Novel high-speed eddy current pulping machine and preparation method thereof

A pulping machine, high-speed technology, applied in the field of new high-speed eddy current pulping machine and its preparation, can solve the problems of increased consumption of manpower and material resources, uneven slurry quality, uneven mixing, etc., to achieve environmental protection, structure Reasonable layout and convenient pulping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

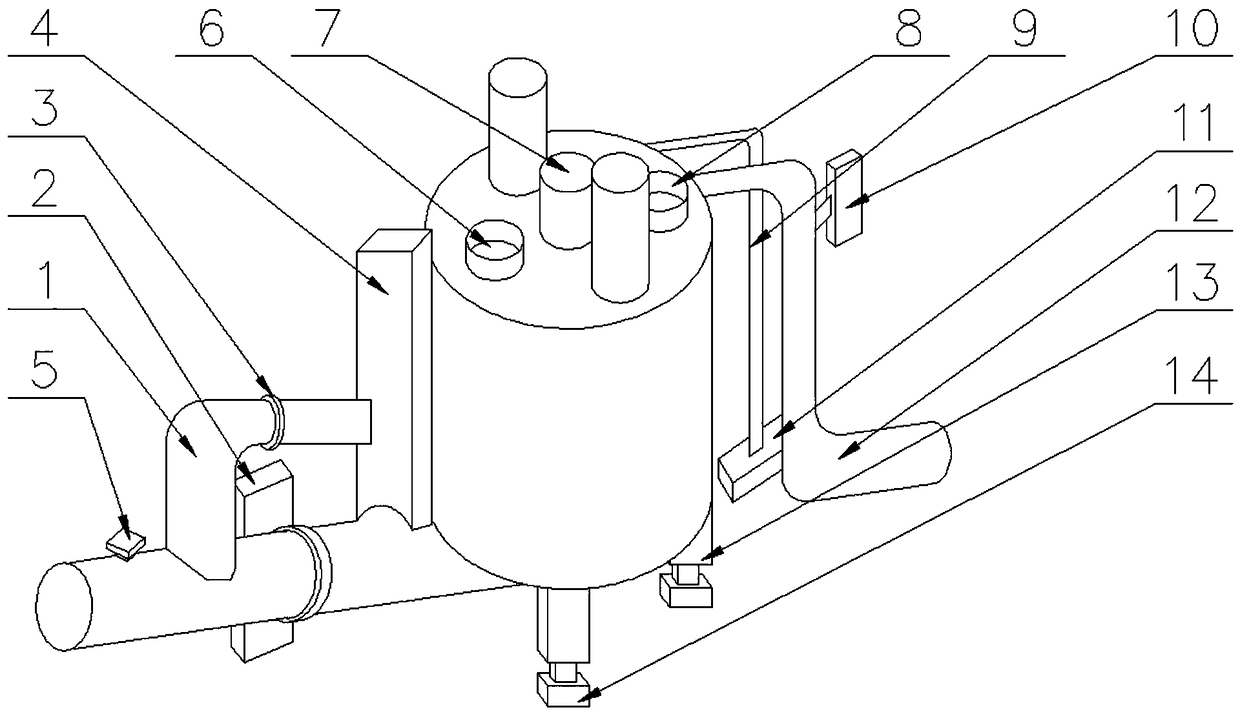

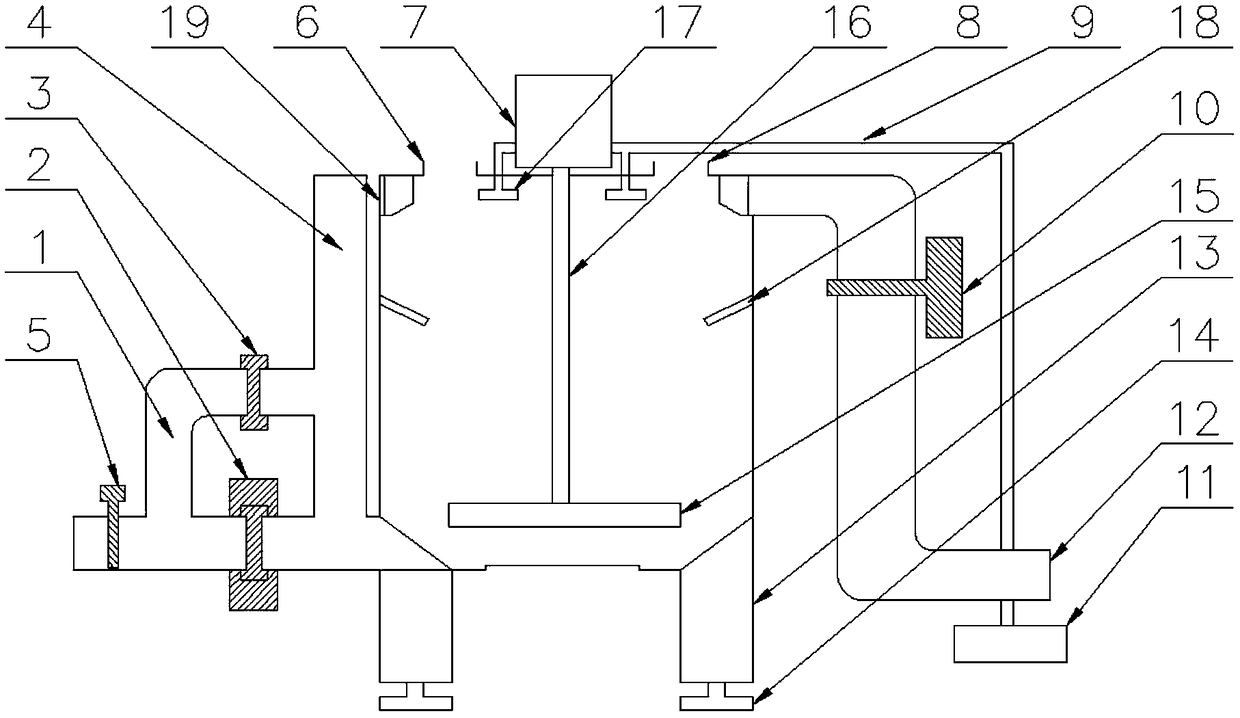

[0032] Provide a new type of high-speed vortex pulping machine, including a mixing tank 19, the upper surface of the mixing tank 19 is provided with a feeding port 8 and an exhaust port 6, the upper surface of the mixing tank 19 is also provided with a high-speed variable frequency motor 7, the mixing tank The lower surface of 19 is provided with supporting legs 13, and the side of mixing bucket 19 is provided with a first overflow pipe 4, and the second overflow pipe 1 is fixedly connected to the first overflow pipe 4, and the second overflow pipe 1 1 is provided with a tuning fork density meter 5, the second overflow pipe 1 is provided with an upper pipe and a lower pipe, the second overflow pipe 1 is provided with a first valve 3 and a second valve 2, and the first valve 3 is provided with On the upper pipeline, the second valve 2 is arranged on the lower pipeline, the side of the mixing bucket 19 is also provided with a liquid inlet pipe 12, and the inner wall of the mixing...

Embodiment 2

[0040] Also provided is a method for preparing a novel high-speed vortex pulper, characterized in that the method includes the following steps:

[0041] a. Fill the mixing tank 19 with powder and clear water, start the high-speed variable frequency motor 7, and the stirring plate 15 will evenly stir the powder and clear water;

[0042] b. The stirred slurry first enters the first overflow pipe 4, then enters the second overflow pipe 1, and the slurry flows out from the second overflow pipe 1;

[0043] c. the tuning fork density meter 5, the flow sensor 10 and the load cell 14 transmit data to the terminal, and monitor the production situation of the slurry in the mixing tank 19 in real time;

[0044] d. Open the second valve 2 after the pulping is finished, so that the remaining slurry in the first overflow pipe 1 , the second overflow pipe 4 and the mixing tank 19 flows out.

[0045] The working process of this example:

[0046]The powder enters the mixing tank 19 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com