A kind of same-color dyeing method of real silk/shrinkproof (mercerized) wool interwoven fabric with reactive dyes

A mercerized wool and reactive dye technology, applied in the field of textile dyeing and finishing, can solve problems such as poor color fastness, and achieve the effects of less fiber damage, high application value and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

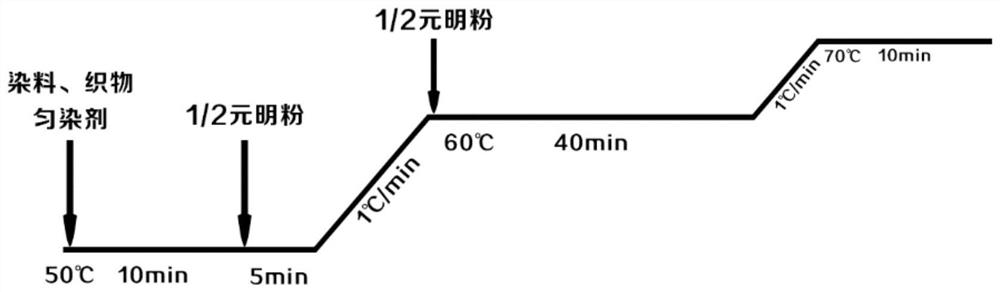

[0025] The fabric is silk / preshrunk wool (mercerized) blended fabric (silk 40%, wool 60%). Respectively dye with 1% reactive dyes such as reactive red 3BS in the same color leveling agent R 0.5g / L, Yuanming powder 60g / L, bath ratio 1:50, dyeing in total for 85min. Heating curve such as figure 1 shown;

[0026] Soaping process: both soap flakes and sodium carbonate are 1g / L, liquor ratio 1:50, soaping at 90°C for 15 minutes, washing with water, and drying.

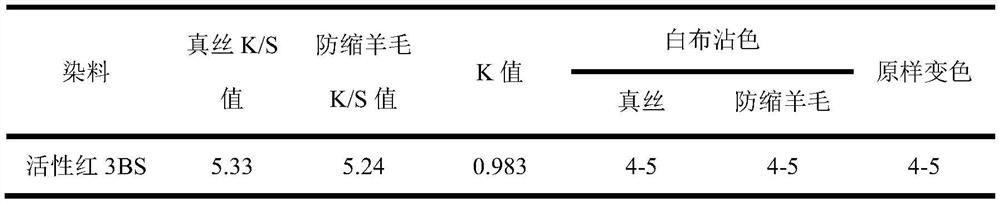

[0027] Table 1 Dyeing K / S value and soaping fastness of silk / shrinkproof wool (mercerized) interwoven fabric

[0028]

Embodiment 2

[0030] The fabric is silk / preshrunk wool (mercerized) blended fabric (silk 40%, wool 60%). Dye with 3% reactive scarlet FN-3GL, reactive yellow 3GL, reactive blue CA respectively under the conditions of homochromatic leveling agent R 1g / L, yuanming powder 65g / L, liquor ratio 1:50, and dye for 85 minutes. Heating curve such as figure 1 shown;

[0031] Soaping process: both soap flakes and sodium carbonate are 1g / L, liquor ratio 1:50, soaping at 90°C for 15 minutes, washing with water, and drying.

[0032] Table 2 Dyeing K / S value and soaping fastness of silk / shrinkproof wool (mercerized) interwoven fabric

[0033]

Embodiment 3

[0035] The fabric is silk / preshrunk wool (mercerized) blended fabric (silk 40%, wool 60%). Respectively dye with 5% active navy blue S-G in the same color leveling agent R 1.2g / L, Yuanming powder 65g / L, bath ratio 1:50, and dye for 85 minutes. Heating curve such as figure 1 shown;

[0036] Soaping process: both soap flakes and sodium carbonate are 1g / L, liquor ratio 1:50, soaping at 90°C for 15 minutes, washing with water, and drying.

[0037] Table 3 Dyeing K / S value and soaping fastness of silk / shrinkproof wool (mercerized) interwoven fabric

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com