Heat-transfer characteristic testing device for nuclear reactor engineering level dual-layer melting pool

A nuclear reactor and test device technology, which is applied in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve problems such as the inability to obtain the characteristic parameters of the molten pool, the small size, and the inability to reflect the solidification characteristics of the non-eutectic mixture of the molten material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

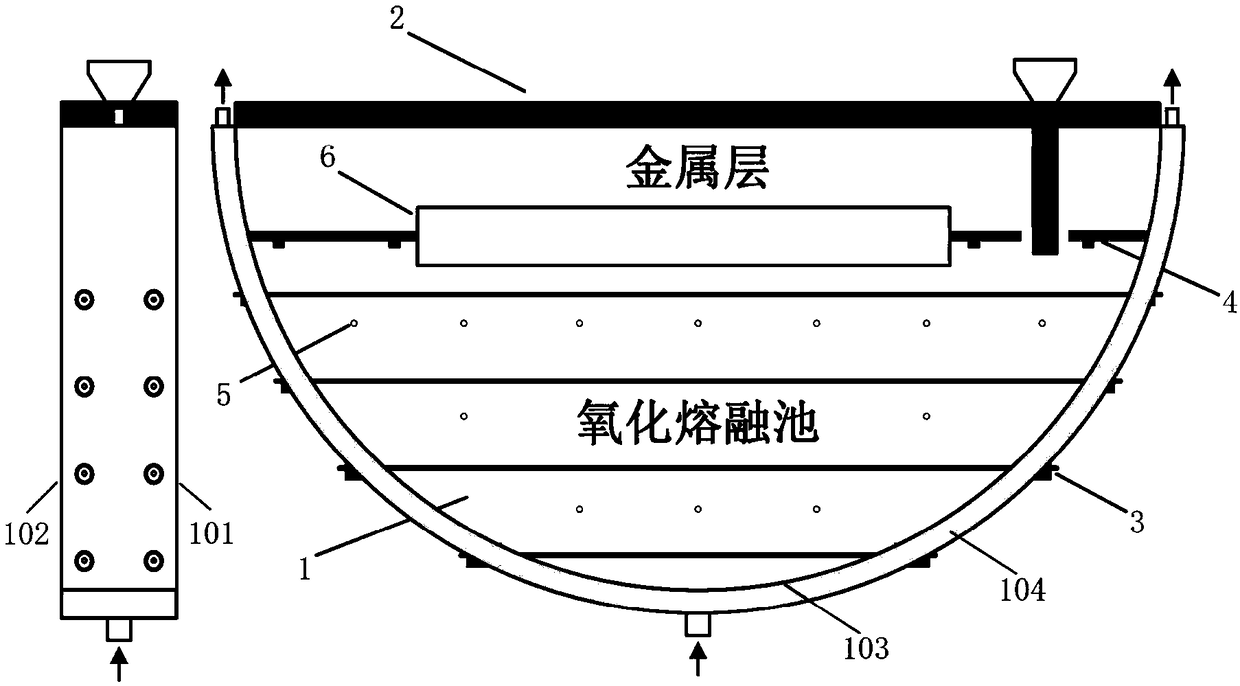

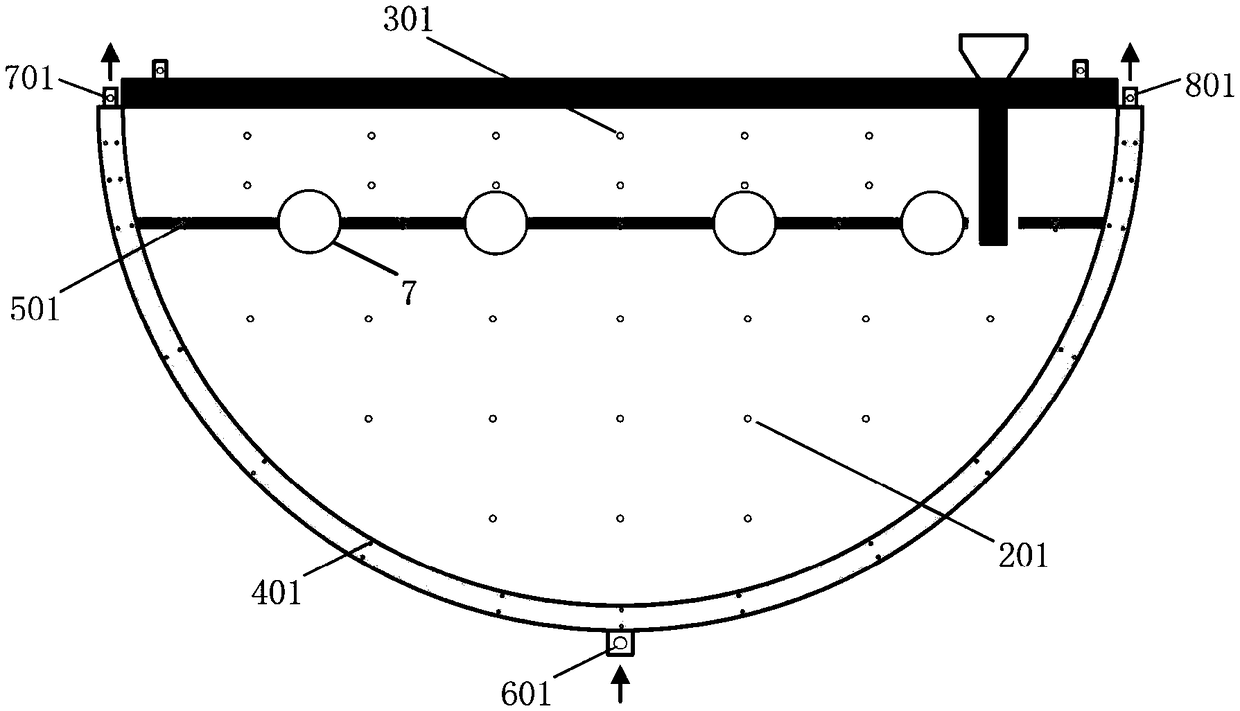

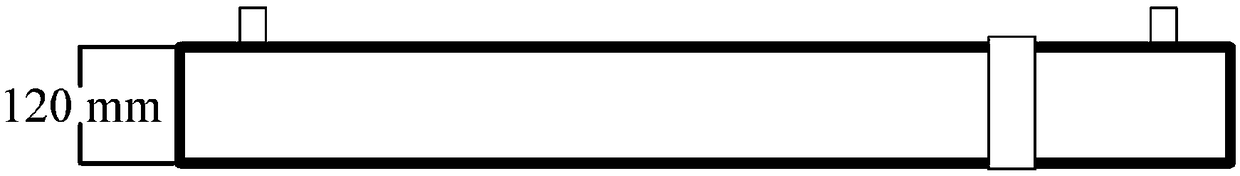

[0024] like figure 1 As shown, the present invention relates to a nuclear reactor engineering level double-layer molten pool heat transfer characteristic test device, including a test section 1, a cover plate 2, an electric heating element 3, a partition plate 4 and a corresponding temperature measuring component 5. Test section 1 is a semicircular slice structure based on the lower head of the real reactor pressure vessel. It is welded by the front side wall 101, the rear side wall 102 and the arc wall 103, with a diameter of 4000mm and an inner width of 300mm. There is a rectangular quartz glass window 6 on the upper part of the front side wall 101, which is used to observe and record the convective heat transfer and hard shell condensation characteristics at the interface of the double-layer molten pool during the test. There are four lighting holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com