Grinding device and sanding equipment

A technology of sanding and grinding mechanism, applied in the field of sanding, can solve the problems such as the inability to effectively control the sanding power, and achieve the effect of avoiding sand leakage and sand passing.

Pending Publication Date: 2019-03-26

北京启醒科技有限公司

View PDF18 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a grinding device and sanding equipment to alleviate the technical problem in the prior art that the sanding force of a manual sander cannot be effectively controlled

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0074] This embodiment provides a sanding equipment, including the sanding device mentioned in the first embodiment. Since the sanding equipment includes a sanding device, it has all the beneficial effects of the sanding device. In order to save space, it will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

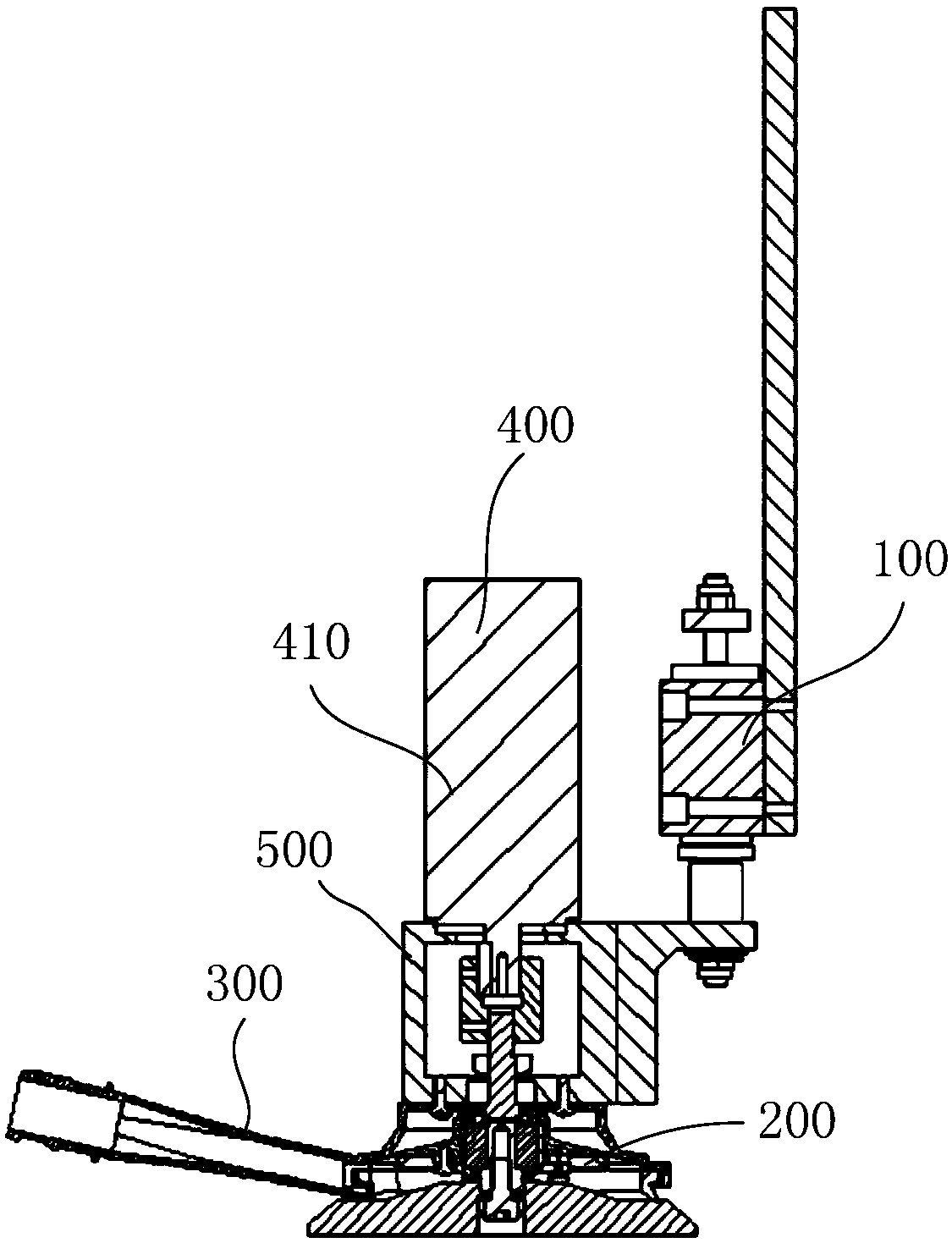

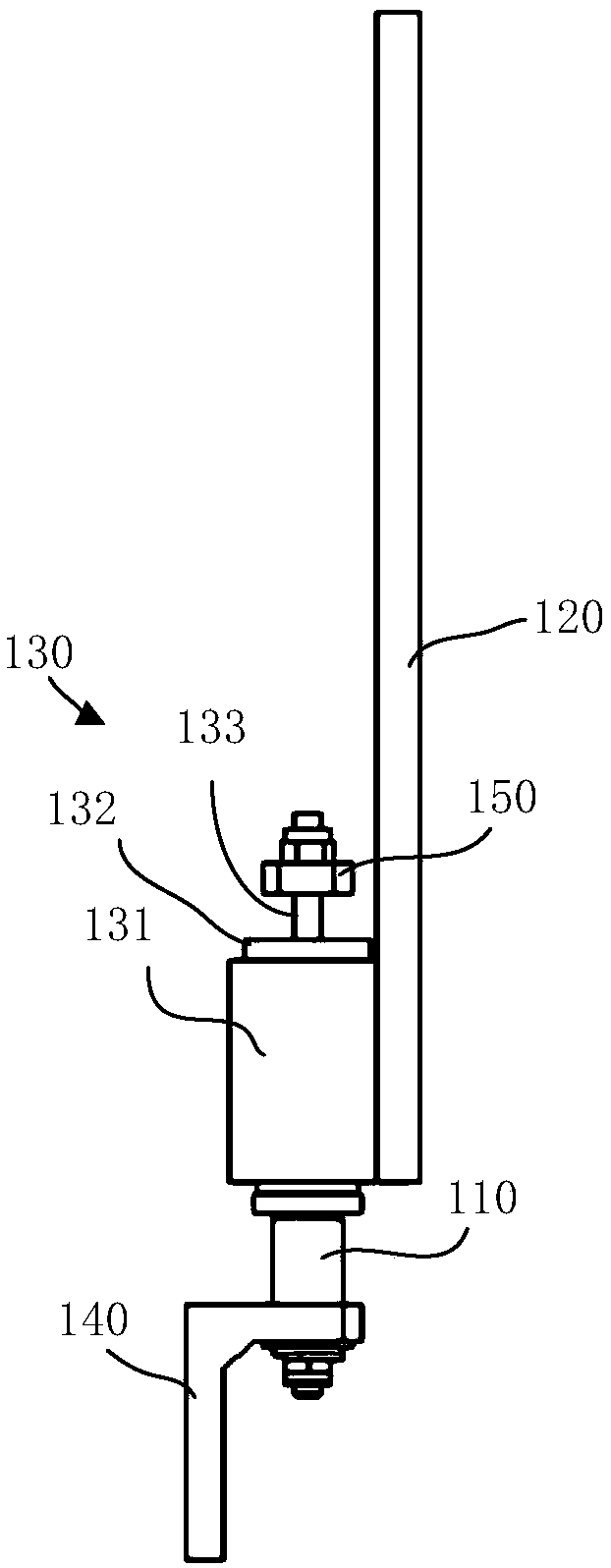

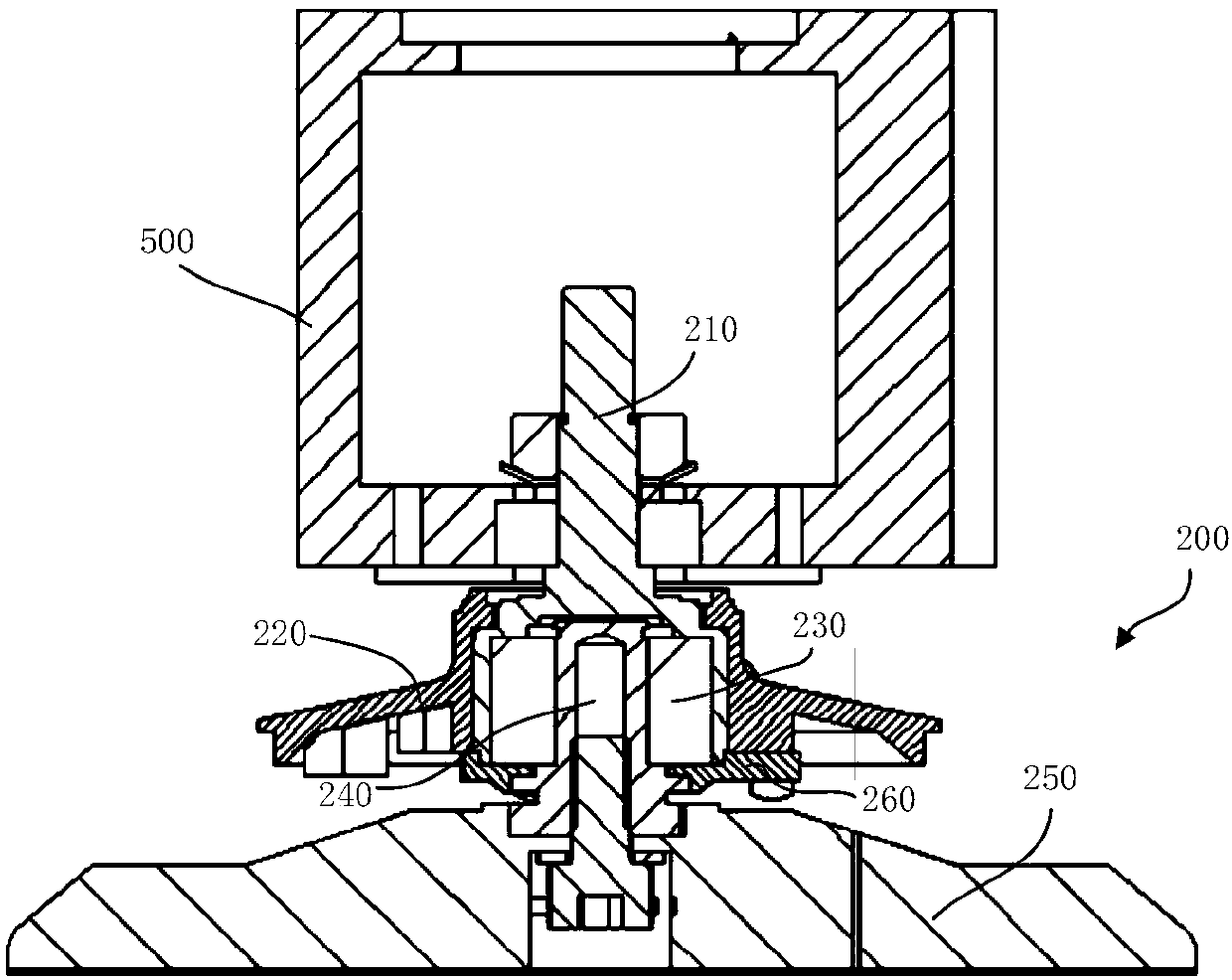

