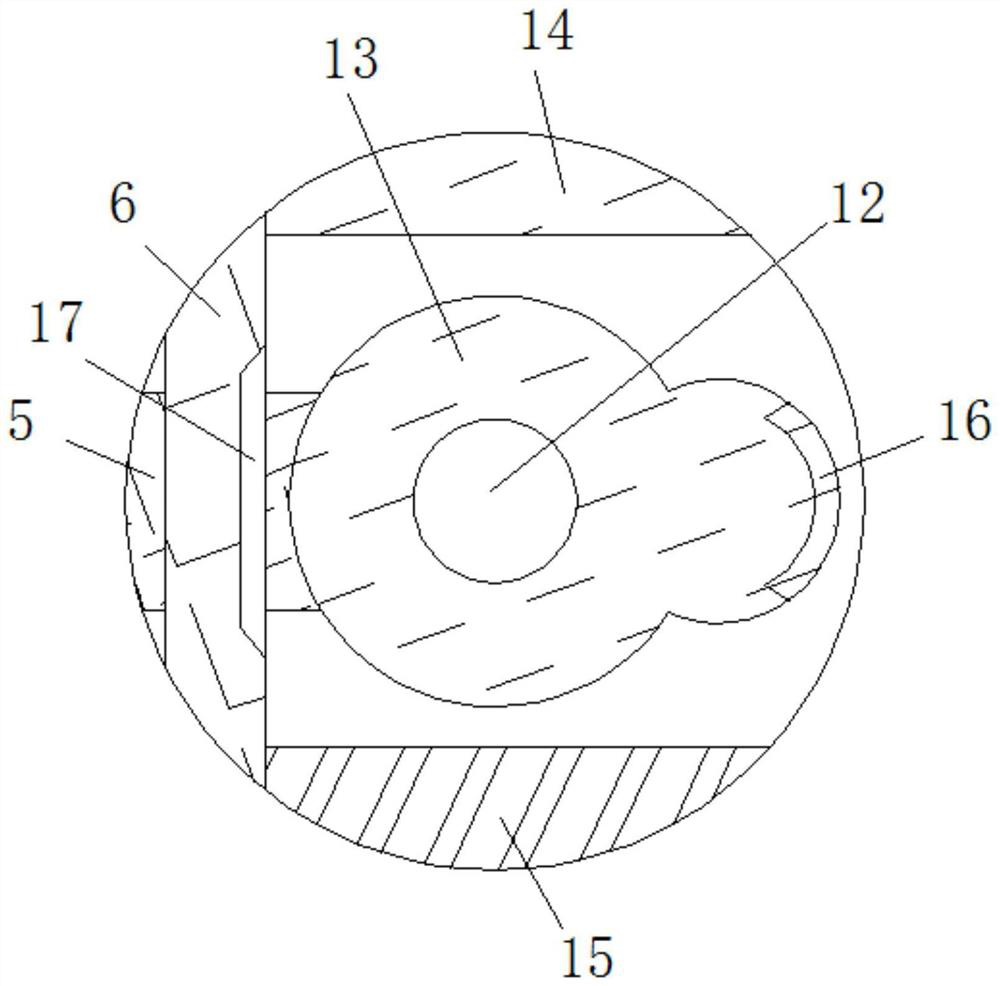

[0027] see Figure 1-6 , a proportioning structure in the processing process of recycled concrete, comprising a housing 1, the inner wall of the housing 1 is provided with a feed port 2, the inner wall of the housing 1 is provided with grooves 3, the number of the grooves 3 is the same as that of the fixing rod The number of 5 is the same, the groove 3 is symmetrically distributed on the inner wall of the housing 1, the inner wall of the groove 3 is fixedly connected with a spring one 4, and the spring one 4 is used to provide restoring force, and the number of the spring one 4 is equal to the number of the fixed rod 5 Twice, the material of the fixed rod 5 is stainless steel, the inner side of the spring one 4 is fixedly connected with the connecting rod 6, the quantity of the connecting rod 6 is the same as that of the fixed rod 5, the material of the connecting rod 6 is stainless steel, and the groove 3 The inner wall is fixedly connected with a fixed rod 5, and the fixed r...

Embodiment 2

[0030] see Figure 1-6 , a proportioning structure in the processing process of recycled concrete, comprising a housing 1, the inner wall of the housing 1 is provided with a feed port 2, the inner wall of the housing 1 is provided with grooves 3, the number of the grooves 3 is the same as that of the fixing rod The number of 5 is the same, the groove 3 is symmetrically distributed on the inner wall of the housing 1, the inner wall of the groove 3 is fixedly connected with a spring one 4, and the spring one 4 is used to provide restoring force, and the number of the spring one 4 is equal to the number of the fixed rod 5 Twice, the material of the fixed rod 5 is stainless steel, the inner side of the spring one 4 is fixedly connected with the connecting rod 6, the quantity of the connecting rod 6 is the same as that of the fixed rod 5, the material of the connecting rod 6 is stainless steel, and the groove 3 The inner wall is fixedly connected with a fixed rod 5, and the fixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com