Electric heating water boiler and railway passenger car with electric heating water boiler

An electric water boiler and water source technology, which is applied in the direction of railway car body components, water heaters, fluid heaters, etc., can solve the problems of large installation space and single function of parts, so as to save installation and use space, save energy, and improve heating efficiency. The effect of water efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

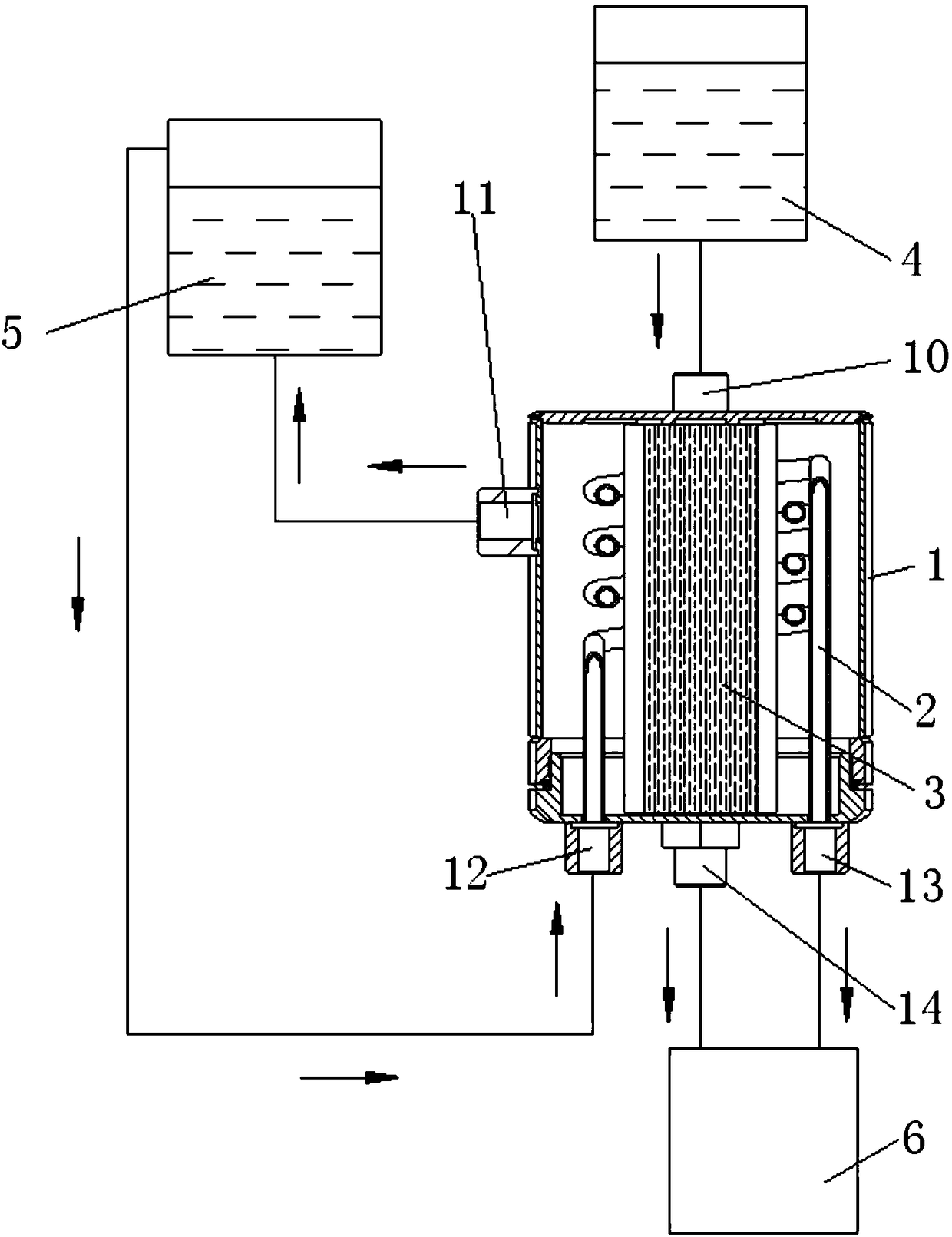

