Bicolor double-colorful strip optical cable and extruder mold thereof

A technology of extruder and color strip, which is applied in the field of double-color double-color strip optical cable and its extruder mold, which can solve the problems of increased installation, maintenance and testing, and difficult identification, and achieve the effect of reducing production processes and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

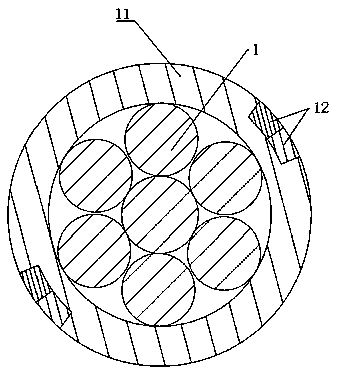

[0041] A double-color double-color strip optical cable, such asfigure 1 , comprising a cable core 1 and an outer sheath 11 arranged outside the cable core 1, two colored stripes are arranged on the outer wall of the outer sheath 11, and the colored stripes are embedded in the outer sheath 11, when the colored stripes are embedded in the outer sheath 11 , the outer wall of the color bar and the outer wall of the outer sheath 11 are on the same cylindrical surface, and each color bar is composed of two color bars 12 of different colors. At this time, one color bar is composed of two kinds of color bars 12 , which can quickly identify the optical cable, which is different from the optical cable without color marking and the optical fiber cable marked with a single color.

Embodiment 2

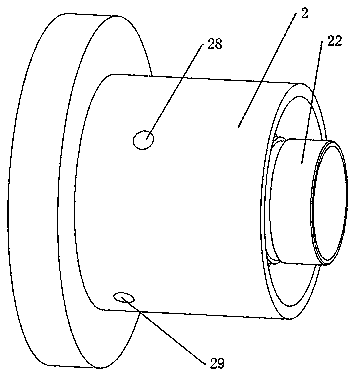

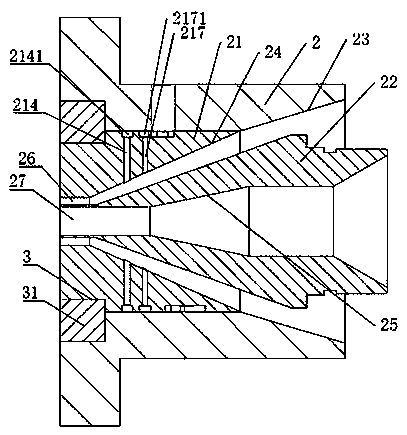

[0043] A kind of extruder mold that manufactures above-mentioned embodiment 1, as figure 2 and image 3 , including the outer mold casing 2, the outer module 21 embedded in the outer mold casing 2, the inner module 22 arranged in the outer module 21, and the outer mold casing 2, the outer module 21 and the inner module 22 are respectively provided with coaxially distributed conical The first feed hole 23, the second feed hole 24, the third feed hole 25, the taper of the first feed hole 23 is greater than the taper of the second feed hole 24, to facilitate the entry of the outer sheath 11 material, the outer sheath The module 21 and the inner module 22 are respectively provided with a coaxially distributed first discharge port 26 and a second discharge port 27 communicating with the second feed hole 24 and the third feed hole 25. The first discharge port 26 There is a first gap between the second discharge port 27, which is convenient for the removal of the outer sheath 11 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com