Patents

Literature

65 results about "Fuse (automotive)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automotive fuses are a class of fuses used to protect the wiring and electrical equipment for vehicles. They are generally rated for circuits no higher than 32 volts direct current, but some types are rated for 42-volt electrical systems. They are occasionally used in non-automotive electrical products.

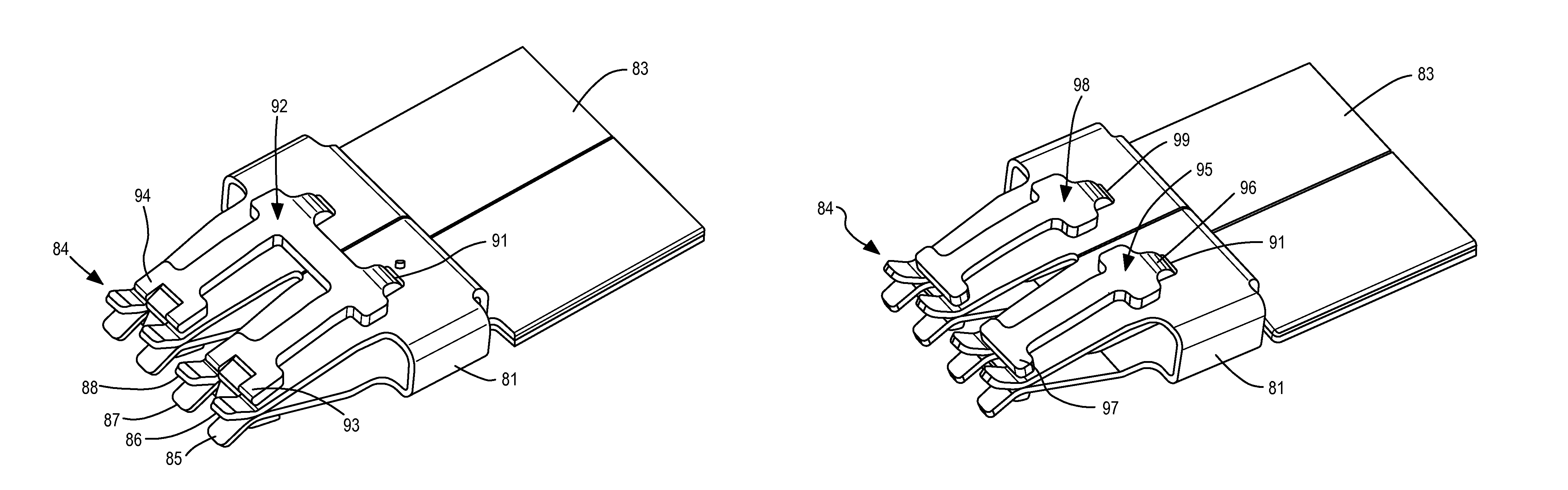

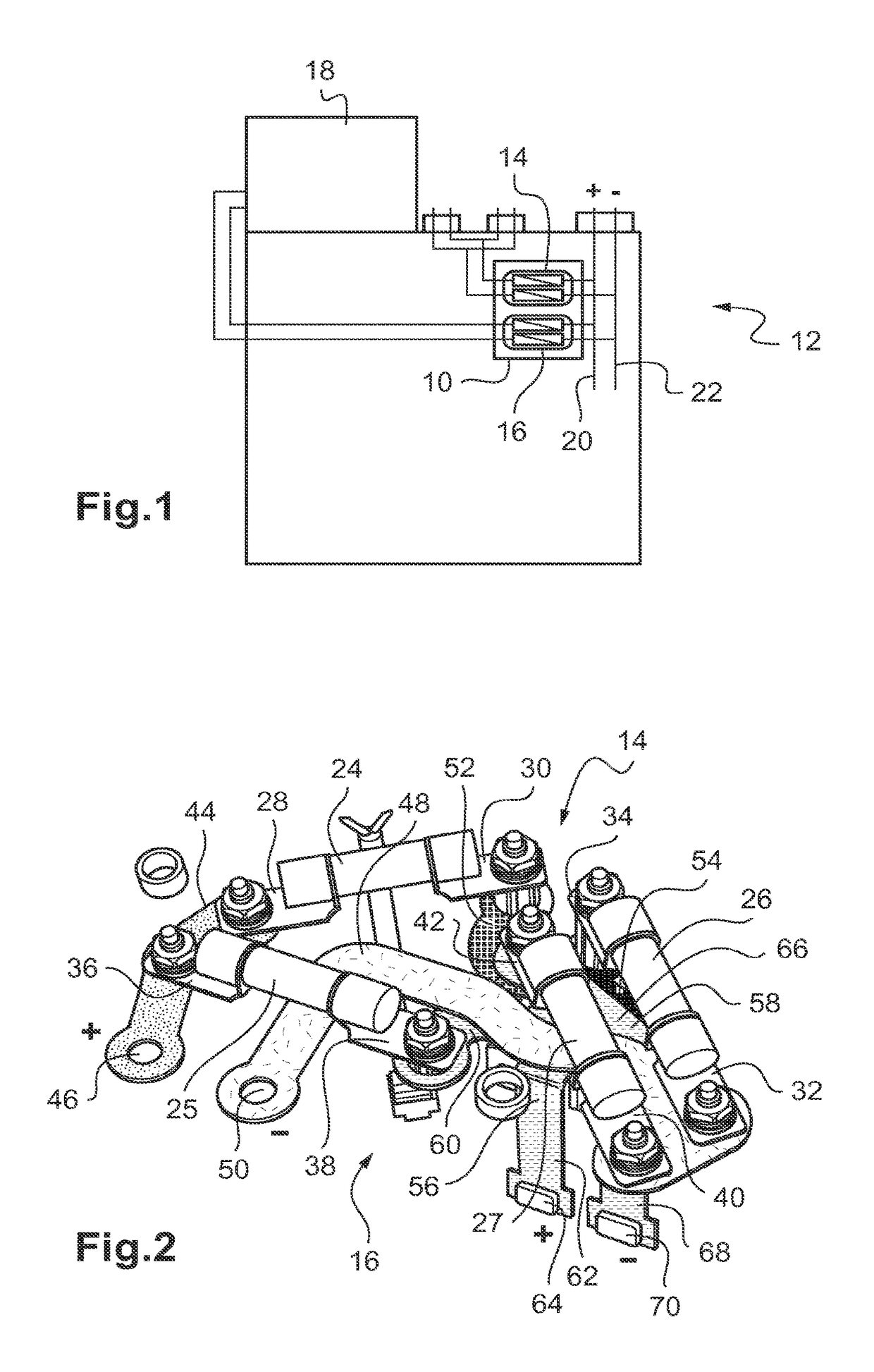

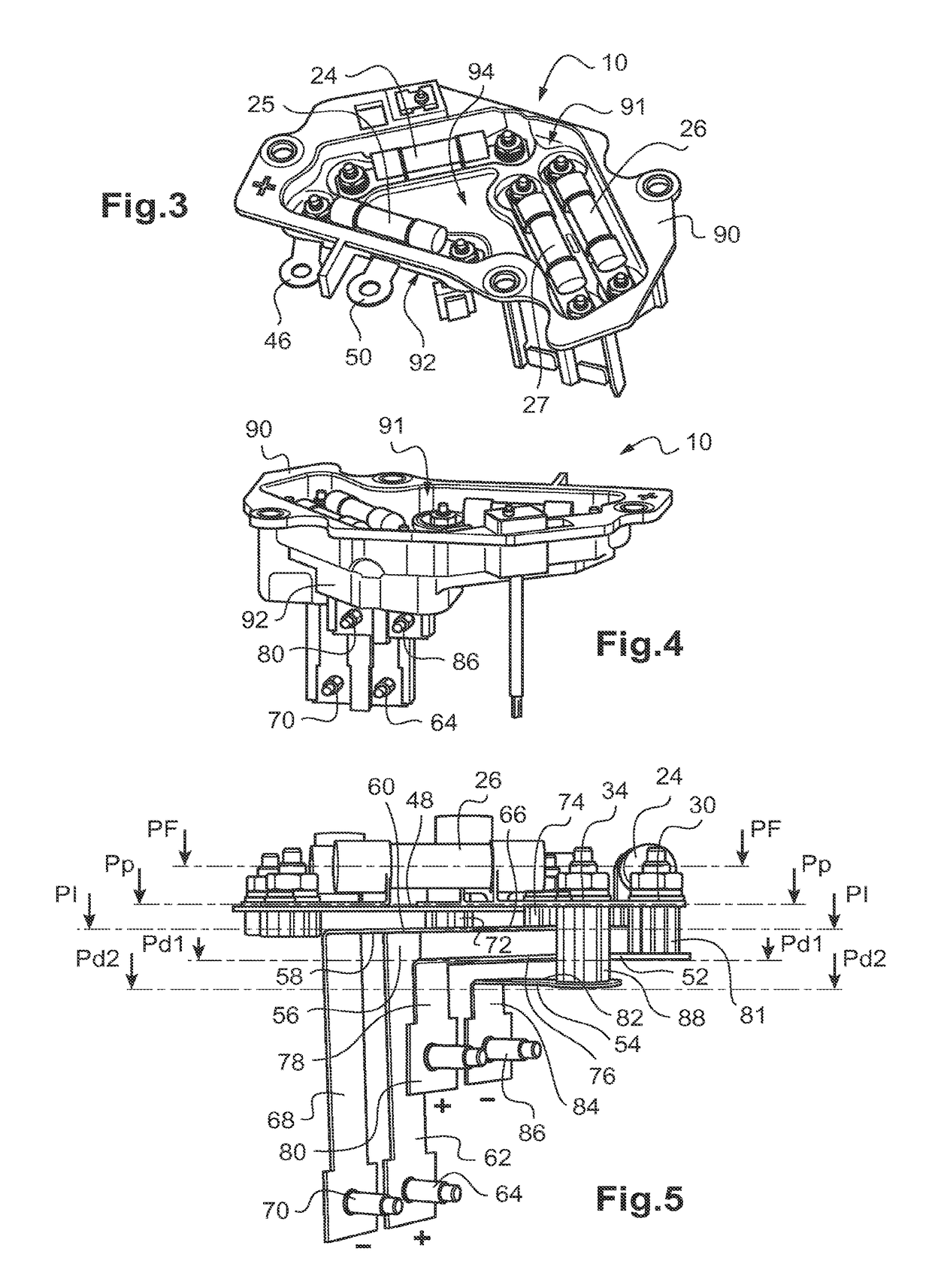

High power fuse terminal with scalability

ActiveUS7892050B2Incorrect coupling preventionCoupling contact membersHigh conductivityFuse (automotive)

Owner:LEAR CORP

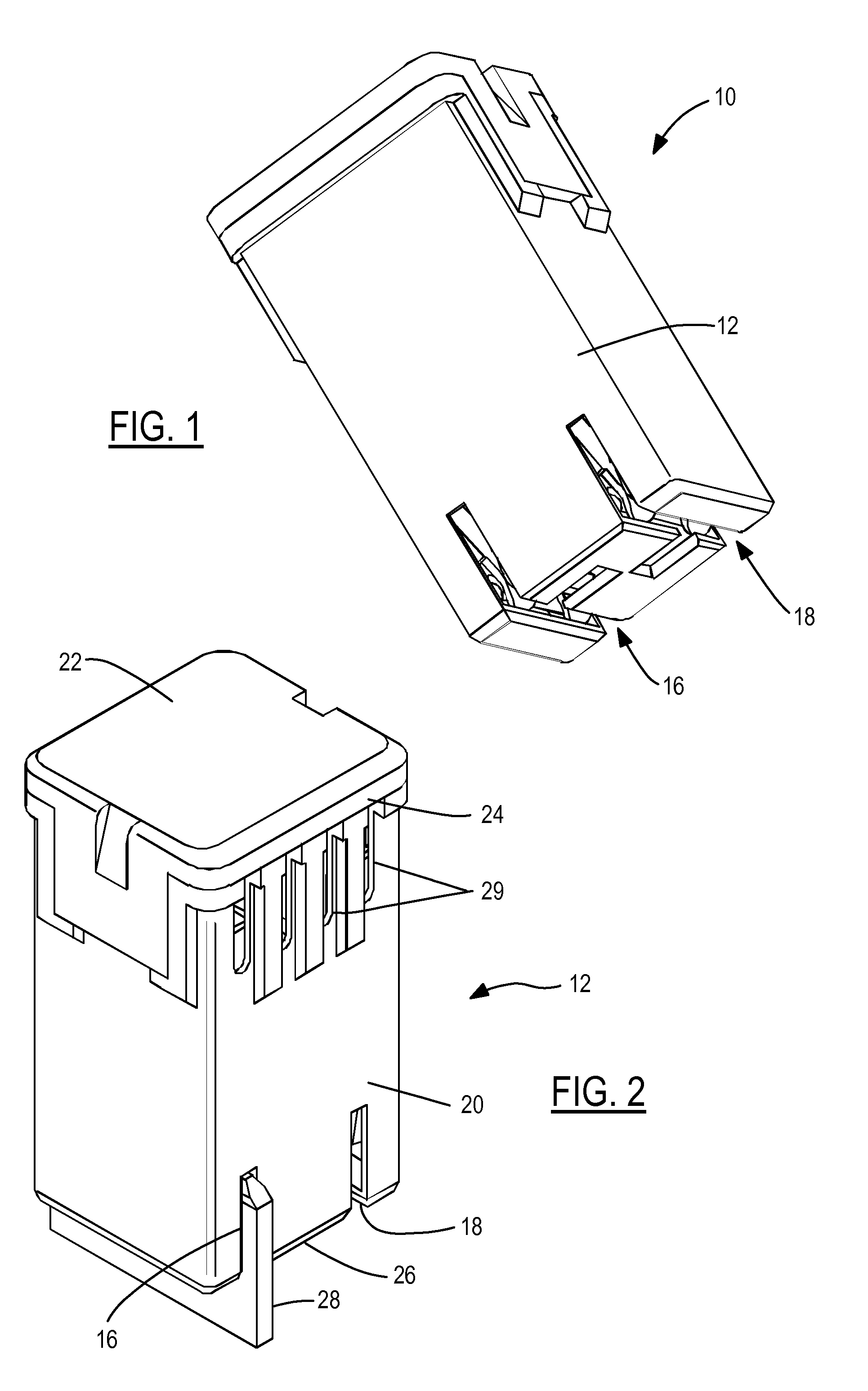

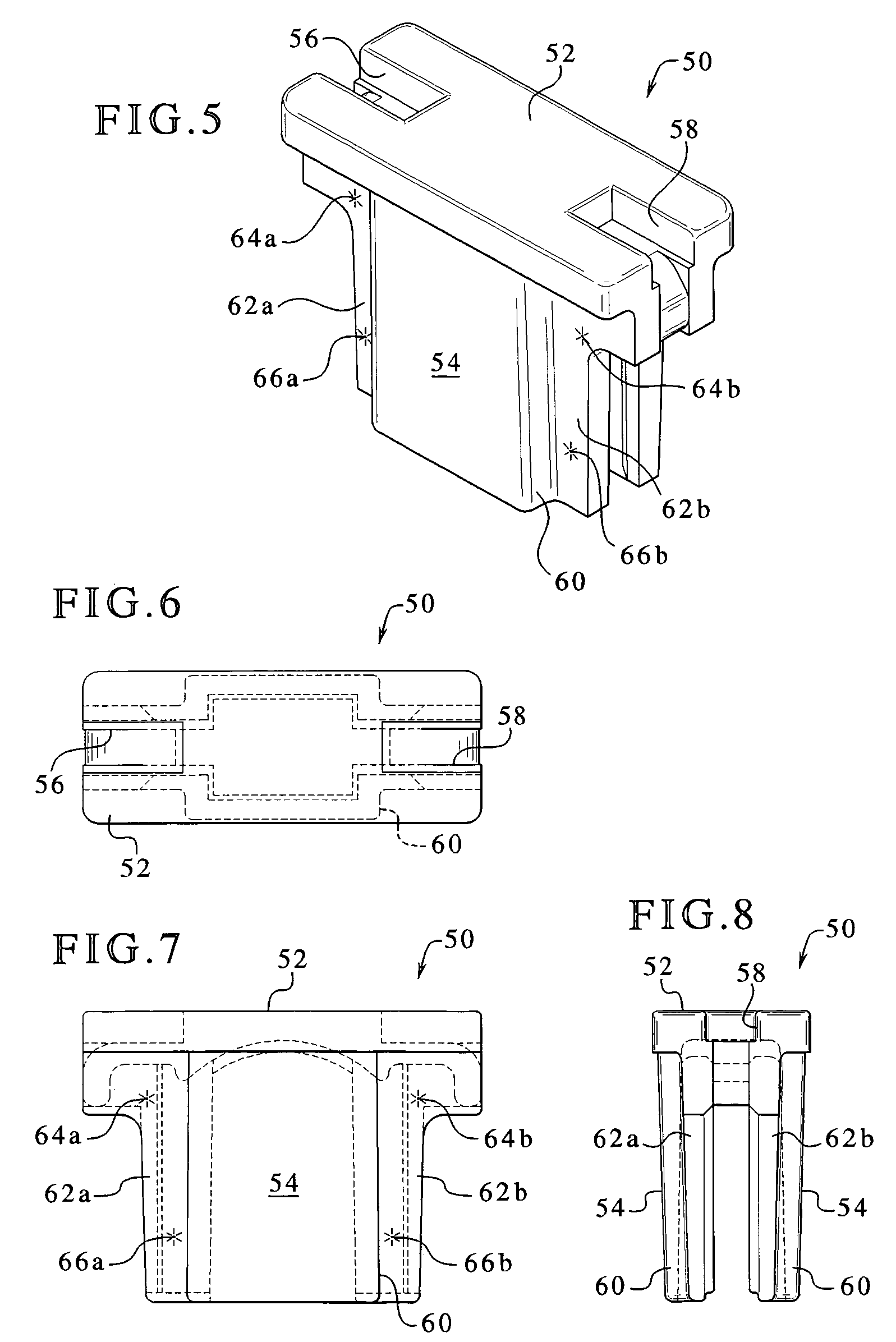

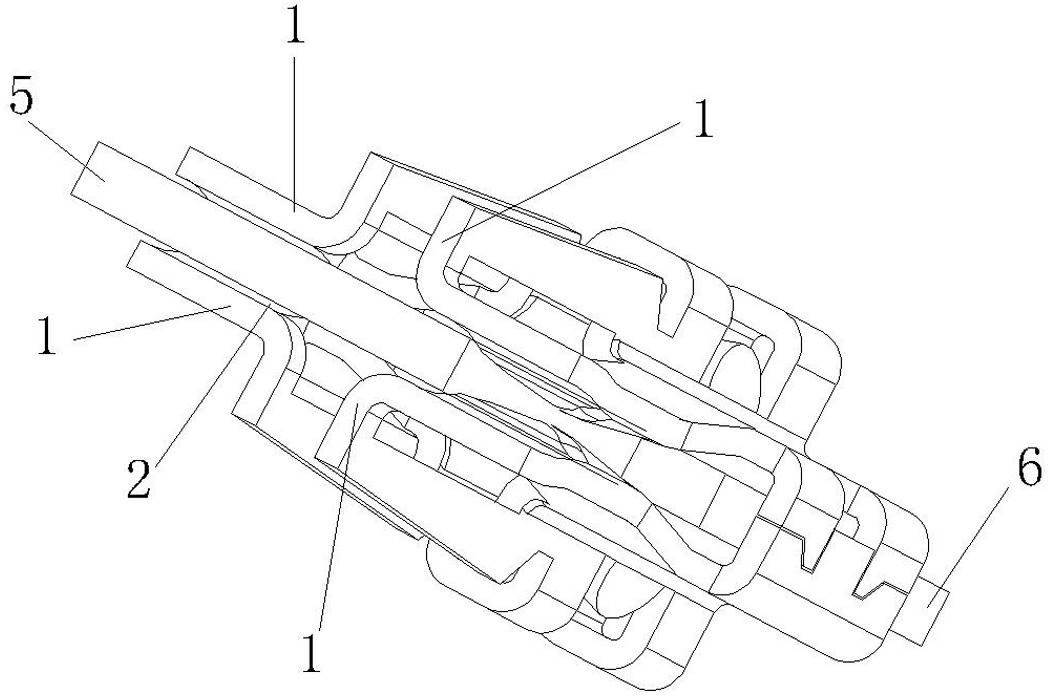

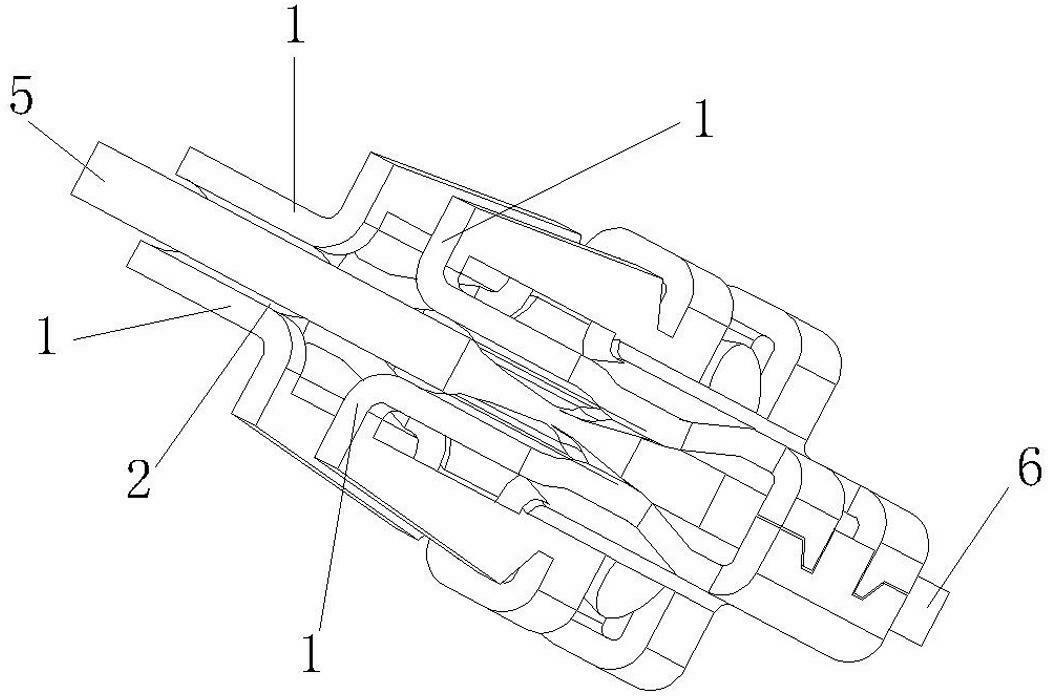

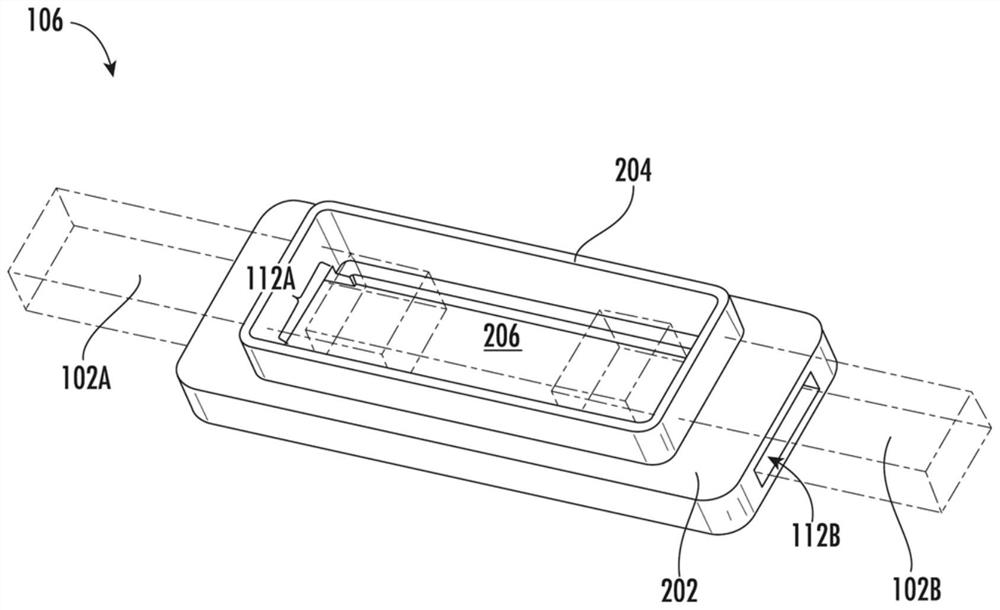

Water resistant in-line fuse holder

ActiveUS20060286868A1Easy to optimizeImprove water resistanceCoupling device detailsElectric switchesEngineeringMechanical engineering

Embodiments for an in-line fuse holder each include at least one housing and two mating pieces, which can snap-fit together and be held moveably together via a strap. Each embodiment houses at least one fuse, such as an automotive fuse. In one example, the fuse includes a first housing forming a first cavity, which is configured to house a first portion of the fuse. The first housing also includes a projection having sides that taper outwardly as the sides extend away from the first housing. The fuse holder also includes a second housing forming a second cavity, which is configured to house a second portion of the fuse. The second housing includes a channel having sides that taper outwardly as the sides extend into the second housing. The projection and channel snap-fit together in a water resistant relationship.

Owner:LITTELFUSE INC

Water resistant in-line fuse holder

ActiveUS7377813B2Improved in-line fuse holder.Improve water resistanceCoupling device detailsElectric switchesWater resistantMechanical engineering

