A combined sample preparation device and method for microbial batch reinforcement of sandy soil

A technology of microorganisms and sand, which is applied in the preparation of test samples, etc., can solve the problems of uneven solidification degree in the axial direction of sand columns and difficulty in preparing sand columns, so as to enhance physical and mechanical properties, maintain mechanical properties, and prevent sand leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

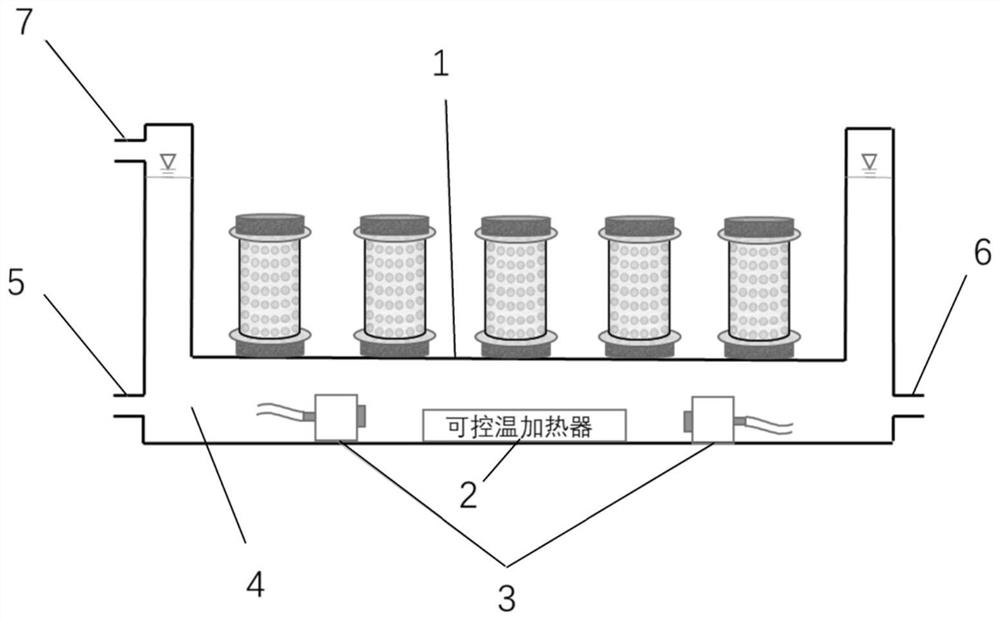

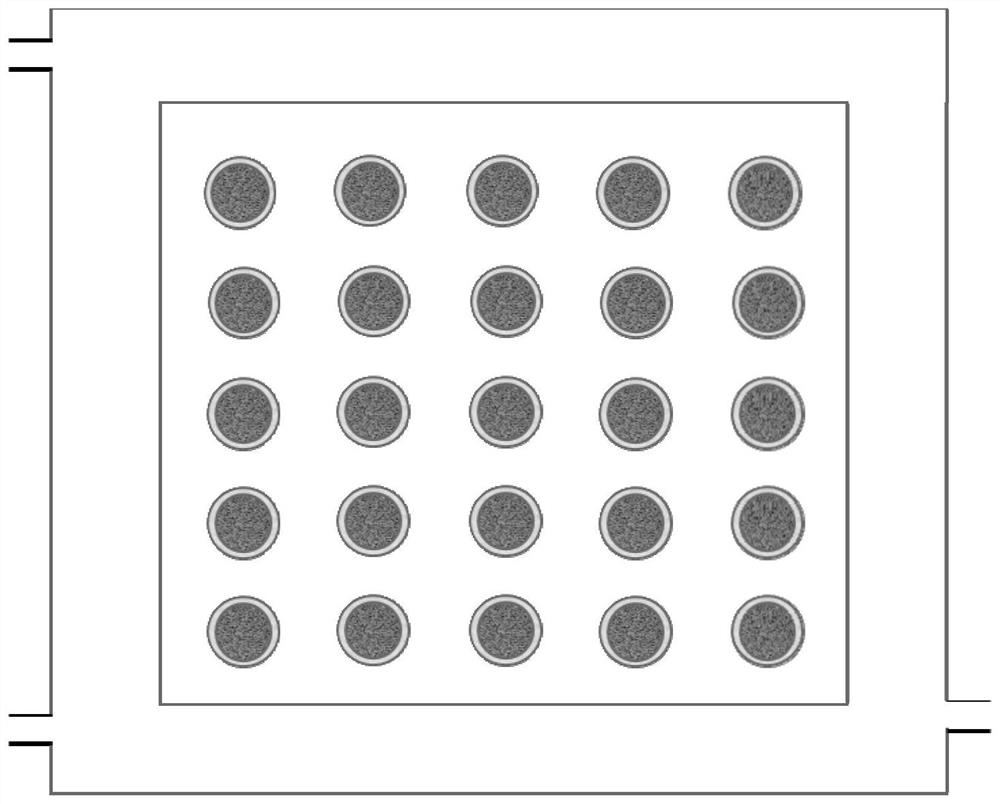

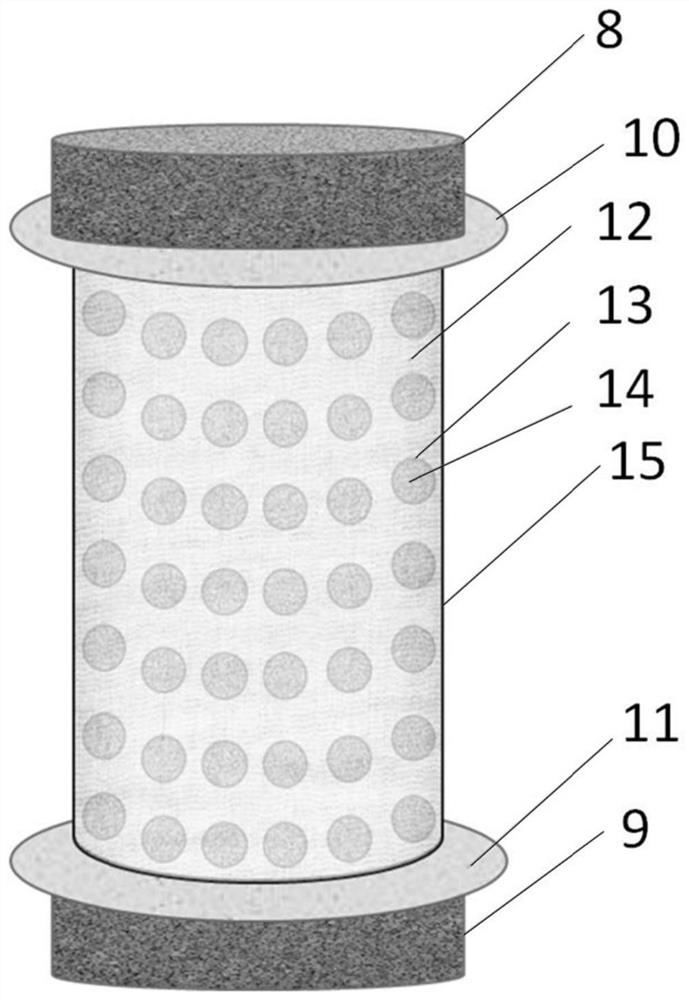

[0071] Such as Figure 1~3 As shown, the sample preparation device of a kind of microbial batch reinforcement sand used in the present invention comprises a cement curing box 1, a sand filling mold combination and a sample loading tool; wherein, the cement curing box includes a interlayer water tank 4, an interlayer water tank 4 Inside is equipped with a temperature-controllable heater 2 and a circulating water pump 3; the sand-filled mold assembly placed in the cement curing box 1 includes a soft plastic tube 12, the outer wall of which is wrapped with gauze 15, the upper and lower openings of the soft plastic tube 12, and the side wall Open air holes 13 with a diameter of 5 mm, and the air hole interval is 5 mm; it also includes filter paper and permeable stones that cover the upper and lower openings of the soft plastic tube 12 in sequence.

[0072] The loading tool adopts Figure 4~7 As shown in the device, the sample loading tool is composed of a hollow semicircular tabl...

Embodiment 2