The invention relates to the technical field of sanding, in particular to a grinding device and sanding equipment. The technical problem that in the prior art, the sanding force of a manual sanding machine cannot be effectively controlled is solved. The grinding device comprises a grinding mechanism and a pressure control mechanism, wherein the grinding mechanism is used for performing grinding operation on a to-be-ground surface; and the pressure control mechanism is connected with the grinding mechanism and comprises a compression spring, and the compression spring is pre-compressed for a distance of travel so as to make the grinding mechanism always have the elastic force for flexibly adjusting the sanding force. By means of the technical scheme provided by the invention, the sanding force can be automatically adjusted according to the unevenness and the depth of the to-be-sanded surface, and the problem of sanding omission and excessive sanding is effectively avoided.

Description

Technical field [0001] The invention relates to the technical field of sanding, in particular to a polishing device and sanding equipment. Background technique [0002] Existing sanding equipment (sanding and sanding are synonymous) usually use belt-type wide sanding rollers to sand wooden boards. Because sanding paint surfaces generally require a higher number of sanding belts, the sanding belt has a short use time and is replaced. The frequency is high and the cost is high. [0003] A manual sander can also be installed on the sanding equipment for sanding the surface of the board, but there are several problems. One is that the connection with the equipment is not strong. Because the manual sander is not specially installed on the sanding equipment, so After being used for a period of time in a vibrating environment, the looseness of the connection will easily cause the board to leak. Second, it is inconvenient to control the sanding force, and it is easy to cause excessive sa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B19/00B24B41/06B24B55/06

CPCB24B19/00B24B41/06B24B55/06

Inventor 李金龙黄旭何激淼李林杰赵森赵金凯

Owner 北京启醒科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com