Owner:LITTELFUSE INC

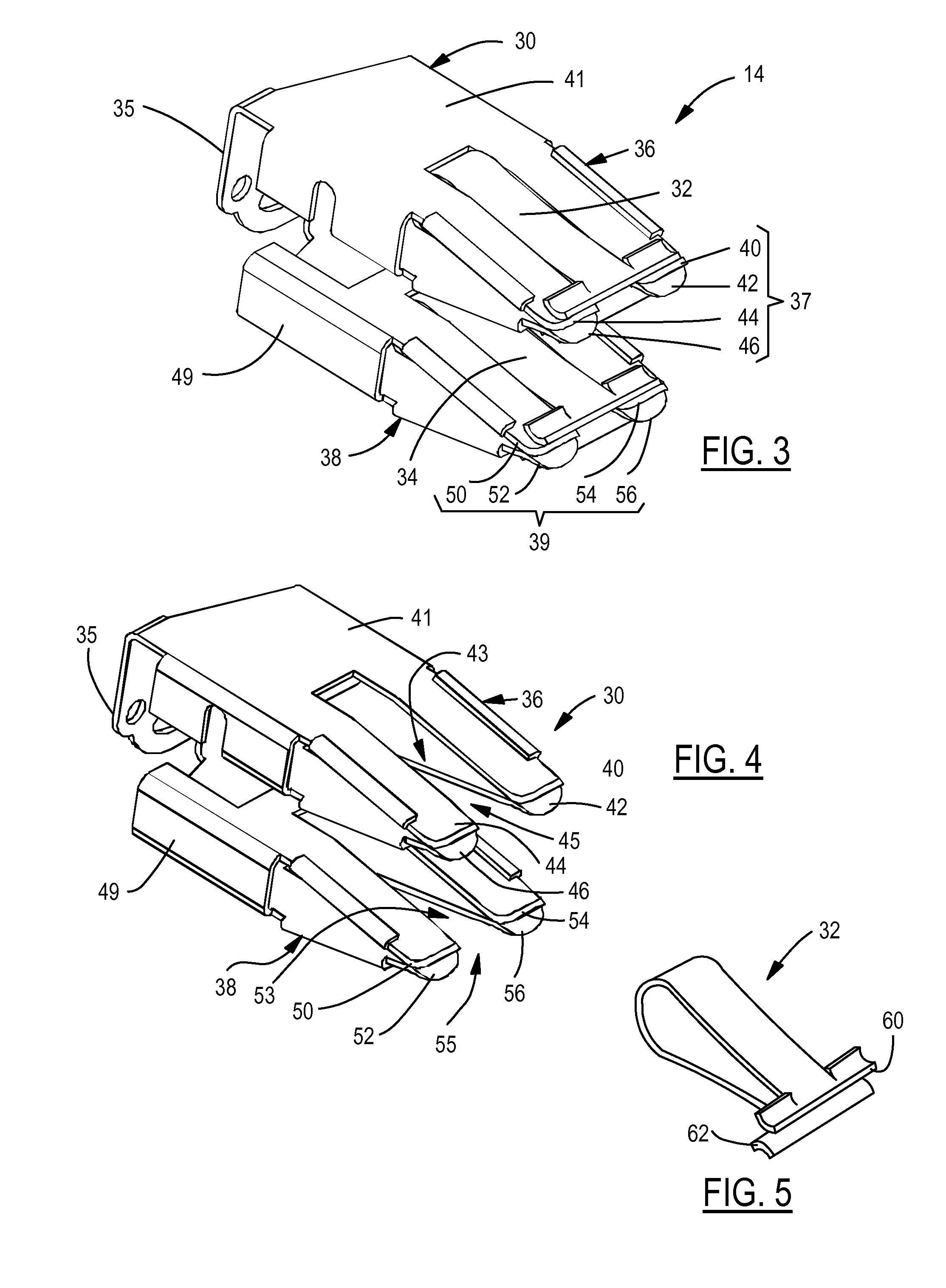

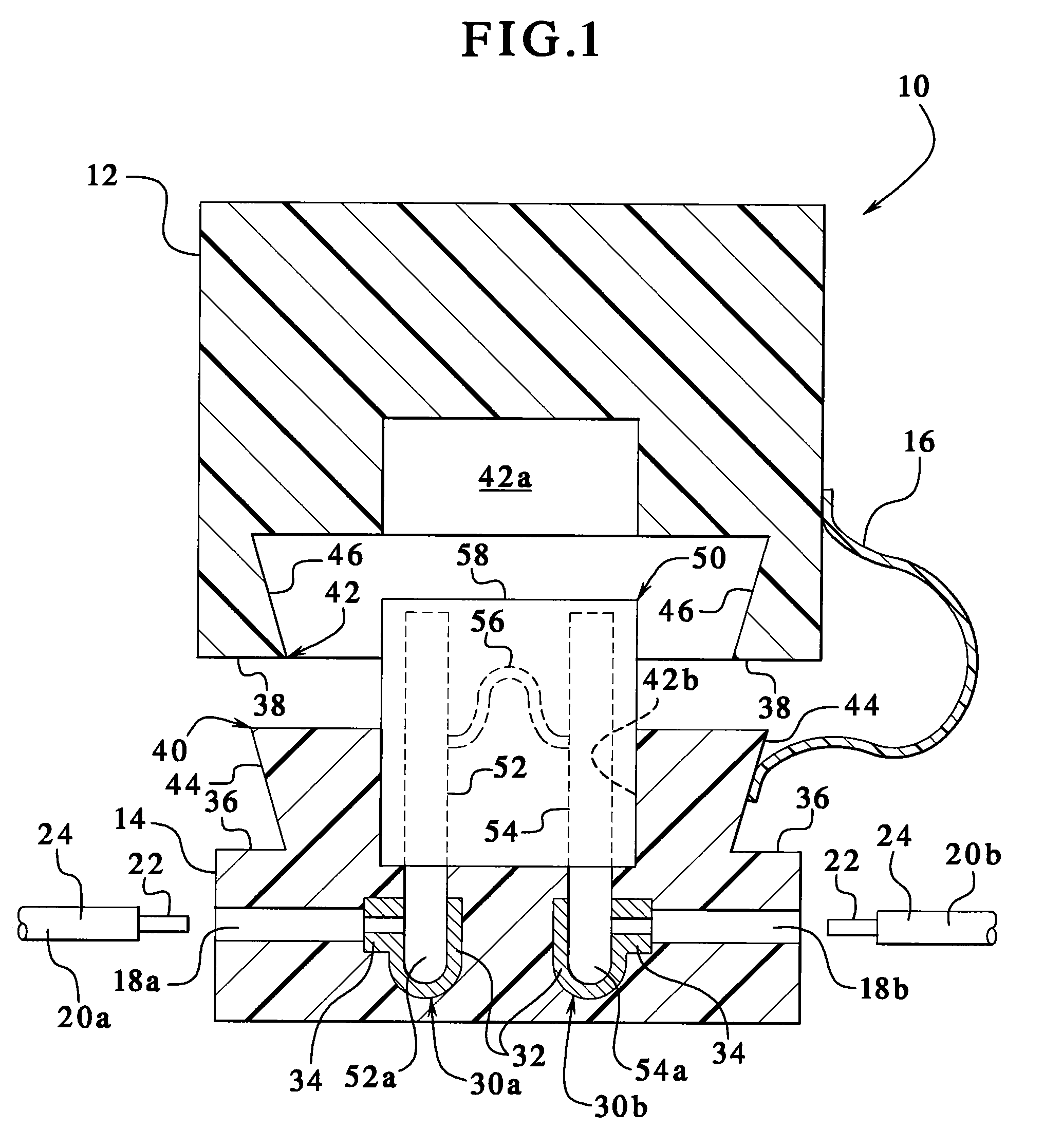

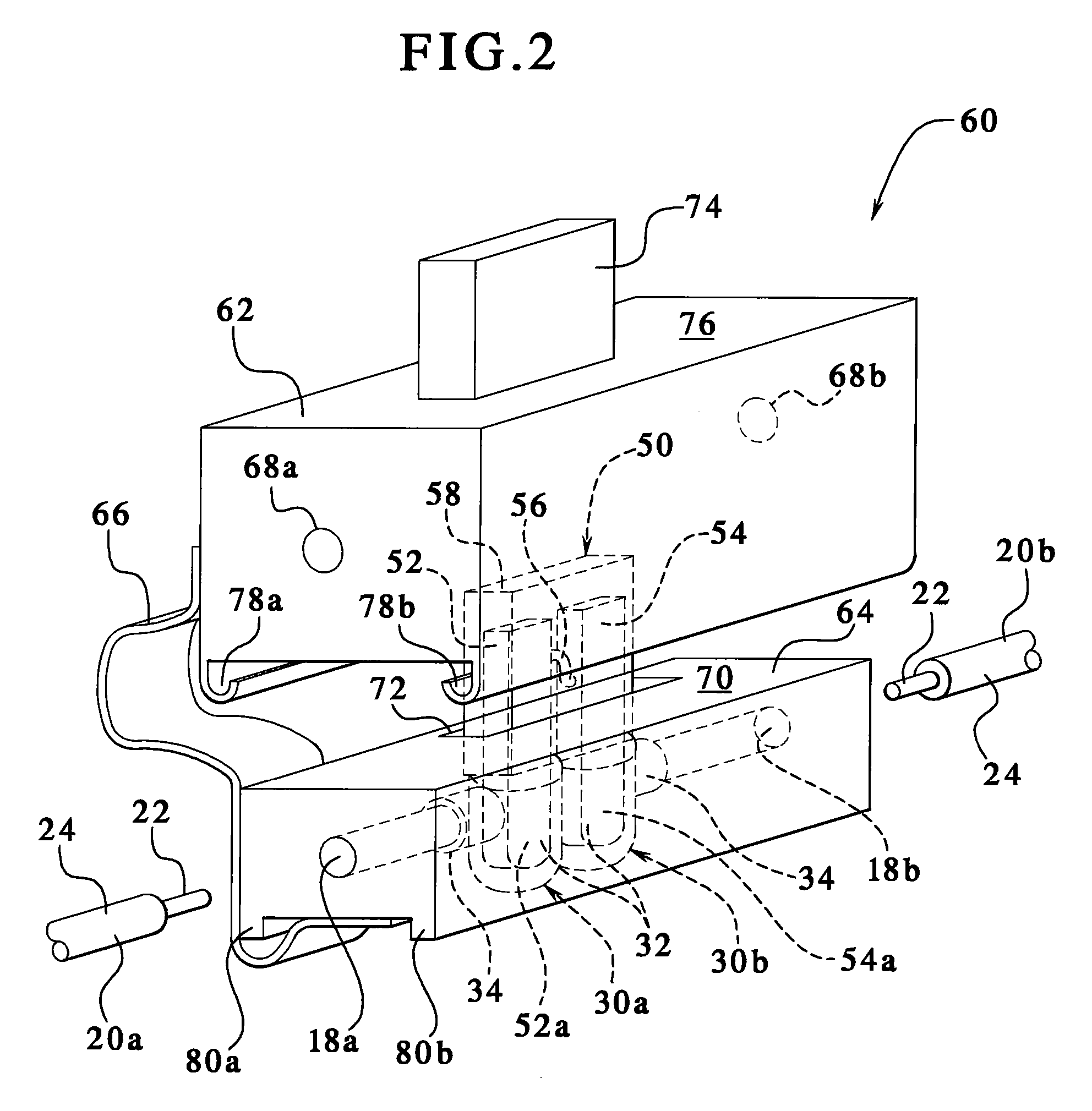

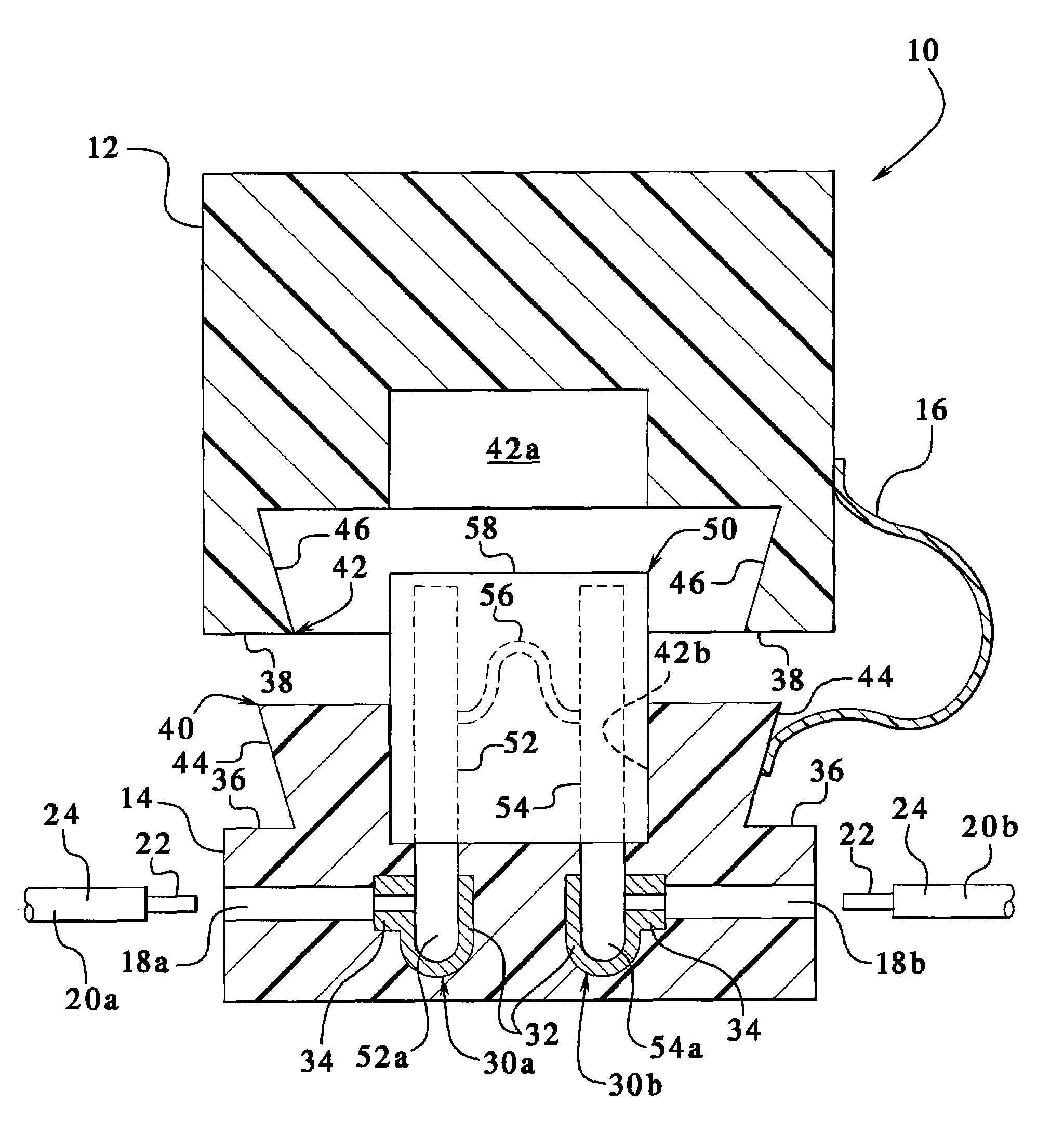

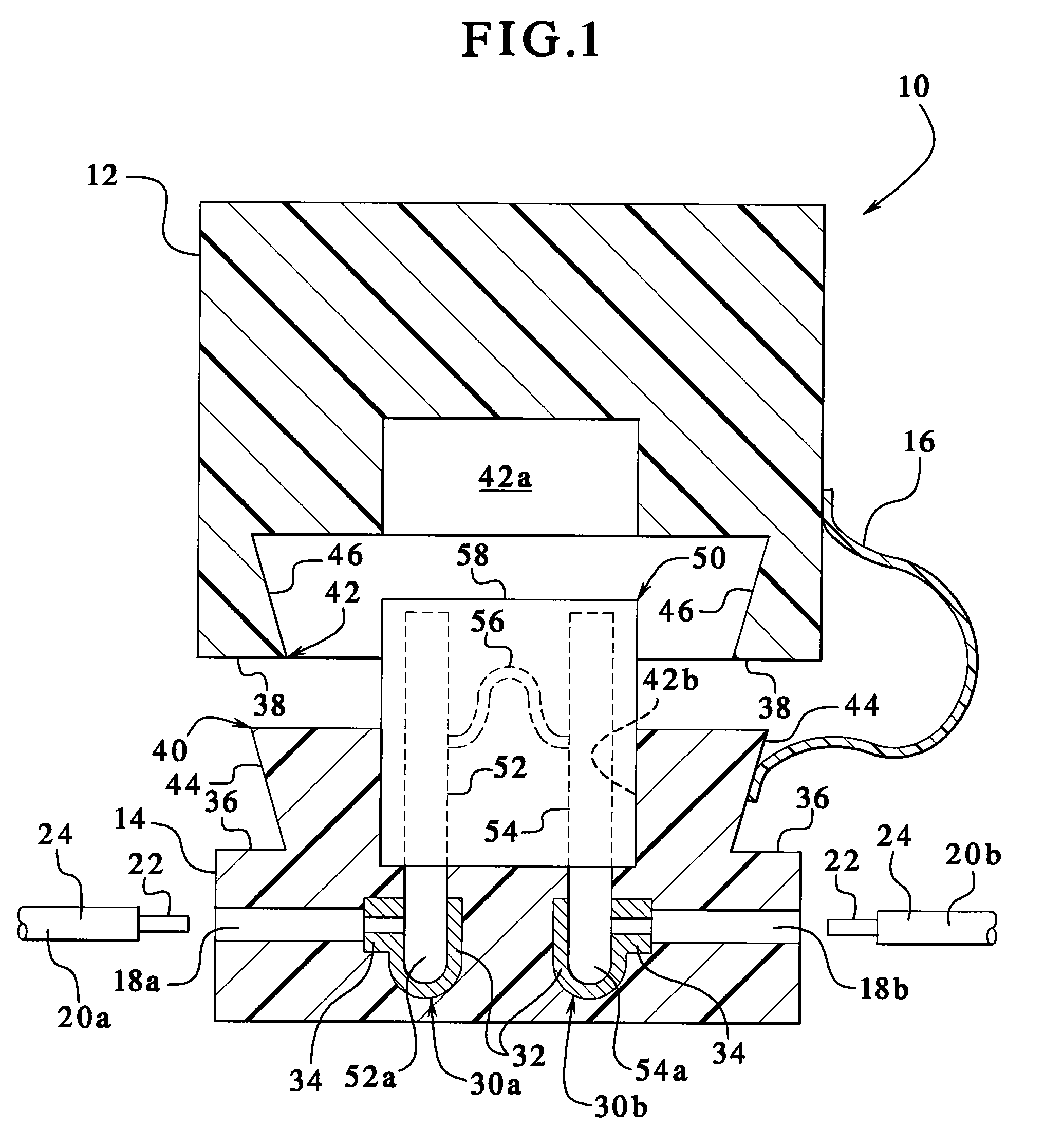

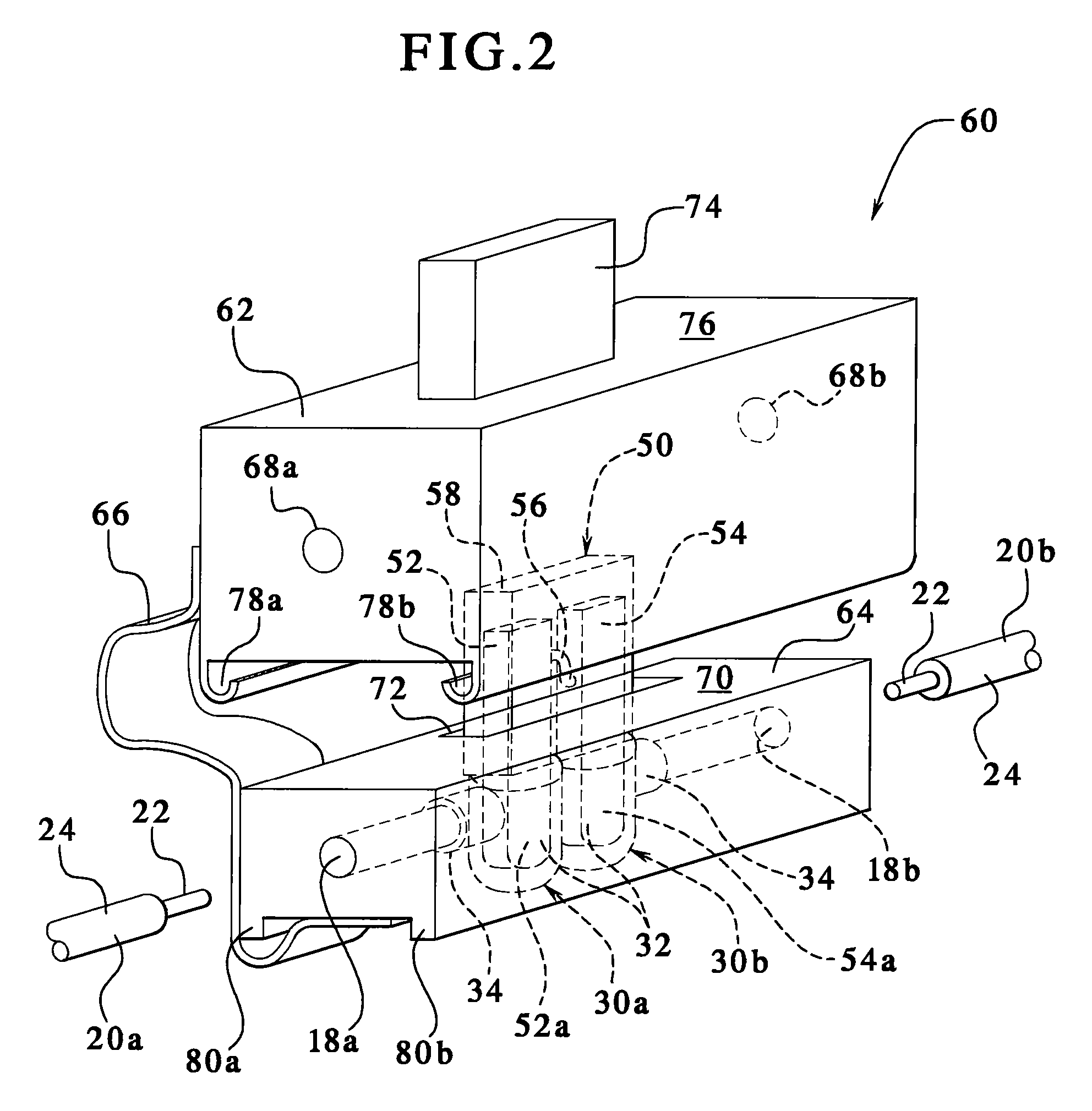

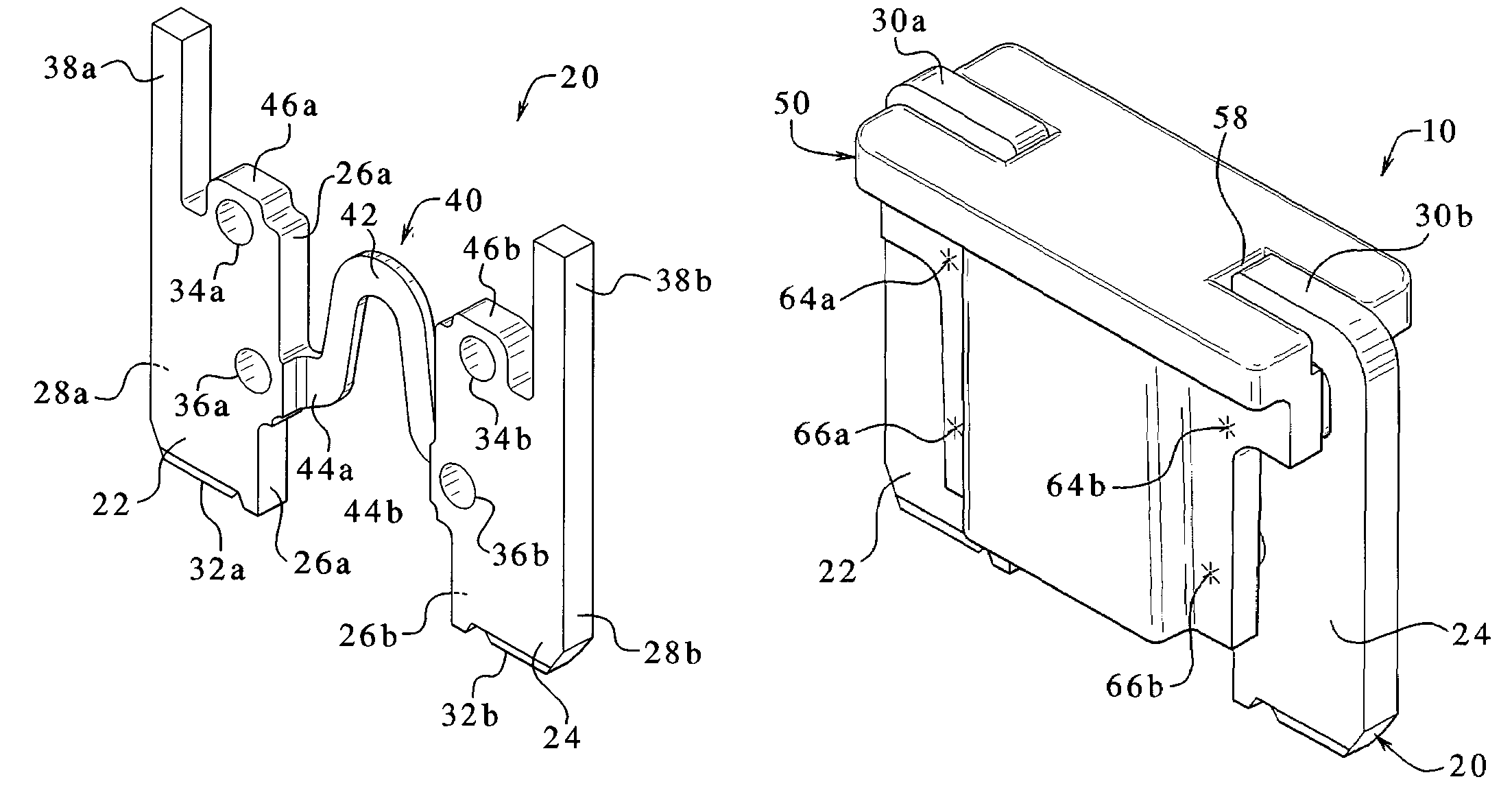

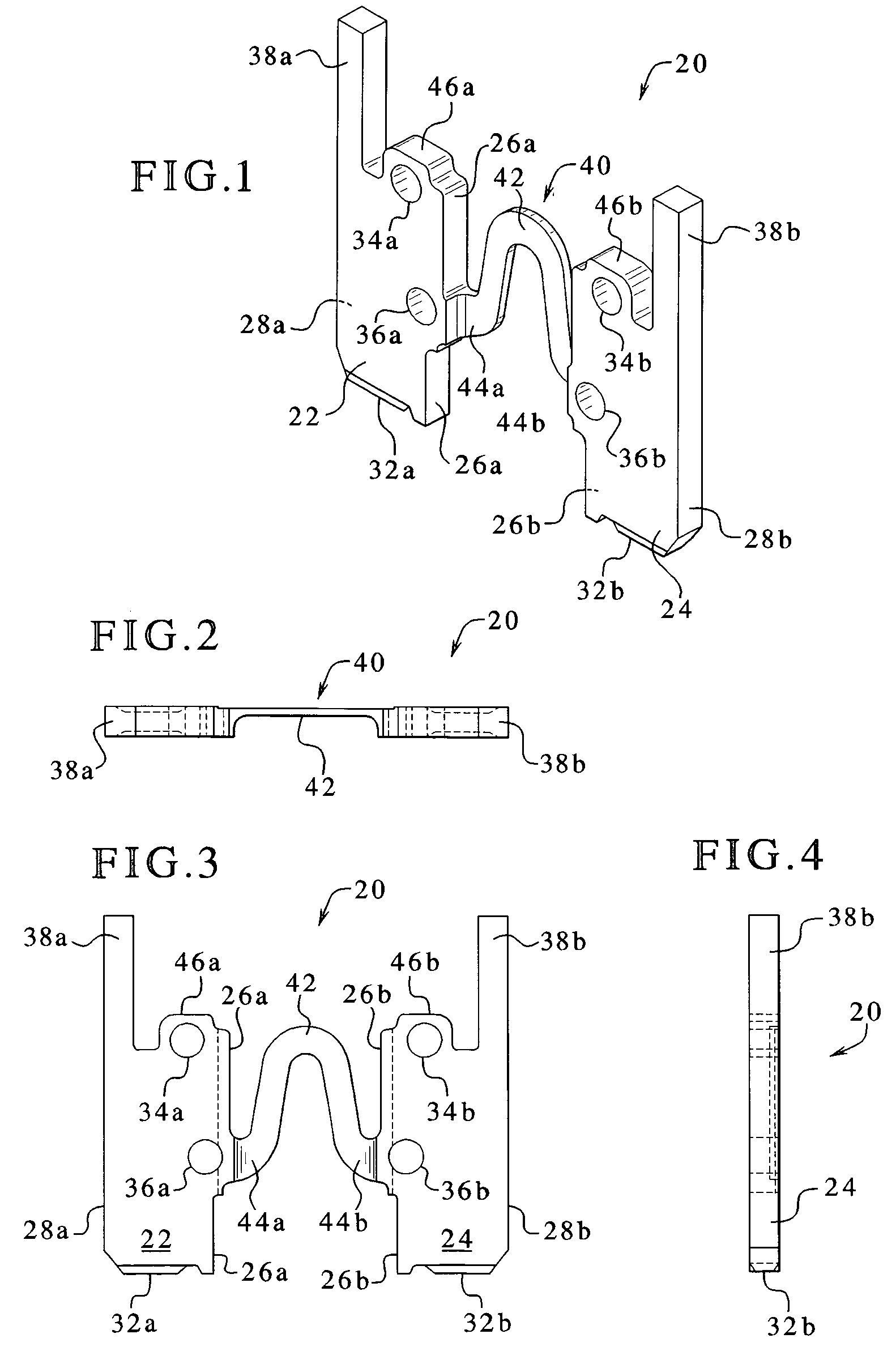

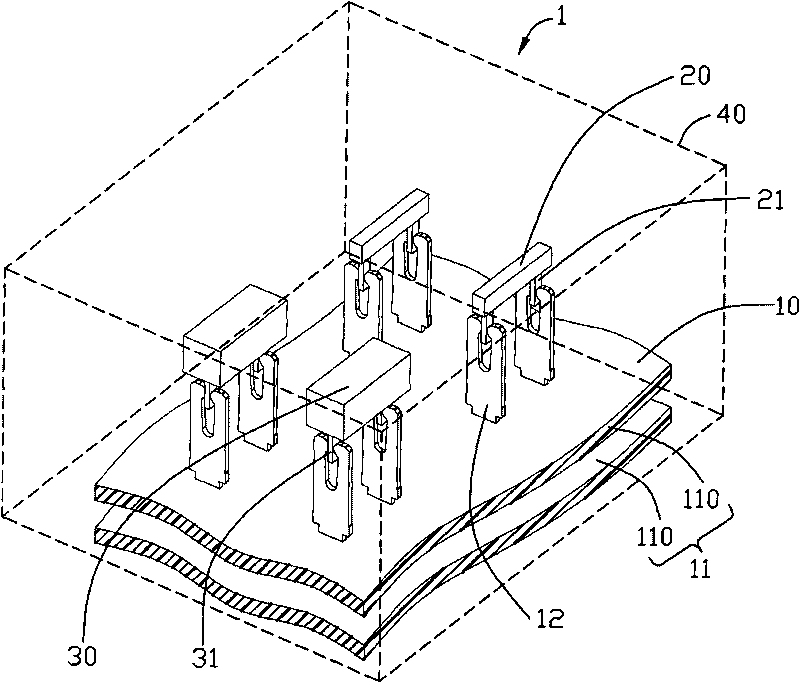

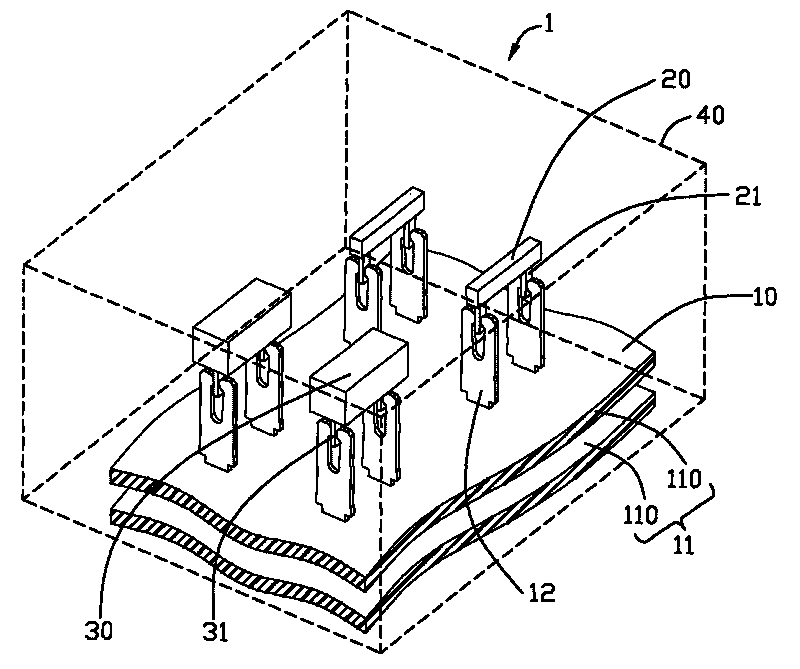

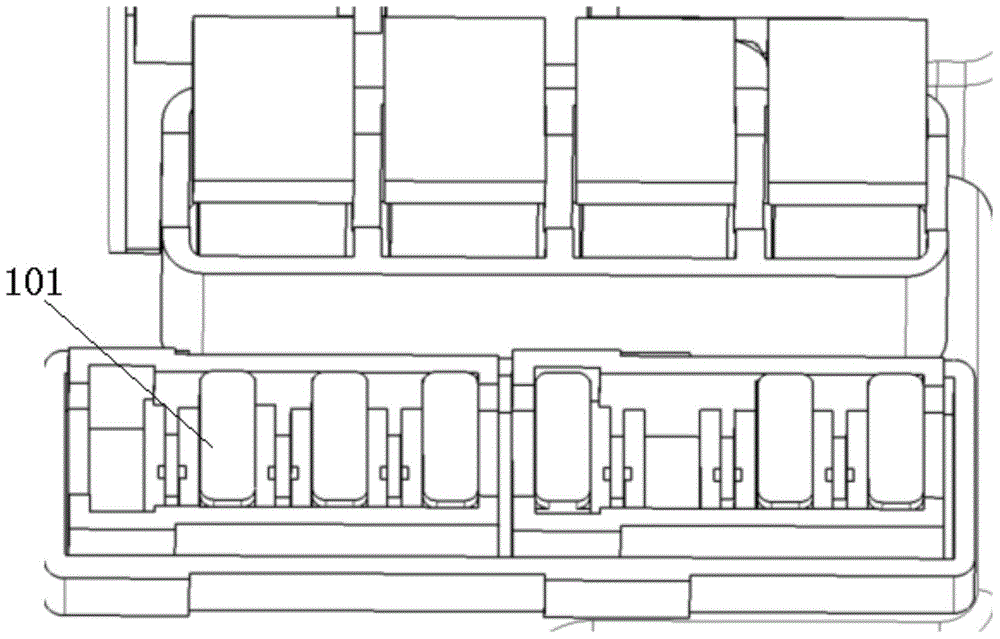

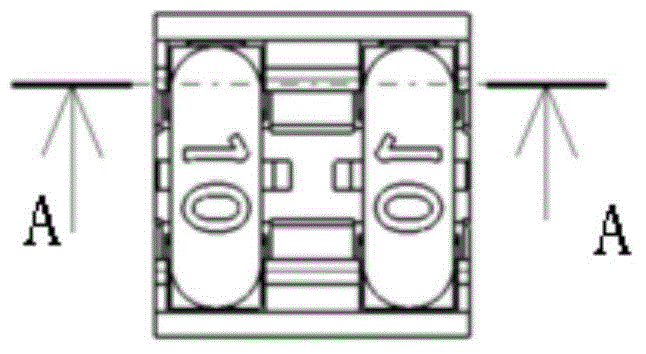

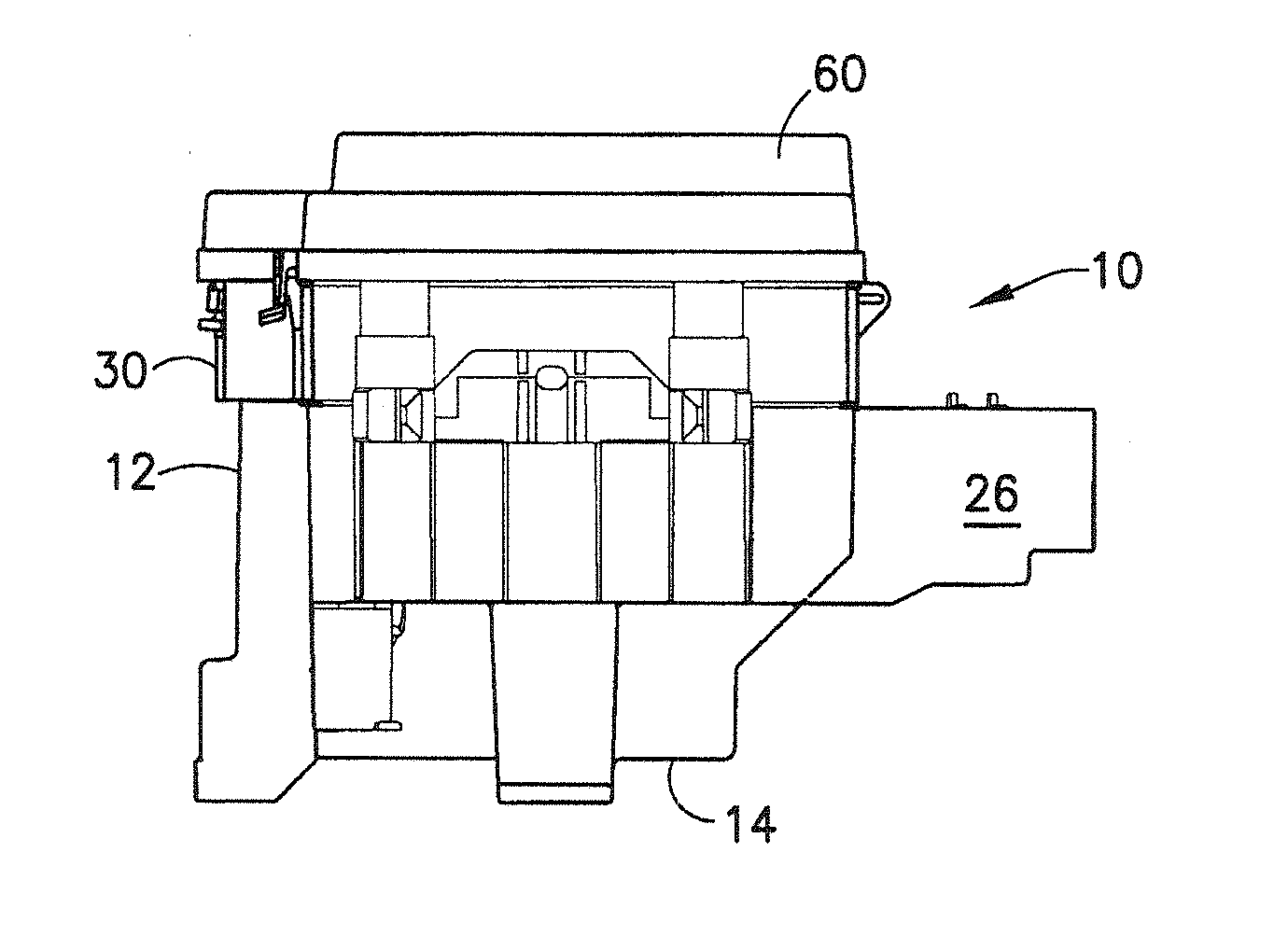

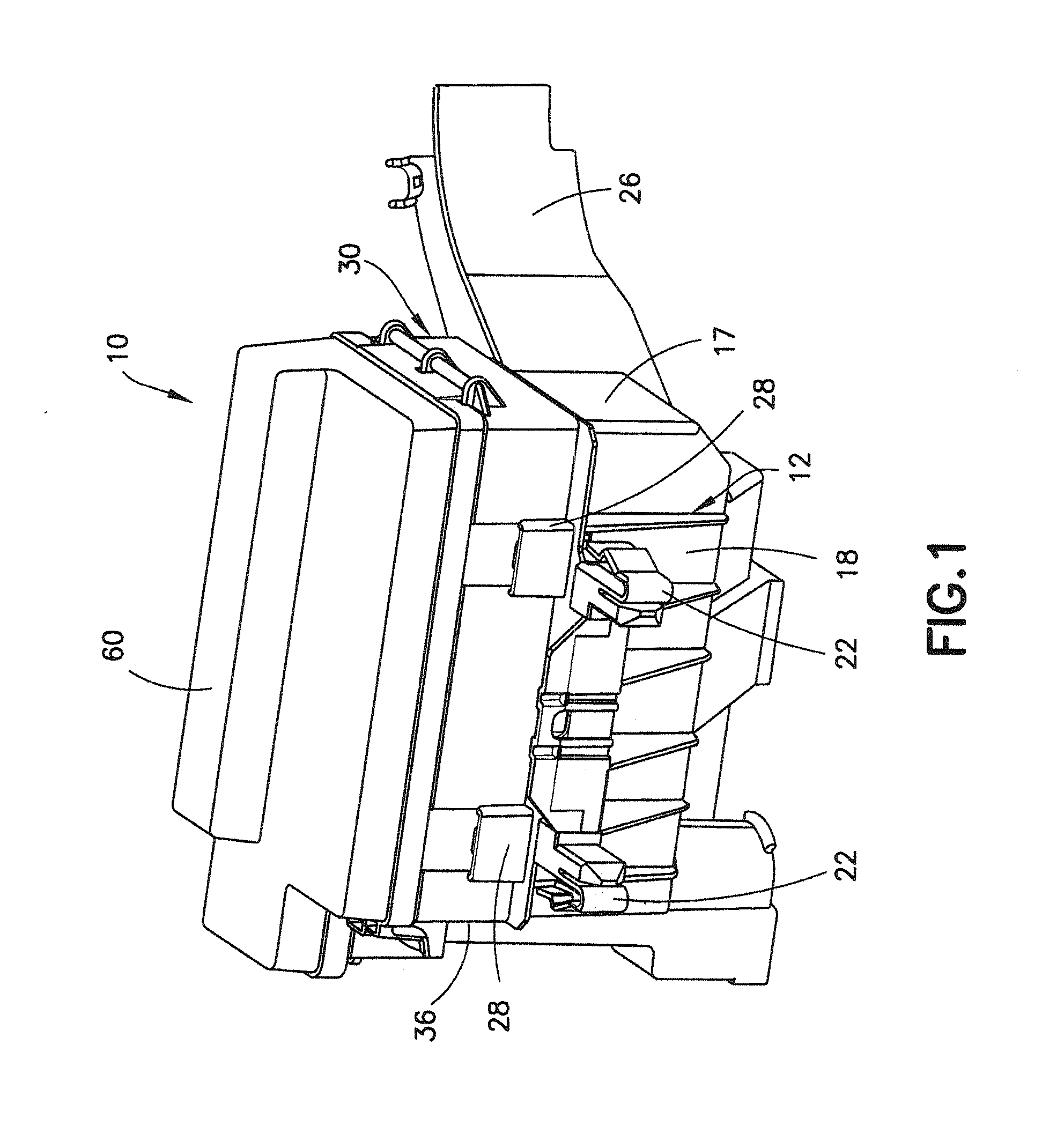

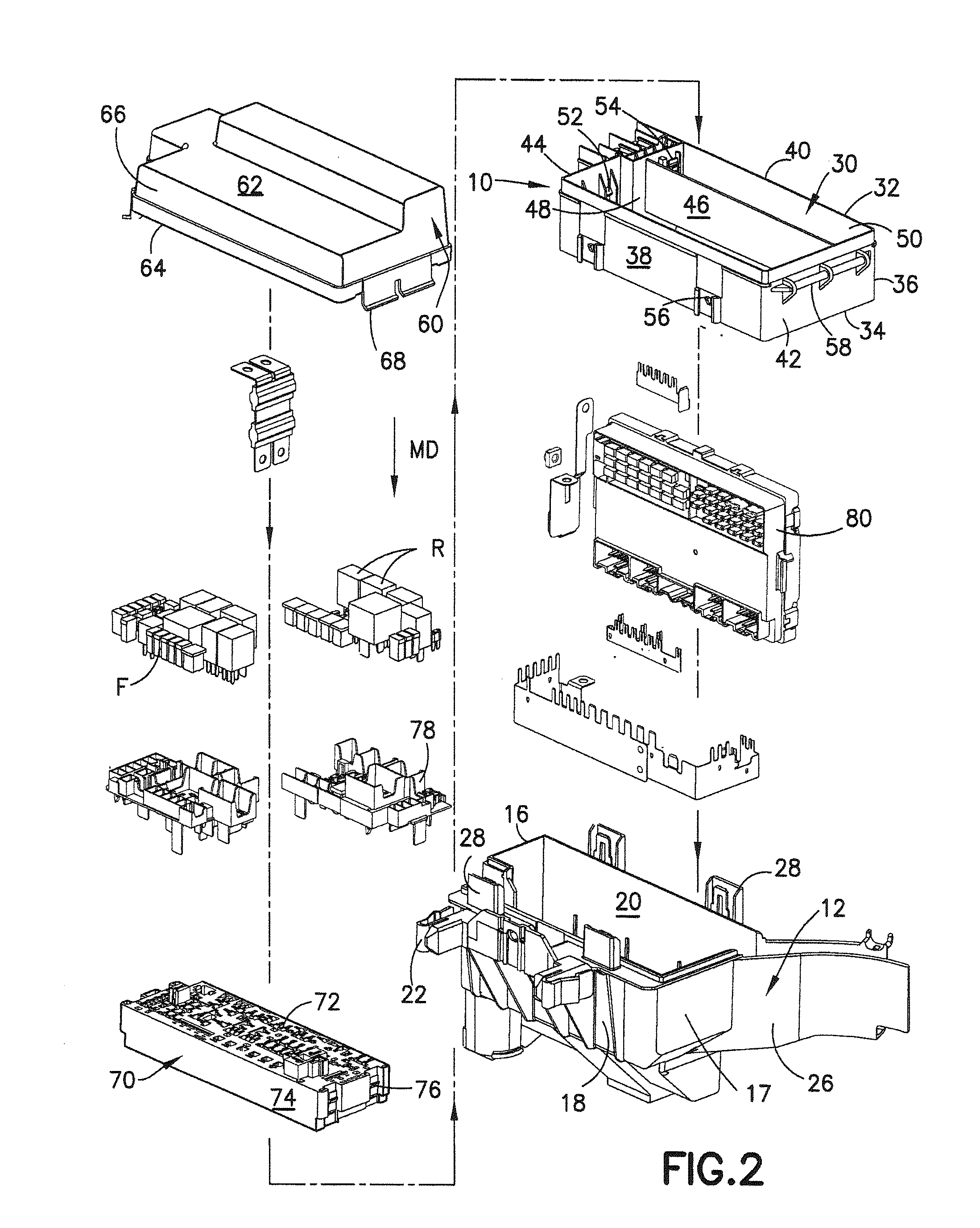

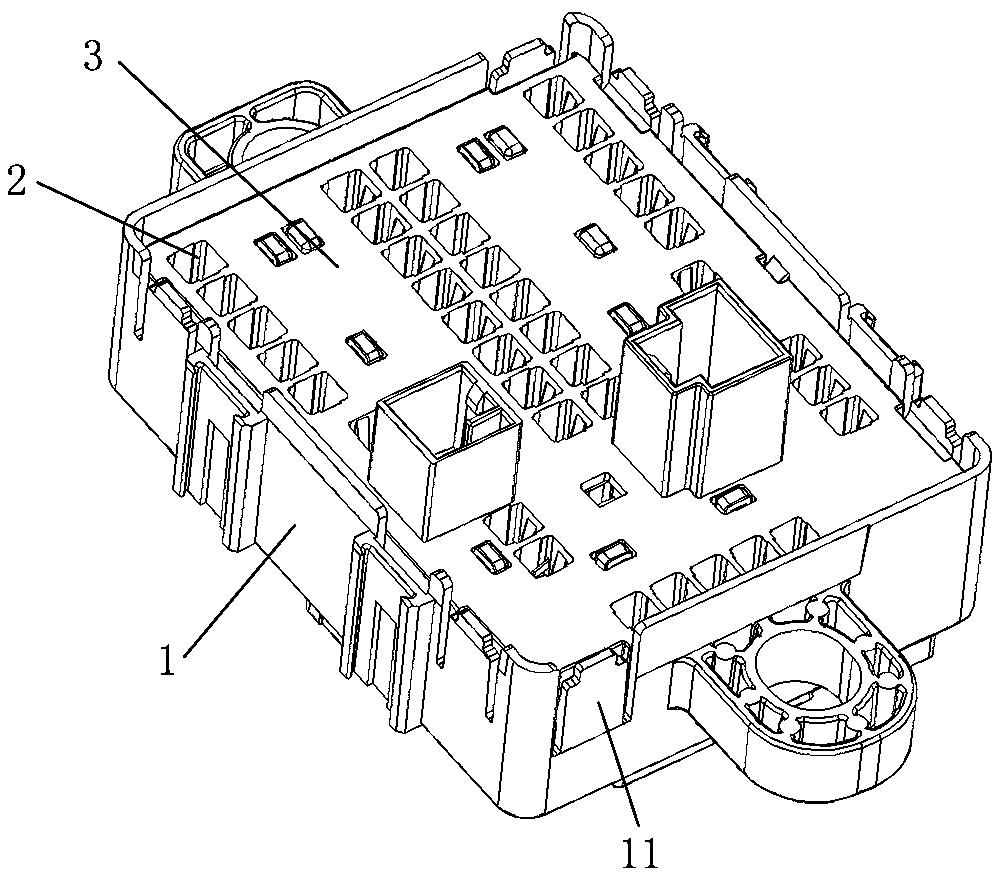

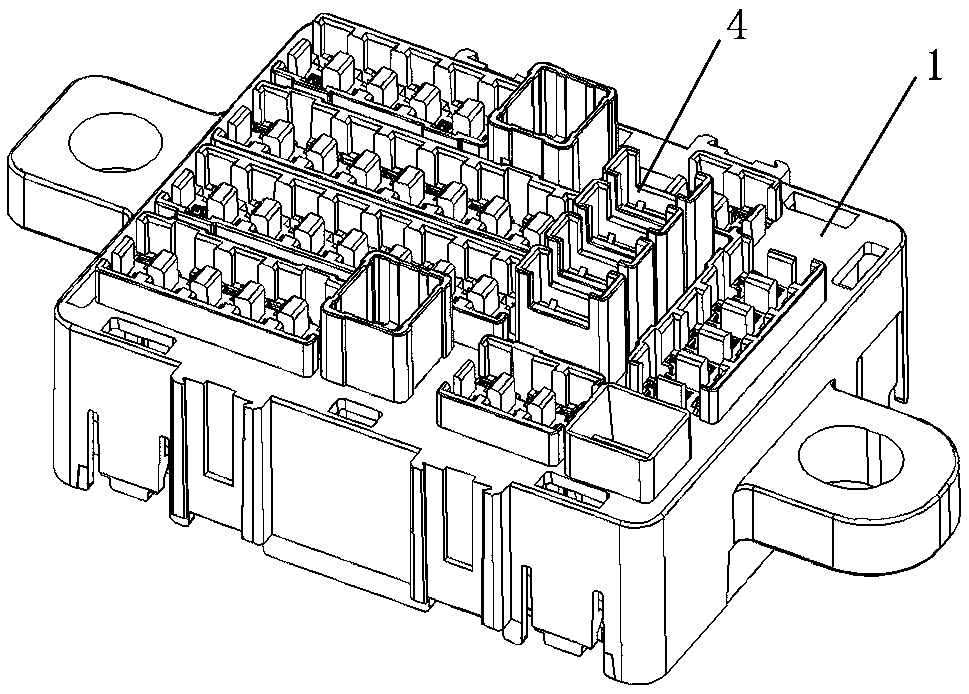

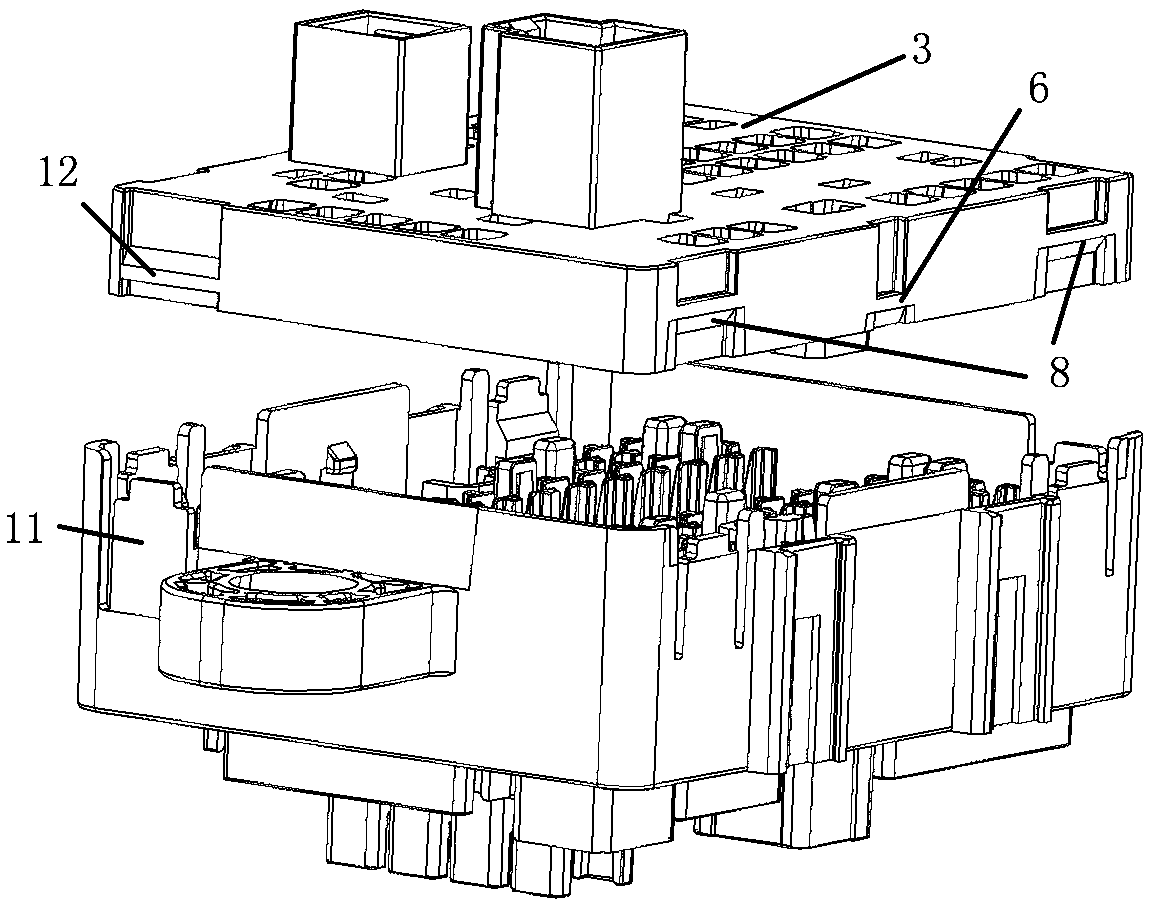

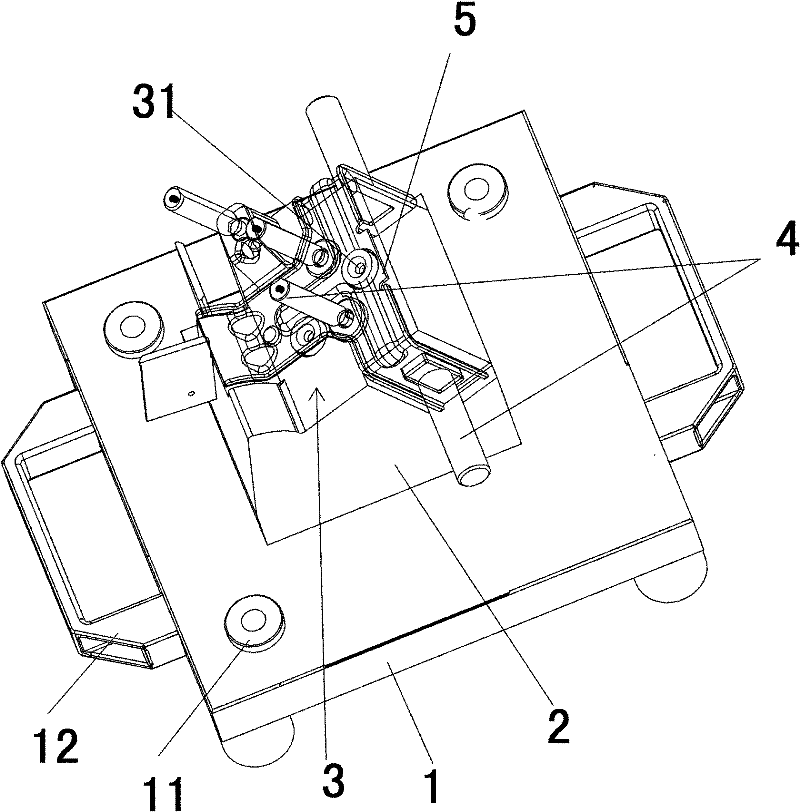

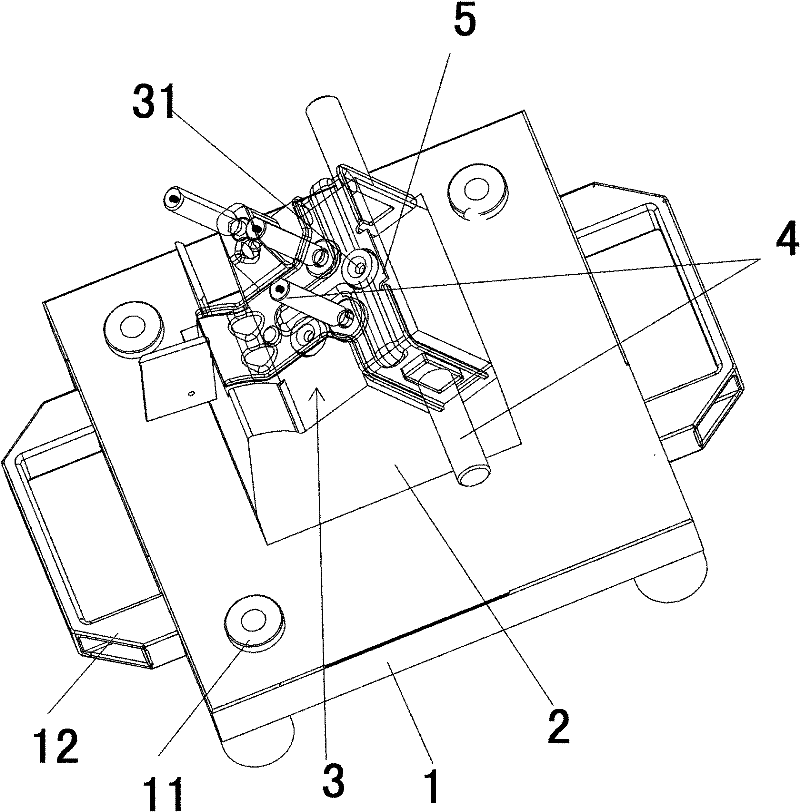

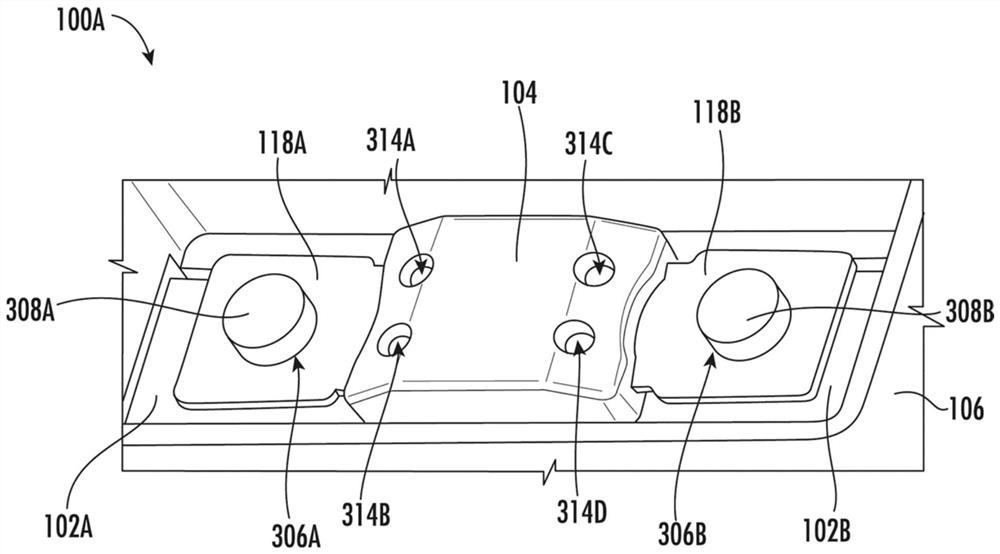

