Zinc alloy, preparation method thereof and automobile fuse

A zinc alloy and fuse technology, which is applied in the field of alloy materials, can solve the problems of insufficient hardness, poor mechanical properties, and high cost, and achieve the effects of reasonable composition ratio, good mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

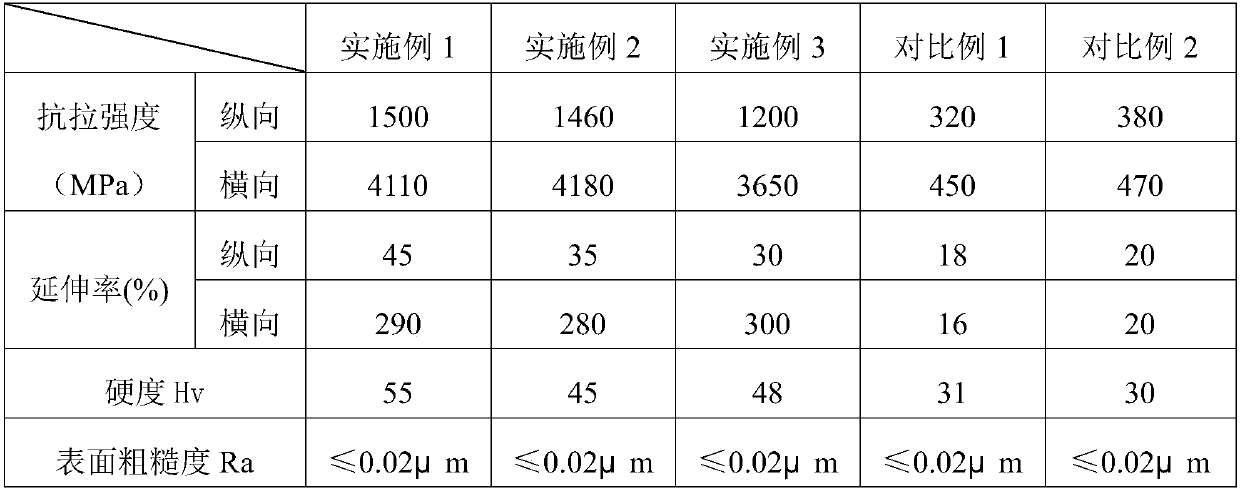

Examples

preparation example Construction

[0027] The present embodiment also provides a method for preparing a zinc alloy, comprising the steps of:

[0028] (1) Smelting: Put zinc into the furnace, add zinc-copper and zinc-titanium intermediate alloys when melting and heating up to 500-550°C, melt and stir evenly;

[0029] (2) Casting: the casting temperature is controlled at 440-480°C, the casting speed is controlled at 2-2.5m / s, the cooling water temperature is controlled at no more than 40°C, and the crystallizer temperature is controlled at 60-90°C;

[0030] (3) Hot rolling: the rolling temperature is controlled at 180-250°C;

[0031] (4) Intermediate rolling: the rolling temperature is controlled at 60-130°C, and the pass compression ratio is 30-50%;

[0032] (5) Smooth rolling: the rolling temperature is controlled at no more than 50°C, the pass compression rate is 8-15%, and the surface roughness of the roll is ≤0.08μm.

[0033] In a preferred embodiment, step (1) also includes the step of adding a rare earth...

Embodiment 1

[0036] The weight composition of zinc alloy is as follows:

[0037] Copper: 0.5%; Titanium: 0.1%; Rare earth metals: 0.01%; Magnesium: 0.08%; the balance is zinc and unavoidable impurities. Copper element and titanium element are respectively added in the form of zinc-copper master alloy and zinc-titanium master alloy during alloy batching; rare earth metal and magnesium element are respectively added in the form of rare earth alloy and zinc-magnesium master alloy.

[0038] (1) Smelting: put zinc into the furnace, and when the melting temperature rises to 550°C, add zinc-copper master alloy, zinc-titanium master alloy, rare earth alloy and zinc-magnesium intermediate, melt and stir evenly;

[0039] (2) Casting: the casting temperature is controlled at 460°C, the casting speed is controlled at 2m / s, the cooling water temperature is controlled at no more than 40°C, and the crystallizer temperature is controlled at 80°C;

[0040] (3) Hot rolling: the rolling temperature is contr...

Embodiment 2

[0044] The weight composition of zinc alloy is as follows:

[0045] Copper: 0.3%; Titanium: 0.08%; Rare earth metals: 0.008%; Magnesium: 0.001%; the balance is zinc and unavoidable impurities. Copper element and titanium element are respectively added in the form of zinc-copper master alloy and zinc-titanium master alloy during alloy batching; rare earth metal and magnesium element are respectively added in the form of rare earth alloy and zinc-magnesium master alloy.

[0046] (1) Smelting: put zinc into the furnace, and when the melting temperature rises to 500°C, add zinc-copper master alloy, zinc-titanium master alloy, rare earth alloy and zinc-magnesium intermediate, melt and stir evenly;

[0047] (2) Casting: the casting temperature is controlled at 440°C, the casting speed is controlled at 2.5m / s, the cooling water temperature is controlled at no more than 40°C, and the crystallizer temperature is controlled at 70°C;

[0048] (3) Hot rolling: the rolling temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com