[0096] The device and steps in this embodiment are basically the same as in Embodiment 1, the difference is that an air pump is installed in the cementing curing box 1 to feed air into the bacteria liquid and the cementing liquid; every filling 1 cm uses a soft plastic with a cross-sectional diameter less than or equal to The metal rod with the inner diameter of the pipe 12 is pressed on the surface of the sand, and the metal rod is hit 10 times with a 1kg hammer at a speed of 2 times per second. The initial dry density ρ of the sand filling is 1.0g / cm 3 In step F, the cementing liquid is cooled to 10°C and then added to the curing box, and the sample is allowed to stand in it for 2 hours, and then the heating thermostat is adjusted to 30°C; in step G, repeat steps E and F twice; The stresses and corresponding strains experienced during uniaxial compression are shown in Table 2.

[0097] Table 2 Comparison of uniaxial compressive strength of calcareous sand in the South China ...

Embodiment 3

[0101] The device and steps in this embodiment are basically the same as those in Example 1, except that the diameter of the pores on the wall of the soft plastic pipe is 8mm, and the distance between the pores is 8mm; the cross-sectional diameter of each filling 1cm is less than or equal to the inner diameter of the soft plastic pipe 12 Press the metal rod on the sand surface, and hit the metal rod 10 times with a 1kg hammer at a speed of 2 times per second. The initial dry density ρ of the sand filling is 1.0g / cm 3 In step F, the cementing liquid is cooled to 10°C and then added to the curing box, and the sample is allowed to stand in it for 1 hour, and then the heating thermostat is adjusted to 30°C; in step G, repeat steps E and F twice; The stresses and corresponding strains experienced during uniaxial compression are shown in Table 3.

[0102] Table 3 Comparison of uniaxial compressive strength of calcareous sand in the South China Sea before and after reinforcement

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com