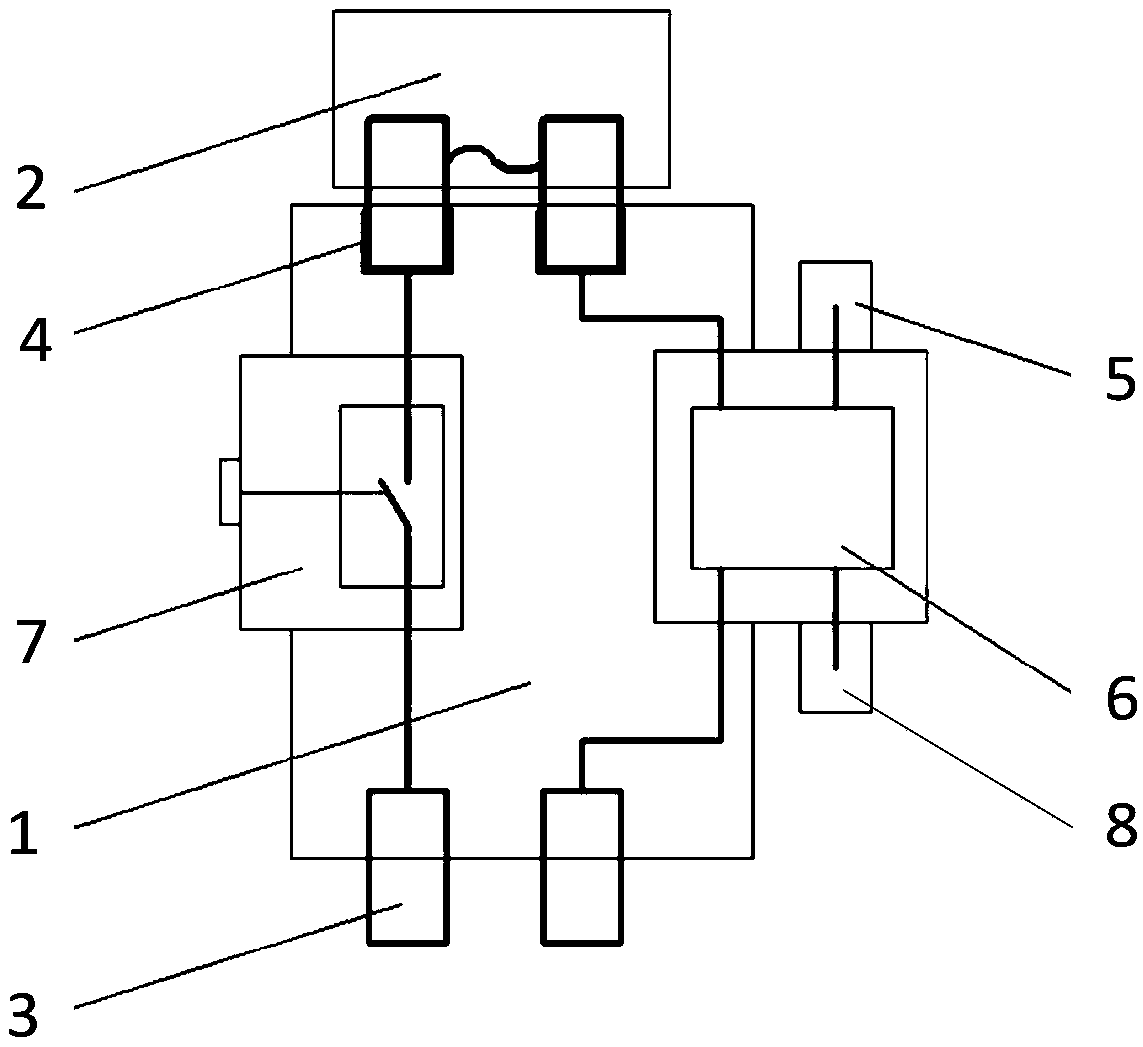

Automotive fuse and relay block assembly

InactiveUS8913371B2Increasing footprintReducing accessibilityElectrically conductive connectionsFuse disposition/arrangementComputer moduleElectrical devices

A fuse and relay block assembly (10) for an automotive vehicle includes a lower cover (12) and an upper cover (60) mounted in substantially opposed relationship to one another. A relay block (70) is mounted between the lower cover (12) and the upper cover (60) and can receive electrical devices (R, F) mounted along a mounting direction (MD). A relay module assembly (80) is mounted between the lower cover (12) and the upper cover (60) and can receive electrical devices (R, F) mounted along a transverse direction (TD) substantially perpendicular to the mounting direction (MD). Thus, a greater density of electrical devices (R, F) can be mounted within a smaller footprint.

