Detergent box assembly and washing machine

A detergent box and component technology, applied in the field of washing machines, can solve the problems of affecting the normal use of the detergent box, blocking the siphon outlet, siphon failure, etc., achieving the effects of low cost, avoiding blockage, and avoiding time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order for those skilled in the art to better understand the technical solutions of the present invention, the technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

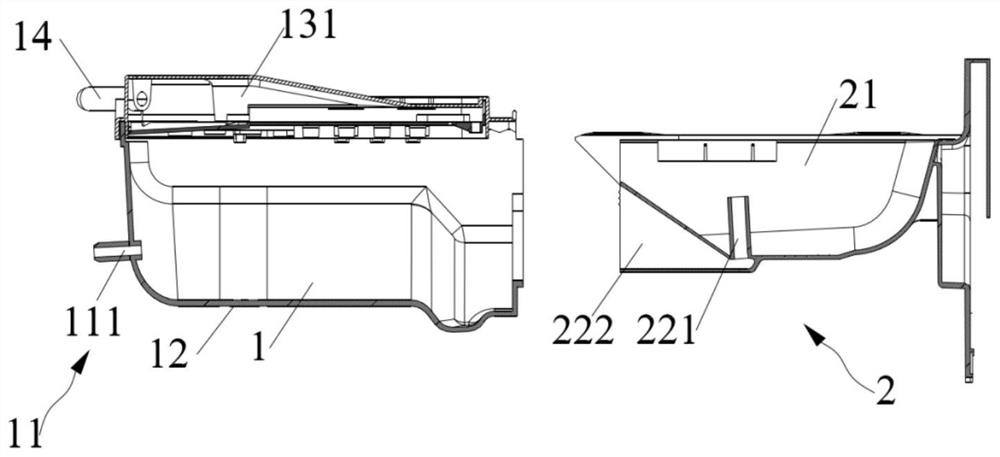

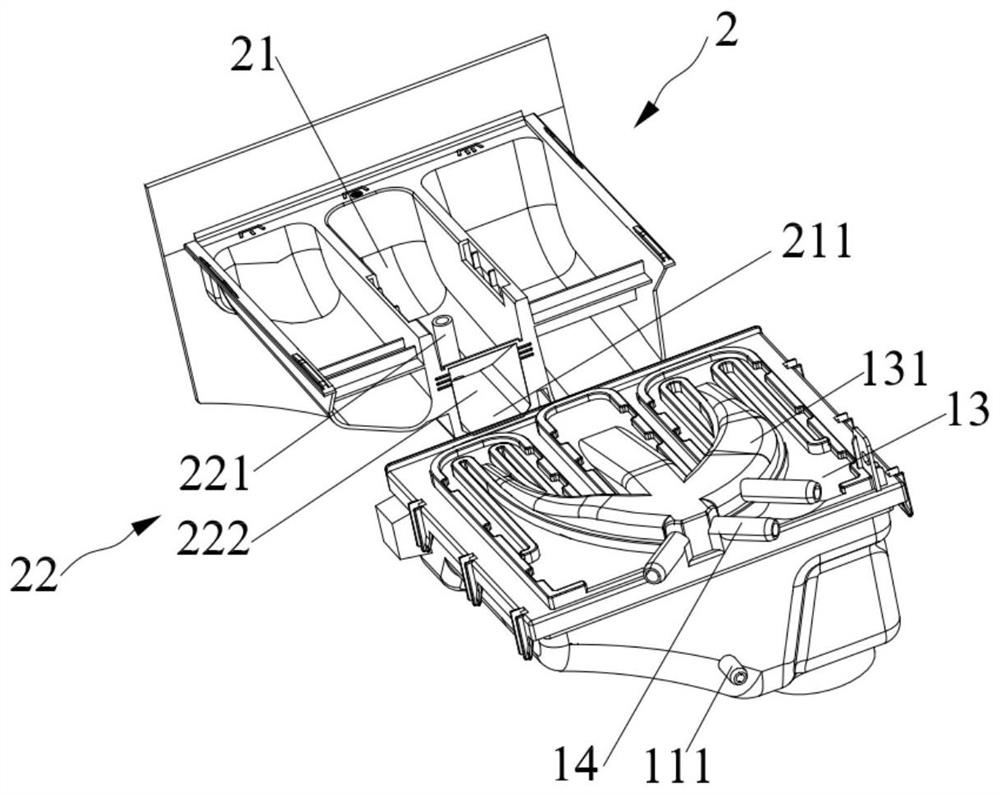

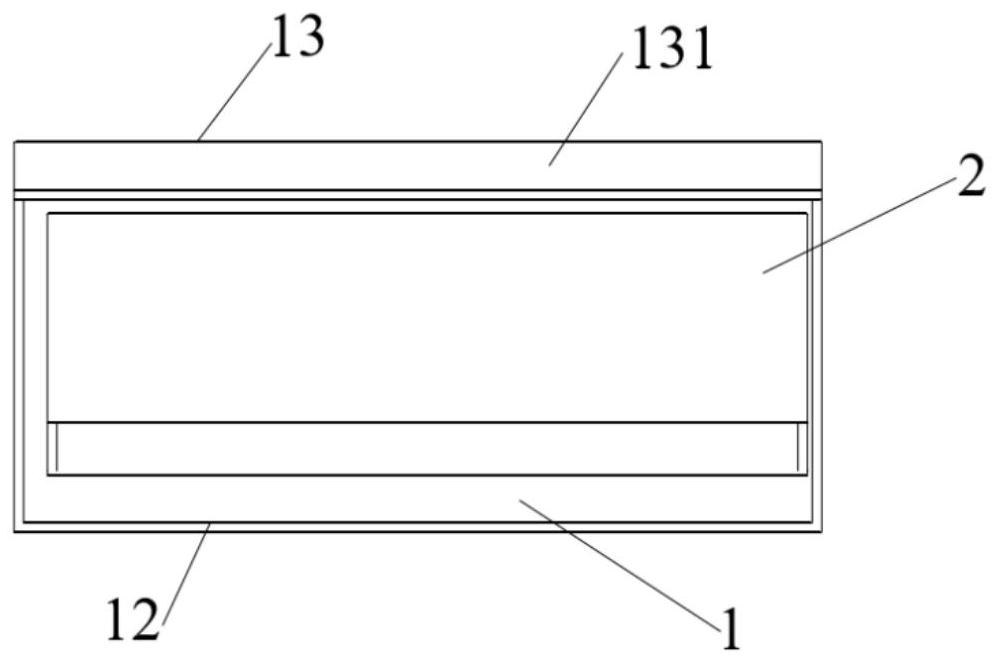

[0027] This embodiment provides a detergent box assembly, such as Figure 1-Figure 3 As shown, it includes a detergent box chamber 1 and a detergent box 2 drawn into the detergent box chamber 1. The detergent box 2 is provided with a dispensing cavity 21, and the dispensing cavity 21 is provided with a The siphon tube 22 is provided with a cleaning part 11 communicating with the siphon tube 22 in the detergent box chamber 1 , for flushing the siphon tube 22 .

[0028] The siphon pipe member 22 in this embodiment can suck the mixture of the clothing care agent and water put into the injection cavity 21 into the siphon pipe member 22 through the siphon effect, and then discharge it into the washing tub; by inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com