Visual recognition detection system for automobile fuse block

A fuse box and detection system technology, applied in the field of auto parts, can solve problems such as low efficiency of detection devices, achieve automatic switching and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

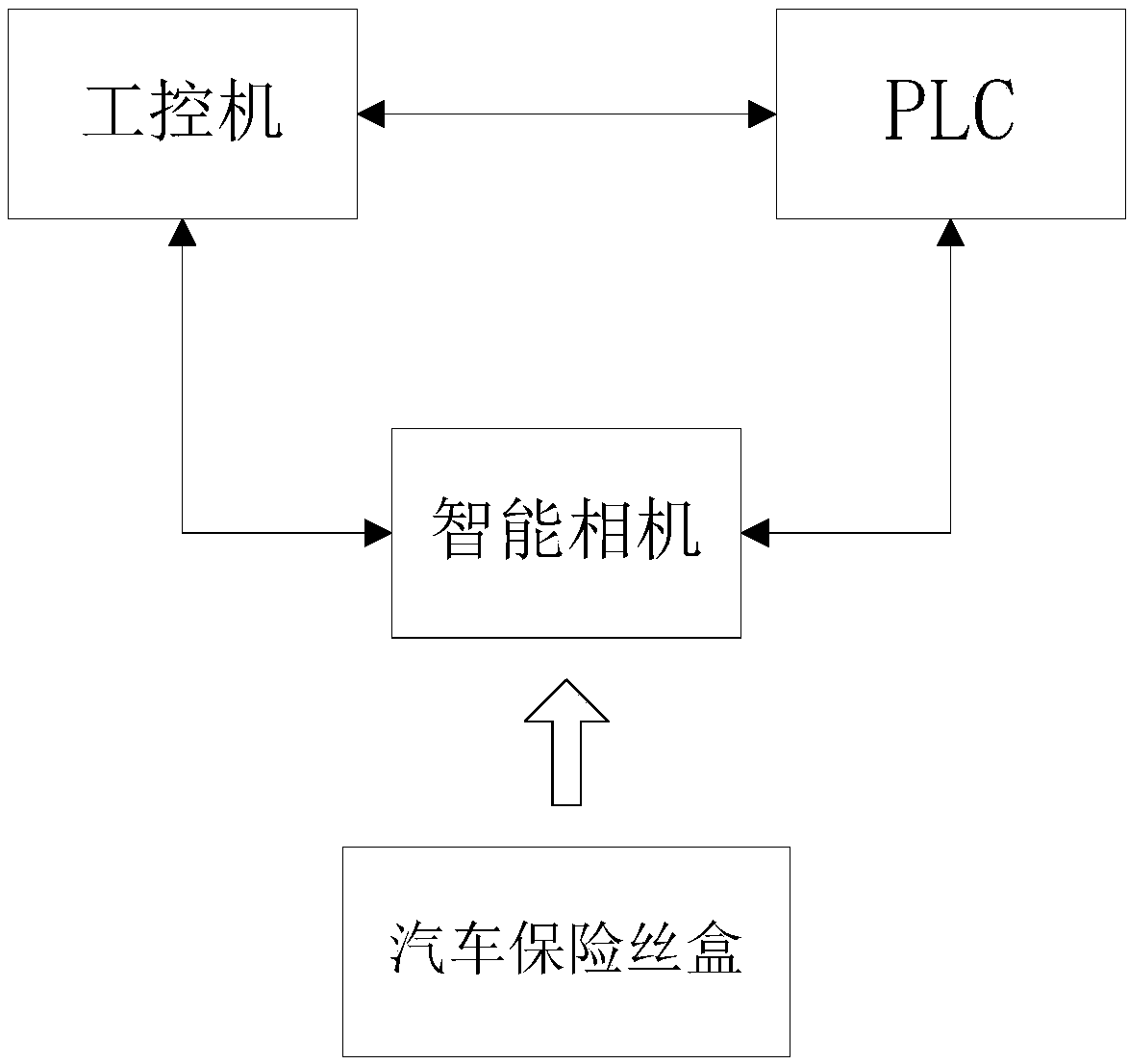

[0016] According to one or more embodiments, such as figure 1 Shown. A visual recognition and detection system for an automobile fuse box. The detection system includes an industrial computer, a PLC, and a smart camera. The smart camera is equipped with an image recognition system. Industrial computer and PLC are connected through serial communication, PLC and smart camera are connected through serial communication, and smart camera and industrial computer are connected through serial communication.

[0017] The smart camera takes an image of the fuse in the car's fuse box and sends the recognition result of the fuse to the industrial computer. At the same time, the smart camera sends the recognition result to the PLC, and the PLC judges whether the image of the tested product is qualified. If it is qualified, the PLC control fixture exits, the green qualified light is turned on, and the smart camera tells the industrial computer to cut the photo of the test to Specify the targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com