Concrete composite tube

A technology of concrete and composite pipes, applied in the field of composite pipes, can solve the problems of glass steel pipes such as weak adhesion, unreasonable formula, and easy falling off, and achieve the effects of reasonable composition ratio, enhanced workability, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

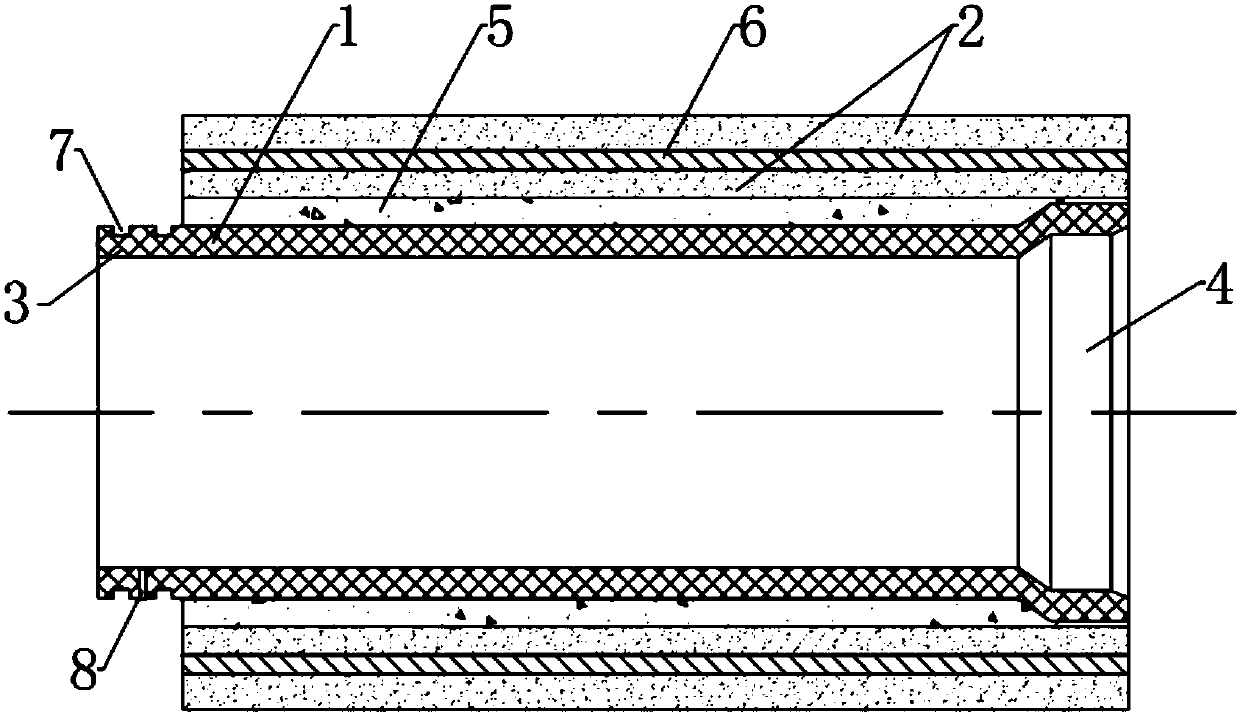

[0017] A concrete composite pipe, comprising a glass steel pipe 1 and a concrete layer 2 sleeved in the glass steel pipe 1, wherein the composition of the concrete layer 2 includes water, sand, cement and a water reducing agent, and the composition of the sand, stone, cement and water reducing agent The ratio is 2380:1040:27, the gravel is 1190kg, the cement is 520kg, and the water reducer is 13.5kg; in the composition of the concrete layer 2, the amount of water added is to add water until the cement slump is 70mm.

[0018] As mentioned above, one end of the concrete composite pipe is the interface 3 protruding from the glass steel pipe 1 relative to the concrete layer 2, and the other end of the concrete composite pipe is the socket 4 protruding from the glass steel pipe 1 relative to the concrete layer 2, and the interface 3 is matched with the socket 4 for convenience. The concrete composite pipes are connected with each other; the joint 3 is provided with an annular sealin...

Embodiment 2

[0023] A concrete composite pipe, comprising a glass steel pipe 1 and a concrete layer 2 sleeved in the glass steel pipe 1, wherein the composition of the concrete layer 2 includes water, sand, cement and a water reducing agent, and the composition of the sand, stone, cement and water reducing agent The ratio is 2380:1040:30, sandstone is 1190kg, cement is 520kg, and water reducer is 15kg; in the composition of concrete layer 2, the amount of water added is to add water until the cement slump is 100mm.

[0024] As mentioned above, one end of the concrete composite pipe is the interface 3 protruding from the glass steel pipe 1 relative to the concrete layer 2, and the other end of the concrete composite pipe is the socket 4 protruding from the glass steel pipe 1 relative to the concrete layer 2, and the interface 3 is matched with the socket 4 for convenience. The concrete composite pipes are connected with each other; the joint 3 is provided with an annular sealing groove 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com