Automobile fuse box with secondary lock structure

A fuse box and secondary lock technology, which is applied in the direction of emergency protection devices, contacts, electrical components, etc., can solve problems affecting the performance of the whole vehicle, wire harness falling off, etc., and achieve the effect of reducing quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

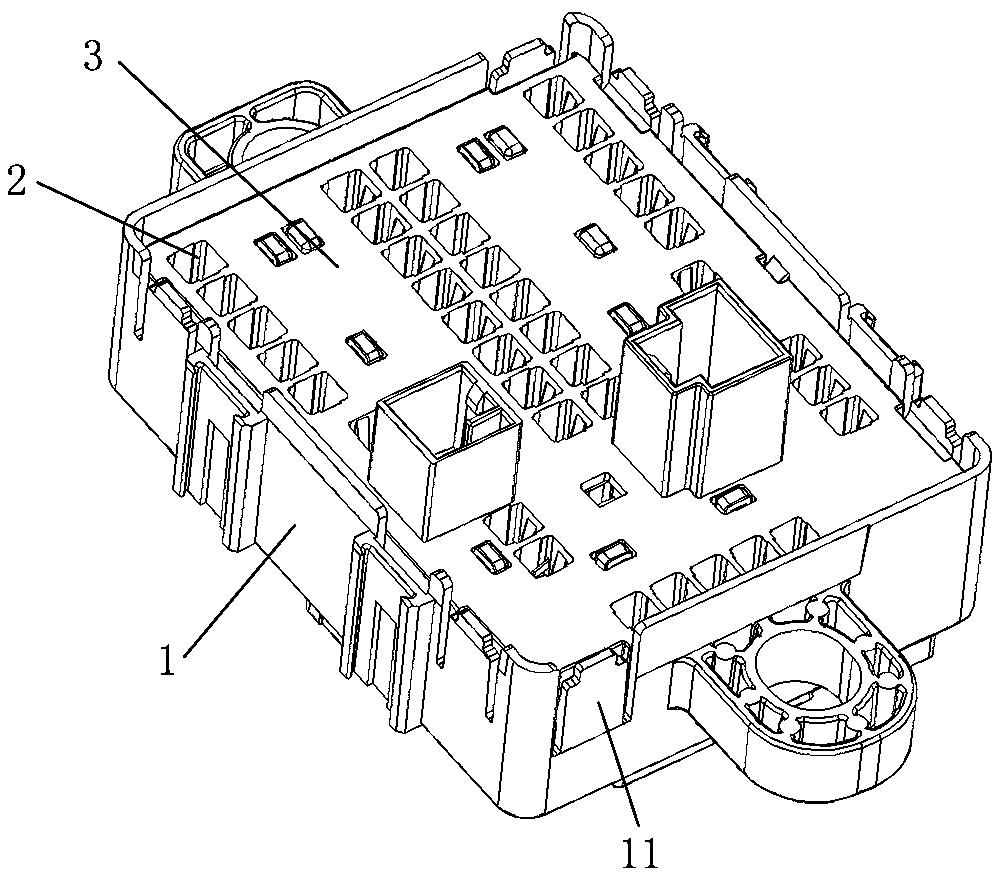

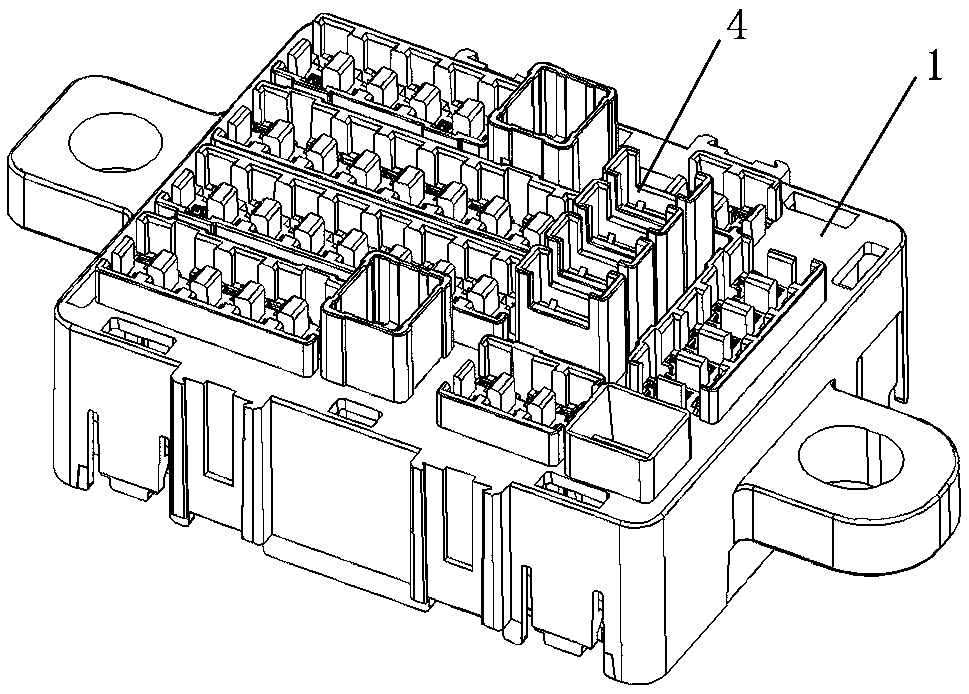

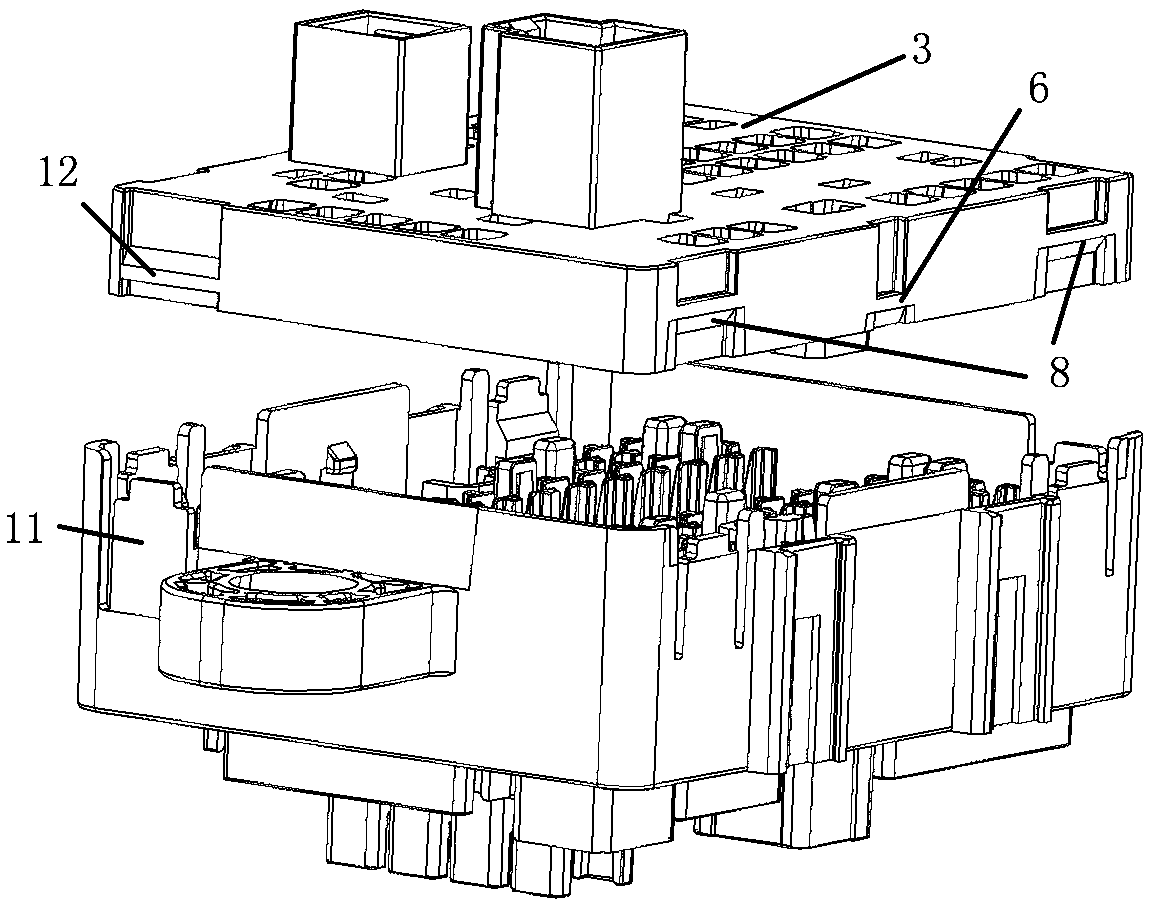

[0022] combined with Figures 1 to 7 , a car fuse box with a secondary lock structure, the back of the car fuse box 1 is provided with a lock plate 3 with a threading hole 2, the fuse box 1 is provided with a terminal hole 4 matching the threading hole 2, the The lock plate 3 and the fuse box 1 have a first clamping position and a second clamping position. When the lock plate 3 and the fuse box 1 are located at the first clamping position, the threading hole 2 of the lock plate 3 penetrates the wiring harness When the terminal 5 and the lock plate 3 go down again and reach the second clamping position, when the second clamping is triggered, the wire harness terminal 5 is clamped by the wall of the threading hole 2 to be fixed, and the locking plate is locked at the second clamping position. 3 is located at the lowest position in the fuse box 1.

[0023] Further, the first clamping position includes a first outer clamping block 6 arranged on the outer edge of the lock plate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com