Owner:SUMITOMO WIRING SYST LTD

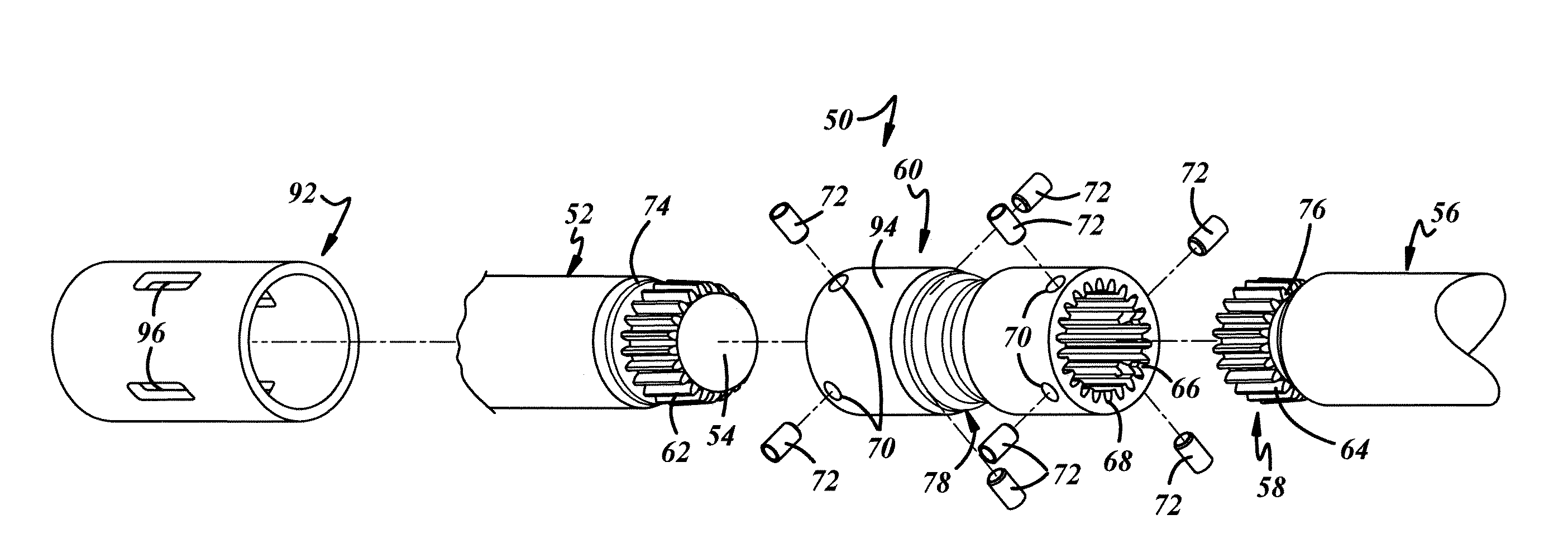

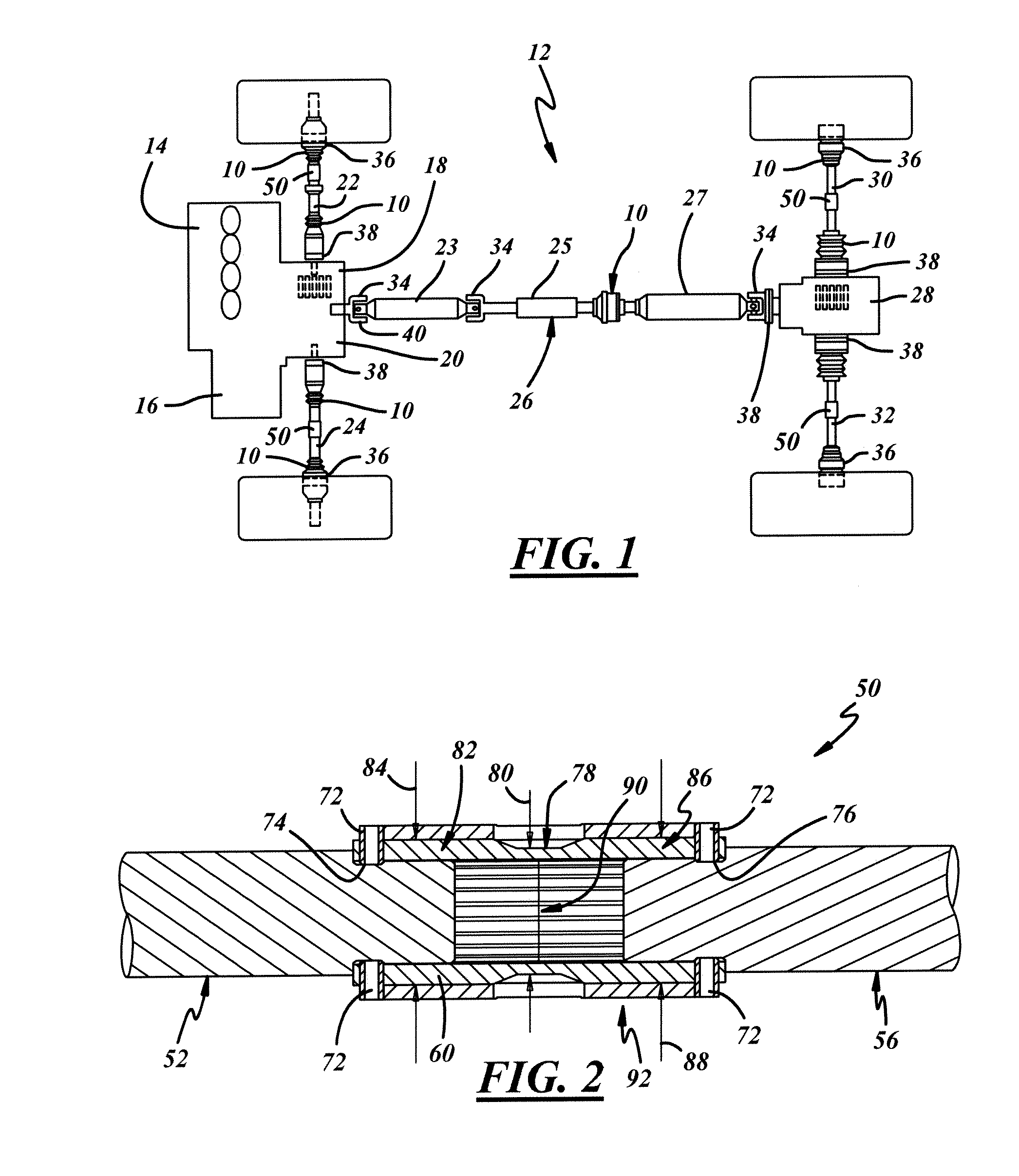

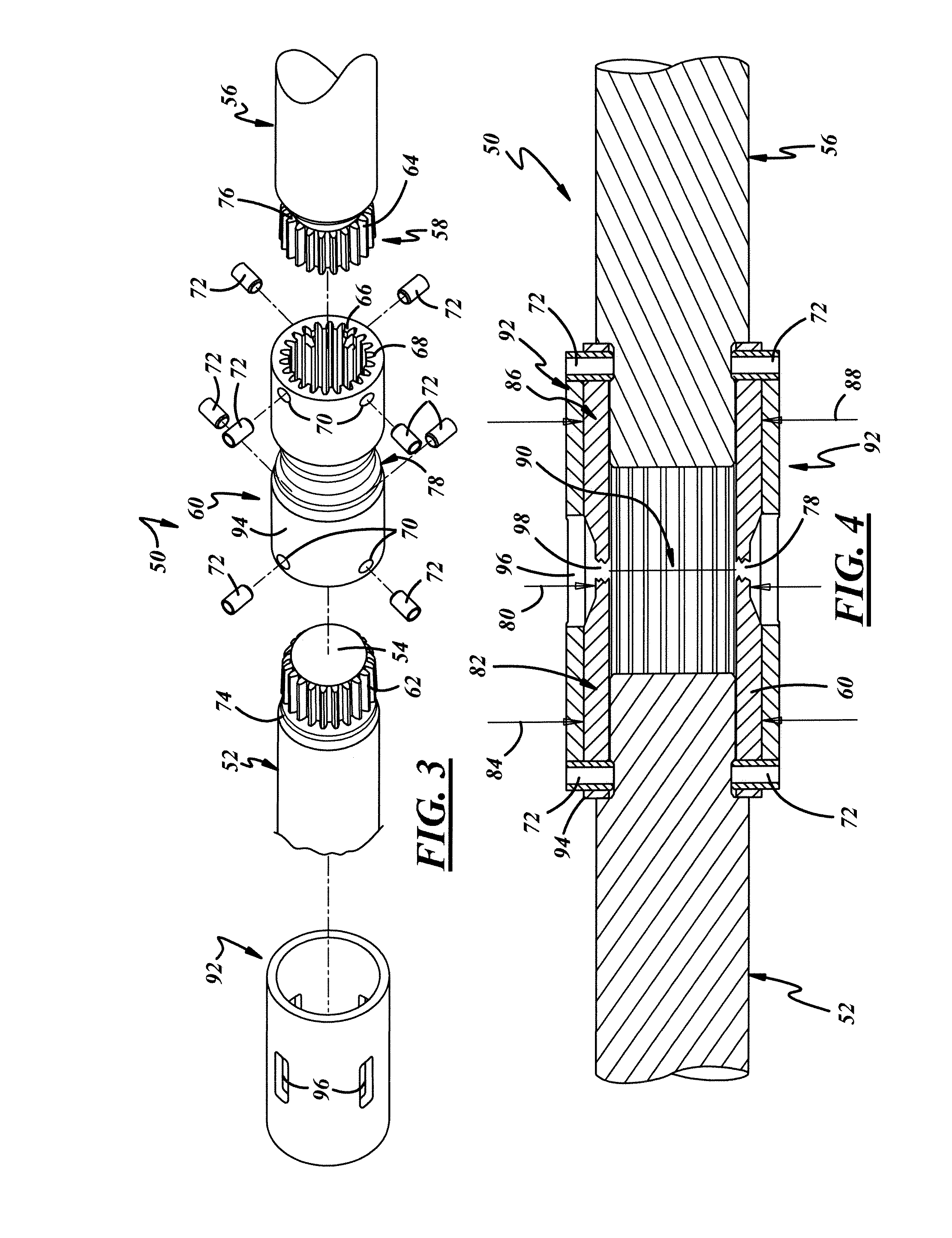

Sideshaft with interconnecting fuse

ActiveUS20090253521A1Metal-working apparatusCouplings with disconnecting safety membersMechanical engineeringFuse (automotive)

An automotive shaft assembly is provided including a first barshaft having a first connection end and a second barshaft having a second connection end. A connection tube rotationally engages the first connection to the second connection end and includes a shear diameter configured to experience shear failure in the presence of an overload torque such that the first connection end is rotationally disengaged the said second connection end.

Owner:GKN DRIVELINE NORTH AMERICA

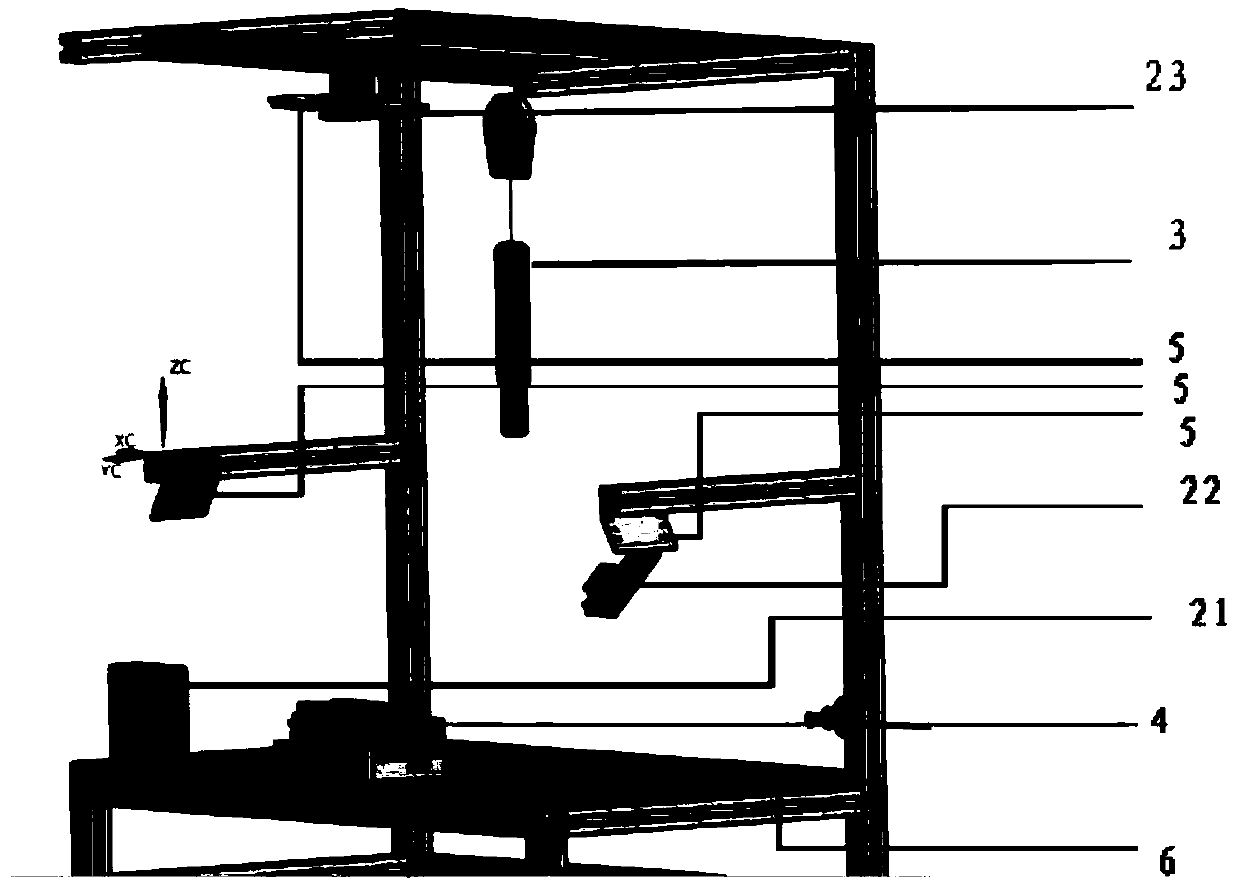

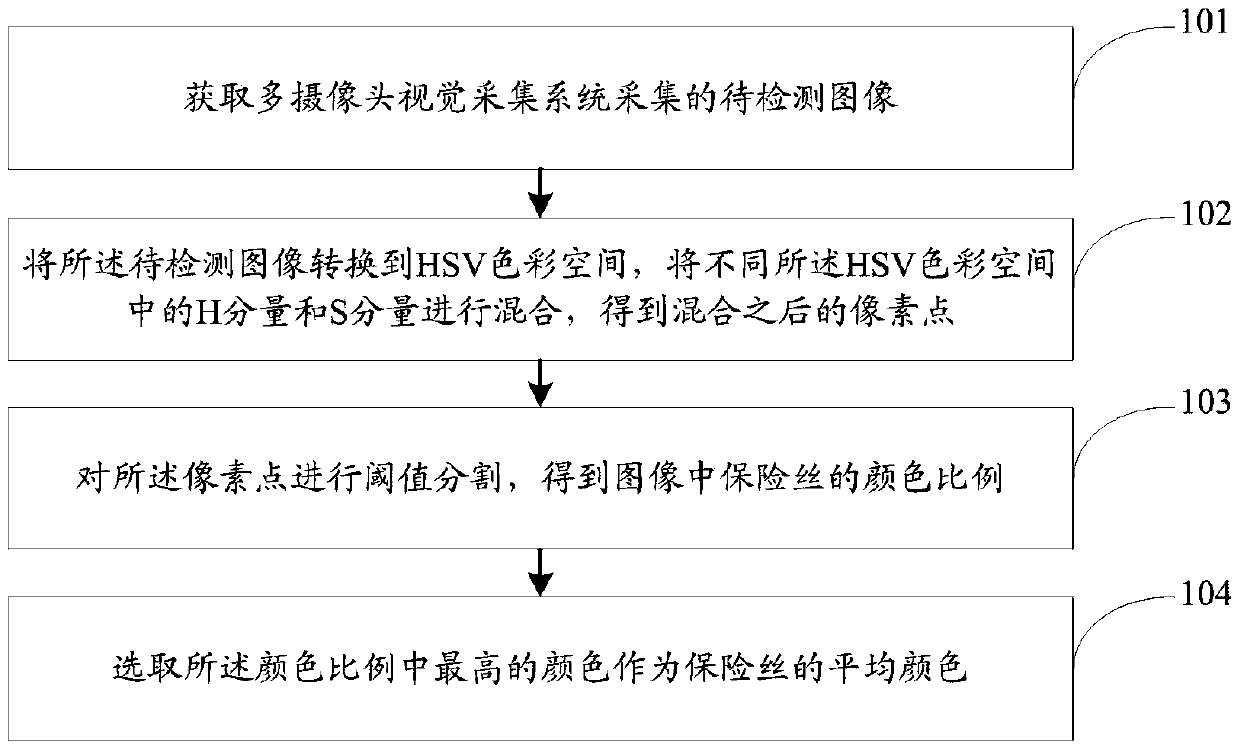

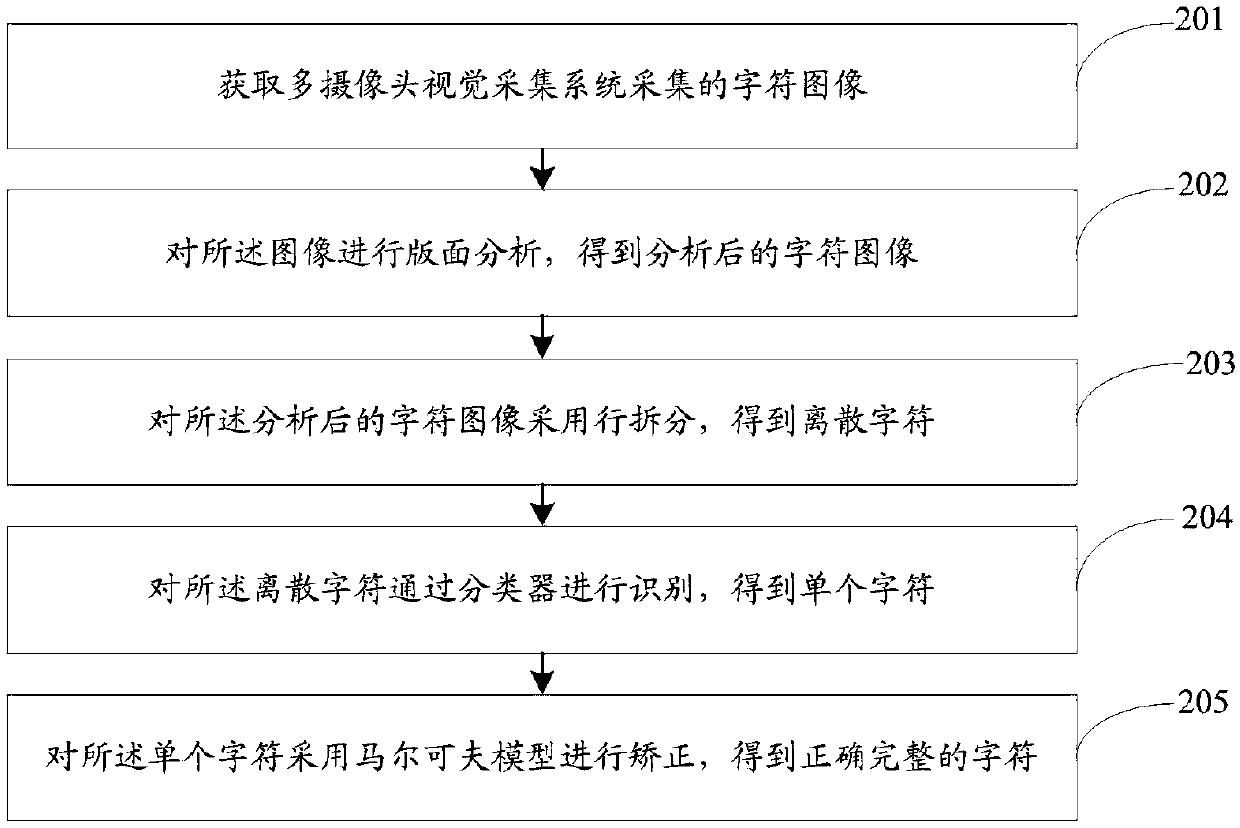

Automobile fuse box assembly detection system, image recognition method and screw hole positioning method

ActiveCN109520706AImprove detection accuracyImprove detection efficiencyOptical apparatus testingMetal working apparatusMulti cameraControl theory

The invention discloses an automobile fuse box assembly detection system, an image recognition method and a screw hole positioning method. The system comprises a detection platform, a multi-camera visual acquisition system, a program-controlled moment torque wrench and a computer; a fuse box to be detected is located on the detection platform, and the multi-camera visual acquisition system is usedfor obtaining images of the fuse box to be detected from three angles; the program-controlled moment torque wrench is positioned above the fuse box to be detected; the program-controlled moment torque wrench is used for selecting proper force by judging the type of the nut so as to tighten the screw on the fuse box to be detected; and the computer is connected with the multi-camera visual acquisition system and the program-controlled moment torque wrench and is used for receiving the image information acquired by the multi-camera visual acquisition system, identifying whether the fuse is correctly assembled according to the image information, and adjusting the program-controlled moment torque wrench to tighten the nut of the fuse box to be detected. The detection precision and the detection efficiency of an automobile fuse box can be improved.

Owner:YUNNAN NORMAL UNIV

Low profile automotive fuse

ActiveUS7479866B2Simple methodLow profileEmergency protective devicesEngineeringMechanical engineering

Owner:LITTELFUSE INC

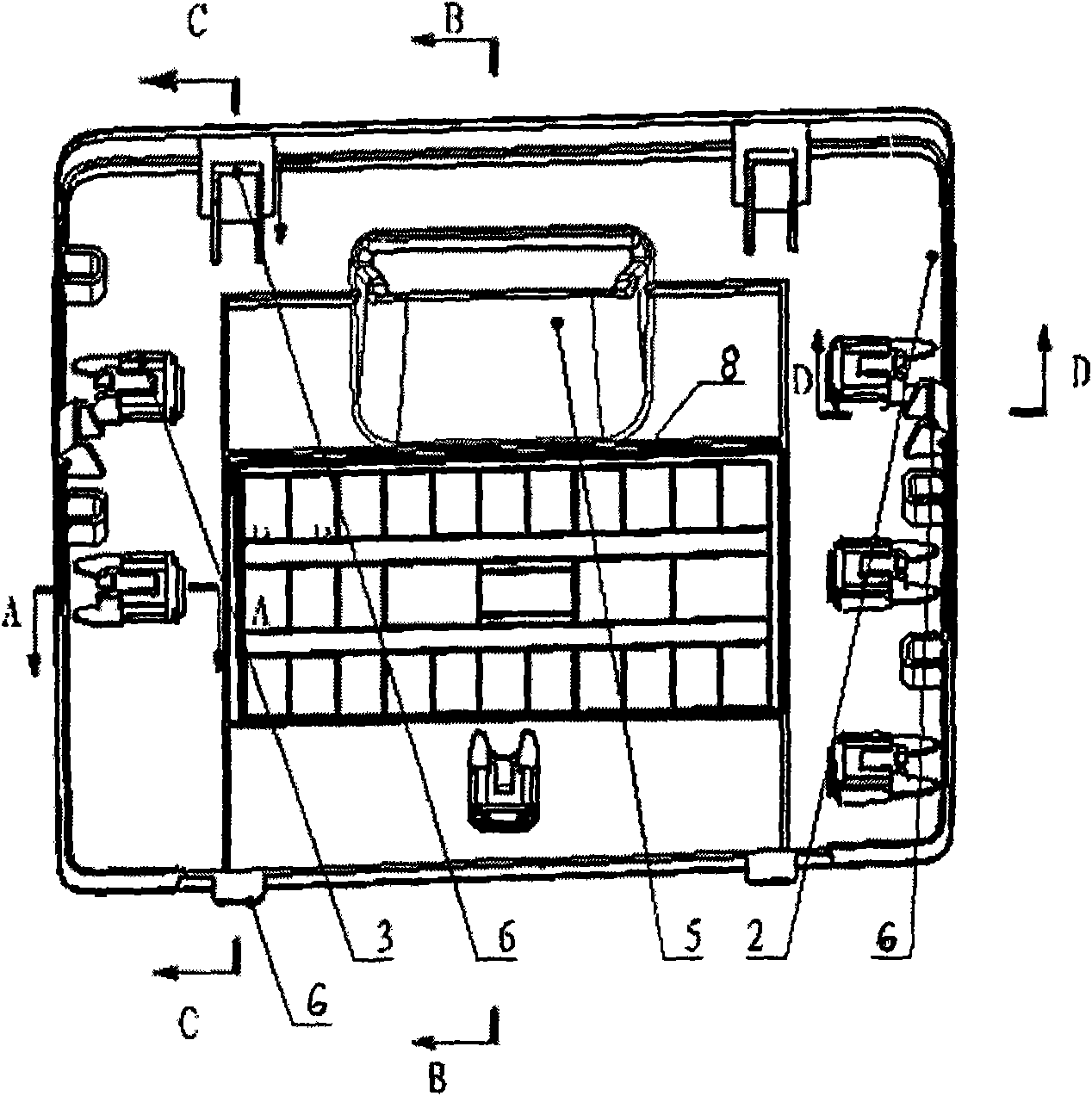

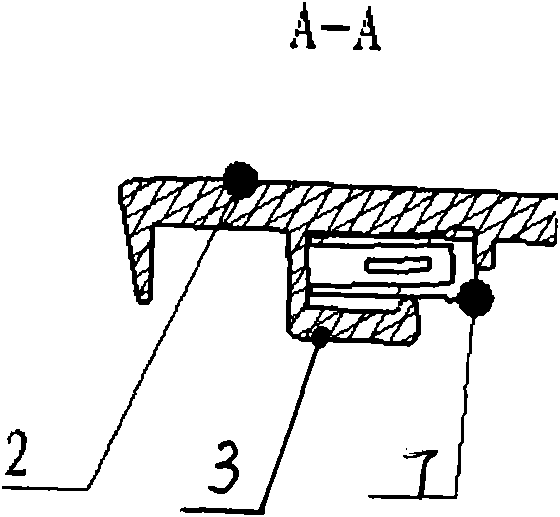

Fuse box of automobile and fuse pinboard thereof

InactiveCN101728139ASimple structureReduce weightCoupling contact membersEmergency protective devicesEngineeringMechanical engineering

The invention discloses a fuse box of an automobile and a fuse pinboard thereof. The fuse box comprises the fuse pinboard, a fuse and a relay which are inserted into the fuse pinboard and a box body for accommodating the fuse pinboard. The fuse pinboard comprises a circuit board and a conducting terminal inserted to the circuit board; each conducting terminal comprises a base and an elastic arm extending from the base; and the tail end of the elastic arm relatively protrudes to form a holding part. The fuse pinboard is inserted to the terminal of the circuit board, has a simple structure, can lighten the weight of the fuse box, and saves cost.

Owner:安泰汽车电气系统(昆山)有限公司 +1

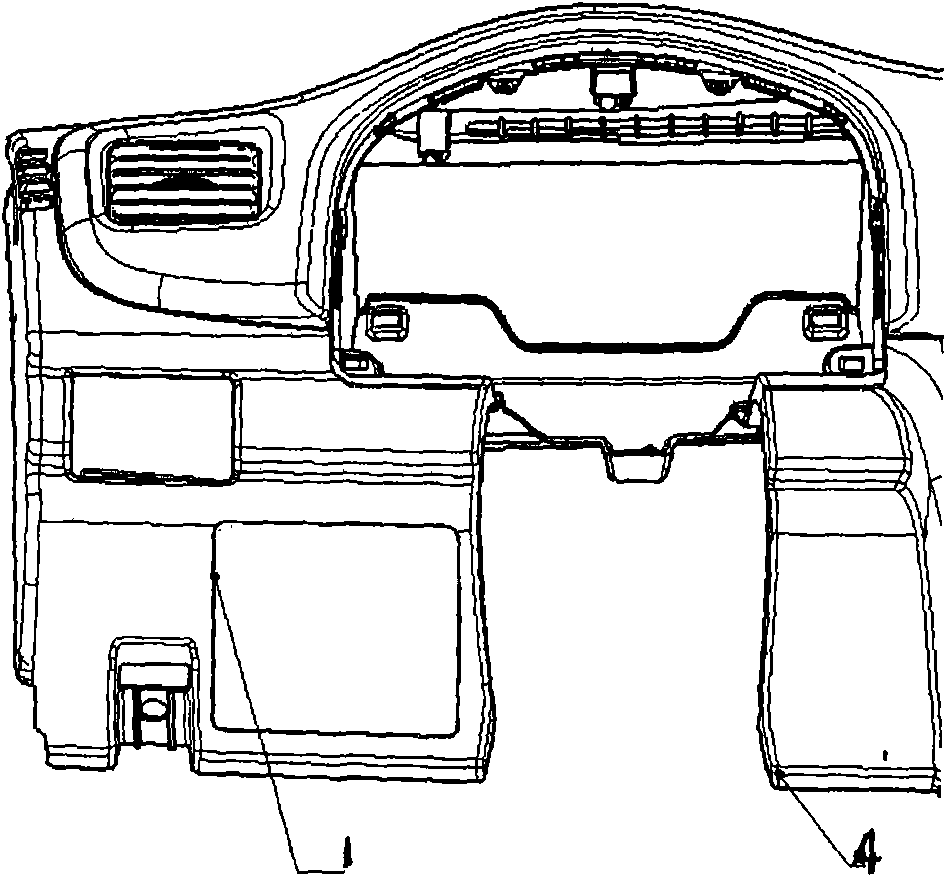

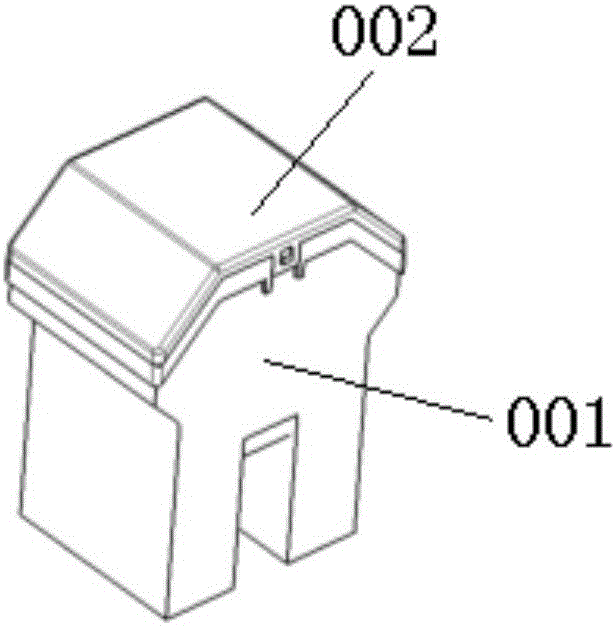

Access cover assembly of automobile fuse box

ActiveCN101859670ALow costEasy maintenanceElectric/fluid circuitEmergency protective devicesSemi openEngineering

The invention discloses an access cover assembly of an automobile fuse box. The access cover assembly of the fuse box is provided with a cover body clamped on an instrument board assembly; clamping structures assembled with the instrument board assembly and clamping slots for clamping standby fuses are integrally arranged on the inner side face of the cover body; the clamping structures are distributed at the upper side, the lower side, the left side and the right side of the cover body and are used for clamping the access box assembly of the fuse box and the instrument board assembly; and the clamping slots are a plurality of raised semi-open slots distributed on the inner side face of the cover body, and are used for clamping the standby fuses so as to prevent the fuses from dropping out in the running process of the automobile. The invention can integrate the functions of an original access cover and an original fuse box cover into one component cover body, and has the advantages of multiple functions, convenient installation and disassembly and low cost.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

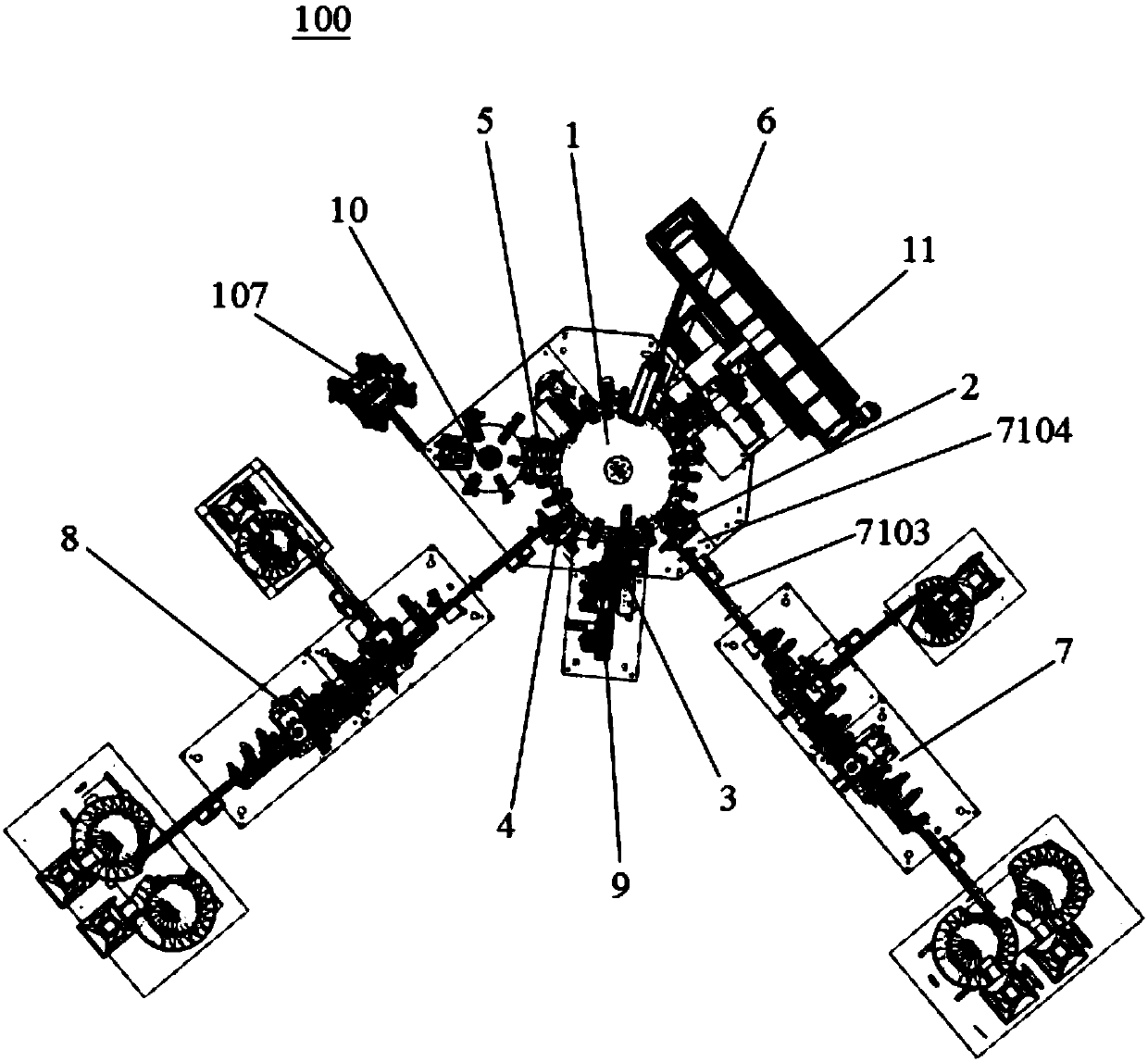

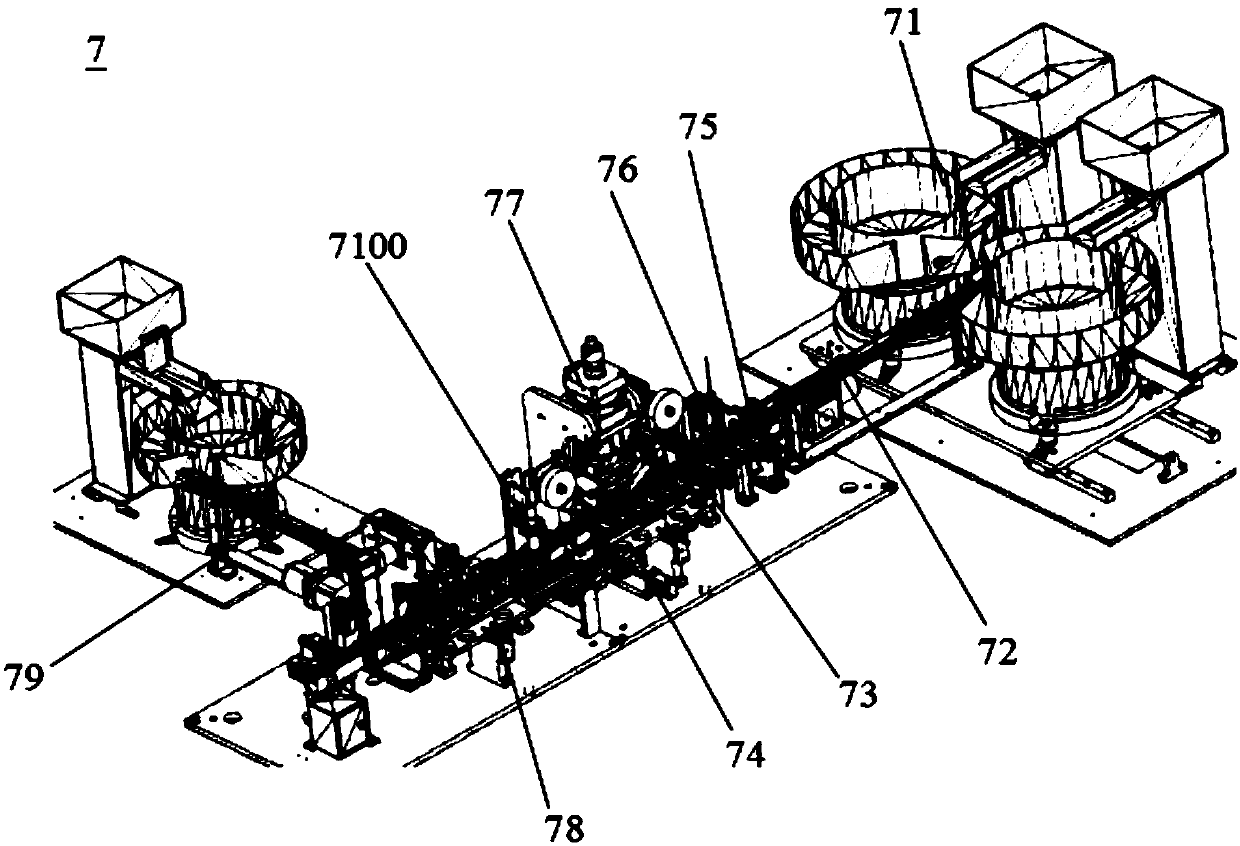

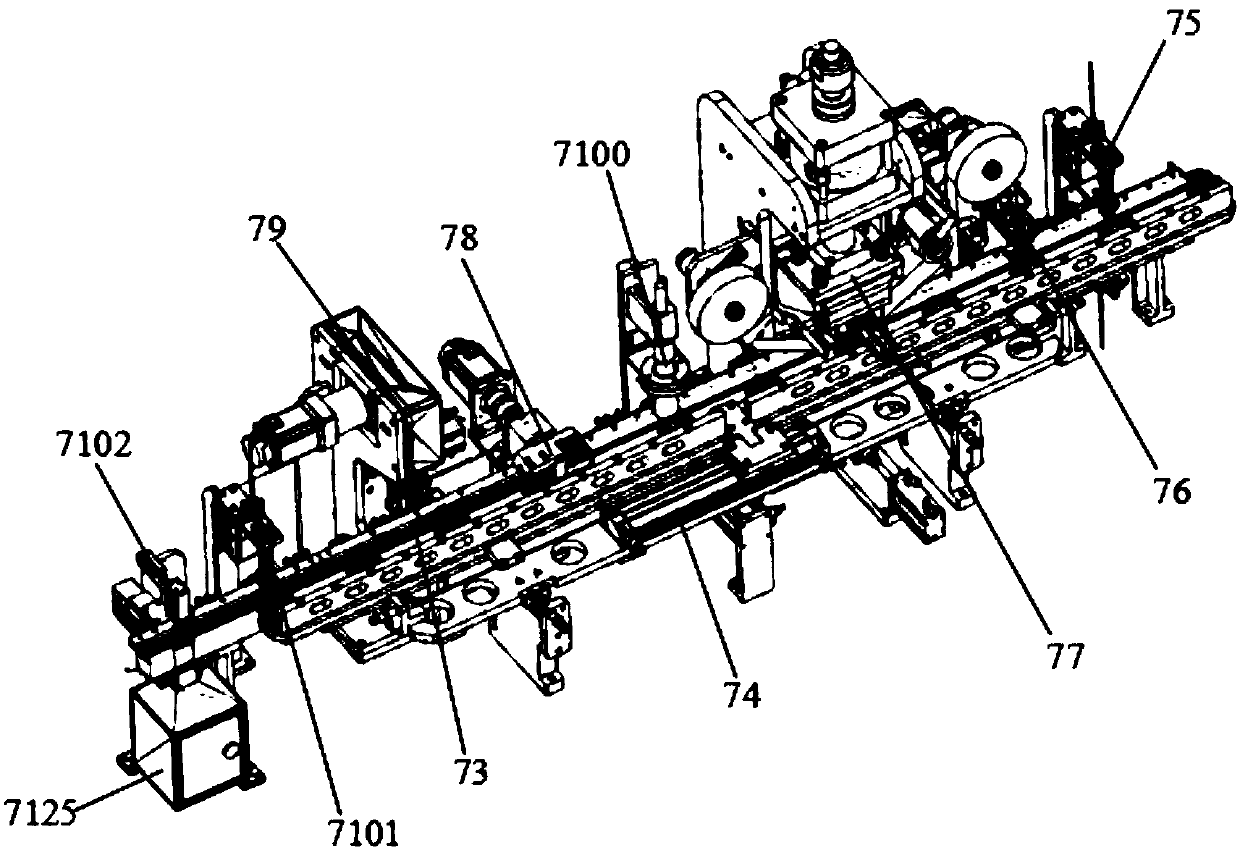

Automobile fuse full-automatic assembling machine

ActiveCN107910230ARealize automatic assemblyRealize automatic rivetingFuse device manufactureFuse (automotive)Rotating disc

The invention discloses an automobile fuse full-automatic assembling machine. The automobile fuse full-automatic assembling machine comprises a first rotating disc, a lower shell inputting station, afuse loading station, an upper shell loading station, a rivet pressing-in station, a product outputting station and detection units arranged between the stations, wherein the surface of the first rotating disc is provided with a plurality of first bearing fixtures which are arranged with an equal angle, the lower shell inputting station, the fuse loading station, the upper shell loading station, the rivet pressing-in station and the product outputting station are arranged around the first rotating disc, a lower shell assembly detecting line is arranged in a butt-joint manner at the lower shellinputting station, an upper shell assembly detecting line is arranged in a butt-joint manner at the upper shell loading station, a fuse cutting detecting device is arranged in a butt-joint manner atthe fuse loading station, a riveting assembly detecting line is arranged in a butt-joint manner at the rivet pressing-in station, and a marking blanking line is arranged in a butt-joint manner at theproduct outputting station. The automobile fuse full-automatic assembling machine realizes full-automatic assembly of automobile fuses, and is high in assembling efficiency and high in assembling accuracy.

Owner:苏州美尔科自动化设备有限公司

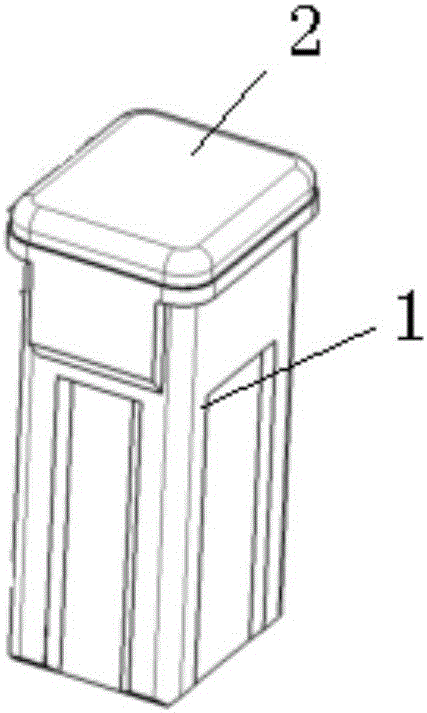

Automobile fuse box

The invention relates to an automobile fuse box. The automobile fuse box comprises a box body, a box cap, a plug-in board, a terminal, nut bases, bolts, bolt bases, bus bars, electricity taking ports, first fuse pieces and second fuse pieces, wherein the box body is rotationally connected with one end of the box cap, and the other end of the box body is in movable clamp connection with the other end of the box cap; the box body is internally provided with a plurality of baffles so as to form a first fuse piece insertion part and a second fuse piece insertion part; the bus bars are arranged in the box body. According to the application, by the structure design of the first fuse piece insertion part, the second fuse piece insertion part, the first fuse pieces and the second fuse pieces, the problem of poor contact due to unreliable fuse installation and fixation is solved. The fuse pieces in the fuse box are firm in installation and are low in contact resistance.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Automobile fuse which changes color when short circuited, and preparation method thereof

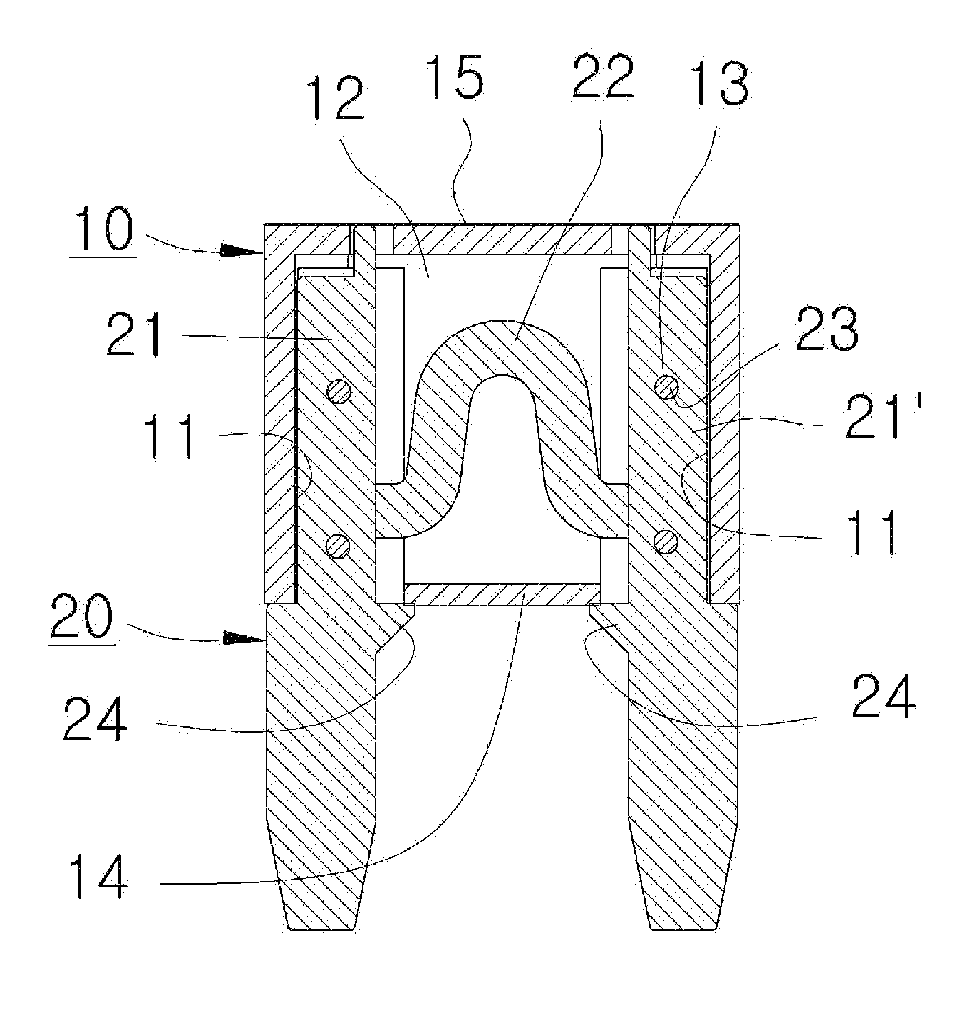

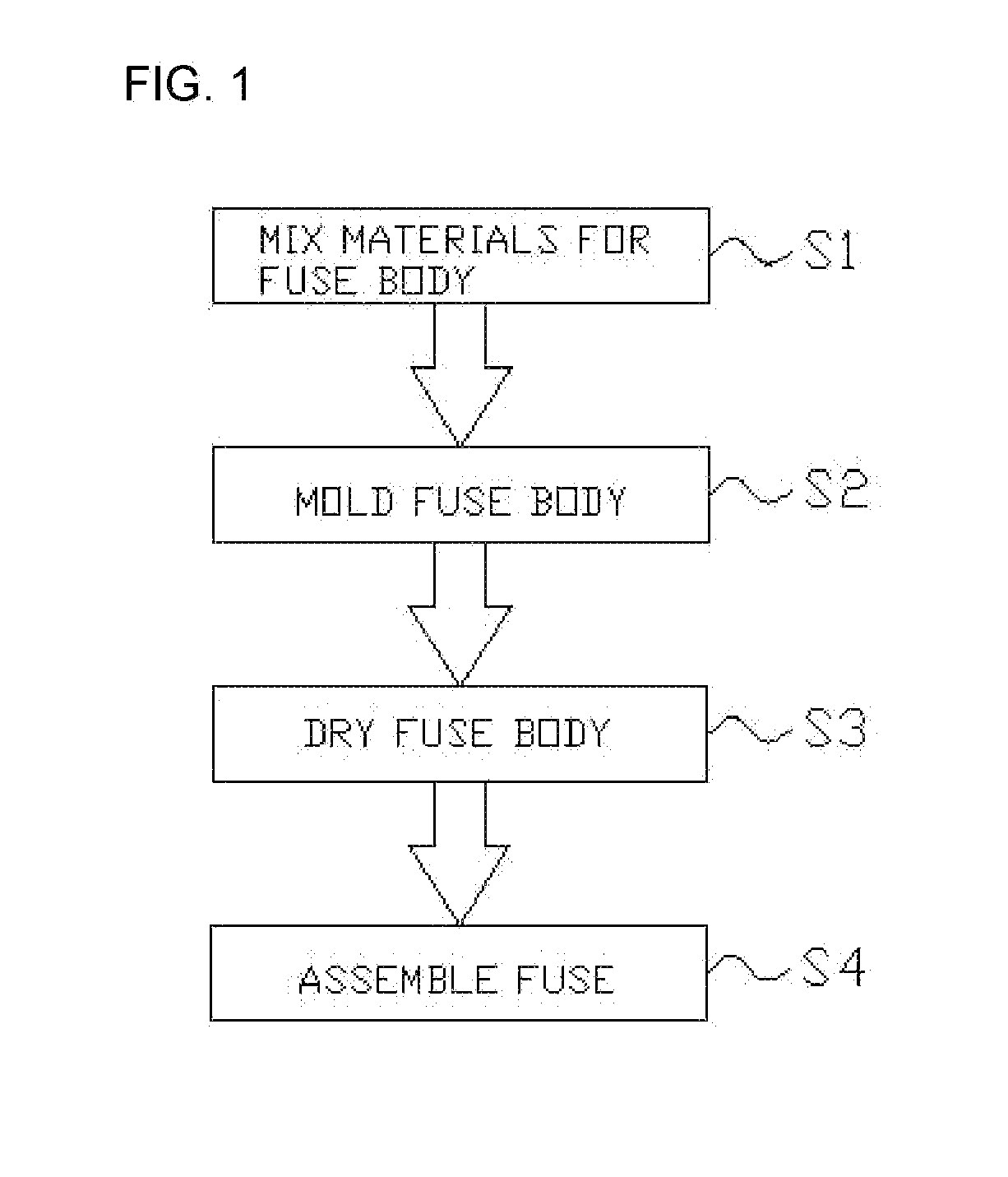

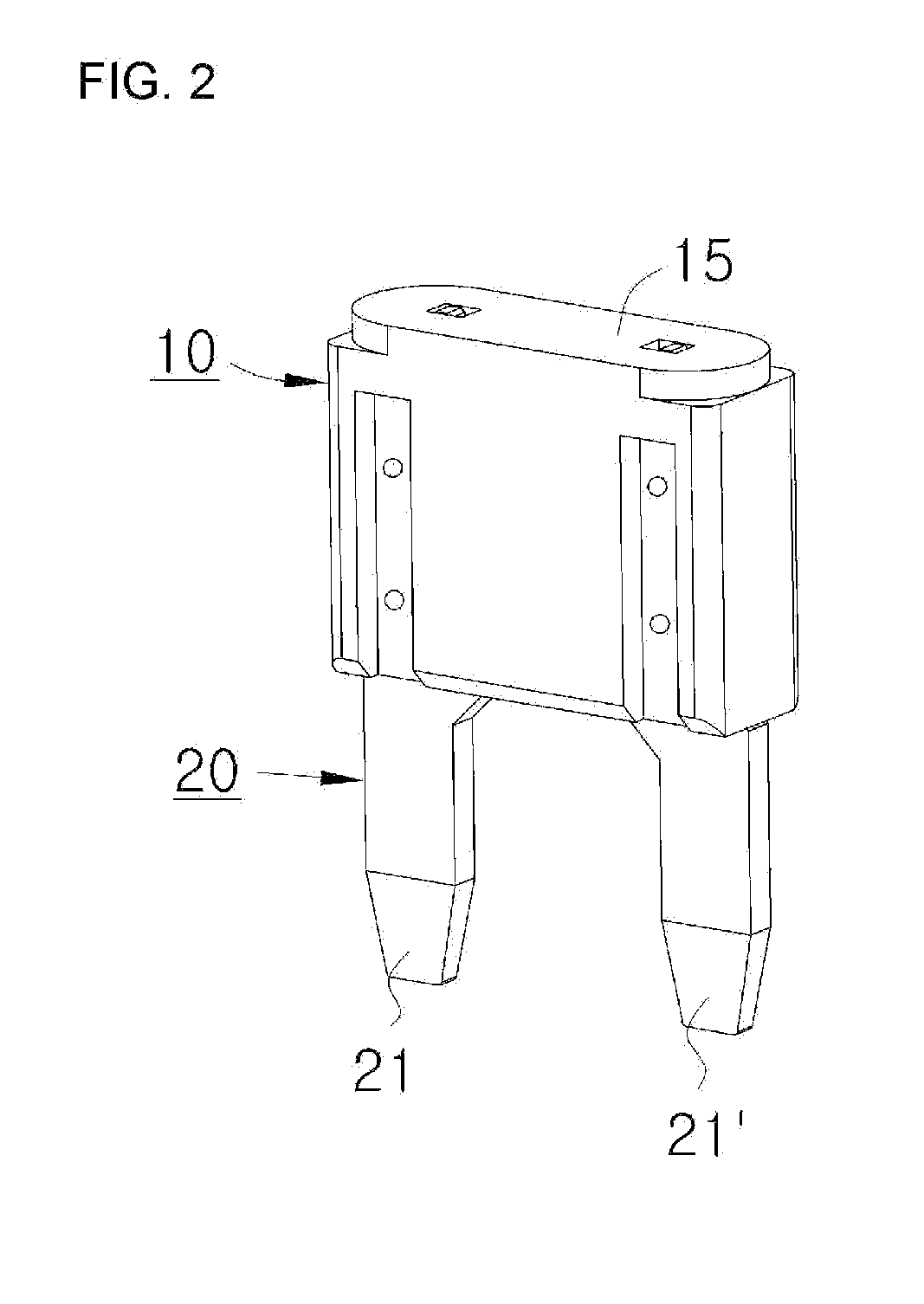

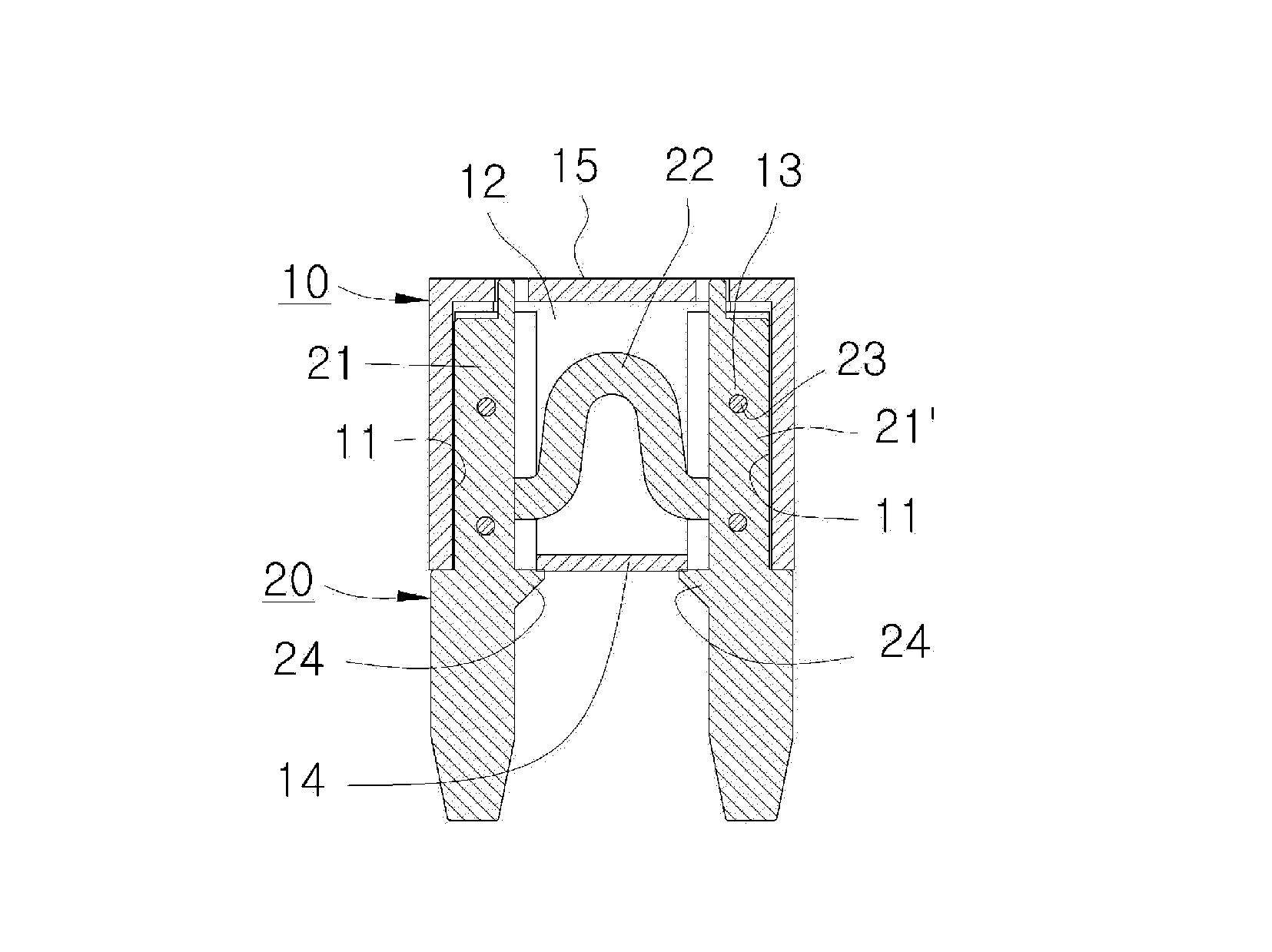

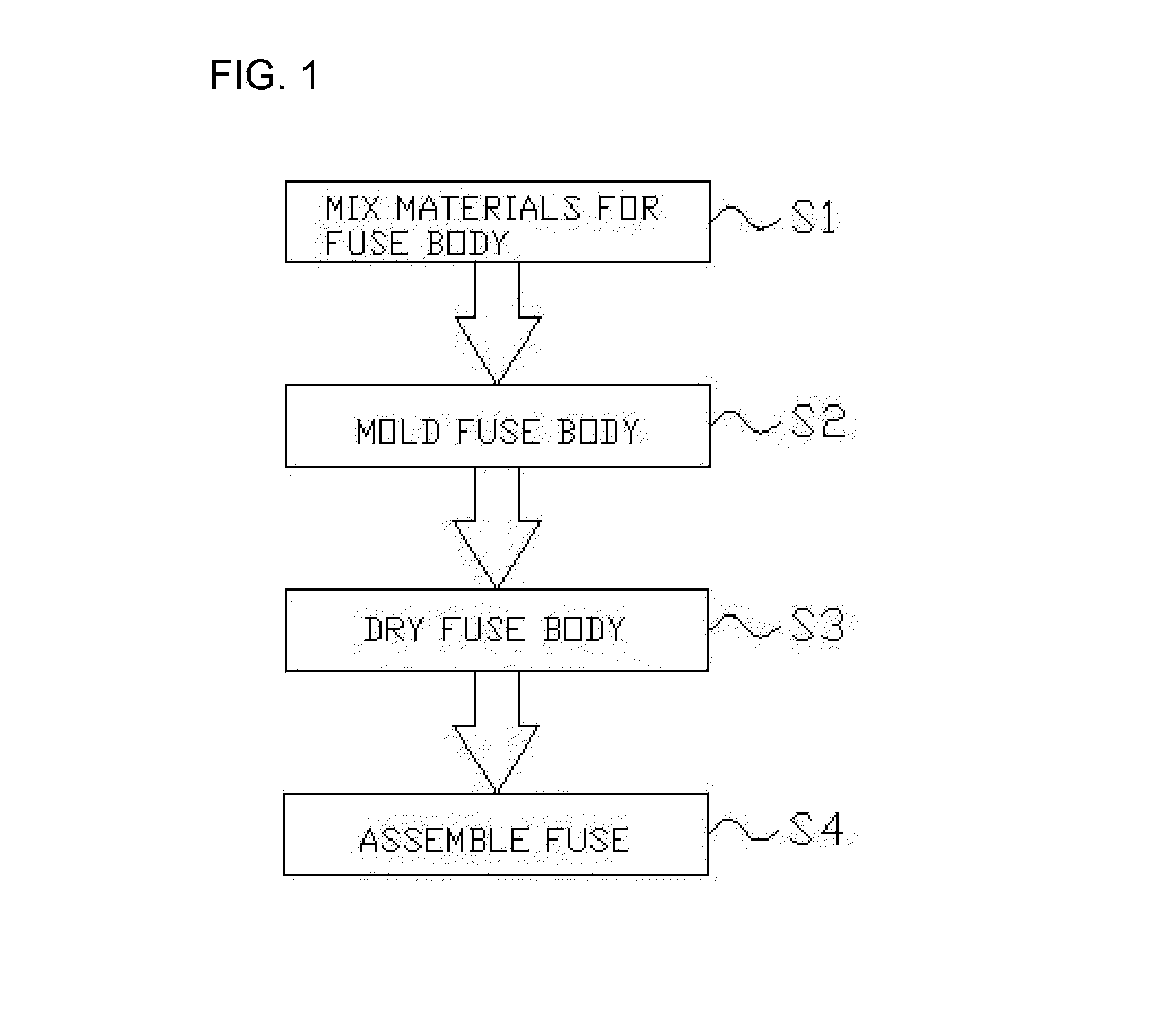

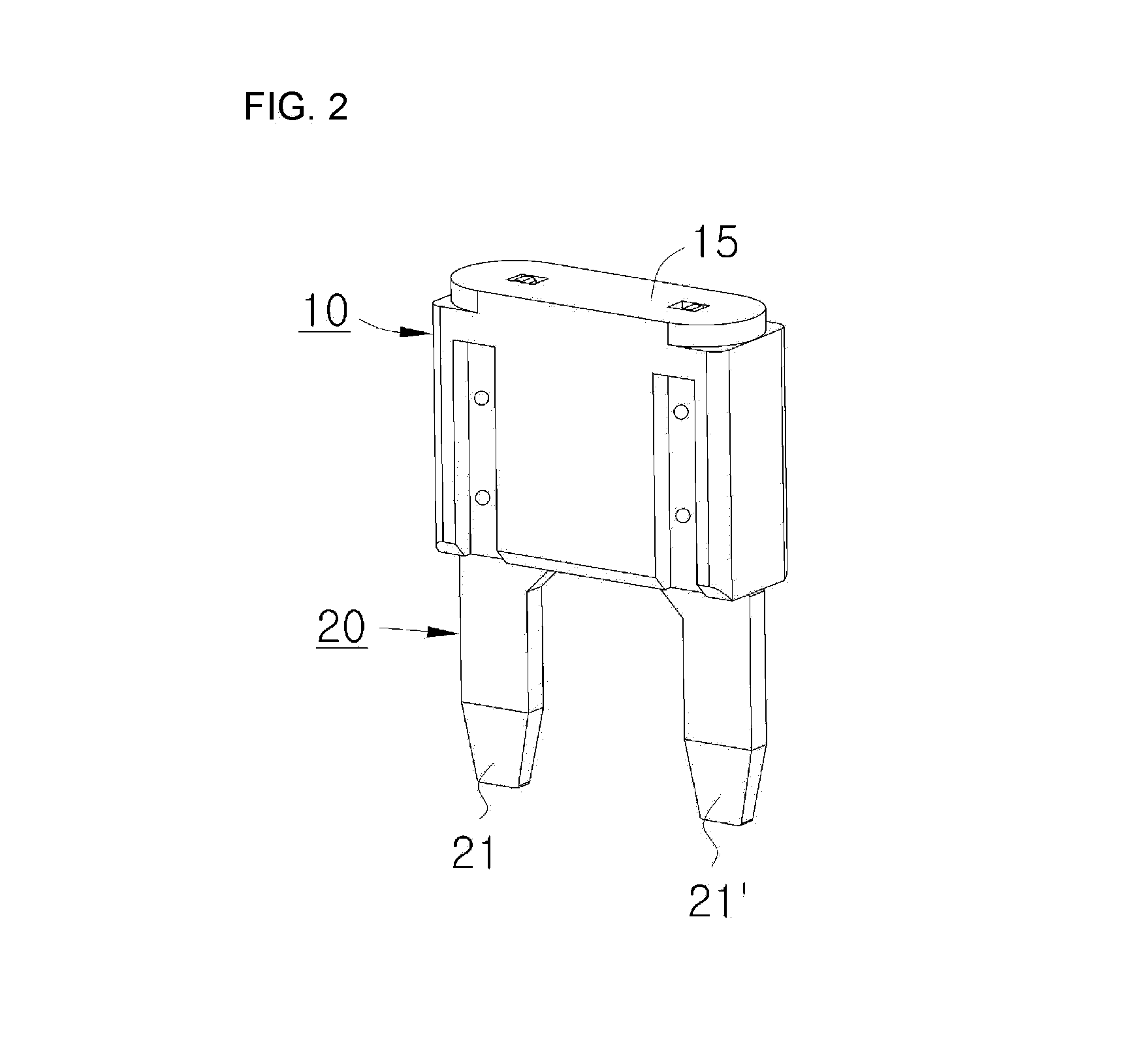

ActiveUS20120223801A1Easy to identifySimply replacedFuse device manufactureInjection pressureChange color

An automobile fuse is provided wherein short circuit of the fuse can be easily identified by naked eye through change of color when a fuse short circuits, and provides an automobile fuse manufacturing method, comprising: the fuse body material mixing step (S1) of mixing 96˜99 wt % colored plastic powder and 1˜4 wt % transparent irreversible thermochromic pigment powder to prepare a mixture material.; the fuse body molding step (S2) of melting the mixture material in an injection molding machine to mold a fuse body containing a thermochromic pigment component in an injection mold at an injection temperature of 300˜310° C. and an injection pressure of 1200˜1600 kgf / cm2; the fuse body drying step (S3) of drying the fuse body containing a thermochromic pigment component at 100˜200° C. for 3˜5 hours to reduce the water content of the fuse body to 0.1 wt % or less; and the fuse assembling step (S4) of inserting a fuse where a fuse member is fixed between a pair of terminal members into a pair of terminal insertion grooves and a fuse charge groove of the fuse body containing a thermochromic pigment component, for coupling thereto. If the fuse short circuits, the color of the shift layer coated on fuse body (10) or a color conversion label adhered on the upper surface of the fuse body (10), changes. Accordingly, a short circuited fuse is easily identified with the naked eye, and the fuse can be easily replaced.

Owner:MOON HYUNGTAI

Halogen-free flame-retardant polypropylene composite for auto fuse holder, preparation method and application

InactiveCN102604221AImprove flame retardant performanceHigh CTI valuePolypropylene compositesHeat deflection temperature

The invention discloses a halogen-free flame-retardant polypropylene composite for an auto fuse holder, a preparation method and application. The polypropylene composite is prepared by 32-83% of polypropylene, 0-1% of heat stabilizer, 0-1% of processing agent, 10-30% of halogen-free intumescent flame retardant, 2-6% of compatilizer and 5-30% of reinforcing filler, wherein the halogen-free intumescent flame retardant refers to phosphorus-nitrogen halogen-free intumescent flame retardant. The halogen-free flame-retardant polypropylene composite for the auto fuse holder has excellent flame-retardant effect, high CTI (comparative tracking index) value, good comprehensive mechanical property, excellent folding resistance and high heat distortion temperature, the flame retardant property can reach 1.6mm V0, tensile strength is larger than or equal to 30MPa, bending modulus is larger than or equal to 2000MPa, CTI is larger than or equal to 500V, hinge folding times are larger than or equal to 106, notch impact strength is larger than or equal to 3.5KJ / m2, and heat distortion temperature (0.45MPa) is larger than or equal to 120 DEG C.

Owner:KINGFA SCI & TECH CO LTD +2

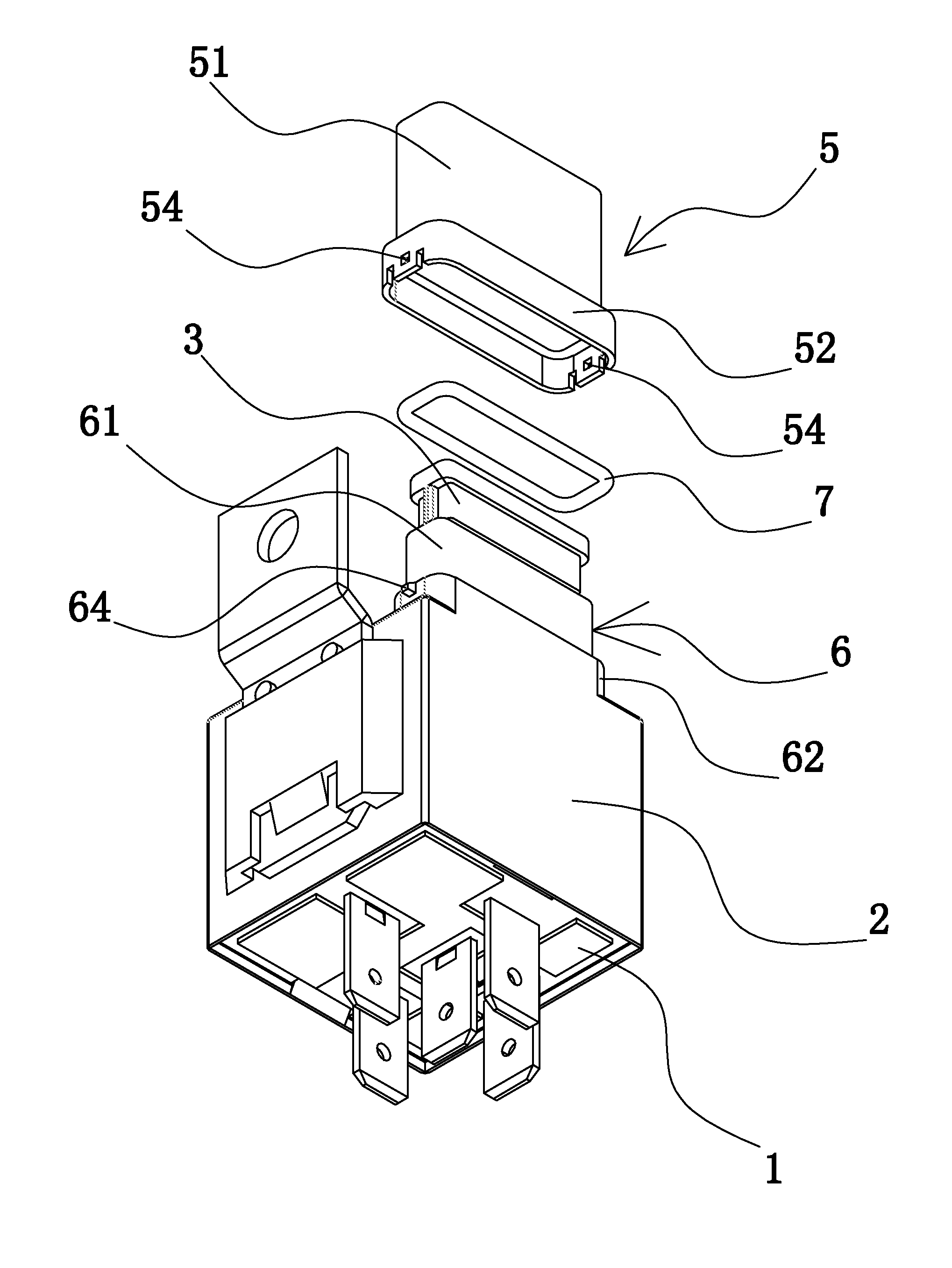

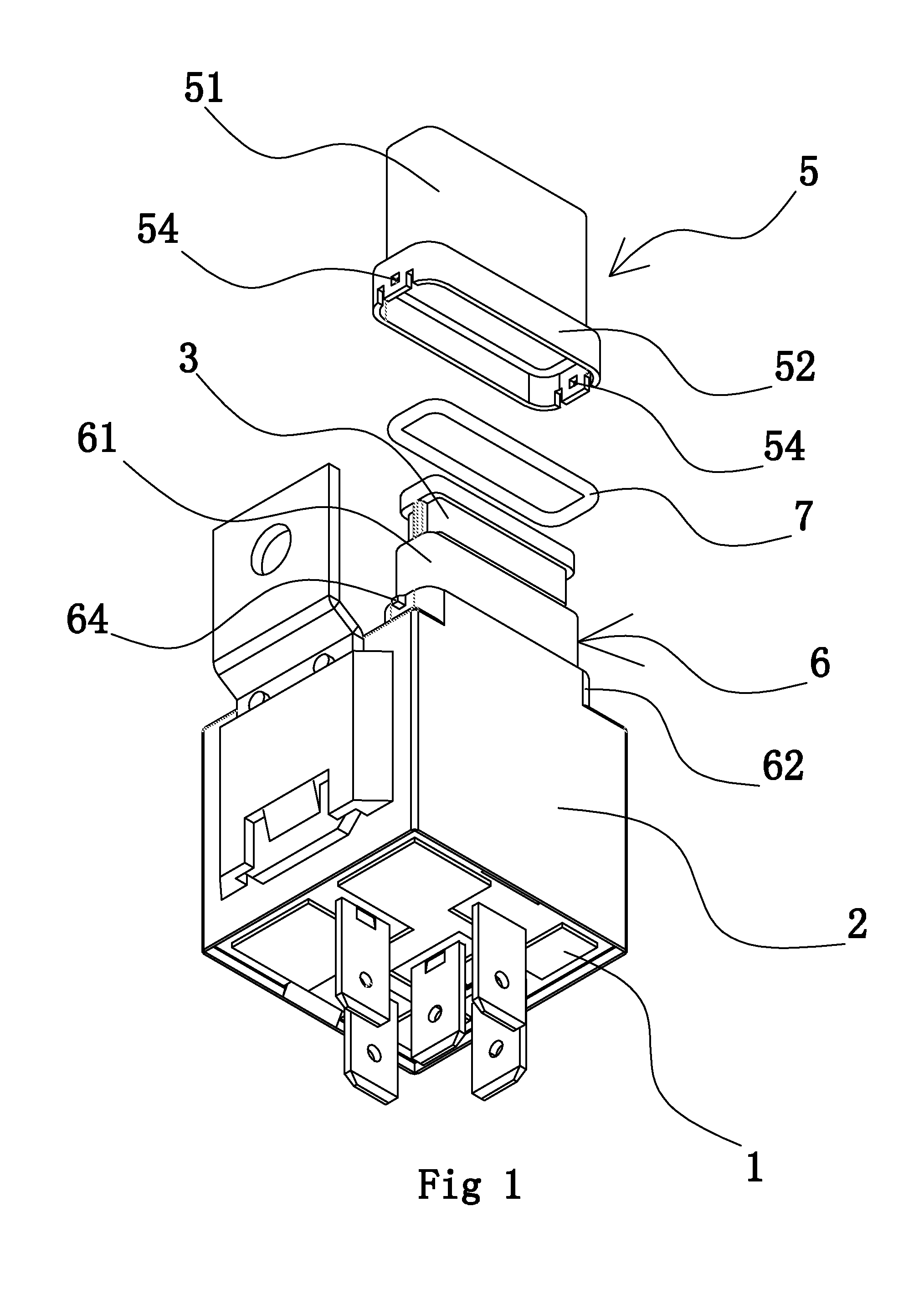

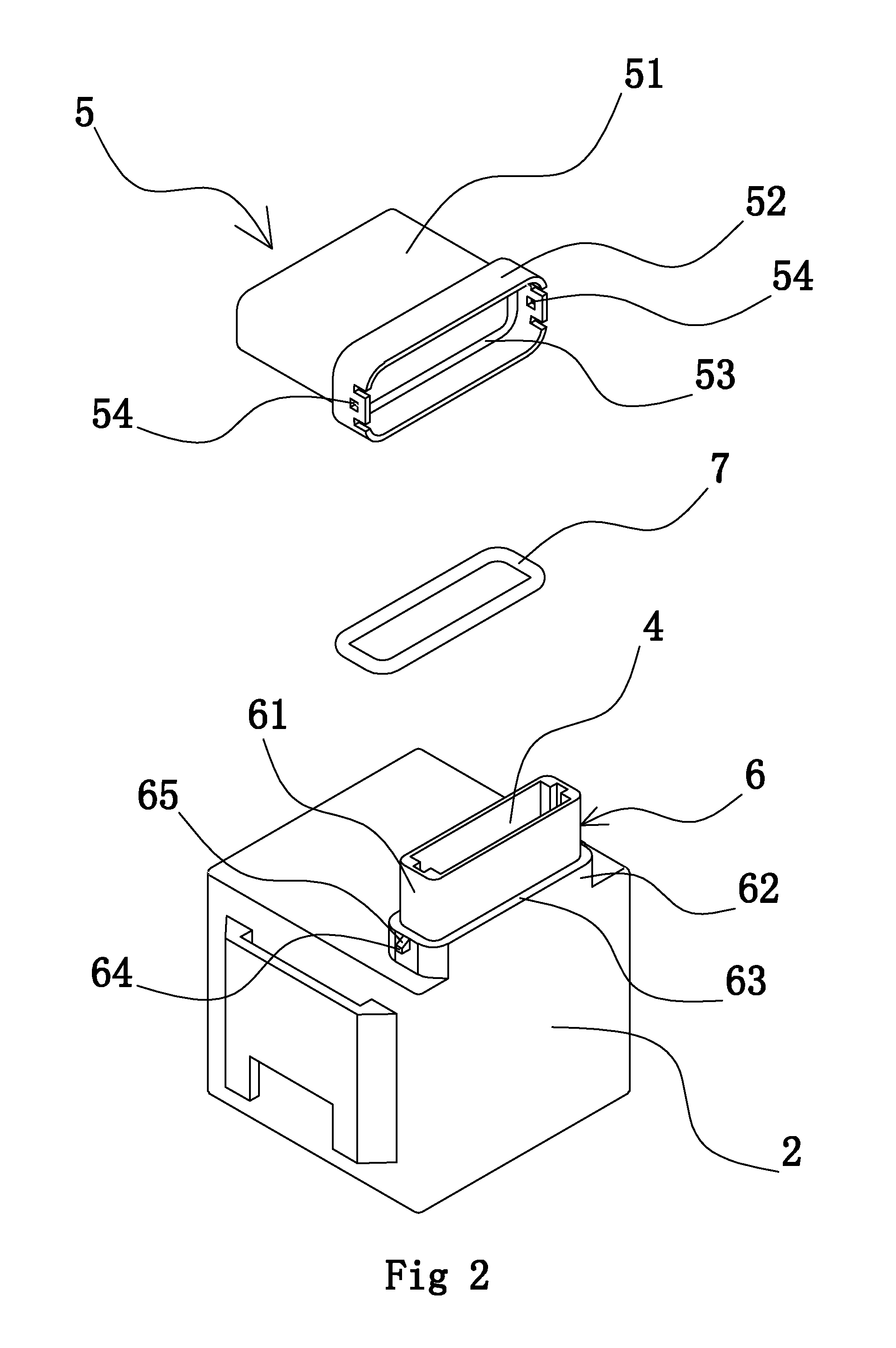

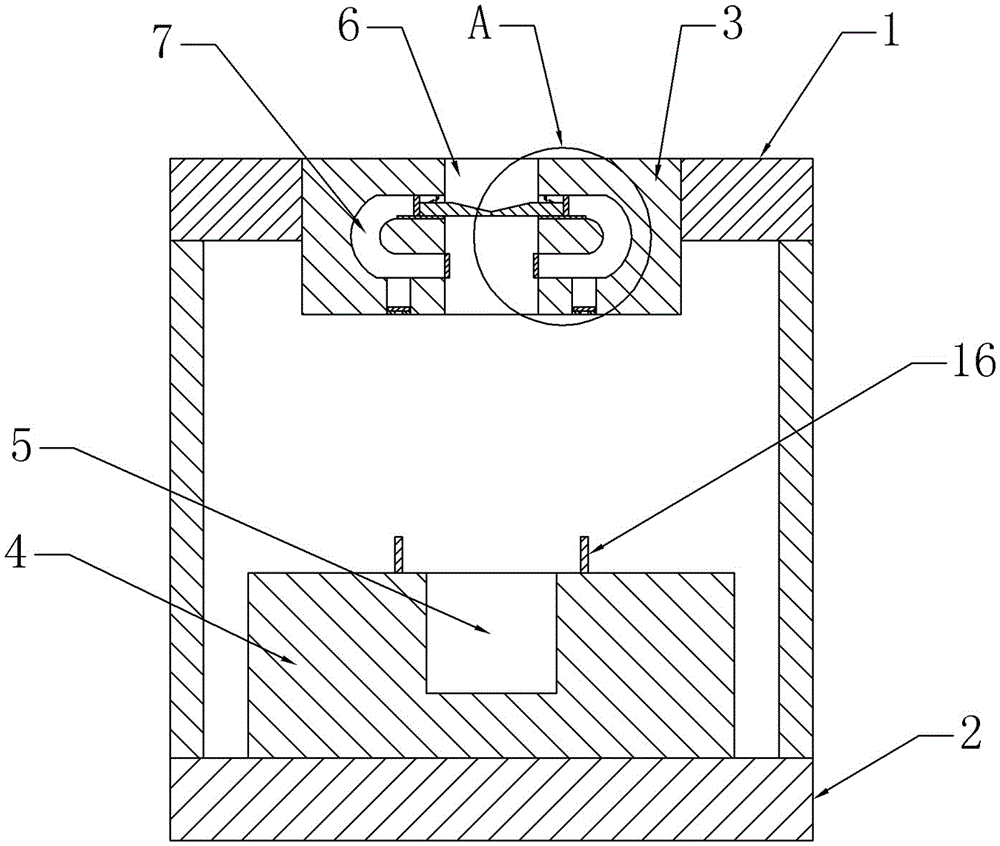

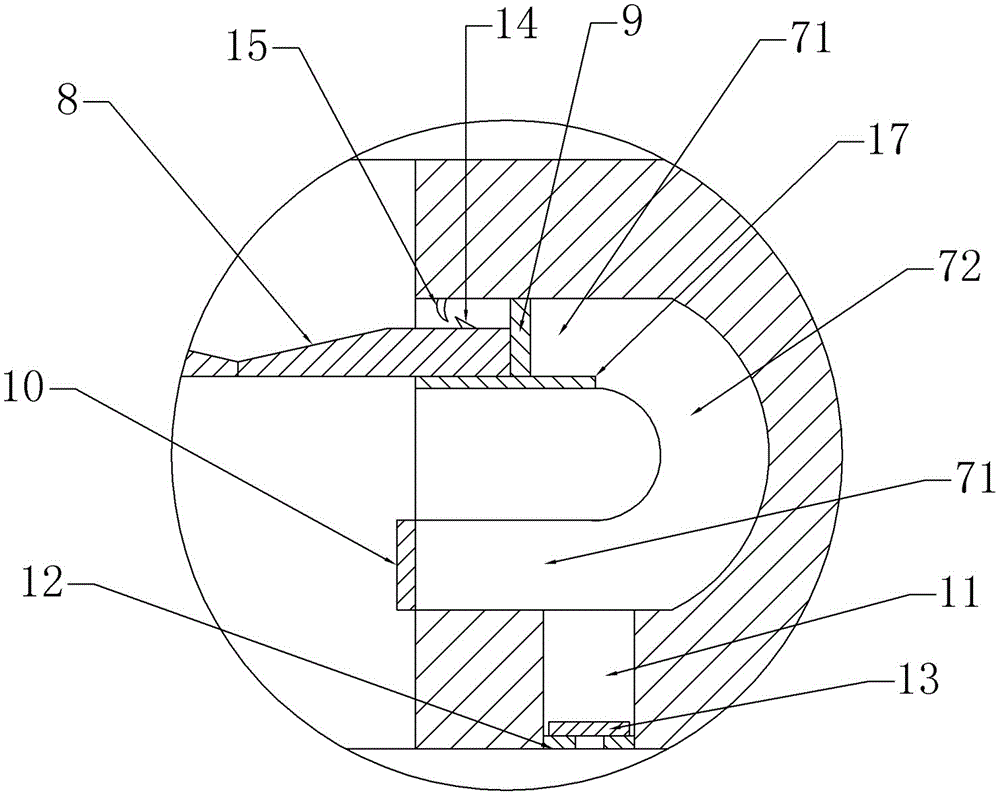

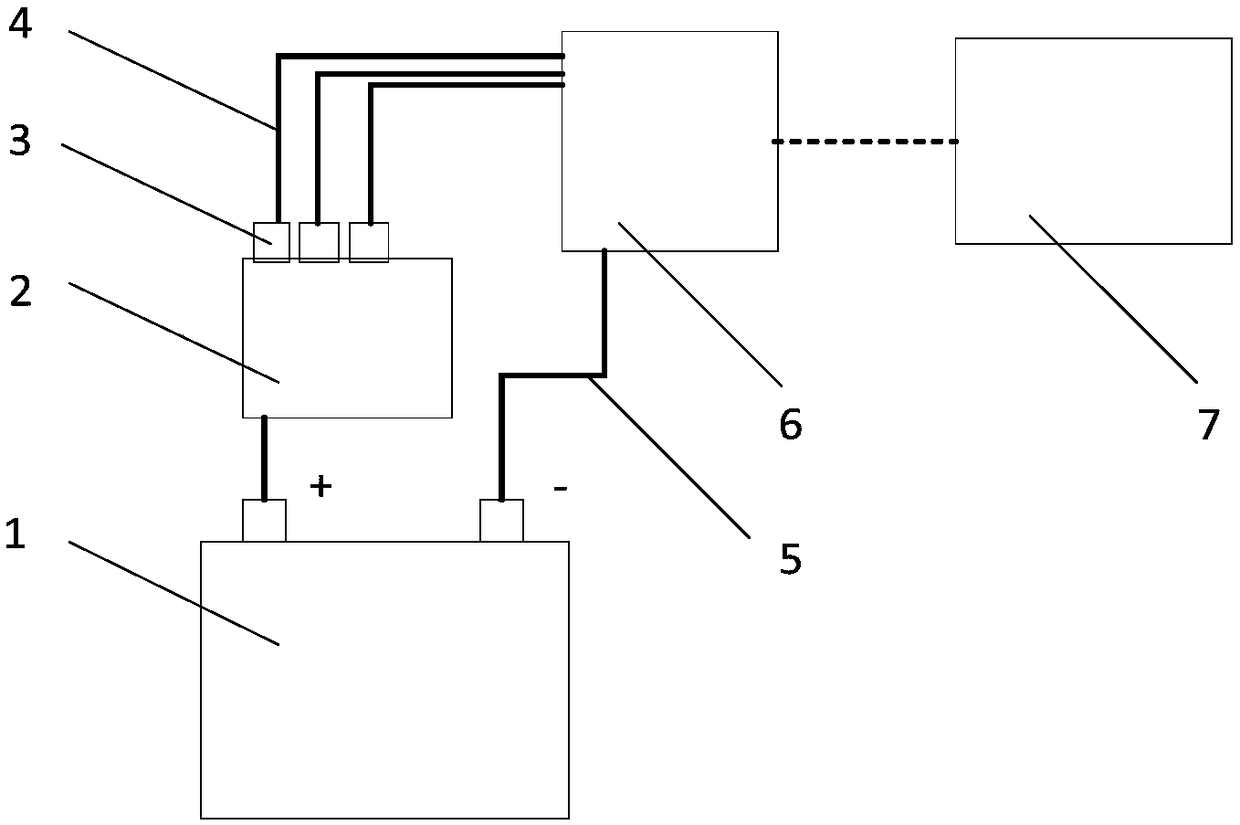

Sealing type automotive relay with a safety device

InactiveUS20150130568A1Improve sealingExtended service lifeEmergency casingsElectrothermal relaysEngineeringMechanical engineering

The present invention provides a sealing type automotive relay with a safety device in the field of automotive relays, which addresses the problems of inconvenient fuse replacement and poor sealing property of the fuse in the existing relays. The sealing type automotive relay with a safety device comprises a relay main body and a safety device. The relay main body includes a base, a casing and a weak current system and a strong current system located on the base. The casing is fixedly connected with the base. The safety device includes two fuse sockets positioned on the base and a fuse inserted between the said two fuse sockets. The top of the casing is provided with a fuse inserting hole corresponding to the said two fuse sockets. The fuse is inserted into the inserting hole. A sealing cover is provided at the port of the fuse inserting hole. The sealing cover is sealedly connected to the port of the fuse inserting hole and the inner cavity of the sealing cover together with the fuse inserting hole forms a sealed cavity. The said fuse is located within the sealed cavity. The relay of the invention has advantages including good sealing property, convenience in fuse replacement and strong universality.

Owner:NINGBO YINZHOU YONGLIN ELECTRON ELECTRICAL EQUIP

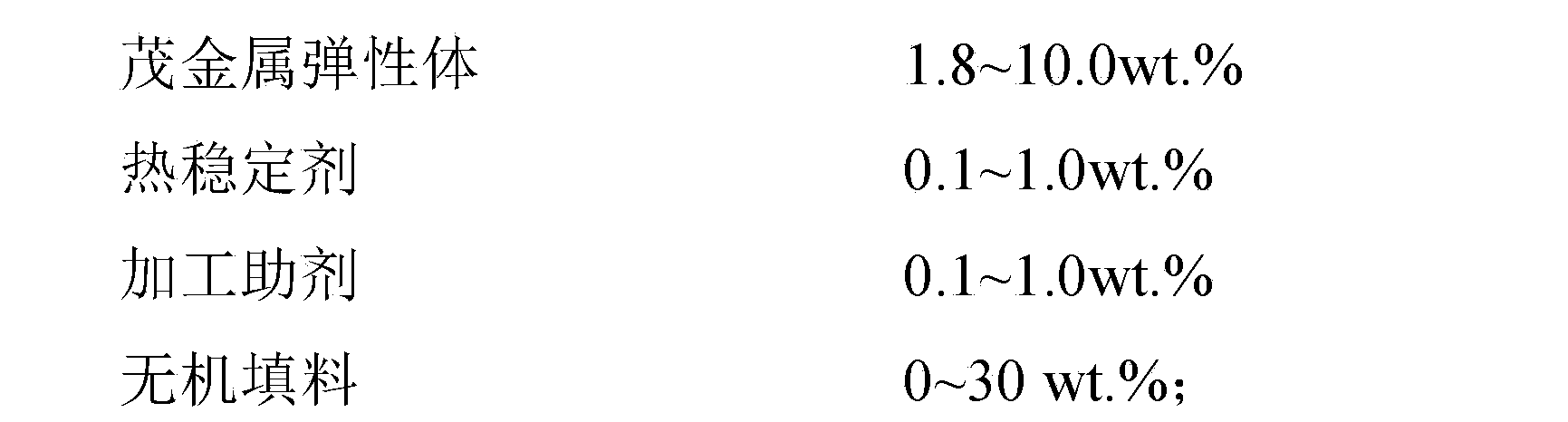

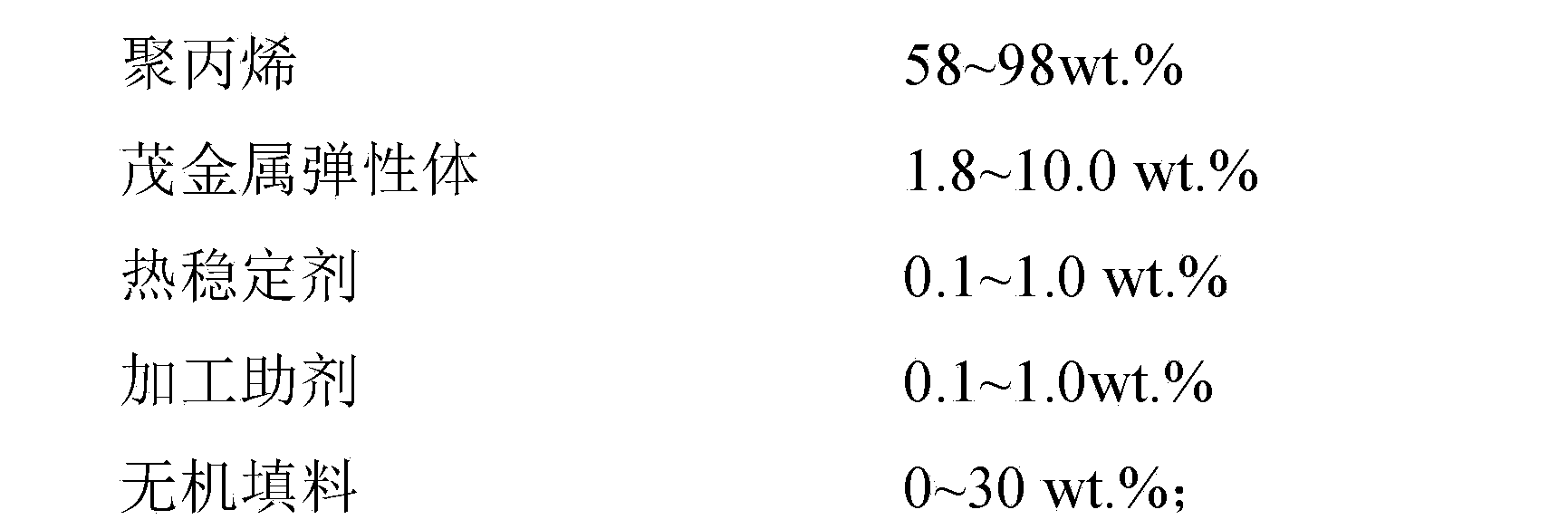

Folding-resistant polypropylene composite material and preparation method for same

InactiveCN103819812AImprove folding resistanceImprove heat resistanceElastomerHeat deflection temperature

The invention discloses a folding-resistant polypropylene composite material and a preparation method for the same. According to the composite material, at least one of homopolymerized propylene and copolymerized propylene with melt flow rate of 0.01 to 100g / 10min is adopted as a resin substrate, and a metallocene elastomer with melt flow rate of 0.5 to 100g / 10min and propylene content of 80 to 90 weight percent is adopted as a toughening agent, so that the folding resistance of the polypropylene under low-temperature and mineral-filled conditions is improved, and the obtained composite material has high rigidity, high heat resistant, extremely high breaking elongation, high folding resistance, tensile strength of more than or equal to 27MPa, bending modulus of more than or equal to 1,500MPa, notch impact strength of more than or equal to 5KJ / m<2> at normal temperature (23 DEG C), breaking elongation of more than or equal to 200 percent, heat distortion temperature of more than or equal to 110 DEG C and minus 20 DEG C hinge (0.5mm) folding times of more than or equal to 106, and is applied to an automotive interior part with a hinge structure such as an automotive fuse box.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

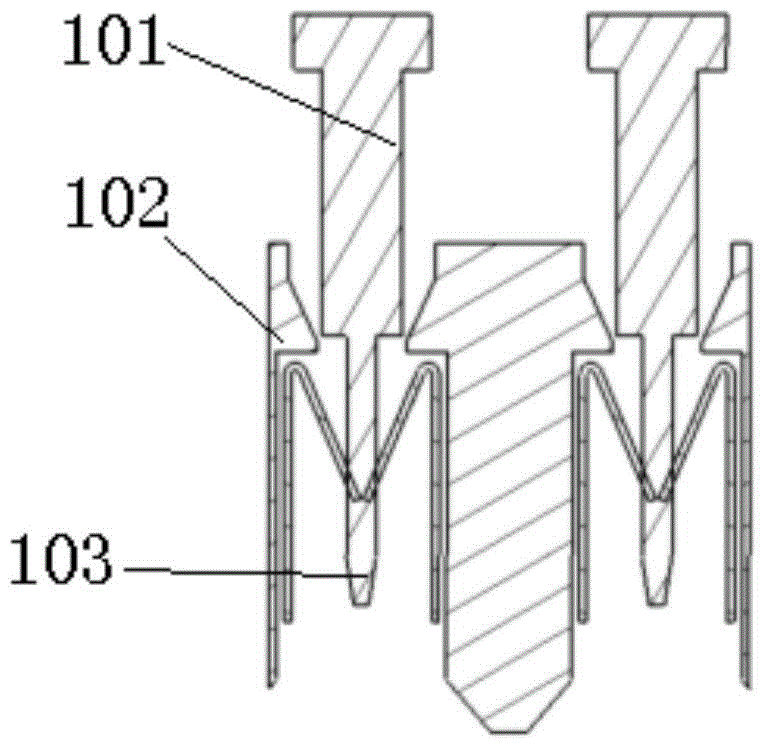

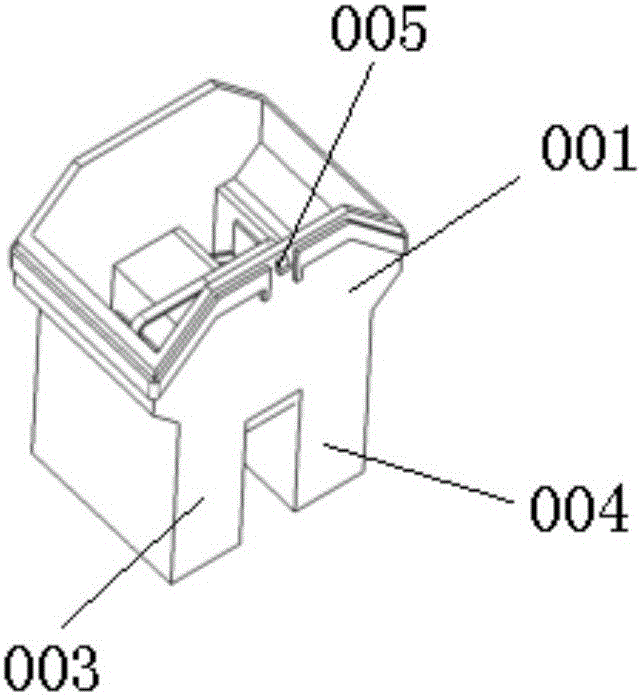

Automotive fuse structure

InactiveCN105161384ANot easy to shakeNot easy to accumulate waterEmergency protective devicesForeign matterEngineering

The invention relates to an automotive fuse structure, which comprises a fuse shell and a fuse, wherein the fuse is clamped into the fuse shell; the fuse shell comprises a shell body, a shell cover, a left pin part and a right pin part; the shell cover is clamped with the upper end of the shell body; the left pin part and the shell body are in a communicated integral structure; and the right pin part and the shell body are in a communicated integral structure. According to the technical scheme provided by the automotive fuse structure, through a spaced structure design of the left pin part and the right pin part, a short-circuit fault is avoided; the protectiveness is improved; through the structural design of a fuse support part, the internal part of the fuse is not easy to shake; the inserted terminal is stable to fix; through a protruding structure and a transparent material of the shell cover, the field of view is large; and water or a foreign matter and the like are not easily accumulated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Manufacturing of an automobile fuse

A method of manufacturing an automobile comprising: mixing 96˜99 wt % of colored plastic powder with 1˜4 wt % of transparent irreversible thermochromic pigment powder thus preparing a material mixture for a fuse body; melting the material mixture using an injection molding machine so that the fuse body containing a thermochromic pigment component is molded at an injection temperature of 300˜310° C. and an injection pressure of 1200˜1600 kg f / cm2 using an injection mold; drying the fuse body containing the thermochromic pigment component at 100˜200° C. for 3˜5 hr; inserting a fuse element comprising a pair of terminal members and a fuse member fixed therebetween into a pair of terminal insertion recesses and a fuse charging recess of the fuse body containing the thermochromic pigment component.

Owner:MOON HYUNGTAI

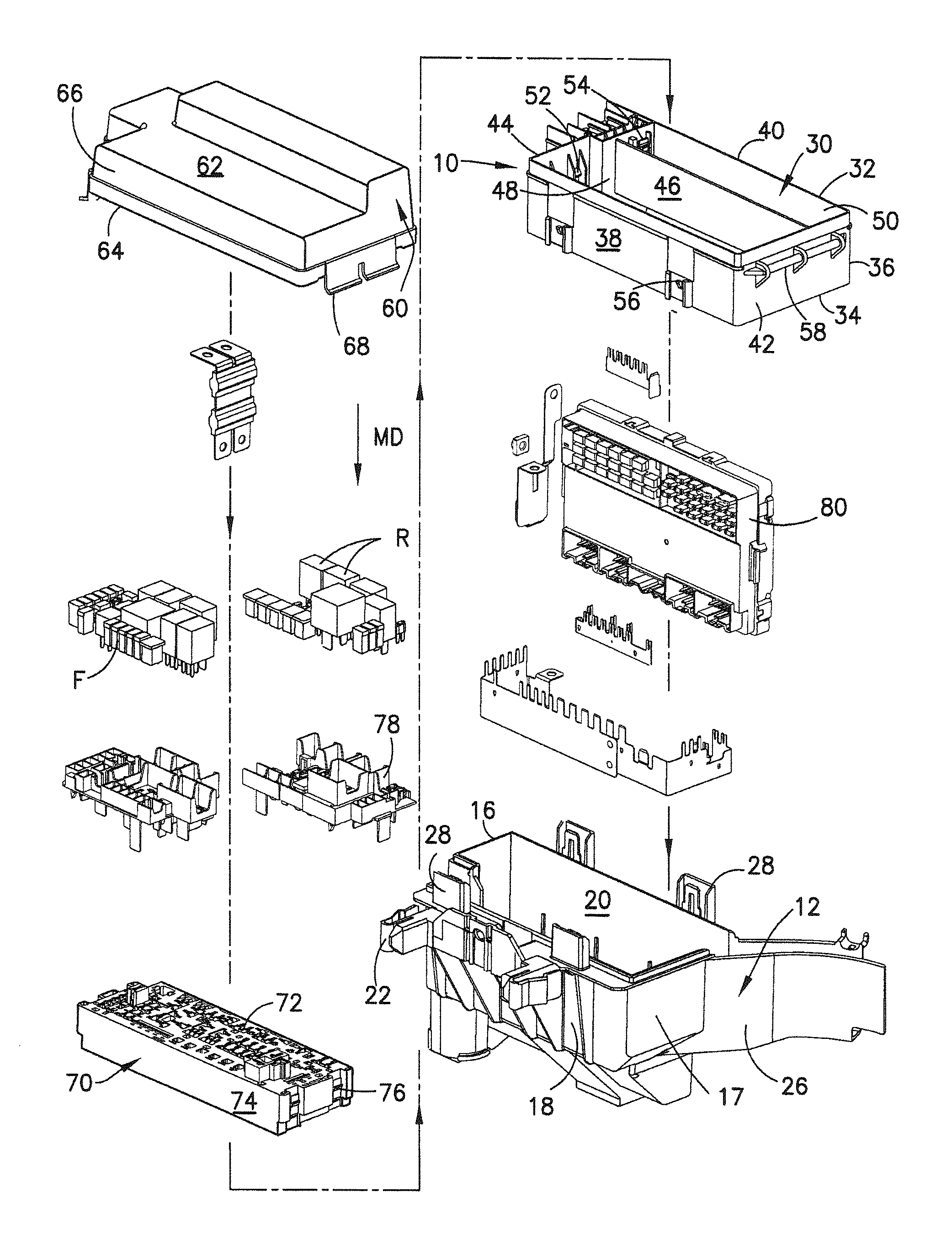

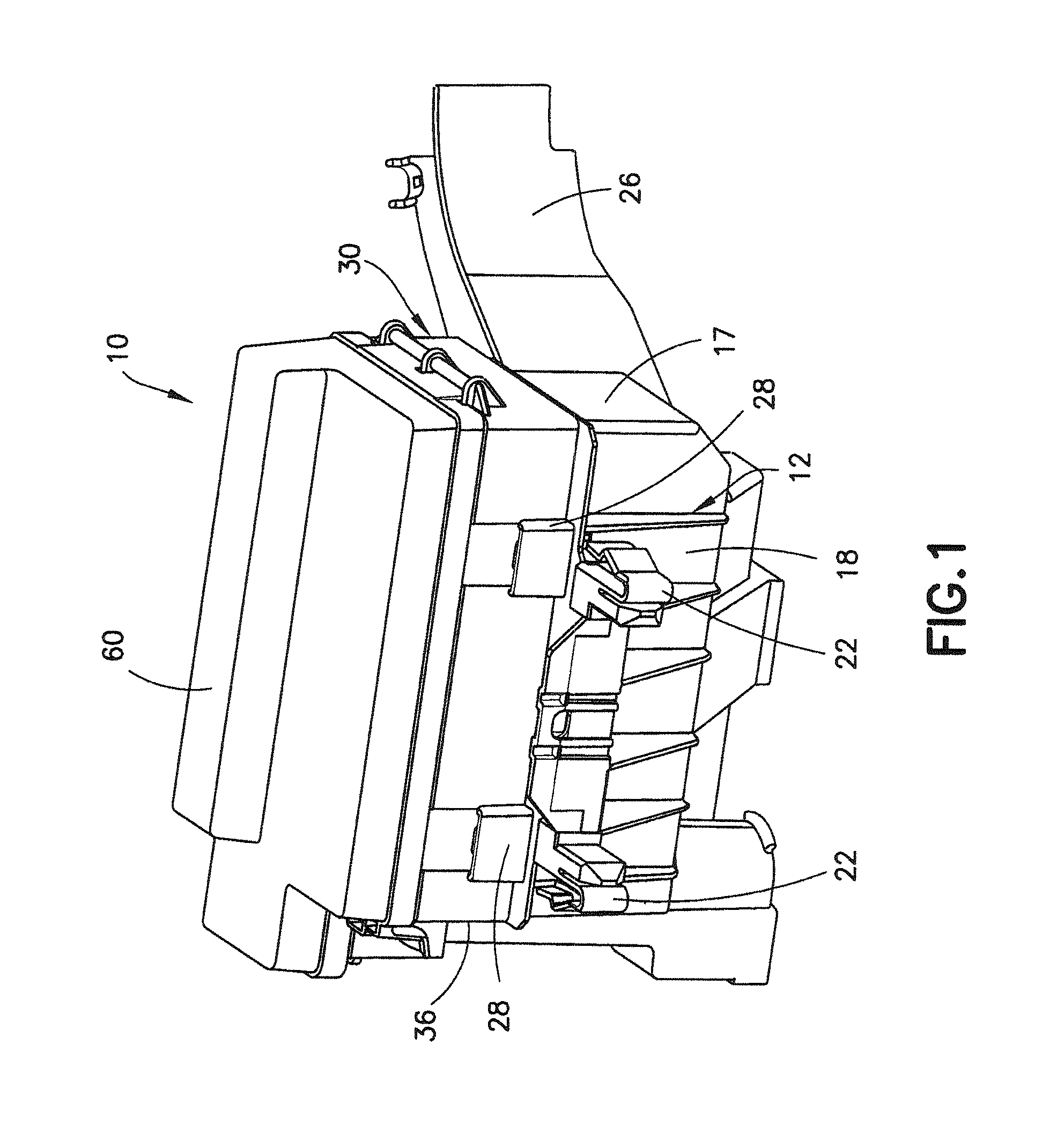

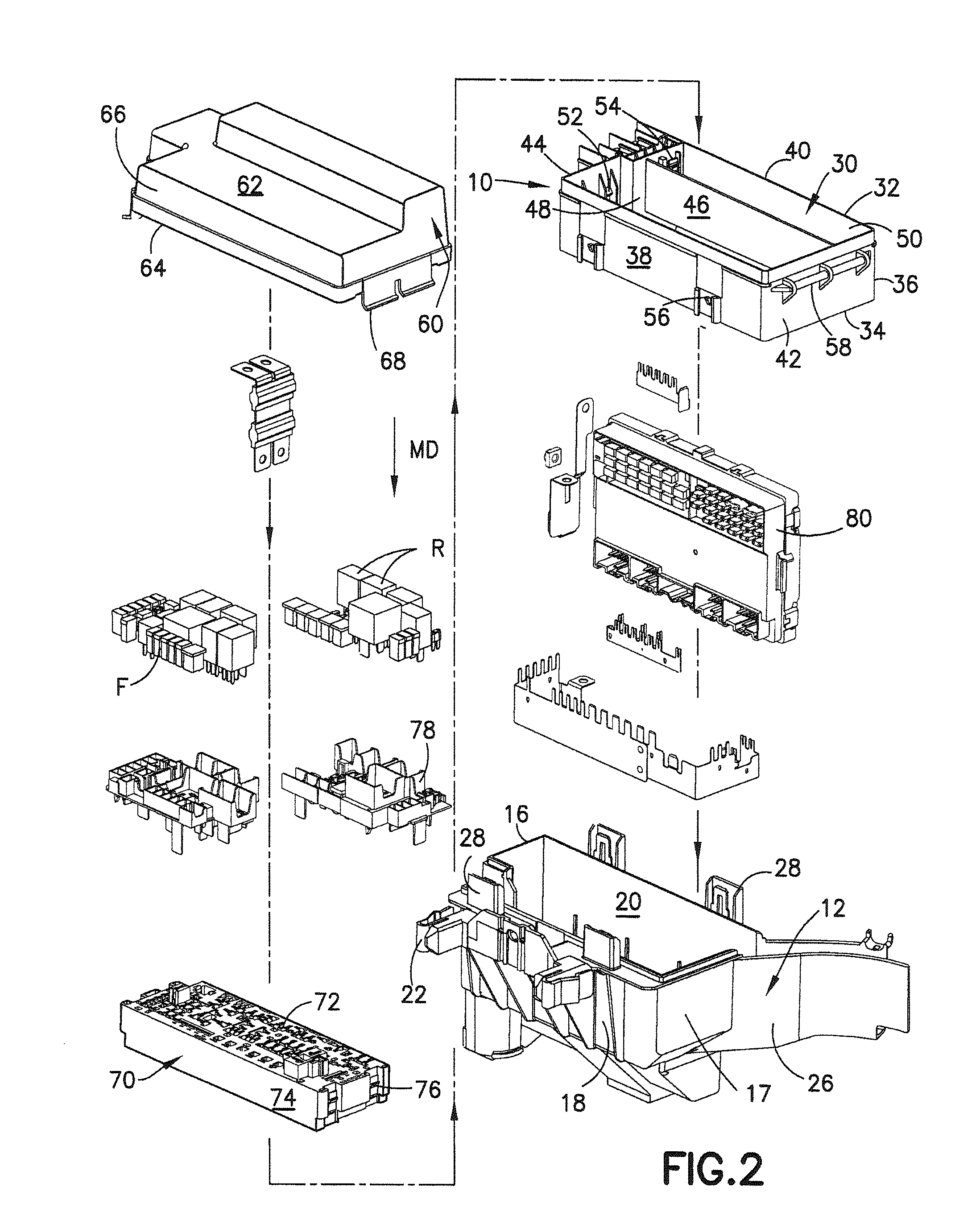

Automotive fuse and relay block assembly

InactiveUS20140118888A1Easy accessIncrease the footprintSubstation/switching arrangement casingsElectromagnetic relay detailsElectrical devicesSmall footprint

A fuse and relay block assembly (10) for an automotive vehicle includes a lower cover (12) and an upper cover (60) mounted in substantially opposed relationship to one another. A relay block (70) is mounted between the lower cover (12) and the upper cover (60) and can receive electrical devices (R, F) mounted along a mounting direction (MD). A relay module assembly (80) is mounted between the lower cover (12) and the upper cover (60) and can receive electrical devices (R, F) mounted along a transverse direction (TD) substantially perpendicular to the mounting direction (MD). Thus, a greater density of electrical devices (R, F) can be mounted within a smaller footprint.

Owner:SUMITOMO WIRING SYST LTD

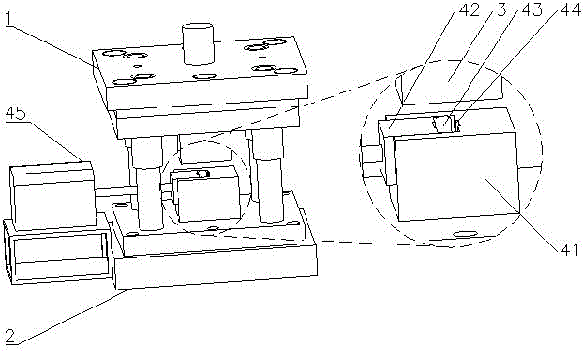

Automobile fuse press-fitting die

InactiveCN104128507AAccurate insertionImprove yieldShaping toolsAtmospheric pressureMechanical engineering

The invention relates to the technical field of automobile part machining, in particular to an automobile fuse press-fitting die which comprises an upper die base and a lower die base. A clamping device is fixedly connected to the portion above the lower die base. A press-fitting die block is fixedly connected to the portion below the upper die base. The clamping device comprises a fixed block and a sliding block. The side edge of the fixed block is provided with a sliding groove perpendicular to the upper surface of the fixed block and forms a first extruding face. The sliding block is arranged in the sliding groove in a sliding mode. One side of the sliding block is fixedly connected with a pneumatic cylinder used for driving the sliding block to slide in the sliding groove. According to the automobile fuse press-fitting die, an automobile fuse shell is fixed on the clamping device, then an automobile fuse insertion piece is fixed on the press-fitting die block, by means of the compressing effect of a die pressing device, the insertion piece can be inserted into the shell in a one-time mode, insertion is accurate, the rate of finished products is high, and the production efficiency is improved; moreover, space matched with the automobile fuse shell in shape is formed between the fixed block and the first extruding face, and therefore the machining error is greatly reduced.

Owner:常州常利来电子有限公司

Automobile fuse box with secondary lock structure

PendingCN108597970ASave man hoursInhibit sheddingContact electric connectionEmergency protective devicesEngineeringFuse (automotive)

The invention discloses an automobile fuse box with a secondary lock structure. The automobile fuse box is characterized in that a lock plate with threading holes is arranged on the back face of the automobile fuse box; terminal holes matched with the threading holes are arranged in the fuse box; the lock plate and the fuse box are provided with a first clamping position and a second clamping position; when the lock plate and the fuse box are located in the first clamping position, wire harness terminals penetrate through the threading holes of the lock plate; when the lock plate reaches the second clamping position again, a second clamping connection is triggered, and the wire harness terminals are clamped and fixed by the walls of the threading holes; and when the lock plate and the fusebox are located in the second clamping position, the locking plate is arranged at the lowest position in the fuse box. The automobile fuse box has the beneficial effects that an integral secondary lock structure is adopted, so that different layouts can be reduced, and different electric appliances can be inserted into the lock plate from different directions, the labor of inserting the wiring harness terminals by a fuse box manufacturer is reduced while a plastic mold is reduced, and an effect of reducing the cost is achieved.

Owner:宁波华科汽车零部件有限公司

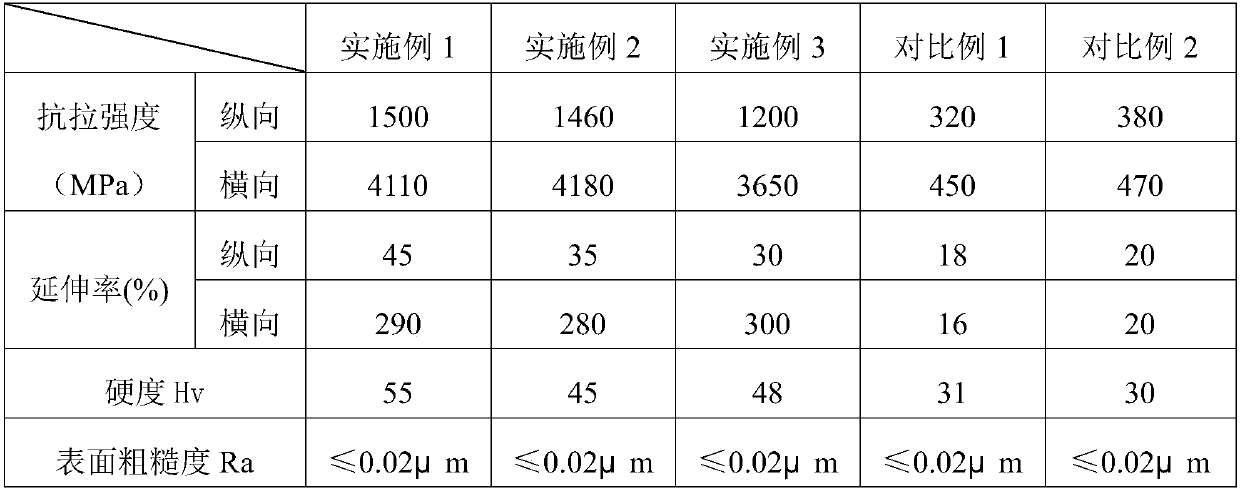

Zinc alloy, preparation method thereof and automobile fuse

InactiveCN107794409AThe proportion of ingredients is reasonableImprove mechanical propertiesZinc alloysTitanium

Owner:广州番禺于一金属加工有限公司

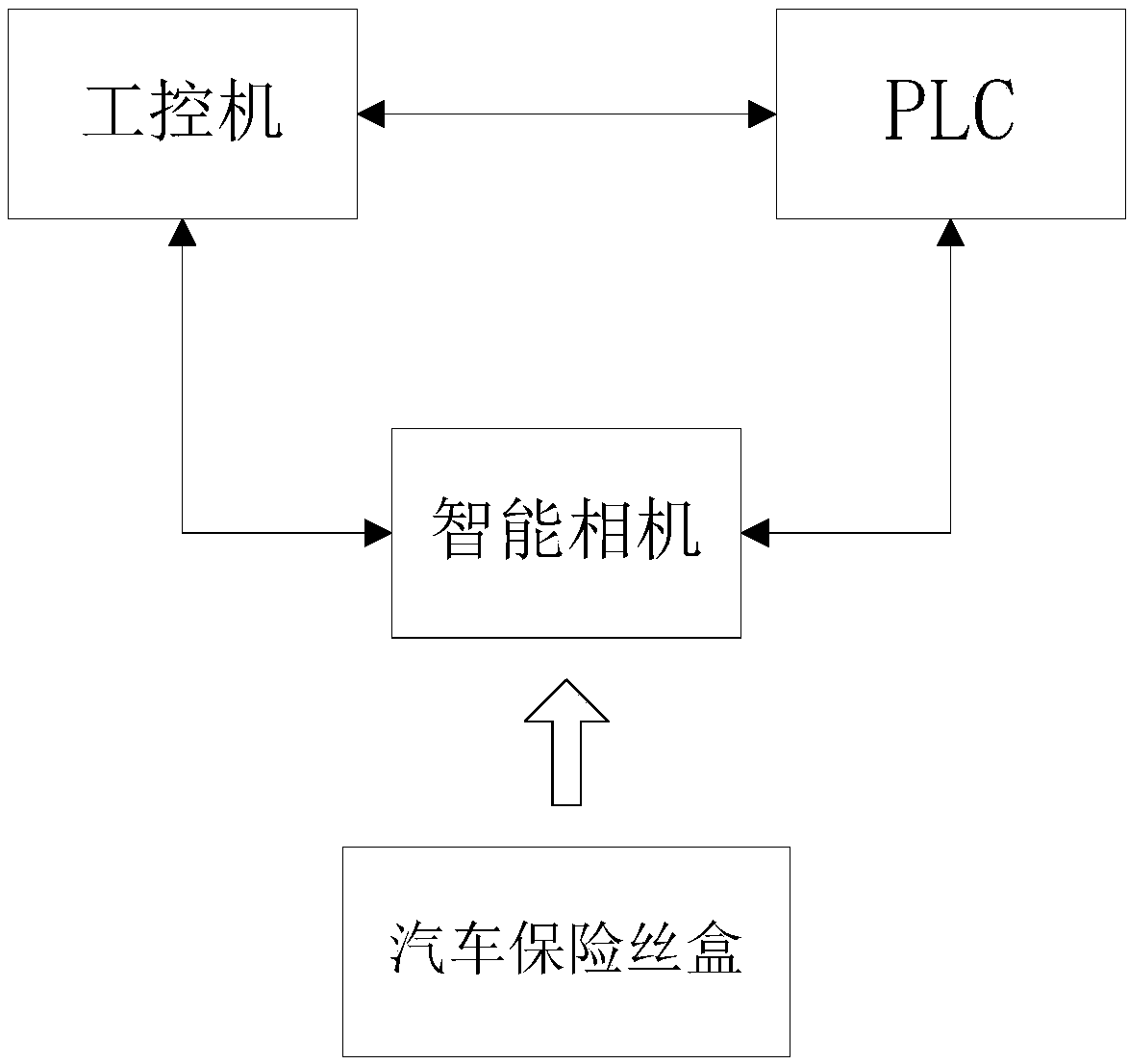

Visual recognition detection system for automobile fuse block

ActiveCN109521015ARealize automatic switchingEasy to operateMaterial analysis by optical meansBarcodeVisual recognition

The invention relates to a visual recognition detection system for an automobile fuse block. The detection system comprises an industrial personal computer, a PLC and an intelligent camera, wherein animage recognition system is loaded in the intelligent camera, the industrial personal computer is in communication connection to the PLC through a serial port, the PLC is in communication connectionto the intelligent camera through a serial port, the intelligent camera is in communication connection to the industrial personal computer through a serial port, the intelligent camera shoots an imageof a fuse in the automobile fuse block and sends the recognition result of the fuse to the industrial personal computer, and sends the recognition result to the PLC, and the PLC judges whether the image of the product is qualified or not, if so, the PLC controls a jig to quit, and a red qualified lamp is turned on. The intelligent camera informs the industrial personal computer to shear the picture of the test to an appointed folder and name the picture by scanning the content of the barcode of the product. If the image is not qualified, the PLC locks the jig which does not quit, the green lamp is turned on and the PLC informs the industrial personal computer to delete unqualified pictures of the test.

Owner:SHANGHAI HUGONG AUTO ELECTRIC

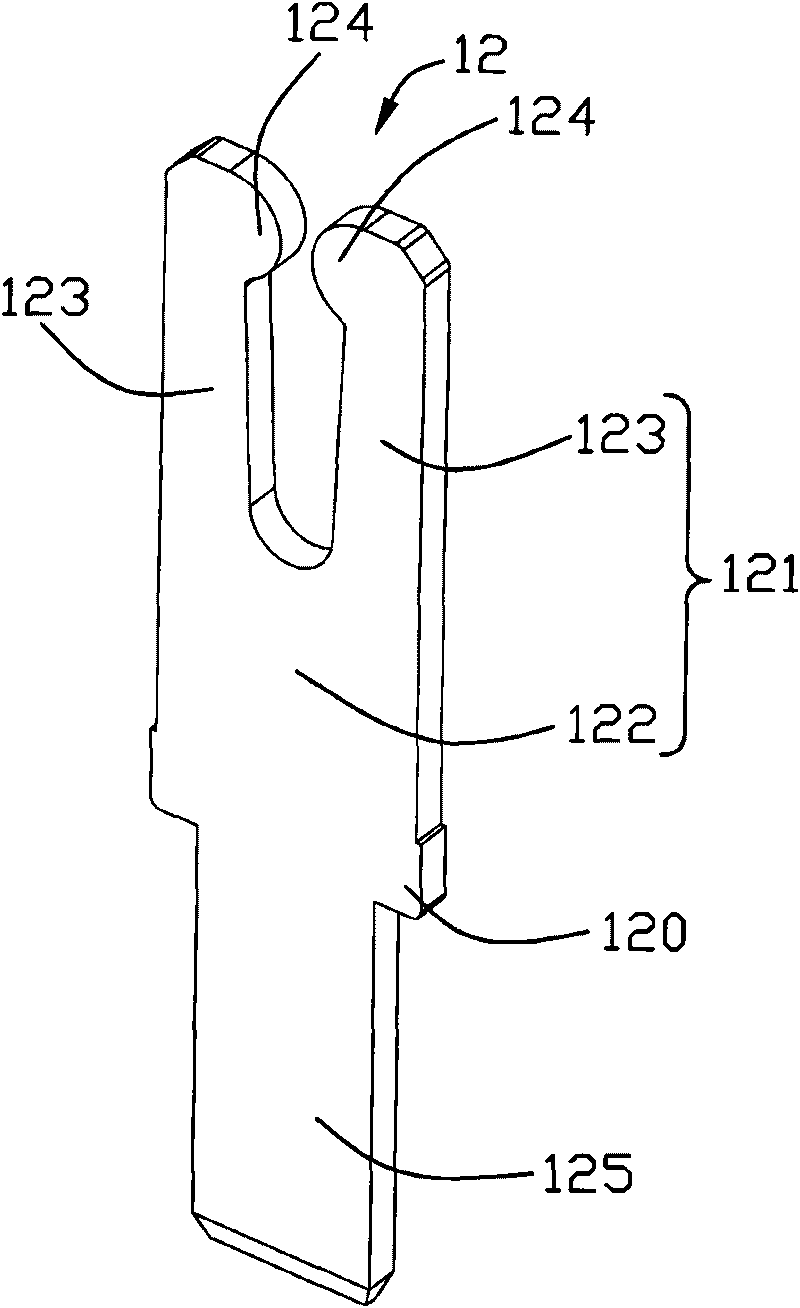

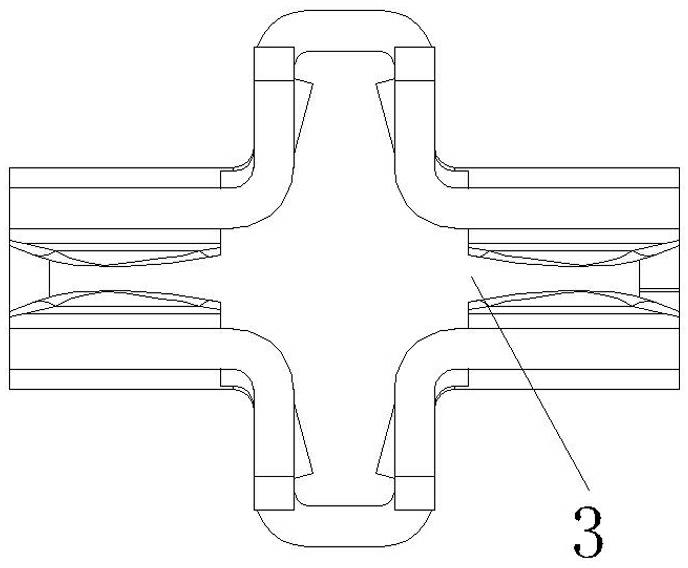

Connection terminal used by automobile fuse box

InactiveCN102496537AIncrease elasticityStable clamping contact forceEmergency protective devicesContact forceEngineering

The invention relates to a connection terminal used by an automobile fuse box. The connection terminal comprises a terminal body; the upper end of the terminal body is provided with a relay pin insertion portion; the lower end of the terminal body is provided with a busbar insertion portion; four right-angle folded fins are arranged at the upper portion of the terminal body, wherein an upper cross space is formed by enclosing of the four right-angle folded fins; and the vertical space of the upper cross space forms the relay pin insertion portion. Besides, a lower cross space is formed at the lower portion of the terminal body; and the vertical space of the lower cross space forms the busbar insertion portion. Because the relay pin insertion portion is in a cross shape and elasticity is strong, relay pins with different dimensions can be inserted; and even multi-time plugging is carried out, a stable clamping contact force can be maintained.

Owner:NINGBO HUADE AUTOMOBILE PARTS

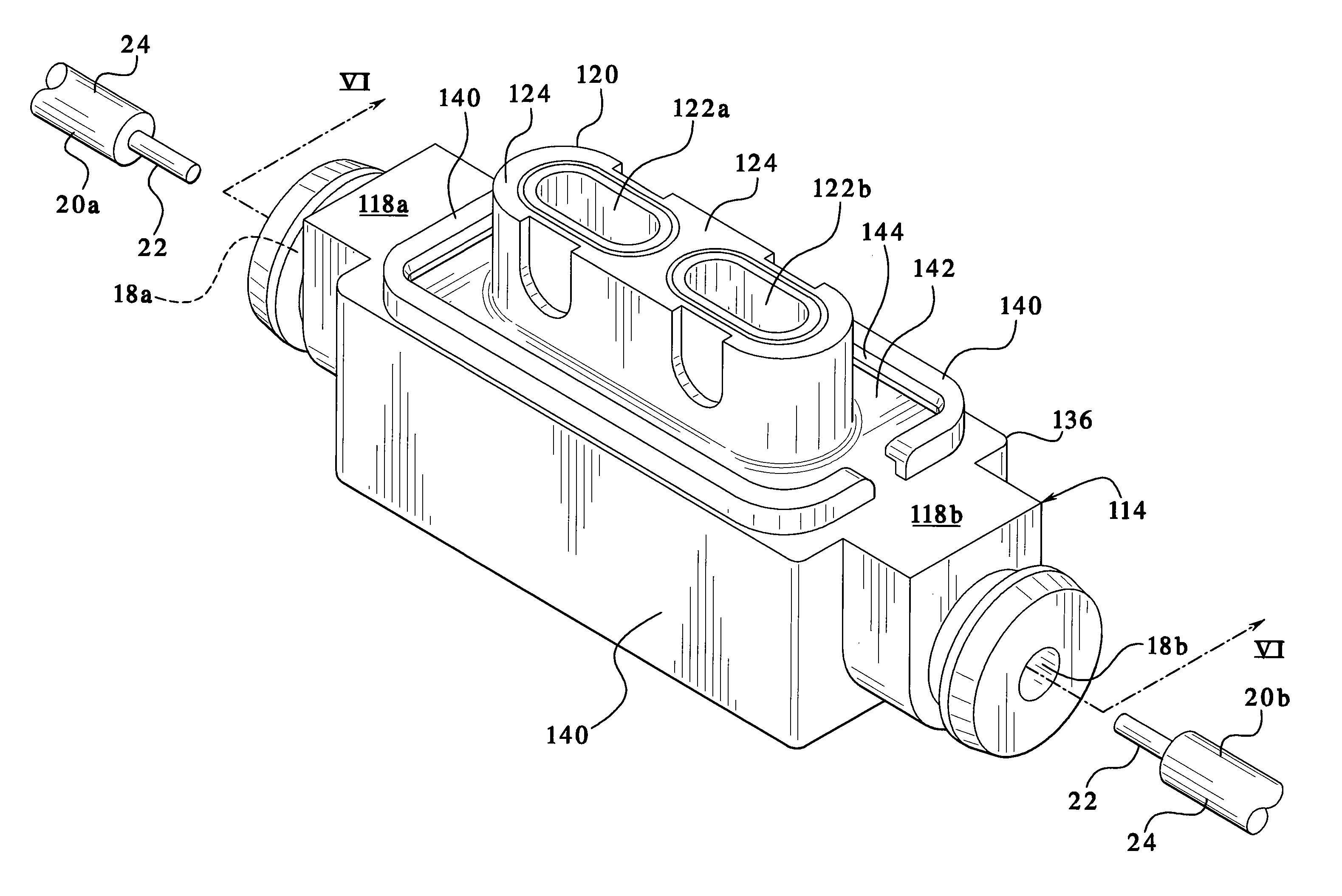

Fuse box for motor vehicle

ActiveUS10217593B2High currentLower resistanceFuse disposition/arrangementEmergency protective devicesEngineeringMechanical engineering

Owner:RENAULT SA

Automotive intelligent fuse box with driving and protecting effects

PendingCN113682248ACut off the output quicklySmall diameterArrangements responsive to excess currentElectric/fluid circuitOvercurrentControl cell

The invention relates to an automotive intelligent fuse box comprising a micro-control unit configured to manage circuit operation, and an intelligent high-side switch configured to drive an electric appliance; the automotive intelligent fuse box is characterized in that the micro-control unit makes a protection judgment on the circuit by comparing a current signal, fed back by an intelligent high-side switch, of an electric appliance with a threshold overcurrent.

Owner:SAIC GENERAL MOTORS +1

Detection tool for detecting automobile fuse box fixing support frame

InactiveCN102538613AAccurate detectionSolve detection difficultiesMechanical counters/curvatures measurementsMechanical diameter measurementsFixed frameEngineering

The invention provides a detection tool for detecting an automobile fuse box fixing support frame. The detection tool has the advantages that the cost performance is high, the operation is simple, and the detection is overall. The detection tool comprises a base and an operation table, wherein the operation table is arranged on the base, one side of the operation table is provided with a downwards inclined groove, the groove bottom surface at the upper end of the operation table is wider than the groove bottom surface at the lower end of the operation table, rectangular side surfaces towards two sides extend from the groove bottom surface at the upper end of the operation table, the groove bottom surface and the groove side surfaces are anastomotic with the outer outline of the fuse box fixing frame, and the groove bottom surface at the upper end of the operation table and the rectangular side surfaces are provided with detection holes corresponding to the fuse box fixing support frame to be detected. The detection tool has the advantages that the defects of high use price, operation complexity and high requirement on operators of a three-coordinate part qualification detection method used in the prior art are overcome, the multi-time standard positioning and the coordinate conversion are not needed, the detection cost is greatly reduced, and the detection tool is particularly suitable for detecting parts in mass production in industry.

Owner:SHANGHAI HEDA AUTOMOBILE FITTINGS

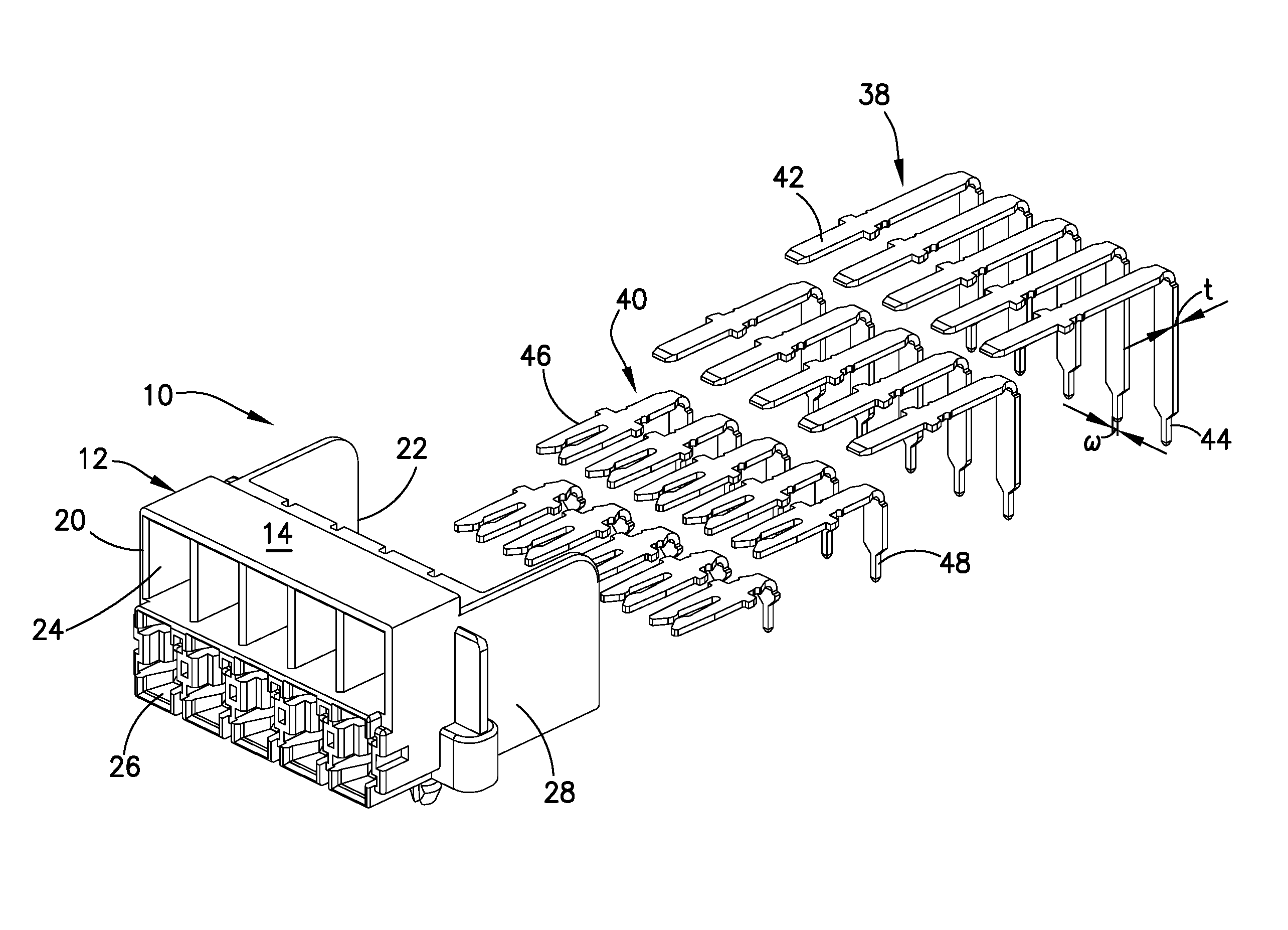

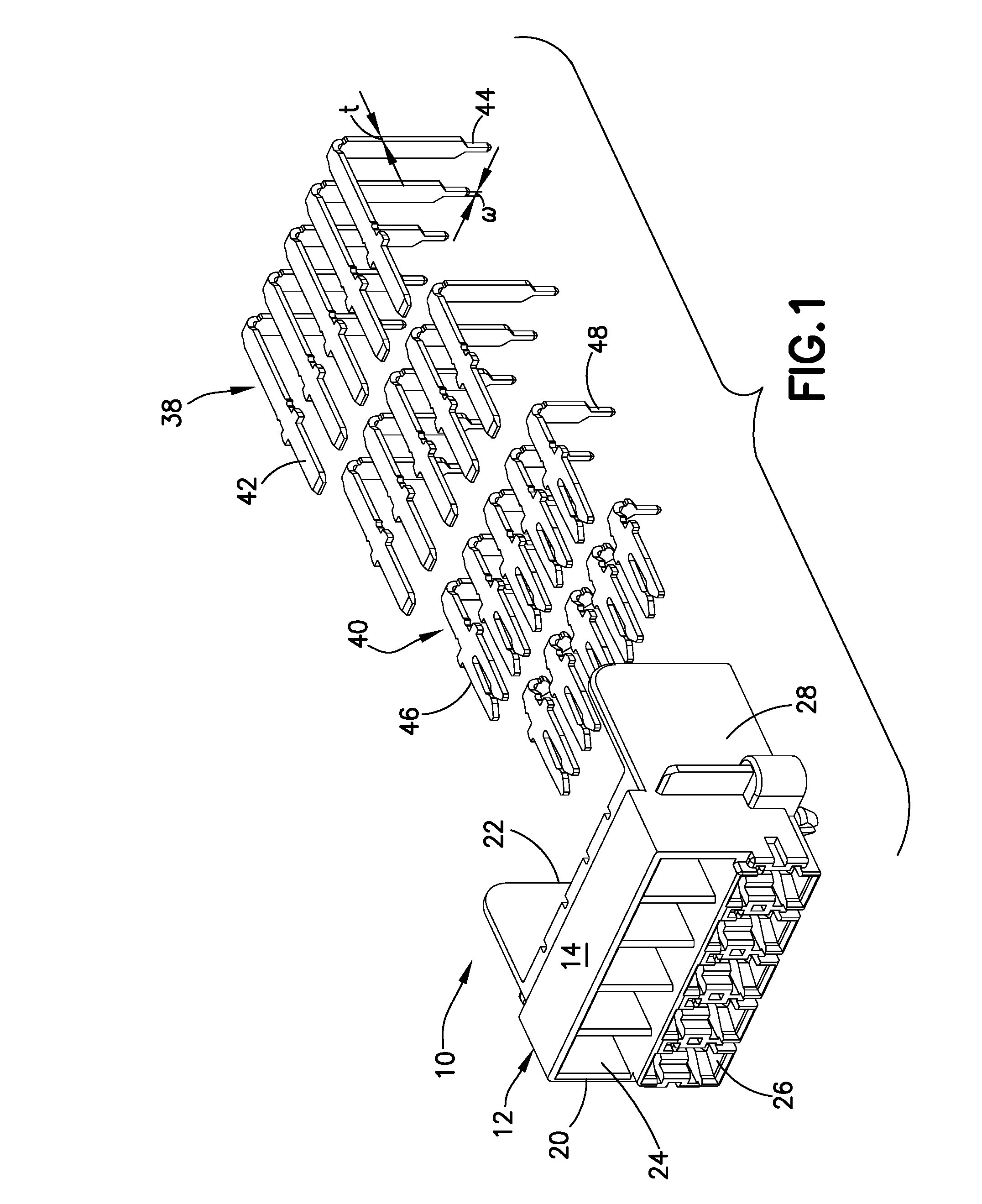

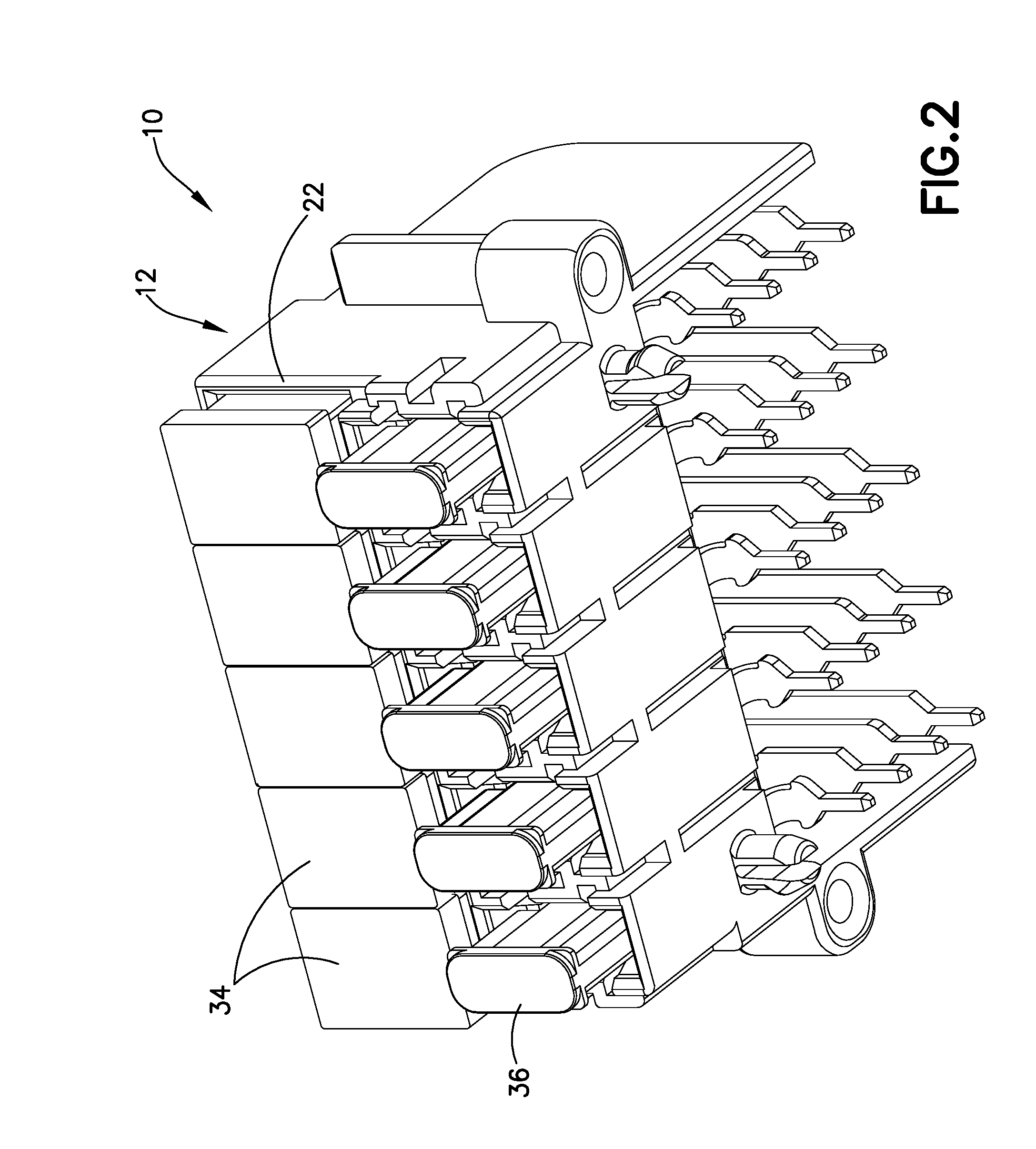

Automotive fuse header assembly

InactiveUS20160288745A1Easy to weldStabilize fuse blow characteristicCoupling contact membersElectric/fluid circuitEngineeringFuse (automotive)

A fuse header includes a housing with cavities and terminals mounted in the housing adjacent the cavities. Fuses can be mounted removably in the cavities so that the fuses connect to the terminals in the respective cavity. Ends of the terminals opposite the fuses have widths that are narrowed substantially and may equal the thickness of the terminals. The narrow widths impede a flow of heat from the fuse to large conductive regions on a circuit board that could function as a heat sink. Thus, the fuses will provide more reliable protection for components downstream of the fuses.

Owner:SUMITOMO WIRING SYST LTD

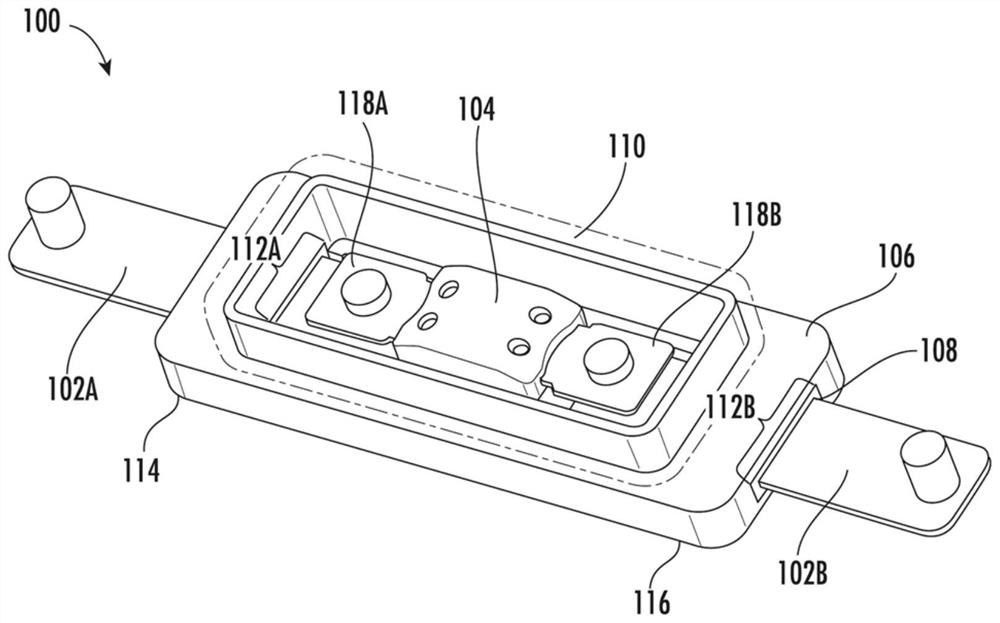

Process for manufacturing sealed automotive electrical fuse box

A fuse assembly including a fuse connected to two busbars, an injection molded base and an injection molded cover. The busbars are powder-coating with a powder-based adhesive or adhesion promoter, then cured in an oven. The busbars are then placed in the cavity image of an injection molding apparatus. Plastic is heated to a liquid form and injected into the cavity image. The resulting injection molded base is resistant to both dust and water, protecting the fuse inside.

Owner:LITTELFUSE INC

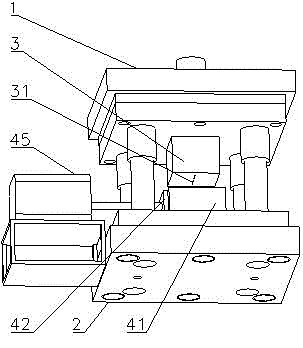

Pressing and assembling mold for automobile fuse

ActiveCN106825234AIncrease air pressureClamping is not stable enoughShaping toolsFuse device manufactureComputer moduleEngineering

The invention relates to the technical field of automobile part machining, in particular to a pressing and assembling mold for an automobile fuse. The pressing and assembling mold for the automobile fuse comprises an upper mold body and a lower mold body; a pressing block is arranged on the upper mold body; a fixing block provided with a positioning groove is fixedly connected to the upper end of the lower mold body; a feeding channel is vertically formed in the pressing block and corresponds to the position of the positioning groove; a plurality of control pipelines are further arranged in the pressing block; check blocks are arranged at one ends of the control pipelines; one ends of the check blocks are located in the control pipelines and are fixedly connected with compression blocks, and the other ends of the check blocks are located in the feeding channel and abuts against the other check blocks; the other ends of the control pipelines are provided with air bags which are connected to the control pipelines in a sealed mode; vent holes are further formed in the pressing block; one ends of the vent holes communicate with the control pipelines, and the other ends of the vent holes are located at the lower end of the pressing block and are provided with annular baffles; and sealing blocks abutting against the annular baffles are arranged at the upper ends of the annular baffles. The pressing and assembling mold for the automobile fuses can solve the problem that an inserting piece still move along with a pressing and assembling module after being assembled and then is separated from a shell.

Owner:CHONGQING BIYANG PROD DESIGN

Automobile fuse loop electrical performance testing device and system thereof

PendingCN108845210AEasy to installEasy to disassembleElectrical testingData acquisitionCurrent divider

The invention provides an automobile fuse loop electrical performance testing device and a system thereof. The automobile fuse loop electrical performance testing device comprises an electrical parameter acquisition device body. The bottom of the electric parameter acquisition device body is provided with a fuse pin for inserting the electrical parameter acquisition device into a fuse slot of theautomobile. The top of the electrical parameter acquisition device body is provided with a fuse slot for inserting the fuse which is pulled out of the automobile into the electrical parameter acquisition device body for recovering the whole fuse loop. One side of the electrical parameter acquisition device body is provided with a quick switch for switching on or switching off the whole fuse loop.The other side of the electrical parameter acquisition device body is provided with a current divider which is connected with a self locking device. The automobile fuse loop electrical performance testing device has advantages of simple mounting, simple detachment, high speed, high convenience, no influence to actual electrical characteristic, simultaneous acquisition of current and voltage, concise line harness, omission of an external current sensor, high precision and high accuracy in data acquisition, high safety and high reliability.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com