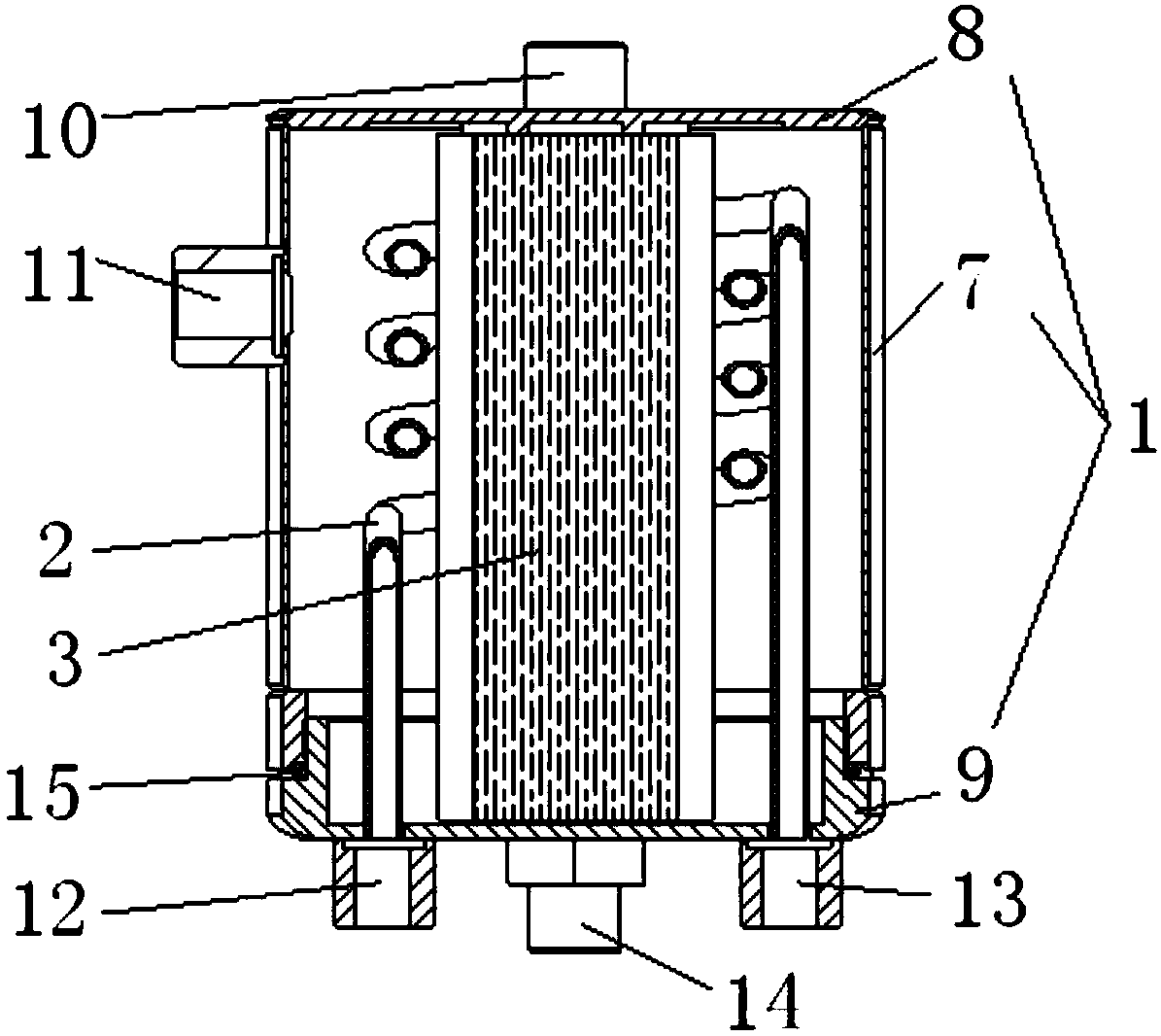

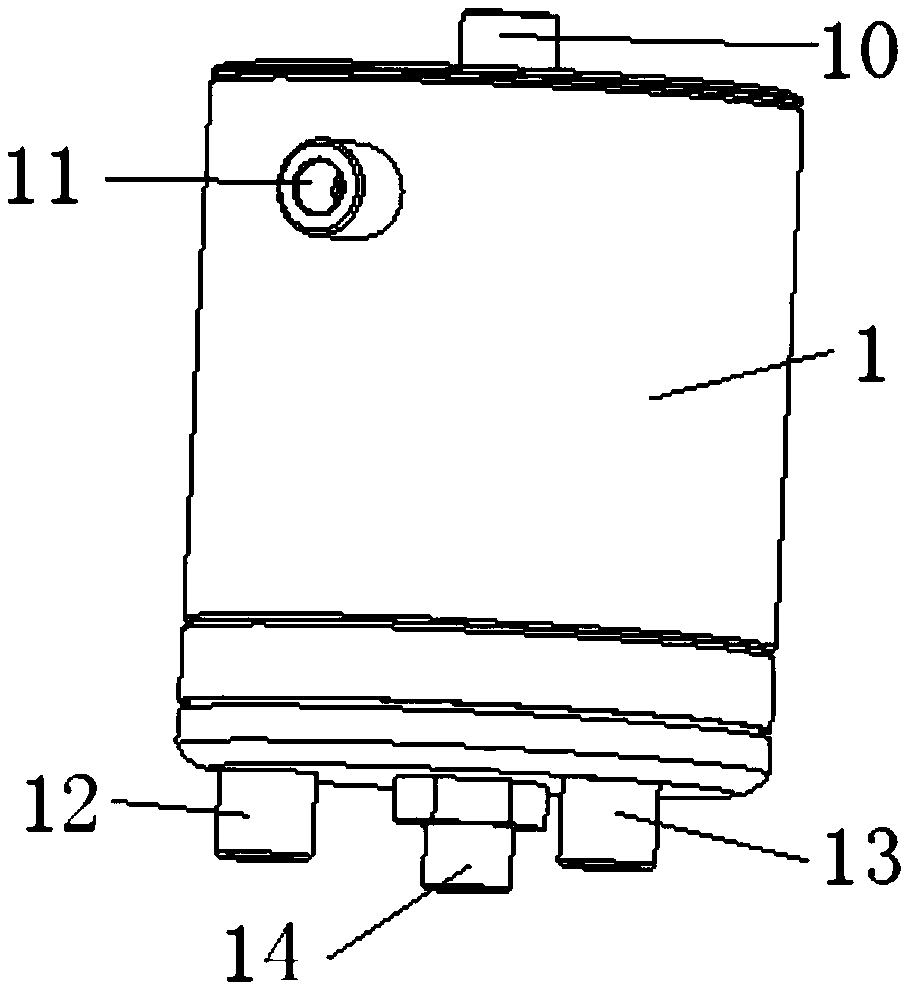

[0018] Such as Figure 1~3 As shown, an electric water boiler includes a boiling water tank, a condensation cylinder 1, a condensation pipeline 2 and a filter element 3, the condensation pipeline 2 and the filter element 3 are both arranged in the condensation cylinder 1, and the condensation pipeline 2 surrounds The filter element 3 is set. In order to increase the contact area between the condensing pipeline 2 and the filter element 3, the condensing pipeline 2 is spirally arranged around the filter element 3. The condensing cylinder 1 is provided with a water source inlet 10, a water source outlet 11, steam Water inlet 12, condensation water outlet 13 and drain outlet 14, described water source water inlet 10 is communicated with filter element 3, and filter element 3 is communicated with the car body water tank 4 on the bullet train through water source water inlet 10, and car body water tank 4 is that filter element 3 conveys to wait Heating water, the heated water flows ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap